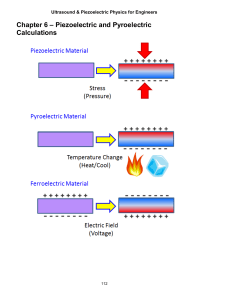

High-performance bio-piezoelectric nanogenerator made with fish scale Sujoy Kumar Ghosh and Dipankar Mandal Citation: Appl. Phys. Lett. 109, 103701 (2016); doi: 10.1063/1.4961623 View online: http://dx.doi.org/10.1063/1.4961623 View Table of Contents: http://aip.scitation.org/toc/apl/109/10 Published by the American Institute of Physics Articles you may be interested in Wireless power transfer based on magnetic quadrupole coupling in dielectric resonators Appl. Phys. Lett. 108, 023902 (2016); 10.1063/1.4939789 Ultra-thin flexible GaAs photovoltaics in vertical forms printed on metal surfaces without interlayer adhesives Appl. Phys. Lett. 108, 253101 (2016); 10.1063/1.4954039 Plasma jet printing for flexible substrates Appl. Phys. Lett. 108, 123103 (2016); 10.1063/1.4943792 Acoustic metasurface-based perfect absorber with deep subwavelength thickness Appl. Phys. Lett. 108, 063502 (2016); 10.1063/1.4941338 APPLIED PHYSICS LETTERS 109, 103701 (2016) High-performance bio-piezoelectric nanogenerator made with fish scale Sujoy Kumar Ghosh and Dipankar Mandala) Organic Nano-Piezoelectric Device Laboratory (ONPDL), Department of Physics, Jadavpur University, Kolkata 700032, India (Received 21 June 2016; accepted 11 August 2016; published online 6 September 2016) Energy harvesting performance of an efficient flexible bio-piezoelectric nanogenerator (BPNG) is demonstrated, where “bio-waste” transparent fish scale (FSC), composed of self-assembled and ordered collagen nano-fibrils, serves as a self-poled piezoelectric active component, exhibiting intrinsic piezoelectric strength of 5.0 pC/N. The dipolar orientation (19%) of the self-polarized FSC collagen is confirmed by the angular dependent near edge X-ray absorption fine structure spectroscopy. The BPNG is able to scavenge several types of ambient mechanical energies such as body movements, machine and sound vibrations, and wind flow which are abundant in living environment. Furthermore, as a power source, it generates the output voltage of 4 V, the short circuit current of 1.5 lA, and the maximum output power density of 1.14 lW/cm2 under repeated compressive normal stress of 0.17 MPa. In addition, serially integrated four BPNGs are able to produce enhanced output voltage of 14 V that turn on more than 50 blue light emitting diodes instantly, proving its essentiality as a sustainable green power source for next generation self-powered implantable medical devices as well as for personal portable electronics with reduced e-waste elements. Published by AIP Publishing. [http://dx.doi.org/10.1063/1.4961623] Energy harvesting from vibrations in the living environment is an effective approach for “battery-free” self-powered devices or nanogenerators (NGs). This is the key requirement for the realization of the fully independent and sustainable operation of low power-consuming devices and systems.1,2 To date, some attractive approaches based on piezoelectric3,4 and triboelectric5 NGs have been proposed for the conversion of mechanical movements into electrical power. However, to utilize the NGs as an eco-friendly and feasible energy harvester in practical life, there are several issues, such as initial toxic compounds for synthesis, harsh conditions and/or complex fabrication steps, and cost factor that need to be addressed.6 In this context, the natural piezoelectric materials, such as collagen fibrils,7,8 hydroxyapatite,9 and cellulose10 which are also known as eco-friendly materials, are the suitable choices for designing bio-piezoelectric nanogenerator (BPNG). Among them, the most abundant piezoelectric biomaterial present in animal tissues such as skin, tendon, cartilage, bone, and even in human heart, is the type I collagen, which is a biocompatible and biodegradable polymer enabling fabrication of the flexible BPNG.11 The cost effective collagen source