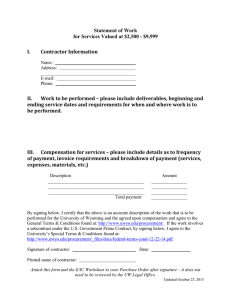

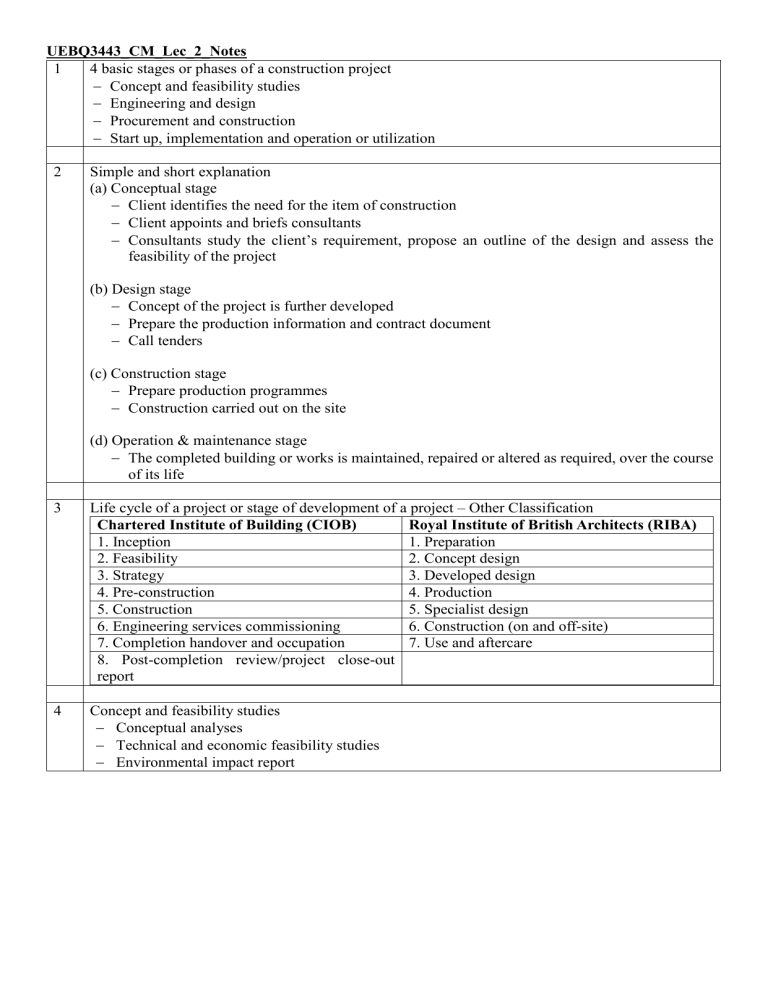

UEBQ3443_CM_Lec_2_Notes 1 4 basic stages or phases of a construction project Concept and feasibility studies Engineering and design Procurement and construction Start up, implementation and operation or utilization 2 Simple and short explanation (a) Conceptual stage Client identifies the need for the item of construction Client appoints and briefs consultants Consultants study the client’s requirement, propose an outline of the design and assess the feasibility of the project (b) Design stage Concept of the project is further developed Prepare the production information and contract document Call tenders (c) Construction stage Prepare production programmes Construction carried out on the site (d) Operation & maintenance stage The completed building or works is maintained, repaired or altered as required, over the course of its life 3 Life cycle of a project or stage of development of a project – Other Classification Chartered Institute of Building (CIOB) Royal Institute of British Architects (RIBA) 1. Inception 1. Preparation 2. Feasibility 2. Concept design 3. Strategy 3. Developed design 4. Pre-construction 4. Production 5. Construction 5. Specialist design 6. Engineering services commissioning 6. Construction (on and off-site) 7. Completion handover and occupation 7. Use and aftercare 8. Post-completion review/project close-out report 4 Concept and feasibility studies Conceptual analyses Technical and economic feasibility studies Environmental impact report 5 Engineering and Design (a) Preliminary engineering & design Stresses on architectural concept Evaluation of technological process alternatives Size and capacity decision Comparative economic studies (choice whether IBS or conventional) types of construction method Eg, in a high rise building: Determines number and spacing of the stories General layout of services and occupied floor spaces General functional allocations Steel or reinforced concrete structure (b) Detailed Engineering & Design Process of breaking down, analyzing and designing the structure and elements to comply with recognized standards of safety and performance Designs will be in the form of a set of explicit drawings and specifications that will tell the constructors exactly how to build the structure at site 6 Types of Construction Method (a) Cast In-situ Method construction on site formwork is used as mould where wet concrete is poured into a temporary system (b) Composite Method Partially pre-fabricated Eg: steel roof truss, wall frames (c) Fully Pre-Fabricated method all elements pre-fabricated in the factory can involve the assembly of precast elements such as floor slabs, in-filled walls, bathrooms, staircases, etc 7 Procurement Contracting and sub-contracting. Obtaining materials and equipment required to construct the project. * Both dependent on the contractual approach taken for the particular project 8 Construction Designer’s plans and specifications are converted into physical structures. Involves the organization & coordination of all the resources for the project. Ex. Labor, construction equipment, money, etc to complete the project within time, cost & quality specified by the designer 9 Start up and implementation To make sure all components function well together as a total system. May involve testing, adjusting and correcting the major electrical and mechanical systems so that they perform at their optimum level 10 Operation and Utilization Utilisation of structure 11 Management in construction can be divided into two distinct levels: 1. Management at the company (corporate) level – [Project Manager] 2. Management at project level – [Construction Manager] 12 Management of construction projects differs from that in other industries due to the unique nature of the construction industry: 1. Heterogeneous and fragmented firms 2. Size of firms 3. Size of the industry 4. Regulator of the economy 5. Characteristics of projects and workforce 6. Ease of entry to the industry 7. Separation of design and production 8. Speculative demand 13 Heterogeneous and fragmented firms Construction industry comprises of a group of heterogeneous and fragmented firms, meaning; there are large differences between firms in terms of size and scope of work, and within firms there is often diversity in activities 14 Size of firms The construction industry is made up of mostly small firms. The small and medium sized firms however accounts for only around 20-30 % of the total construction works 15 Size of the industry The size of the construction industry is large: 3 to 14 % of a nation’s GDP and employs between 512 % of the total workforce These figures for GDP and labour employed would be much higher if other closely related industries, especially construction material manufacturers, are considered 16 Regulator of the economy Due to its large size and its wide influence over other related industry, the government has very often used the construction industry as a regulator of the national economy. This done in the following ways: Direct intervention as a major client for the industry Indirectly through the manipulation of interest rates to control private sector building demand 17 Ease of entry to the industry There are few constraints to setting up a contracting or property/housing development business. The authorities have imposed mandatory registration for contractors as well as developers, but the conditions for registration are relatively easy compared to the consultants 18 Separation of design and production (For traditional procurement) Traditionally design is separated from production, making the management of the construction process difficult and complicated; reasons being: conflict of interests between the designers and constructors poor communication