MATERIAL SAFATY DATA SHEET

For welding consumables

Rev. No : - 01

MSDS No. : - 006

Prepared Date: - 31.05.2011

Revision Date: - 14.08.2013

FLUX CORED ARC WELDING WIRE

SECTION 1 IDENTIFICATION

Manufacturer name: - RAAJRATNA ELECTRODES PVT.LTD.

Address: - Regd. Off. : 11, Sona Roopa, Opp. Lal Bunglow, C.G. Road, Navrangpura, Ahmedabad-380 006. Gujarat

(INDIA)

Phone: - +91-79-2644 5258, 2643 1543

Fax

: +91-79-2656 8085, 2754 3085

Emergency No. +91-79-26445258

E-mail

: exports@raajratnaelectrodes.com

Website : www.raajratnaelectrodes.com

Product Type : flux cored welding wires, Carbon Steel FCAW Wires for MAG/MIG welding process.

AWS specification: All products as per AWS A5.20-2010

Classification:

E71T-1, E71T-1(GAS SHILED)

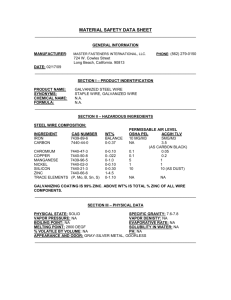

SECTION -2: HAZARDOUS INGREDIENTS

Important: This section covers the materials from which this product is manufactured. The fumes and gases produced

during welding with normal use of this product are covered by section 5. The terms “Hazardous” in this section should

be interpreted as a term required and defined in OSHA Hazard communication Standard (29 CFR Part 1910.1200).

HAZARDOUS

INGREDIENTS

% WEIGHT

CAS NO

EXPOSURE LIMIT

(mg/m3)

) OSHA PEL

ACGIH TLV

5 R*, (Fe2O3) {A4}

0.2 I*{A4} ◊

0.02r* ◊, ◊◊

3 R*

0.025 R* {A2}

0.2 (Fume), 1 (Dust and Mists)

10 I*; 3R* (Elemental and

Insoluble)

0.5R* (Soluble Compounds)

{A3}

1.50 !*(Metal) {A5}

10 {A4}

1 R* {A4}

5 as Zr

3 R* ,2 ( as Cao)

0.5 (Metal) {A4}

0.5 (Cr III Cpnds) {A4}

0.05 ( Cr VI sol Cpnds) {A1}

0.01 ( Cr VI Insol Cpnds) {A1}

2.5 ( as F) {A4}

3 R*

10 I* {A4}

5 R*

IRON+

MANGANESE#

95

<5

7439-89-6

7439-96-5

SILICON+

Silica++

(Amorphous silica

Fume )

COPPER# (1)

Molybdenum (2)

<2

-----

7440-21-3

14808-60-7

5 R*, 10 (Oxide Fume)

5 CL** (Fume)

1, 3 STEL***!

5R*

0.1 R*

0.1-0.5

0.1-1

7440-50-8

7439-98-7

0.1 (Fume), 1 (Dust)

5 R*

Nickel#

Titanium dioxide

Aluminum oxide

Zirconium Oxide

Calcium carbonate

Chromium#

0-2

2-10

0-5

0-2

0-15

0-3

7440-02-0

13463-67-7

1344-28-1

1314-23-4

1317-65-3

7440-47-3

1 (Metal)

15 (dust )

5 R*

5 as Zr

5 R* ,5 ( as Cao)

1 (Metal)

0.5 (Cr II & III Cpnds)

0.005 ( Cr VI Cpnds)

Fluorspar

Magnesium

Magnesium oxide

Titanium+

0-10

0-2

<2

<2

7789-75-5

7439-95-4

1309-48-4

7440-32-6

2.5 ( as F)

5 R*

15 (fume, Total part )

5 R*

R*- Reparable Function I* - Inhalable Fraction, ** - Ceiling Limit, *** - Short Term Exposure Limit, # - Reportable

material under

Section 313 of SARA, {A3} – Confirmed Animal Carcinogen with Unknown Relevance to Humans per ACGIH, {A4} –

Not Classifiable as a Human Carcinogen per ACGIJ, ! – NIOSH REL TWA and STEL, ◊ - Listed under ACGIH Notice

of Intended Changes for Mn in 2010, ◊◊ - Limit of 0.02 mg/m3 is proposed for Reparable Mn in 2011 by ACGIH

The exposure limit for welding fume has been established at 5 mg/m 3 with OSHA’s PEL. The individual

complex compounds within the fume may have lower exposure limits than the general welding fume PEL. An

industrial Hygienist, the OSHA Permeable Exposure Limits for Air Contaminants (29 CFR 1910.1000), and the

ACGIH Threshold Limit Values should be consulted to determine the specific fume constituents present and

their respective exposure limits.

