Fluid Flow Exam Questions: Manometers, Pitot Tubes, Reynolds Number

advertisement

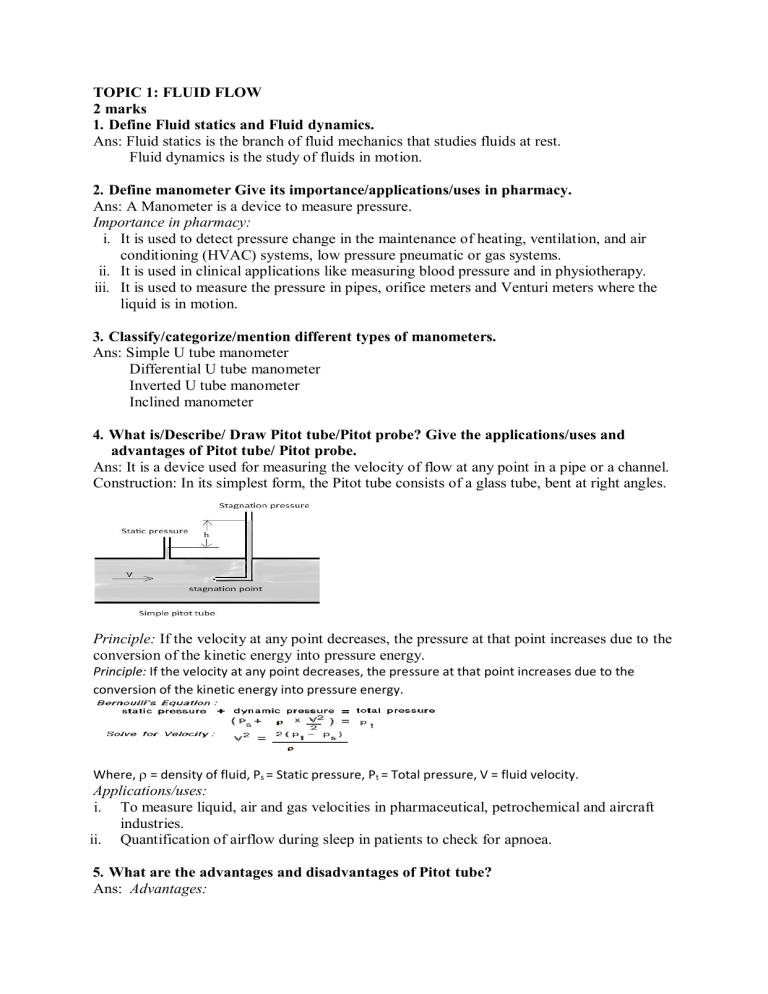

TOPIC 1: FLUID FLOW 2 marks 1. Define Fluid statics and Fluid dynamics. Ans: Fluid statics is the branch of fluid mechanics that studies fluids at rest. Fluid dynamics is the study of fluids in motion. 2. Define manometer Give its importance/applications/uses in pharmacy. Ans: A Manometer is a device to measure pressure. Importance in pharmacy: i. It is used to detect pressure change in the maintenance of heating, ventilation, and air conditioning (HVAC) systems, low pressure pneumatic or gas systems. ii. It is used in clinical applications like measuring blood pressure and in physiotherapy. iii. It is used to measure the pressure in pipes, orifice meters and Venturi meters where the liquid is in motion. 3. Classify/categorize/mention different types of manometers. Ans: Simple U tube manometer Differential U tube manometer Inverted U tube manometer Inclined manometer 4. What is/Describe/ Draw Pitot tube/Pitot probe? Give the applications/uses and advantages of Pitot tube/ Pitot probe. Ans: It is a device used for measuring the velocity of flow at any point in a pipe or a channel. Construction: In its simplest form, the Pitot tube consists of a glass tube, bent at right angles. Principle: If the velocity at any point decreases, the pressure at that point increases due to the conversion of the kinetic energy into pressure energy. Principle: If the velocity at any point decreases, the pressure at that point increases due to the conversion of the kinetic energy into pressure energy. Where, = density of fluid, Ps = Static pressure, Pt = Total pressure, V = fluid velocity. Applications/uses: i. To measure liquid, air and gas velocities in pharmaceutical, petrochemical and aircraft industries. ii. Quantification of airflow during sleep in patients to check for apnoea. 5. What are the advantages and disadvantages of Pitot tube? Ans: Advantages: Low cost Low maintenance Single point reading Disadvantages: Not accurate Can get blocked easily 6. Give the advantages and disadvantages of Venturi- meter. Ans: Advantages of venturi meter: 1. Less chances of getting clogged with sediments. 2. Can be installed vertically, horizontally or inclined. 3. They are more accurate and can be used for a wide range of flows. 4. Around 90% of pressure drop can be recovered. Disadvantages of Venturi meter: 1. They are large in size and hence where space is limited, they cannot be used. 2. Expensive initial cost, installation and maintenance. 3. Cannot be used in pipes below 7.5 cm diameter. 4. Maintenance is not easy. 5. Cannot be altered for measuring pressure beyond a maximum velocity. 7. Give the advantages and disadvantages of orifice-meter. Ans: Advantages of orifice meter: 1. Orifices are small plates and easy to install/remove. 2. Orifice meter can be easily maintained. 3. Measures a wide range of flow rates. 4. They have a simple construction. 5. They have easily fitted between flanges. 6. They are most suitable for most gases and liquids. 7. They are inexpensive. Disadvantages of orifice meter: 1. Causes a pressure drop in fluid. 2. Requires homogeneous fluid. 3. Requires axial velocity vector flow. 4. Their accuracy is affected by density, pressure and viscosity of fluid. 5. Fluid viscosity limits measuring range. 6. Requires straight pipe runs to ensure accuracy is maintained. 8. What is a rotameter/variable area meter? Give its advantages and disadvantages, importance/applications/uses. Ans: Construction: Rotameter also known as variable area meter consists of a vertical pipe/tube made of glass, or plastic tapered downward. There is cylindrical type metallic float or plummet inside the tube. Working: The flow passes from the bottom to the top. The fluid flows upward through the gap between the tube and the float. As the float moves up or down there is a change in the gap, as a result changing the area of the orifice. The float settles down at a position, where the pressure drop across the orifice will create an upward thrust that will