and coordination The above difficulties can be overcome by using Design & Build method of procurement 19 Speculative demand The demand for construction projects is called ‘derived’ demand; meaning it is derived from the need for buildings or infrastructure in which to live, play, work and to manufacture, store and transport goods, etc 20 Characteristics of projects and workforce projects are large discrete units, works are carried out over relatively long duration and having variety of work force, projects are constructed away from where the firms are located, projects undertaken by any one firm are geographically dispersed and need many specialist input, majority of projects are designed and tailor-made to a client’s requirements there is wide variability in the types of construction projects and man power requirements, prices for projects are established through competitive tendering; meaning the products are sold before they are produced, each individual project frequently constitutes a significant proportion of a firm’s workload, and projects are built based on speculative demand 21 The contractual relationships among parties The contractual relationships among the parties involved in a project depend on the procurement method used for the project Procurement methods can be broadly classified under the following: Traditional approach Design-and-Build – Turnkey, BOOT and PFI (PPP) Management Type – (i) Construction management and (ii) Management contracting Partnering 22 Traditional Method This is based upon rigid separation of design and construction The promoter, usually after undertaking a feasibility study, appoint a team of consultant (led by architect/engineer) to undertake the detail design. The design team prepares detailed drawing, specifications and often Bill of Quantities. The tender documents are prepared and the contract awarded, usually to the contractor with the lowest bid. Traditionally, field construction does not begin until the architect‐engineer has completed and finalized the design. This sequence is still predominant in the industry and is referred to as the design‐bid‐construct procedure. 23 Contractual and Function Relationship – Traditional Method 24 25 Design and Built Usually one building contractor or a construction company to take full responsibility and carry sole liability for the design and construction of a building. The contractor has its own design section with architects and engineers as company employees. In other cases, however, the (a) architect‐engineer can be a contractor’s corporate affiliate or (b) subsidiary, or (c) the contractor can enter into a joint venture arrangement with an independent architect‐engineer firm for a given project or contract. The contractor provides substantial input into the design process on matters pertaining to materials, construction methods, cost estimates, and construction time schedules. These lead to cheaper and faster completion. 26 When to use D & B? Early delivery of project is required Project is of technical complexity There is the need for early start on site Price certainty (usually fixed lump sum) is required prior to production Construction project is prestigious and hence single point responsibility is required Economy (time, cost, function, quality, value for money) is required. 27 Contractual and Function Relationship – D & B Method 28 Turnkey The Turnkey contractor is made fully and totally responsible for the planning, design, construction and supervision. A turnkey contract is similar to a design & Built method. The difference lies in the greater range of responsibilities that the contractor undertakes on behalf of the owner under a turnkey arrangement. For example, a turnkey contract often includes such services as land selection and acquisition, project financing, project equipage procurement, and leasing of the completed facility. 29 Management Type The term construction management is applied to the provision of professional management services to the owner of a construction project with the objective of achieving high quality at minimum cost. Construction management does not include design or construction services per se but involves management direction and control over defined design and construction activities. Construction management services can be performed for the owner for a stipulated fee by a range of firms, including design firms, contractors, and professional construction managers. The Construction Management approach is practiced in two distinct variations With Agency Construction Management (Construction Management), the construction manager operates throughout the project as the agent of the owner to manage the entire project in the best interest of the owner and does not perform any of the construction work. With Construction Management At Risk (Management Contracting), the construction manager will, at some relatively early stage of design, provide cost and schedule commitments to the owner and take on the responsibility of completing the job within the time frame and cost stated. 30 31 Partnering Partnering is not a procurement choice per se; rather it is an enacted philosophy that can be applied to other procurement forms. It is a concept based on co-operative efforts for mutual benefits. Its use is widely in other countries and in other economic sectors. The application of partnering as an approach in construction procurement may lead to improved performance in the construction industry In partnering, efforts are made to design for each project a problem-finding and problem-solving team comprising of members from both parties and recognises and honours the objectives of all parties, thus creating synergy for project success Eg, BRT-Sunway Line is public-private partnership (PPP) between Prasarana Malaysia Berhad (Prasarana) and Sunway Berhad