SECTION 3

HAZARD IDENTIFICATION

These products consist of solid metal that are odorless. There are not any immediate health effects. These products

are not flammable nor reactive. These product generates irritations iron fumes by welding. A Varity of iron compound,

carbon dioxide, carbon monoxide and metal oxide are generate.

Symptoms of over exposure

During welding operation, the most signification route of over exposure is via inhalation of fumes.

Inhalation --Inhalation of large amount of particulates generated by this product during welding operation

may result disease of lungs repeated over exposure via inhalation of dust and fumes, generated by this products

during welding operation effect the lungs. Nickel (a component of some of these products) can cause Asthma,

damage the lungs

Contact of skin or eyes

Contact of wire of these products with skin cannot producing any irritation. Contacts of these products can physically

damage to eye or body. Fumes generated during welding can irritation the skin and eye. Symptoms of overexposure

may include irritation and redness.

Skin absorption

Skin absorption is not anticipated to be significant route to over exposure to components of these products

Ingestion—ingestion is not anticipated to be significant route to over exposure to components of these products.

Injection --injection is not anticipated to be significant route to over exposure to components of these products.

Health effects- symptoms associated with over exposure to these products and fumes generated during welding

operation are as follows –

ACUTE- the chief acute health hazard with these products would be potential for irritation of skin and eyes, when

exposed to fumes during welding operation. Inhalation of large amount of particles during welding can result of

disease of lungs. Inhalation of copper oxide fumes can cause mental fever. Burns may occur from connect with

molten metal.

Chronic –chronic skin over exposure to fumes generated during welding operation may produce red, inflammamed

skin. Repeated over exposure to the fumes generated by these products via inhalation can adverse effect on lungs

Skins, eyes, respiratory system, liver are target organs

SECTION 4 – PHYSICAL/CHEMICAL CHARACTERISTICS

Density

: 7.80-7.90 g/mm3

Melting point

: 1500C

Boiling point

: High

Appearance and Odor : Solid, metallic gray, ranging from dull to bright

Finish Odorless.

PH

: Not applicable

Water solubility

: Insoluble.

Magnetic properties

: Magnetic

Welding consumables applicable to this sheet are solid and nonvolatile as shipped.

SECTION 5 – FIRE AND EXPLOSION HAZARD DATA

Flash point—not flammable.

Auto ignition temperature---not flammable.

Fire extinguishing material ---- product are non flammable. Fire extinguishing agents needs for surroundings

materials.

Water spray—yes dry chemical ---yes Carbon dioxide ---yes

Others ABS TYPE---yes

foam ---yes

Welding consumables applicable to this sheet as shipped are nonreactive, nonflammable, nonexposive and

essentially nonhazardous until welded. Welding arcs and sparks can ignite combustibles and flammable products.

See American National Standard Z49.1 referenced in section 7.

SECTION 6–REACTIVITY DATA-HAZARDOUS DECOMPOSITION/INDUSTRIAL HYGIENE

INFORMATION

Stability –stable

Decomposition products---iron fumes, iron compound, carbondioxide, carbonmanooxide, metal powder.

NOTE-Welding fumes and gases cannot be classified simply. The composition and quantity of both are dependent

upon the metal being welded, the process, procedures and electrodes used. Most fume ingredients are present as

complex oxides and compounds and not as pure metals.