balance the downward force due to the gravity. The position of the float is calibrated with the flow rate. Advantages: i. It is simple in construction and ready to install ii. It provides linear scale and the flow rate can be directly seen on a calibrated scale iii. It is useful for a wide range of variation of flow rates (10:1). iv. The cost of rotameter is low. v. It has good accuracy for low and medium flow rates. vi. The pressure loss is nearly constant and small. vii. Usability for corrosive fluid. Disadvantages: i. It can be only be used in a vertical pipeline. ii. When opaque fluid is used, float may not be visible. Importance/Applications/Uses: i. The rotameter is used in process industries. ii. It is used for monitoring gas and water flow in plants or labs. iii. It is used for monitoring filtration loading. 9. Write a short note on differential manometer. Ans: These manometers are suitable for measurement of small pressure differences. It is also known as two – Fluid U- tube manometer. It contains two immiscible liquids A and B having nearly same densities. The U tube contains of enlarged chambers on both limbs. 5 marks 1. Write a note on/describe construction and working, advantages, disadvantage, applications of inclined/inclined-tube manometer. Ans: Construction: An inclined/inclined-tube manometer is usually made of transparent material such as glass. It involves a gradual incline (angle) in the design. One limb is usually made much greater in cross-section than the other. Working: When a pressure difference is applied across the manometer, the movement of the liquid surface in the wider limb is practically negligible compared to that occurring in the narrower limb. If the level of the surface in the wider limb is assumed constant, the displacement of the meniscus in the narrower limb needs only to be measured, and therefore only this limb is required to be transparent. The equation is: Advantages: If is small, a large magnification of the movement of the meniscus may be achieved. This is helpful in measurement of small pressure differences Disadvantages: Angles less than 5 are not usually satisfactory, because it becomes difficult to determine the exact position of the meniscus. Applications: A small blockage within the gas system can be detected with an inclined manometer. Low pressure and low differentials are better handled with an inclined manometer. 2. What is the significance/importance of Reynolds number? How is it derived? Ans: The Reynolds number expresses the ratio of inertial forces to viscous forces. The inertial forces are characterized by the product of the density (), the velocity (V) and the gradient of the velocity dV/dL. The viscous forces are characterized by the product of dynamic viscosity coefficient and the second gradient of the velocity d2V/dL2. The Reynolds number Re then becomes: Re = ( × V× dV/dL) / ( × d2v/dx2) The gradient of the velocity is proportional to the velocity divided by a length scale L. Similarly, the second derivative of the velocity is proportional to the velocity divided by the square of the length scale. Then: Re = ( × V × V/L) / ( × V/ L2) Re = ( × V × L) / 3. Describe Reynolds experiment. Ans: Reynolds’ Experiment: • The existence of streamline flow and transition to turbulent flow may be demonstrated by Reynolds’ experiment. • A glass tube is connected to constant over head water tank. • The rate of flow of water controlled by the cock. • Dye solution is fed from a hypodermic needle forming a fine jet on the pipe axis. • At low flow rates a continuous, straight and steady line of dye may be caused to flow down the whole length of the centre of the pipe The dye stream is seen as parallel lines. The flow of water is considered to be in streamline. • When the velocity of water increased, the dye line begins to waver and the entire mass of water gets uniformly colored. Such type of flow is known as a turbulent flow. • On reducing the flow of water again this turbulence is damped out and the continuous dye line reestablishes itself. • The flow regime (either laminar or turbulent) is determined