is the fish constituents such as skin, fins, maws, and swim bladder which are mainly treated as “bio waste” materials because different fish species are consumed daily in large quantities worldwide.12,13 The disposal of these bio-wastes causes an increasing environmental pollution. The recycling of the fish byproducts into the BPNG via one step process is a promising solution for the development of value-added products and also to reduce the e-waste elements. It is noteworthy that collagen consists of three polypeptide chains (a-chain) with two identical a1(I) chains and a different a2(I) chain. Each a-chain is composed of repeated triplet amino acid motif a) Author to whom correspondence should be addressed. Electronic mail: dipankar@phys.jdvu.ac.in. Tel.: þ91-94333-73530, Fax: þ91-33-24138917. 0003-6951/2016/109(10)/103701/5/$30.00 sequence of Gly (Glycine)-X-Y, where X and Y are often proline (Pro) and hydroxyproline (Hyp), respectively. The three a-chains twist together into a unique triple-helical structure to form tropocollagen. The quarter staggered arrangement of collagen molecules contributes to collagen fibrils with a characteristic axial periodic structure, and the fibrils further assemble into a collagen fiber.14,15 The intrinsic presence of polar uniaxial orientation of hydrogen bonding motifs between the polypeptide chains acts as molecular dipoles that cause spontaneous polarization and piezoelectricity. It causes the collagen to become a natural electret or bioelectret material as well.16 To date, there are very few initiatives to explore the mechanical energy harvesting performance of biomaterials.17,18 However, the bio-waste fish scale (FSC) has not been applied as piezoelectric power generator until now. Herein, a simple, cost-effective and one-step approach is initiated where bio-waste FSC was chosen to make an ultrasensitive BPNG. To fabricate the BPNG, FSCs (Figure 1(a)) (of Catla catla, a sweet water fish) were collected from the fish processing market and washed thoroughly with deionised water followed by a solvent system of NaOH, 1.0 M NaCl, FIG. 1. Fabrication of flexible BPNG from bio-waste FSC. (a) Photograph of the bio-waste raw FSC. Digital photographs of the demineralised FSC, showing transparency and flexibility (by rolling) (in the insets). (b) The flexibility of the BPNG is shown by human fingers. (c) The schematic diagram of BPNG showing the simple structure of the device. 109, 103701-1 Published by AIP Publishing. 103701-2 S. K. Ghosh and D. Mandal 0.05 M Tris HCl, and 20.0 mM EDTA. Finally, the FSCs were immersed in a solution of 0.5 M EDTA to obtain transparent and flexible demineralised FSCs (thickness 250 6 10 lm). Therefore, after demineralisation, the collagen layers serve as active piezoelectric element in the resulting FSC which is not only transparent (34% to 46% transparency) (upper inset of Figure 1(a) and supplementary Figure S1) but also rollable (lower inset of Figure 1(a)) that makes suitable to a flexible BPNG (Figure 1(b)). To fabricate the robust BPNG, we have made the gold electrodes of 90 nm thickness on both sides of FSC by sputtering followed by lamination with polypropylene (PP) film (of thickness 125 lm). The simple structure of BPNG is illustrated in Figure 1(c). The presence of selfassembled well-aligned collagen nano-fibrils (diameter ca. 40 nm) is revealed from the FE-SEM image (Figure 2(a)). The banded pattern collagen nano-fibrils with D-periodicity of 62 6 4 nm (inset of Figure 2(a)) affirmed that the polypeptide chains are packed together in a self-organized manner with native helical conformation. The presence of amino acids in the triple helix structure of the polypeptide chains is confirmed by Raman spectroscopy (Figure 2(b)). For example, the band arises at 1671 cm1 due to stretching () vibration of carbonyl group ( (C ¼ O)) of peptide backbone in Gly-X-Y tripeptide