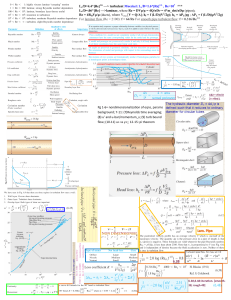

PLEDGE OF HONOR (AS A GROUP) "We accept responsibility for our role/s in ensuring the integrity of the work submitted by our group in which we have participated." AMIHAN, JIM KENNETH S. AROLA, NUR MOHAMMAD I. BAGON, ALYSSA MARIE G. BALINO, RUSSEL CHRISTIAN M. BAYUMBON, MARK GENESIS S. Group No. 1 Group Members 1. Amihan, Jim Kenneth S. 2. Arola, Nur Mohammad I. 3. Bagon, Alyssa Marie G. 4. Balino, Russel Christian M. 5. Bayumbon, Mark Genesis S. Date of Activity: March 22, 2021 Arola, Nur Mohammad I. Date of Submission: March 24, 2021 Engr. Crispulo G. Maranan Laboratory Experiment No. 1 Flow of Fluids Through Pipes 1. Objective: To determine system profiles of the piping system (pressure losses, frictional losses, flow resistance) 2. Intended Learning Outcomes (ILOs): At the end of this experiment. the students shall be able to: 2.1 To determine the frictional losses encountered in a hydraulically smooth pipe under laminar and turbulent flow situations. 2.2 To determine the effect of Reynolds number on Fanning friction factor for laminar and turbulent flow situations in a hydraulically smooth pipe. Verify the correlations for laminar flow and turbulent flow (Blasius correlation and Nicurdse’s correlation) 3. Discussion: In the chemical and manufacturing industries, uninterrupted transport of products and raw materials from different processing units is attained by large flow networks. It requires deeper understanding of fluid flows in pipes. Knowing of energy that you need to input is necessary because there is frictional energy loss or frictional pressure drop between the fluid and the pipe wall and internal friction within the fluid. The energy is lost due to frictional resistance. Calculation of pressure drop/pressure loss/frictional losses is necessary for determining the sizes of pumps that will be used to force the fluid to flow through pipes and essential in calculating power requirements. As the pump size increases, the maximum viscosity that it can handle also increases, and as the viscosity increases, the power requirements will also increase. Pressure drop or pressure loss is defined as decrease in pressure and measured between two points of fluids carrying network. Pressure drop is proportional to fluid velocity, specific gravity, viscosity, size, and inner roughness of the pipe. Unit operations used in the industry and in designing plants mostly involve the presence of fluids may it be in forms of liquid or gas. Hence, understanding fluid flow and it’s different profiles and characteristics that may affect the overall design is necessary. The flow of fluids outside immersed bodies appears in many chemical engineering applications and other processing applications. These occur, for example, in flow past spheres in settling, flow through packed beds in drying and filtration, flow past tubes in heat exchangers, and so on. It is useful to be able to predict the frictional losses and/or the force on the submerged objects in these various applications. The fluid flow in pipes are classified into laminar, turbulent, and transient. If you have been around smokers, you probably noticed that the cigarette smoke rises in a smooth plume for the first few centimeters and then starts fluctuating randomly in all directions as it continues its rise. Likewise, a careful inspection of flow in a pipe reveals that the fluid flow is streamlined at low velocities but turns chaotic as the velocity is increased above a critical value. The flow regime in the first case is said to be laminar, characterized by smooth streamlines and highly ordered motion, and turbulent in the second case, where it is characterized by velocity fluctuations and highly disordered motion. The transition (transient flow) from laminar to turbulent flow does not occur suddenly; rather, it occurs over some region in which the flow fluctuates between laminar and turbulent flows before it becomes fully turbulent. Most flows encountered in practice are turbulent. Laminar flow is encountered when highly viscous fluids such as