by evaluating the Reynolds number of the flow • The Reynolds number (Re), is a dimensionless number comprised of the physical characteristics of the flow. 4. Explain the construction, working, applications, advantages and disadvantages of orifice meter. Ans: Construction: It is a device used for measuring the rate of flow of a fluid flowing through a pipe. It consists of flat circular plate which has a circular hole, in concentric with the pipe. This is called orifice. The diameter of orifice is generally 0.5 times the diameter of the pipe (D), although it may vary from 0.4 to 0.8 times the pipe diameter. Principle: When a fluid passes through the orifice, its pressure P 1 builds up slightly upstream of the orifice but as the fluid is forced to converge to pass through the hole, the velocity increases and the fluid pressure decreases P2. If d1 is the diameter of the pipe line and the d2 diameter of orifice opening respectively, then the flow rate can be obtained by measuring the pressure difference upstream and downstream (P 1-P2) and using the equation: Where Q = Flow rate, C = Correction factor, A2 = Area of the flow at orifice, = density of fluid. C= the ratio of the actual flow and the ideal flow. C is always less than one due to which the actual flow rate is less than the ideal because of two reasons: The first reason is there is loss of flow due to friction and secondly, the minimum flow area known as the Vena contracta is not the orifice area, but is somewhat less and it occurs at a distance from the orifice plate. Advantages: It is low cost device. Simple in construction Easy to install in the pipeline Disadvantages: Permanent pressure drop is experienced in the orifice plate. Meant for measuring only single-phase fluids, not meant for mixture of gases and liquids, or of liquids and solids. Applications: To measure flow rate of fluids. To reduce pressure of fluids To restrict flow, in which case they are often called restriction plates. 5. Describe the construction, working, applications, advantages and disadvantages of simple U tube manometer. Ans: Construction:It is made up of a glass tube in U shape. One end of this glass tube is connected to the pipe where we need to measure the pressure and another end will be open to atmosphere.The tube is filled with mercury or any other liquid having more density compared to the density of the liquid in pipe. Working: Gauge pressure is defined as the pressure which is measured above or below the atmospheric pressure (which is considered zero). Consider P = Pressure at point B;A-A = Datum Line;h1= Height of lighter liquid above datum line;h2 = Height of heavier liquid above datum line;ρ1=Density of the light liquid; ρ2 = Density of the heavy liquid Pressure in the left column above the datum line = P + ρ 1g h1 Pressure in the right column above the datum line = ρ2g h2 As pressure on same level is equal, we can write equation as: P + ρ1g h1 = ρ2g h2 P = ρ2g h2 - ρ1g h1 P = (ρ2h2 - ρ1h1)g Application: To measure the pressure of fluid in a container. Advantages: Simple and economical. Can measure liquids and gas pressure Disadvantages: Difficult to measure pressure if h is small. Manometric liquid is exposed to contamination. 6. Discuss energy losses in fluid flow. Ans: The change in velocity of the liquid in a flow (either in magnitude or direction) induces large-scale turbulence due to formation of eddies. So, a portion of energy possessed by the flowing liquid is ultimately dissipated as heat and is considered to be the loss of energy. Some of the losses of energy caused by the change in velocity are, Some are termed as 'minor' losses because the magnitude of these losses is quite small compared to the loss due to friction in long pipes which are ‘major’ losses. The 'minor losses' are confined to a very short length of the passage of the flowing liquid. Loss of Energy due to Sudden Enlargement: Loss of Energy due to Sudden Contraction: Loss of Energy at the Entrance to a pipe: Where, V is the mean velocity of flow of liquid in the pipe. Loss of Energy at the Exit from a Pipe: Loss of Energy due