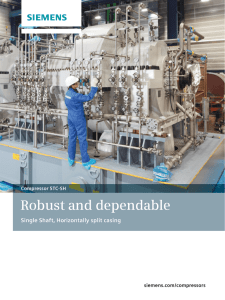

6_STC_SH___MH 14.06.2005 14:19 Uhr Seite 1 C M Y CM MY CY CMY K Industrial Applications STC-SH Siemens single-shaft centrifugal compressors with horizontally split casing Robust and dependable Perfect process control Single-shaft centrifugal compressors with horizontally split casings in the STC-SH series can be used for the majority of process applications. They are designed according to API 617 specifications. Casings are mostly fabricated, but can also be cast for special applications (e.g. low temperature). The horizontally split casing split permits easy access to all compressor internals by simply removing the upper half of the casing. STC-SH compressors can be controlled by either throttling, bypass operation or speed variation, and can therefore be operated with all available drive systems (i.e. electric motors, steam and gas turbines, as well as expanders). Adjustable inlet guide vanes in front of the first impeller offer special advantages regarding turn-down and part-load efficiencies as required in certain applications. Flexible adaptation The design concept of STC-SH compressors is very flexible, allowing easy adaptation to the requirements of specific process applications. These centrifugal compressors can be equipped with up to ten impellers, divided into up to four process stages per casing. This enables multiple intercooling and side streams. Designs include straight through, double-flow and back-to-back configurations. A well-proven, fully-parametric aerodynamic design, based on comprehensive in-house research & development, allows for the perfect matching of compressor performance and rotor dynamics for any application. State-of-the-art sealing With a wide variety of sealing systems (labyrinth seals, carbon ring seals, brush seals and mechanical dry gas seals), this robust compressor design is suited for a wide range of process gases. Mechanical dry gas seals, in combination with active magnetic bearings for compressor and driver, yield the special economic and environmental benefits of dry-dry (oil-free) equipment operation. Single-shaft centrifugal compressor with horizontally split casing Power Generation Probedruck 6_STC_SH___MH 14.06.2005 14:19 Uhr Seite 2 C M Y CM MY CY CMY K Technical performance data Volume flows from 500 to 480,000 m3/h (300 to 280,000 cfm) Discharge pressure for oxygen and inert gas up to 100 bar (1,450 psi) Discharge pressure for other process gases up to 50 bar (725 psi) Fields of application On-/offshore Oil & Gas Refineries Petrochemicals General chemicals Fertilizers and others Olefins Application range STC-SH 100 1000 50 500 Speed min-1 Discharge pressure p.bar Frame sizes 05 06 08 10 12 14 17 20 23 p.psi 21,000 10 Speed range 100 15,000 5 50 Boil-off turbocompressor in an LNG plant 9,000 3,000 1 0 10 0,4 1 0,5 V .1,000 m3/h 1 V .1,000 cfm 10 50 10 100 50 500 100 280 Actual suction flow rate Eight-stage coker gas turbocompressor for a refinery Published by and copyright © 2005: All rights reserved. Siemens AG Power Generation Industrial Applications Wolfgang-Reuter-Platz 47053 Duisburg, Germany e-mail: welcome.pgi@siemens.com www.pg.siemens.com Siemens Industrial Turbomachinery, Inc. 10730 Telge Road Houston, Texas 77095, USA Order No. A96001-S90-A149-V1-4A00 Printed in Germany 1388 177140M DA 06052. Subject to change without prior notice Trademarks mentioned in this document are the property of Siemens AG, its affiliates, or their respective owners . The information in this document contains general descriptions of the technical options available which do not always have to be present in individual cases. The required features should therefore be specified in each individual case at the time of closing the contract. Probedruck