oils flow in small pipes or narrow passages. The transition from laminar to turbulent flow depends on the geometry, surface roughness, flow velocity, surface temperature, and type of fluid, among other things. After exhaustive experiments in the 1880s, Osborne Reynolds discovered that the flow regime depends mainly on the ratio of inertial forces to viscous forces in the fluid. This ratio is called the Reynolds number which is denoted as Re and expressed by, 𝑅𝑒 = 𝑖𝑛𝑒𝑟𝑡𝑖𝑎𝑙 𝑓𝑜𝑟𝑐𝑒 𝑣𝑖𝑠𝑐𝑜𝑢𝑠 𝑓𝑜𝑟𝑐𝑒 = 𝐷𝑉ρ µ where, 𝑅𝑒= Reynolds number 𝐷= diameter of the pipe 𝑉= average velocity of the fluid ρ= density of the fluid µ= dynamic viscosity of the fluid The Reynolds number can be written in terms of kinematic viscosity (η), 𝑅𝑒 = 𝐷𝑉 η where, η= 𝑑𝑦𝑛𝑎𝑚𝑖𝑐 𝑣𝑖𝑠𝑐𝑜𝑠𝑖𝑡𝑦 𝑑𝑒𝑛𝑠𝑖𝑡𝑦 = µ ρ The type of flow is based on the value of Re: ➔ If Re < 2100, the flow is called Laminar ➔ If Re > 4000, the flow is called turbulent ➔ If 2100 < Re < 4000, the flow is called transient At large Reynolds numbers (turbulent), the inertial forces, which are proportional to the fluid density and the square of the fluid velocity, are large relative to the viscous forces, and thus the viscous forces cannot prevent the random and rapid fluctuations of the fluid. At small or moderate Reynolds numbers (laminar), however, the viscous forces are large enough to suppress these fluctuations and to keep the fluid “in line.” The Reynolds number at which the flow becomes turbulent is called the critical Reynolds number, Recr. The value of the critical Reynolds number is different for different geometries and flow conditions. For internal flow in a circular pipe, the generally accepted value of the critical Reynolds number is 2300. Frictional Losses are also considered in overall operational efficiency of the piping system. This may be affected by some factors including the density and viscosity of the liquid, internal pipe diameter, roughness of the inner surface of the pipe, change in elevation, the length of the pipe where the fluid travels, and acceleration. This overall frictional loss is related to the energy loss in the pipe referred to as the pressure drop, where it relationship is denoted by, (− ∆𝑃)𝑓 = ρ𝑔ℎ𝑓𝑠(frictional pressure drop) where, ρ= fluid density 𝑔= acceleration due to gravity ℎ𝑓𝑠=frictional head loss due to inner surface of pipe, where its relation to the wall shear is: ℎ𝑓𝑠 = (− ∆𝑃)𝑓𝑠/ρ𝑔 = (4τ𝑤𝐿)/(ρ𝑔𝐷) τ𝑤= shear stress of the inner wall of the pipe Frictional Losses are mainly considered in sizing a piping system. Engineers would compensate for the friction in the piping system by increasing pipe size and flow rate of fluids in the design, and at times increasing the flow velocities for smaller piping utilization that would require increase in power requirements from pumps. Considering the presence of length, inner diameter, and velocity in the piping system, its relationship with frictional head loss in the system is commonly referred by the Darcy- Weisbach Equation, 2 𝐿 𝑣 ℎ𝑓𝑠 = 𝑓( 𝐷 )( 2𝑔 ) where, ℎ𝑓𝑠= frictional head loss 𝐿= length of pipe 𝐷= inner diameter of pipe 𝑣= velocity of fluid 𝑔= acceleration due to gravity 𝑓= friction factor, a dimensionless value four times that of the *fanning friction factor denoted by, 𝑓 = 2τ𝑤 2 ρ𝑣 . *defined as the ratio between the local shear stress and the local flow kinetic energy density. Darcy- Weisbach Friction loss equation is considered to be the most accurate representation of friction loss, valid for both liquid and gas fluids. This equation uses a friction factor generated from ColebrookWhite Equation, 𝑒 1/ 𝑓 = 1. 12 − 2𝑙𝑜𝑔10( 𝐷 + 9.35 𝑅𝑒 𝑓 ) Re> 4000 The friction factor data from this equation resulted in Moody Chart, which plots the relative roughness of the pipe against the reynold’s number. Friction factors are relative to that of the fluid flow and are computed based on the reynold’s number. The relationship between the reynolds number and fanning friction factor for both laminar and turbulent flow in variety of pipes can be represented by following equation: Hagen-Poiseuille equation for laminar flow, it relates the friction pressure drop to fluid velocity, viscosity and pipe dimension − (𝑃) 𝑓 32µ𝑉𝐿 = 𝐷 2 equating the fanning equation to the pressure drop due to friction in the Hagen-Poiseuille equation results in the relation for laminar flow that can be used to develop a relation between Reynolds number and friction factor. 