to Obstruction in Flow Passage: Loss of Energy due to Gradual Contraction or Enlargement: The energy loss due to sudden contraction of enlargement can be minimized substantially by gradual decrease or increase in area of cross-section of the flow because the dissipation of energy due to turbulent eddies will be eliminated. In such case, the head loss is expressed as, Where V1 and V2 are the mean velocities at the inlet and outlet; k is the loss coefficient whose value depends on the angle of convergence/divergence and cross-sectional areas at the upstream and downstream respectively. Loss of Energy in Bends: The bends are provided in a flow passage to change the direction of the flow. This causes the loss of energy due to flow separation from the boundary and subsequent formation of turbulent eddies. In general, the head loss may be expressed as, Where V is the mean velocity of flow and k is the loss coefficient. The value of k depends on the total angle of bend, radius of curvature of the pipe axis and pipe diameter. Loss of Energy in Various Pipe Fittings: All pipe fittings such as valves, couplings etc. cause loss of energy and is also represented by: However, the value of k depends on the type of pipe-fittings. Approximate Loss Coefficients, K for Commercial Pipe Fittings . Type and position of Values of fittings K Globe valve,wide open 10 Gate valve, wide open 0.2 Gate valve, three-quarters 1.15 open Gate valve, half open 5.6 Gate valve, quarter open 24 Pump foot valve 1.5 90°elbow(threaded) 0.9 45°elbow(threaded) 0.4 Side outlet of T junction 1.8 7. Explain the construction, working, applications, advantages and disadvantages of Vertical single column manometer (one limb enlarged). Ans: Construction: One limb is enlarged (like a well), other limb of glass tube is vertical. This is connected to a pipe filled with a liquid whose pressure is measured at point A. Working: Volume of heavy liquid in the left limb (enlarged) will drop and there is rise in the volume of heavy liquid in the right limb. A x Δh = a x h2 ∴ Δh = a /A x h2 Pressure in the left limb above YY = P + ρ1g (Δh + h1) Pressure in the right limb above YY = ρ2g (Δh + h2) As pressure is equal at same level: P + ρ1g (Δh + h1) = ρ2g (Δh + h2) P = ρ2g (Δh + h2) - ρ1g (Δh + h1) P = Δh (ρ2g - ρ1g) + ρ2g h2 - ρ1g h1 P = (a /A x h2) (ρ2g - ρ1g) + ρ2g h2 - ρ1g h1 Therefore, Application: Used for detecting pressure of fluid in a container. Advantages: Simple and economical. Can measure liquids and gas pressure. Little drop in left limb level causes significant increase in level of right limb. Disadvantages: Manometric liquid is exposed to contamination. 10 marks 8. Mention the different types of flow meters. Explain the construction, principle, working, applications, advantages and disadvantages of Venturi meter. Ans: Differential Pressure Flow meters: i. Orifice meter ii. Venturi meter iii. Pitot tube iv. Variable Area meter (Rotameter) Velocity Flow meters Positive Displacement Flow meters Mass Flow meters Venturi meter: i. Construction: Venturimeter is a device used for measuring the rate of flow of a fluid flowing through a pipe. It consists of three parts: Short converging part: It is a tapered portion whose radius decreases gradually forward. ii.Throat: It is middle portion of the Venturi. Here the velocity of the fluid increases and pressure decreases. It possesses the least cross section area. iii. Diverging part: In this portion the fluid diverges. Principle: Here we have considered two cross sections, first at the inlet and the second at the throat. The difference in the pressure heads of these two sections is used to calculate the rate of flow through Venturi meter. Working: As water enters at the inlet section it converges and reaches to the throat. The throat has uniform and least cross section area. As the water enters in the throat its velocity gets increased and the pressure drops to the minimum. There is a pressure difference of the fluid at the two sections. At section 1(i.e. at the inlet) the pressure of the fluid is maximum and the velocity is minimum. And at section 2 (at the throat) the velocity of the fluid is maximum and the pressure is minimum. The pressure difference at the two sections can be seen in the manometer attached at both the sections. This pressure difference is used to calculate the rate flow of a fluid flowing through a pipe. Let d1 = diameter at the inlet (section 1); p1 = pressure at section 1; v1 = velocity at section 1 A1= area at section1; d2, p2, v2, A2 are the corresponding values at the throat (section 2) The flow rate is given by: H (or h) = Height recorded in the manometer. Cd = correction factor. The discharge coefficient Cd varies between 0.95 and 0.98. Applications: To calculate the velocity of fluids in running through a pipeline Used in carburetors is used to measure airflow in a car engine To calculate flow of chemicals in pipelines Advantages: Pressure drop is minimal. Friction losses are less than orifice meter. Disadvantages: It is costlier than an orifice meter. Precise design is a must. 9. Derive Bernoulli’s theorem/equation. Give its assumptions and importance. Ans: Statement: In a steady state ideal flow of an incompressible fluid, the total energy per unit mass, at any point of the fluid is constant. Assumptions: • Fluid is incompressible. • Unit mass of fluid • Neglect changes in magnetic and electrical energy • Considering no accumulation of energy • The system is isothermal • Consider a pump working at isothermal conditions between points A and B. Consider a pump working at isothermal conditions between points A and B. Mathematically, it is P + ρgh + ρu2/ 2 = constant For particular fluid ρ(density) is constant. Hence divide the whole equation with ρg. Pressure energy = P/ρg; Potential energy = h (here ‘X’); Kinetic energy = u 2/2g; At point ‘A’ one kilogram of liquid is assumed to be entering. At point A, Pressure energy = P A/g ρA Where, PA = Pressure at point A g= Acceleration due to gravity ρA = Density of the liquid uA = velocity of the liquid Potential energy of a body is defined as the energy possessed by the body by the virtue of its position. Potential energy at A = XA Kinetic energy of a body is defined as the energy possessed by the body by virtue of its motion,kinetic energy = U2A/ 2g Total energy at point A = Pressure energy + Potential energy +Kinetic energy Total energy at point A = PAV/g +XA+U2A/ 2g According to the Bernoulli's theorem the total energy at point A is constant. Total energy at point A = PAV/g +XA + (U2A / 2g) = Constant After the system reaches the steady state, whenever one kilogram of liquid enters at point A, and one kilogram of liquid leaves at point B. Total energy at point B = PBV/g +XB + UB2/ 2g V is specific volume and it is reciprocal of density. Pump has added certain amount of energy W which can be added to A Loss due to friction can be subtracted from A. Then, according to Bernoulli’s theorem total energy at all points is equal. PA/ρAg+XA+ U2 A/2g – F + W = PB/ρB g+XB+ U2B/ 2g Or in terms of volume PAV/g+XA+ U2A/2g – F + W = PBV/g+XB+ U2B/ 2g This is called as Bernoulli’s theorem Applications of Bernoulli’s equation: Measurement of fluid speed is based on Bernoulli’s principle using equipments such as a Pitot tube, venturi meter and orifice meter. The maximum possible drain rate for a tank with a hole or tap at the base can be calculated directly from Bernoulli's equation. 10. Explain the construction, working, applications, advantages and disadvantages of Differential manometer (with two enlarged legs) Construction: The U tube contains of enlarged chambers on both limbs. It contains two immiscible liquids A and B having nearly same densities and third Working:Using the principle of simple manometer The pressure differences can be written as ∆P =P1 –P2 =R (ρc – ρA) g Applications: To measure pressure difference at two different points Advantages: Easy to use. Economical. Sensitive to slight pressure differences Disadvantages: Sensitive to temperature change. P1+𝜌Bga+𝜌Agb-𝜌CgR -𝜌Agd-𝜌Bga = P2 P1+𝜌Agb-𝜌CgR -𝜌Agd = P2 P1+𝜌Ag(b-d) - 𝜌CgR = P2 But b-d = R P1+(𝜌A - 𝜌C) gR = P2 𝛥P = P1- P2 = - (𝜌A - 𝜌C) Or 𝛥P = P1- P2 = (𝜌C - 𝜌A)