Other conditions which also influence the composition and quantity of the fumes and gases to which workers may be

exposed include: coating on the metal being welded (such as paint, plating or galvanizing), the number of welders

and the volume of area, the quality and amount of ventilation, the position of the welders head with respect to the

fume plume, as well as the presence of contaminants in the atmosphere (such as chlorinated hydrocarbon vapors

from cleaning and degreasing activities).When the electrode is consumed, the fume and gas decomposition products

generated are different in percent and form from the ingredients listed in section 2. Decomposition products from

normal operation include those originating from the volatilization, reaction or oxidation of the materials shown in

section2, plus those from the base metal and coating, etc. as noted above. Reasonably expected constituents of the

fume would include: Primary – complex oxides of iron; secondarily - complex oxides of manganese, silicon and

copper.

Monitor for the materials identified in Section 2. Fumes from the use of this product may contain copper,

manganese compounds and amorphous silica whose exposure limits are lower than the 5 mg/m 3 PEL for

general welding fume.

Gases reaction products may include carbon monoxide and carbon dioxide. Ozone and nitrogen oxides may be

formed by the radiation from the arc. One recommended way to determine the composition and quantity of fumes and

gases to which workers are exposed is to take an air sample inside the welder’s helmets if worn or in the workers

breathing zone. [See ANSI/AWS F1.1, available from the “American welding society”, P.O. Box 351040, Miami, FL

33135. Also, from AWS is F1.3 “Evaluating contaminants in the welding Environment - A sampling strategy Guide”,

which gives additional advice on sampling.]

SECTION 7 – TOXICOLOGICAL INFORMATION

EFFECT OF OVEREXPOSURE:

Electric arc welding may create one or more of the following heath hazards:

ARC RAYS can injure eyes and burn skin.

ELECTRIC SHOCK can kill. See section 7.

FUMES AND GASES can be dangerous to your health.

PRIMARY ROUTES OF ENTRY are the respiratory system, eyes and/or skin.

Short Term (Acute) Overexposure Effects:

Welding fumes - may result in discomfort such as a dizziness, nausea or dryness of irritation of nose, throat or eyes.

Iron, Iron Oxide - None are known. Treat as nuisance dust or fume. Manganese - Metal fume fever characterized by

chills, fever, upset stomach, vomiting irritation of the throat and aching or body. Recovery is generally complete within

48 hours of the overexposure. Silica (Amorphous) Dust and fumes may cause irritation of the respiratory system,

skin and eyes. Copper - Metal fume fever characterized by metallic taste, tightness of chest and fever. Symptoms

may last 24 to 48 hours follow overexposure. Molybdenum – Irritation of the eyes, nose and throat.

LONG TERM (CHRONIC) OVEREXPOSURE EFFECTS:

Welding fumes - Excess levels may cause bronchial asthma, lung fibrosis, pneumoconiosis or “siderosis”. Iron, Iron

Oxide Fumes - can cause siderosis (deposit of Iron in lungs) which some researchers believe may affect pulmonary

function. Lungs will clear in time when exposure to iron and its compounds cease. Iron and magnetite (Fe3O4) are

not regarded as fibrogenic materials. Manganese - Long-term overexposure to manganese compounds may affect

the central nervous system. Symptoms may be similar to Parkinson’s disease and can include slowness, change in

handwriting, gait impairment, muscle spasms and cramps and less

Commonly, tremor and behavioral changes. Employees who are overexposed to manganese compounds should be

seen by a physician for early detection of neurological problems. Overexposure to manganese and manganese

compounds above safe exposure limits can cause irreversible damage to the central nervous system, including the

brain, symptoms of which may include slurred speech, lethargy, tremor, muscular weakness, psychological

disturbances and spastic gait. Silica (Amorphous) - Research indicates that silica is present in welding fume in the

amorphous form. Long term overexposure may cause pneumoconiosis. Non-crystalline forms of silica (amorphous

silica) are considered to have little fibrotic potential. Copper - Copper poisoning has been reported in the literature

from exposure to high levels of copper. Liver damage can occur accumulating in the liver characterized by cell

destruction and cirrhosis. High levels of copper may cause anemia and jaundice. High levels of copper may cause

central nervous system damage characterized by nerve fiber separation and cerebral degeneration. Molybdenum –

Prolonged overexposure may result in loss of appetite, weight loss, loss of muscle coordination, difficulty in breathing

and anemia.

MEDICAL CONDITION AGGRAVATED BY EXPOSURE: Persons with pre-existing impaired lung functions (asthmalike conditions). Persons with a pacemaker should not go near welding and cutting operations until they have

consulted their doctor and obtained information from the manufacturer of the device. Respirators are to be worn only

after being medically cleared by your company-designated physician.