sequence, attributed to amide I band.14 The strong absorbance at 1456 cm1 corresponds to the CH2 deformation (d (CH2)). The vibrational bands arise at 1279 cm1 and 1250 cm1 due to in plane Appl. Phys. Lett. 109, 103701 (2016) deformation of N-H (d(N-H)) coupled to C-N stretching mode ((C-N)), respectively, ascribed to amide III band. This band signifies the polar triple helix structure of collagen.19,20 Additionally, bands corresponding to carboxyl groups (such as at 1432 cm1 from aspartic acid and 1060 cm1 from glutamic acid) and protonated amino residues, i.e., NH3þ (1110 cm1), are also observed. The region of 1000–800 cm1 in the spectra is very much significant where amino acids such as Phenylalanine (1037 and 1007 cm1), Proline (Pro) (917 and 855 cm1), and Hydroxyproline (Hyp) (881 cm1) show strong Raman scattering due to aromatic or saturated side chain rings. The peak at 942 cm1 represents the C-C stretching ((CC)) vibration of the peptide backbone. Thus, Raman spectrum confirms the presence of helical structure in collagen of FSC with the tripeptide sequence of Gly-Pro-Y and Gly-X-Hyp.14,19–22 The presence of amide II band (which is Raman inactive) in collagen nano-fibrils is confirmed by the FT-IR spectrum (supplementary material, Figure S2). The purity of collagen nanofibrils is also examined by the UV-vis spectroscopy (supplementary material, Figure S3). The highly stable crystalline structure of polypeptide chains of collagen nano-fibrils is confirmed via X-ray diffraction (XRD) analysis (Figure 2(c)). The peak arising at 2h 8:8 signifies the compact intermolecular lateral packing structure of collagen nano-fibrils with d spacing of 1.0 nm. A broad diffraction pattern arises from the amorphous components of FSC. In addition, the linear translational length (d 0:283 nm) per amino acid in a single a-chain FIG. 2. (a) FE-SEM image of FSC with histogram profile of D-periodicity in the inset. (b) Raman spectrum in the range of 1800–800 cm1. (c) XRD pattern in the region of 2h 5:5 70 . (d) Angular dependent O K-edge NEXAFS spectra. The inset shows the incident beam geometry with respect to FSC. (e) Polarization vs. electric field (P-E) curve and (f) corresponding strain vs electric field (es-E) of the FSC under an electric field of 6200 kV=cm at 1 kHz. 103701-3 S. K. Ghosh and D. Mandal Appl. Phys. Lett. 109, 103701 (2016) along triple helix structure of the collagen is determined from the deconvoluted peak at 2h 31:6 . Furthermore, the axial translation length in amino acid residues in the N (d 0:224 nm) and C (d 0:207 nm) terminal telopeptides is obtained from the deconvoluted peaks at 2h 40:2 and 43:7 , respectively.21,22 In addition, it is important to identify the alignment of molecular dipoles (–CONH hydrogen bonding motifs) in the polypeptide chains in order to investigate the origin of piezoelectricity in FSC. Thus, angular dependent (30 and 90 ) near edge X-ray absorption fine structure (NEXAFS) spectroscopy was employed (Figure 2(d)) by measuring the total electron yield (TEY).23 The Lorentzian type sharp resonance peak at 531.6 eV has been observed in the O K-edge spectra (Figure 2(d)) due to O 1s ! pCONH transition.24 Also, the spectra manifest the broad feature of hydroxyproline due to r ðO CÞ transition.25 Interestingly, the spectra revealed significant differences in the intensity of pCONH resonant peak under different incidence angles (30 and 90 ) of polarized X-ray photon, indicating the presence of oriented dipoles. This change in peak intensity is attributed to X-ray linear dichroism phenomena.23 The degree of molecular alignment in the FSC is determined from the linear dichroism (P) expressed as P¼ IEk IE? 100%; IEk þ IE? (1) where IEk and IE? are the maximum of pCONH resonance intensities for the field vector Ek (at angle, h 90 ) and E? (at angle, h 30 ), respectively, determined from the angle ~ of the