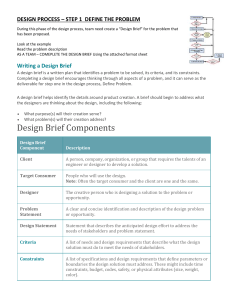

Chapter 1: Introduction To Materials Selection CHAPTER 1 INTRODUCTION TO MATERIALS SELECTION 1.1 Methods of Selection There are three methods of materials selection: classical, imitative and comparison. Classical Method Selection is done through analysis of function and properties specification. Characteristic – functional and requirement of component and materials properties. Imitative Method Selection is made by equality or similarity of function. Comparison Method Assume the component is made from a normal & low cost material; the material disability is then evaluated, if it is not suitable then the other material is selected and evaluated – the process goes on until a suitable material is obtained. Classical method is more specified, more global, high cost, required longer time to complete the selection and need to do a prototype test. Imitative and Comparison method are faster and involve low cost, however they are more suitable for an experience person or designer. 1.2 Materials in Design Design is a process of translating new idea or a market need into the detailed information from which a product can be manufactured. Normally, the choice of material is dictated by design. However, the development of new product, or the evaluation of the existing one, was suggested or made possible by the new material. What is the ROLE of material in design??? At the beginning of the design process – all materials must be considered. As the design becomes more focused and take shape – the shortlist of materials are considered. In the final stage of design, precise data are needed – few materials or perhaps only one material is chosen. Figure 1.1 shows the relationship between materials, function, process and shape in the design process. 1 Chapter 1: Introduction To Materials Selection FUNCTION MATERIALS SHAPE PROCESS Figure 1.1: Function, material, process and shape interact (M.F.Ashby, 1999). Design problem, almost always, are open-ended. They do not have a unique or correct solution, although some solution will clearly be better than others will. This module focuses on the materials aspects of the design process. It provides a methodology which properly applied, gives guidance through the forest of complex choices the designer faces. 1.3 Evolution of Engineering Materials The evolution of engineering material and its increasing pace are shown in Figure 1.2. It started with ceramics and glasses (>10 000BC, the Stone Age) and then came to the Bronze Age and followed by Iron Age. In 1620s, cast iron technology has been established. However, there were also developments in the other classes of material. The rapid rate of materials change offers opportunities which the designer cannot afford to ignore. The following case study (evolution of materials in vacuum cleaners) is an example. - - The vacuum cleaners of 1900 and before were human-powered (Figure 1.3(a)). It was largely made of wood and leather. The electric vacuum cleaner first appeared around 1908. By 1950 the design had evolved into the cylinder cleaner shown in Figure 1.3 (b). This cleaner is almost entirely made of metal. Developments have been rapidly driven by the innovative use of new materials. The 1985 vacuum cleaner of Figure 1.3 (c) are now available. The casing is entirely polymeric, no metal is visible anywhere, metal in all earlier models is now substitute with polypropylene. Figure 1.3 (d) exploits a different concept, the product is larger, noisier, heavier and much more expansive, yet it sells – a testament to good industrial design and imaginative, aggressive marketing. 2 Chapter 1: Introduction To Materials Selection Figure 1.2: The evolution of engineering materials with time. The time scale is non-linear. The rate of change is far faster today than at any previous time in history (M.F.Ashby, 1999). Figure 1.3: The evolution of materials in vacuum cleaners (M.F.Ashby, 1999). 3 Chapter 1: Introduction To Materials Selection All this has happened within one lifetime. Competitive design requires the innovative use of new materials and the clever exploitation of their special properties, both engineering and aesthetic. The same process happened to other product such as telephone, car, sport equipments, aero plane etc. 1.4 Source of Information As an engineer or designer, he should have a sufficient knowledge and information about materials and their properties. This information can be obtained from : Standard – ASTM (American Society Testing Methods), BS (British Standard), DIN, JIS, MS etc. Software - CES, NOVA, PERITUS etc. IDEA Component category Complex solid, long, short, hollow Concentric, non-hollow concentric, Solid non concentric, cup, dish, cone, Spirals, repititive, flat, bent, flanged Low temp limit High temp limit Joining method Shape category Operational factors Process characteristics Quantity, Size, Precision, Complexity,Finish, Cost Housings, covers, gears, bolts, Bearings, wear surfaces, Electrostructural, thermostructural, Insulators, conductors, large Mechanical, springs, clips, force Absobers, light transmitters Environment resistance Surface coating Cost allowance Materials characteristics Candidate materials & processes Stability, Stiffness, Density, Max. Stress, Toughness, Cost Materials data & optimisation Figure 1.4: The linkage of information in material selection (K.G.Budinski, 1997) The number of engineering materials is large, estimates more than 80 000. Therefore, an engineer or designer must select from this vast menu the material best suited to his task. This, without guidance, can be a difficult and tedious business; so the knowledge about material selection is very important in order to get the opportunity for innovation. 4 Chapter 1: Introduction To Materials Selection Engineering materials are evolving faster, and the choice is wide than ever before. As a result, it is important in the early stage of design, or of re-design, to examine the full materials menu, not rejecting options merely because they are unfamiliar. 5