EMERGENCY AND FIRST AID PROCEDURES: Call for medical aid. Employ first aid techniques recommended by

the American Red Cross. Eyes and Skin: If irritation or flash burns develop after exposure, consult a physician.

CARCINOGENICITY:

Welding fumes must be considered as possible carcinogens under OSHA (29 CFR

1910.1200)

CALIFORNIA PROPOSITION 65: WARNING: This product, when used for welding or cutting produces fumes or

gases which contain chemicals known to the state of California to cause birth defects and, in some cases cancer.

(California Health & Safety Section 25249.5 et seq.)

SECTION 8 – EXPOSURE CONTROL / PREVENTIVE MEASURES

Read and understand the manufactures instructions and the precautions and the precautionary label on the product.

See American National standard Z49.1; safety in welding and cutting published by the American welding Society,

P.O. Box 351040, Miami, FL 33135 and OSHA Publication 2206 (29 CFR 1910), U.S. Government printing Office,

Washington, DC 20402 for more detail on any of the following.

VENTILATION: Use enough ventilation, local exhaust at the arc or both to keep the fumes and gases below

PEL/TLVs in the worker’s breathing zone and the general area. Train the welder to keep his head out of the fumes.

RESPIRATORY PROTECTION: Use NIOSH approved or equivalent fume respirator or air supplied respirator when

welding in confined space or where local exhaust or ventilation does not keep exposure below PEL/TLVs.

EYE PROTECTION: Wear helmet of use face shield with filter lens. As a rule of thumb begin with shade Number 14.

Adjust if needed by selecting the next lighter and or darker shade number. Provide protective screens and flash

goggles, if necessary, to shield others.

PROTECTIVE CLOTHING: Wear hand, head and body protection which help to prevent injury from radiation, sparks

and electrical shock. See ANSI Z49.1. At a minimum this includes welder’s gloves and a protective face shield and

may include arm protectors, aprons, hats, shoulder protection as well as dark non-synthetic clothing. Train the welder

not to touch live electrical parts and to insulate himself from work and ground.

PROCEDURE FOR CLEANUP OF SPILLS OR LEAKS: not Applicable.

WASTE DISPOSAL: Prevent waste from contaminating surrounding environment. Discard any product, residue,

disposable container or liner in an environmentally acceptable manner, in full compliance with federal, state and local

regulations.

SPECIAL PRECAUTIONS (IMPORTANT): Maintain exposure below the PEL/TLVs. Use industrial hygiene

monitoring to ensure that your use of this material does not create exposures which exceed PEL/TLVs. Always use

exhaust ventilation. Refer to the following sources for important additional information: ANSI Z49.1 from The

American Welding Society, P.O. Box 351040, Miami, FL 33135 and OSHA (29 CFR 1910) from the U.S. Department

of Labor, Washington, DC 20210.

SECTION 9 FIRST AID MEASURES

Victim of chemical espouser must be taken for medical attention. If necessary take a copy of label and MSDS to

health professional with victim

SKIN EXPOSURE---if fumes generated by welding operation involving these product contaminate the skin, begin

decontamination with running water. If molten metals touch with skin, immediately dip your skin in cold water. Victim

must seek medical attention if any adverse reaction occur.

EYE EXPOSURE – if fumes Generated by welding operation including this product enter in the eyes, then open

victim eyes under gently running water. Use sufficient force to open eyelids. Victim must seek immediate medical

attention

INHALATION---- if fumes generated by welding operation involving this product are inhaled, remove victim to fresh

air. If necessary use artificial respiration to support vital function.

INGESTION ----if this product is swallowed, call physician or poison control centre.

MEDICAL CONDITION AGGRAVATED BY EXPOSURE

Skin condition, respiration, and disorder, liver disorder may be aggravated by prolonged over exposure to dusts or

fumes, generated by this product.

SECTION 10:TRANSPORT INFORMATION

No international regulations or restriction are applicable. These product are not hazardous by the US department of

transportation.