incident X-ray photon and macromolecular between E axis of collagen in FSC.23,26 We have found very strong degree of molecular alignment (19%) of –CONH hydrogen bonding motif in the FSC, thus treated as a self-polarized one. Besides this, the dielectric constant (er 154 at 1 kHz) and loss tangent (tan d 2.07 at 1 kHz) over a wide range of frequency (100 Hz to 1 MHz) (supplementary material, Figure S4a) suggest a good insulating property of FSC. The sudden increase of er and tan d in the low frequency region (1 kHz to 100 Hz) is mainly influenced by trapping of free charges present in the large number of interfaces between fibers and air pores that primarily constitute the collagen networks in FSC. It is well known as Maxwell–Wagner–Sillars (MWS) interfacial polarization effect. Other secondary processes may also play the role due to the ionic movements and hydrogen bonds bound to the protein structure.27 The FSC exhibits a good ferroelectric property with the remnant polarization (Pr) of 0.29 lC/cm2 as revealed from Figure 2(e). Furthermore, the mechanical strain response under the electric field (known as converse piezoelectric effect) is demonstrated by the symmetrical butterfly shaped strain– electric field (es-E) hysteresis loop (Figure 2(f)), where maximum 0.08% of longitudinal strain was found. The relationship between es and P is given by es ¼ Q c P 2 ; (2) where the proportional coefficient Qc is the charge-related longitudinal electrostrictive coefficient. The plot of es versus P2 is nearly a straight line (supplementary material, Figure S4b), yielding the magnitude of Qc ¼ 0.47 m4/C2 which is more than fifteen times greater than the conventional inorganic piezoelectric materials, e.g., BaTiO3 and PZT ceramics.28,31 Thus, the adequate signature of piezoelectricity in the FSC is stemmed from the remnant polarization in the P-E loop because longitudinal piezoelectric charge coefficient (d33) follows the Pr value (according to the macroscopic dimensional effect).29–31 In our study, the experimentally measured d33 value (5:0 pC=N) (supplementary material, Figure S5) is in very close agreement with the theoretical calculation (supplementary material, Associate discussion S1). The ferroelectricity in FSC arises due to flips of the polar –CONH hydrogen bonding motifs (supplementary material, Figure S4c) present in the collagen crystal of FSC.7,11,15,16 As a result, well-aligned, regular outof-plane polarization domains are formed due to appearance of the spontaneously polarized state. The enhanced polarization in the FSC resulting from the cooperative electromechanical mutual interaction among the well-aligned adjacent collagen nano-fibrils during compressive stress, called Maxwell stress, generated when a high electric field is applied, compared to a single fiber.8 Interestingly, this behaviour is observed without any prior electric poling treatment, and thus, FSC is attributed as a bioelectret material.16 Consequently, possessing the intrinsic d33, FSC is expected to provide piezoelectric output without post-poling technique that might be well suited for the fabrication of BPNG. The BPNG is able to convert several forms of mechanical energy into electricity. For example, gentle press-holdrelease motions of single human finger (i.e., under uniaxial compressive stress of amplitude (ra) 3.75 kPa and strain rate of 0.017% s1) (supplementary material, Associated discussion S2, Tables S1 and S2, where theoretical calculation is also given) results in the output voltage (680 mV) with perfect switching of polarity (supplementary material, Figure S5a and Associated discussion S3). In addition, it harvests vibrational energy during walking and running conditions (supplementary material, Figure S6b and Associated discussion S3). Furthermore, BPNG scavenges mechanical energy from high level vibration, such as machine vibration (supplementary