16 𝑓 = 𝑅𝑒 Blasius equation This equation is used to develop a relation between friction factor and Reynolds numbers for turbulent flow. this correlation valid for 4000 < 𝑅𝑒 ≤ 10 𝑓 𝑏𝑙𝑎𝑠𝑖𝑢𝑠 = 5 0.079 𝑅𝑒 0.25 von Kármán-Nikuradse equation this use to represent the entire turbulent region of fluid for Re>4000 1 𝑓 = 4. 0𝑙𝑜𝑔𝑅𝑒 𝑓 − 0. 4 4. Resources: Microsoft Excel/Matlab 5. Procedure: 1. Keep the valve leading to the smooth pipe open and valves leading to other lines closed. 2. Keep the bypass valve completely open and the main valve completely closed. Switch on the pump. 3. Connect a CCl4 manometer to the pressure taps across the smooth pipe. Ensure that no air bubbles present and height in both the limbs of the manometer are the same. 4. Set a flow rate of water through the pipe by opening the main valve and throttling the bypass valve suitably using the rotameter. 5. Note down the rotameter reading and manometer reading after a steady state is attained. 6. Increase the flow rate of water by opening the main valve and throttling the bypass valve suitably and repeat step 4 and 5. 7. Use a mercury manometer for higher flow rates. 8. Take eight readings with CCl4 manometer as well as with Hg manometer. Course: CHE 314 (Chemical Engineering Laboratory 1) Group No.: 1 Group Members: 1. Amihan, Jim Kenneth 2. Arola, Nur Mohammad 3. Bagon, Alyssa Marie 4. Balino, Russel Christian M. 5. Bayumbon, Mark Genesis S. 6. a. Data: b. Results: 7. Conclusion: Laboratory Experiment No.: 1 Section: CHE32S1 Date Performed: March 22, 2021 Date Submitted: March 24, 2021 Professor: Engr. Crispulo G. Maranan Grade: 9. Assessment (Rubric for Laboratory Performance): TECHNOLOGICAL INSTITUTE OF THE PHILIPPINES RUBRIC FOR MODERN TOOL USAGE (Engineering Programs) Student Outcome (e): Use the techniques, skills, and modern engineering tools necessary for engineering practice in complex engineering activities. Program: Chemical Engineering Course: CHE 314 Section: CHE32S1 2nd Sem SY 2020-2021 Performance Unsatisfactory Developing Satisfactory Very Satisfactory Score Indicators 1 2 3 4 1. Apply Fails to identify Identifies Identifies modern Recognizes the appropriate any modern modern techniques and is benefits and techniques, techniques to techniques but able to apply constraints of skills, and perform fails to apply these in modern modern discipline-speci these in performing engineering tools tools to fic engineering performing discipline-specific and shows perform a task. discipline-spec engineering task. intention to apply discipline-sp ific them for ecific engineering engineering engineering task. practice. task. 2. Demonstrat Fails to apply Attempts to Shows ability to Shows ability to e skills in any modern apply modern apply fundamental apply the most applying tools to solve tools but has procedures in appropriate and different engineering difficulties to using modern effective modern techniques problems. solve tools when solving tools to solve and modern engineering engineering engineering tools to problems. problems. problems. solve engineering problems. 3. Recognize Does not Recognizes Recognizes the Recognizes the the benefits recognize the some benefits benefits and need for benefits and benefits and and constraints of and constraints of constraints constraints of constraints of modern modern of modern modern modern engineering tools engineering tools engineering engineering engineering and shows and makes good tools. tools. tools. intention to apply use of them for them for engineering engineering practice. practice. Total Score Mean Score = (Total Score / 3) Percentage Rating = (Total Score / 12) x 100% Evaluated by: Engr. Crispulo G. Maranan March 24, 2021 Printed Name and Signature of Faculty Member Date End of Laboratory Experiment 1