SECTION -11 ACCIDENTAL RELEASE MEASURE

Spill and leak response ----not applicable

Personal precaution—wear safety glasses and gloves, gather the loose stand of wires

SECTION -12 HANDLING AND STORAGE

Store in clean and dry place. Storage should include provision to minimize rough handling, excessive vibration and

physical abuse. Don’t open the material until ready for use. All employs who handle this product should be trained to

handle safely.

SECTION -13 DISPOSAL CONSIDERATION

Preparing wastes for disposal –waste disposed must be accordance with appropriate federal, state and local

regulations. These product may be disposed as per advice of local hazarded waste regulatory regulation authority.

SECTION - 14 ECOLOGICAL INFORMATION

Products persistence the continues solid wire and are expected to slowly corrode in outdoor ambient environments.

Iron will react with water and air to form a variety of stable iron oxide.

Effect of material on plants or animal: the components of these products occur naturally in environment and are

essential for plant and animal life.

Effect of chemical on aquatic life; these products are not expected to cause adverse effects. Copper: copper is

concentrated by plankton by 1000 or more .copper may concentrate to toxic level in food chain.

SECTION --15 REGULATORY INFORMATION

US CERCLA REPORTABLE QUANTITY (RQ)—Chromium=5000lbs, copper=5000LBS, Nickel=100LBS.RQS

chromium, copper, nickel are applicable to particles 100 micrometers or low diameters.

OTHERS US FEDERAL REGULATIONS—not applicable.

OTHERS US FEDERAL REGULATIONS -Alaska designated toxic and hazardous substances: chromium, copper fume, chromium 3 compound, molybdenum,

nickel, phosphorus

California –permissible exposure limit for chemical contaminates: chromium, copper, manganese, nickel, phosphorus,

silicon

Florida –substance list: chromium, copper, manganese molybdenum, nickel, phosphorus, sulfur, phosphorus..

Kansas – section 302/313 lisit: chromium, copper, manganese and nickel,

Massachusetts – substance list: chromium, copper, chromium 3 compound, molybdenum, nickel, phosphorus, sulfur,

manganese.

Michigan –critical material list: chromium, copper and nickel.

Missouri –employer information/toxic substance list: chromium, copper, chromium 3 compound, molybdenum, nickel,

phosphorus, manganese. And silicon

New Jersey right to know hazardous substance list: chromium, copper, chromium 3 oxide, phosphorus, manganese,

molybdenum, nickel and sulfur,

West Virginia –hazardous substance list: chromium, phosphorus, manganese, molybdenum nickel and copper fume.

CALIFORNIA SAFE DRINKING WATER AND TOXIC ENFORCEMENT ACT (PROPOSITION 65):

The chromium and nickel compounds of these products are on the California proposition 65 list

Warning –these products may contains chemicals and when used for welding, may produce fumes or gases

contain chemicals

Warning

Before use read and understand the manufacture instruction

Keep your head out of fumes.

Use enough ventilation, exhaust at the arc or both to keep fumes and gases from breathing zone and the general

area.

Wear correct eye ear body protection.

Fumes and gases can be dangerous to your health.

See American national standard z49.1 safety in welding, cutting and allied processes. Published by the American

welding society, 550NW Lejeune road Miami, Florida, 33126. OSHA safety and health standards 29 CFR 1910,

Available from U S the Government printing office Washington. D C -20402.

Do not remove this information.

ADDITIONAL CANADIAN DSL/NDSL INVENTORY STATUS

inventory.

OTHER CANDIAN REGULATION ----not applicable.

-the component of these product are on the DSL list

CANADIAN ENVIRONMENT PROTECTION ACT (CEPA) PRIORITIES SUBSTANCE LIST.

CANADIAN WHMIS SYMBOLS – CLASS D2A/D2B .Material causing other toxic effect contain potential sensitizer.

SECTION -16 OTHER INFORMATION

RAAJRATNA Company believes this data sheet to be accurate and to reflect qualified expert opinion

regarding current research. However RAAJRATNA Company cannot make any expressed or implied warranty

as to this information.

FOR WELDING CONSUMABLES AND RELATED PRODUCTS

Prepared to US OSHA, ANSI AND CANDIAN WHIMS (class D2A, D2B) standards

Warning

Product components present in health and safety hazards. Read and understand the material safety data sheet. Also

follow your employer’s safety precautions.