material, Figure S6c and Associated discussion S3) and also from very low level vibration, arises from sound (e.g., ra 0.2–2.0 Pa by music) and wind motions (e.g., air flow, 3.6 m/s) (supplementary material, Figure S6d,e and Associate discussion S3). To investigate the suitability of the BPNG as energy harvesting power source, it was imparted repeatedly by hand slapping (Figure 3(a)) as reported earlier.10,29 The periodical impact of ra 0.17 MPa with 0.77% s1 strain rate (supplementary material, Associate discussion S2) generates the rectified open circuit voltage (Voc) of 4 V (Figure 3(b)) which is quite stable over large cycles (supplementary material, Figure S7) and short circuit current (Isc) of 1.5 lA (supplementary material, Figure S8a). The sensitivity of BPNG is 23.5 lV Pa1. The integral of a single cycle of Isc (supplementary material, Figure S8b) gives the charge value (Qe) of 213 pC generated under the applied force (F) of 37.6 N (supplementary material, Table S2) where Qe is given as ð Qe ¼ Isc dt: (3) 103701-4 S. K. Ghosh and D. Mandal Appl. Phys. Lett. 109, 103701 (2016) Thus, the quasi-static piezoelectric coefficient17,32 is evaluated as d33 ¼ Qe/F ¼ 5.6 pC/N, which is in close agreement with the calculated (d33 5.5 pC/N) as well as the directly measured (d33 5.0 pC/N) value. Theoretically, the total charge (Qe 201 pC) generated at the short-circuit system during the mechanical deformation of BPNG can be described as Qe ¼ As rYd3j ; (4) where As is the surface area of the piezoelectric material, r is the strain, Y is the Young’s modulus, and d3j is the piezoelectric charge constant (5.5 pC/N) induced polarization in direction 3 (Z-axis) of a three dimensional coordinate system; the subscript ‘j’ denotes direction 1 (X-axis) or 3 (Z-axis) of the induced strain.33 It should be noted that the d33 value of collagen arises because it displays a piezoelectric response mainly executed in the axial direction, rather than radial. To validate this output voltage and to demonstrate the excellent integratability performance, linear superposition tests were performed. Thus, at first, two BPNGs were integrated serially and placed as layer stacking (inset of Figure 3(b)) to be impacted simultaneously by hand slapping. In this case, the output voltage is simply added up to give Voc 8 V. A largely enhanced Voc 11 V by integrating three BPNGs and Voc 14 V by integrating four BPNGs in serial configuration are observed (Figure 3(b)). The slight loss of output could be attributed to the leakage of electric charge through the connection of the circuit. To understand the observed piezoelectric response in terms of ultrasensitivity and output voltages, in this approach, the interaction behaviour between the applied external stress and BPNG is qualitatively predicted by finite element method (FEM) simulation conducted by the COMSOL multiphysics software. To perform the FEM simulation model, a geometrical configuration was considered where the fixed constraint is the lower electrode and the bottom of the BPNG was electrically grounded (supplementary material, Figure S9a). To simplify the simulation, an external boundary load (ra 0.17 MPa) was applied to the upper electrode, and other boundaries of the BPNG were considered as symmetric. The detailed simulation process is described in supplementary material, Figure S9, Table S3, and Associate discussion S4. It not only shows the close proximity of simulated piezopotential distribution (supplementary material, Figure S9d) with our experimental observation but also reveals the resulting deformation (i.e., displacement) distribution of BPNG at the ra 0.17 MPa (Figure 3(c)). Interestingly, the maximum deformations (5.25 nm) occur at the upper edge portions of the BPNG during application of ra to the upper surface. In FSC, though the self-assembled peptide bonds are in a compact form, the presence of air gap between the fibers makes the FSC porous and soft. This behaviour yielding considerably higher elongation (i.e., displacement) in the upper edge portions than the middle portion of the FSC that leads to an increased piezoelectric potential and its sensitivity. Effective electric power output of the BPNG is obtained by measuring the output FIG. 3. (a) Digital photograph of BPNG driven by hand slapping. (b) Generated rectified open circuit voltages when the BPNGs (up to four) are integrated in serial connection (shown in inset). (c) Simulated total displacement distribution of BPNG. (d) The variation of output voltage and current (inset shows corresponding equivalent circuit diagram) as well as (e) effective output power density as a function of variable external resistances ranging from 0.25–50 MX. The instant glow of 55 blue and 22 green LEDs are shown in the inset. (f) The transient response of an external capacitor connected to BPNG via equivalent circuit diagram (shown in the inset). 103701-5 S. K. Ghosh and D. Mandal Appl. Phys. Lett. 109, 103701 (2016) voltage as a function of the external load resistors (RL) ranging from 0.25 MX to 50 MX (Figure 3(d)). Consequently, output power density (P) is calculated as 1 VL 2 : ; P¼ Ae R L (5) where Ae is the effective contact area, and VL is the voltage drop across load resistance RL . The output current (IL) is found to be reducing across the incremental RL , depicted in Figure 3(d), which is evaluated from rffiffiffiffiffiffiffiffi PAe : (6) IL ¼ RL The variation of P with RL is shown in Figure 3(e), where as high as 1.14 lW/cm2 is obtained at the RL of 5 MX. At this condition, a superior instantaneous piezoelectric energy conversion efficiency (gpiezo ) of BPNG up to 46.7% is achieved (supplementary material, Associate discussion S5). In accordance with such high P and gpiezo , layer by layer serially integrated four BPNGs are enabled to instantly turn on more than 50 blue light emitting diodes (LEDs) displaying the letters “ONPDL” and 22 green LEDs showing the letters “JU” (inset of Figure 3(e)) by repeating gentle hand slapping impact, where external storage devices, such as capacitors or batteries, are not required. Moreover, BPNG is also able to charge up an external capacitor (Ce 1 lF) up to the charging voltage (Vc) 1 V only in 30 s (Figure 3(f)) where Ce was connected via parallel connection through a full-wave bridge rectified circuit (inset of Figure 3(f)). Overall, a potential applicability of BPNG as an energy harvesting power source can be concluded to be interesting as across variable resistors, VL is found to be sensitive to the large range of resistance. The result fits well with linear circuit theory (supplementary material, Figure S11 and Associate discussion S6) and gives rise to 3.5 MX internal resistance of BPNG. The equivalent circuit model, shown in the inset of Figure 3(f), indicates that BPNG can also be considered as a charge (q) source in parallel with an internal capacitor (Ci).33 Considering the RC circuit model, the evaluated internal capacitance of the BPNG is 3.43 lF (supplementary material, Associate discussion S7). Relatively higher internal capacitance with relatively smaller resistance and also smaller optimum resistance (RL 5MX) of the BPNG is another advantage in the impedance match for improving the piezoelectric response, leading to numerous potential applications ranging from healthcare monitoring to robotics. In summary, the origin of intrinsic piezoelectricity from FSC and underlying physics is spotlighted, besides this the possibility of mechanical energy harvester fabrication, such as BPNG, has also been proposed. It enables to capture several forms of abundant ambient vibration motions available around us. Owing to the distinctive features of high sensitivity, good stability, and efficient piezoelectric power-generating performance, BPNG may open an era in the field of self-powered implantable medical device, surgery, e-healthcare monitoring, and in vitro and in vivo diagnostics apart from its broad range applications in personal portable electronic devices. See supplementary material for further experiment and simulation details. This work was financially supported by a grant from the Science and Engineering Research Board (SERB/1759/201415), Government of India. The authors are also grateful to DST, Government of India, for awarding INSPIRE fellowship (IF130865) to Mr. Sujoy Kumar Ghosh. They also thank Dr. D. K. Shukla and Dr. D. M. Phase, particularly for providing the NEXAFS facility (BL-01 beamline, INDUS-2), and those who helped in several aspects to carry out this work. 1 Y. Qi and M. C. McAlpine, Energy Environ. Sci. 3, 1275 (2010). Z. L. Wang and J. Song, Science 312, 242 (2006). 3 A. Tamang, S. K. Ghosh, S. Garain, M. M. Alam, J. Haeberle, K. Henkel, D. Schmeisser, and D. Mandal, ACS Appl. Mater. Interfaces 7, 16143 (2015). 4 S. S. Won, M. Sheldon, N. Mostovych, J. Kwak, B. S. Chang, C. W. Ahn, A. I. Kingon, I. W. Kim, and S. H. Kim, Appl. Phys. Lett. 107, 202901 (2015). 5 S. Jang, H. Kim, Y. Kim, B. J. Kang, and J. H. Oh, Appl. Phys. Lett. 108, 143901 (2016). 6 Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, and M. Nakamura, Nature 432, 84 (2004). 7 E. Fukada and I. Yasuda, Jpn. J. Appl. Phys., Part 1 3, 117 (1964). 8 M. Minary-Jolandan and M. Yu, Nanotechnology 20, 085706 (2009). 9 A. A. Gandhi, M. Wojtas, S. B. Lang, A. L. Kholkin, and S. A. M. Tofail, J. Am. Ceram. Soc. 97, 2867 (2014). 10 M. M. Alam and D. Mandal, ACS Appl. Mater. Interfaces 8, 1555 (2016). 11 C. Ribeiro, V. Sencadas, D. M. Correia, and S. Lanceros-Mendez, Colloids Surfaces B: Biointerfaces 136, 46–55 (2015). 12 F. Shahidi, in Seafood Proteins, edited by Z. Sikorski, B. Pan, and F. Shahidi (Springer, USA, 1995), pp. 171–193. 13 FAO, “Food Outlook” (Food and Agriculture Organization of the United Nations, Rome, 2014). 14 T. Ikoma, H. Kobayashi, J. Tanaka, D. Walsh, and S. Mann, Int. J. Biol. Macromol. 32, 199 (2003). 15 R. D. B. Fraser, T. P. Macrae, and E. Suzuki, J. Mol. Biol. 129, 463 (1979). 16 S. Sun, T. Kou, and H. A. Zhu, J. Appl. Polym. Sci. 64, 267 (1997). 17 B. Y. Lee, J. Zhang, C. Zueger, W. Chung, S. Y. Yoo, E. Wang, J. Meyer, R. Ramesh, and S. W. Lee, Nat. Nanotechnol. 7, 351 (2012). 18 K. N. Kim, J. Chun, S. A. Chae, C. W. Ahn, Ill. W. Kim, S. W. Kim, Z. L. Wang, and J. M. Baik, Nano Energy 14, 87 (2015). 19 S. K. Ghosh and D. Mandal, “Efficient Natural Piezoelectric Nanogenerator: Electricity Generation from Fish Swim Bladder,” Nano Energy (published online). 20 B. G. Frushour and J. L. Koenig, Biopolymers 14, 379 (1975). 21 B. Wu, C. Mu, G. Zhang, and W. Lin, Langmuir 25, 11905 (2009). 22 P. Thanikaivelan, N. T. Narayanan, B. K. Pradhan, and P. M. Ajayan, Sci. Rep. 2, 230 (2012). 23 J. St€ ohr, NEXAFS Spectroscopy (Springer-Verlag, Berlin, 1992). 24 M. L. Gordon, G. Cooper, C. Morin, T. Araki, C. C. Turci, K. Kaznatcheev, and A. P. Hitchcock, J. Phys. Chem. A 107, 6144 (2003). 25 Y. Zubavichus, A. Shaporenko, M. Grunze, and M. Zharnikov, J. Phys. Chem. A 109, 6998 (2005). 26 K. M€ uller, D. Mandal, K. Henkel, I. Paloumpa, and D. Schmeisser, Appl. Phys. Lett. 93, 112901 (2008). 27 V. P. Tomaselli and M. H. Shamos, Biopolymers 12, 353 (1973). 28 B. G. Baraskar, S. G. Kakade, A. R. James, R. C. Kambale, and Y. D. Kolekar, AIP Conf. Proc. 1731, 140066 (2016). 29 S. K. Ghosh, T. K. Sinha, B. Mahanty, and D. Mandal, Energy Technol. 3, 1190 (2015). 30 W. H. Liew, M. S. Mirshekarloo1, S. Chen, K. Yao, and F. E. H. Tay, Sci. Rep. 5, 9790 (2015). 31 T. Furukawa and N. Seo, Jpn. J. Appl. Phys., Part 1 29, 675 (1990). 32 Y. Wan, L. Xie, X. Zhang, and Z. Zhong, Appl. Phys. Lett. 98, 122902 (2011). 33 C. Chang, V. H. Tran, J. Wang, Y. K. Fuh, and L. Lin, Nano Lett. 10, 726 (2010). 2