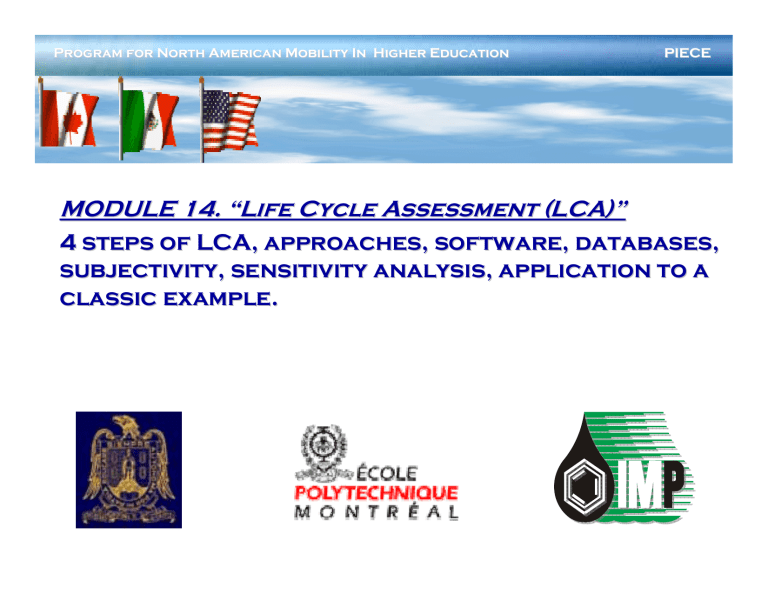

Program for North American Mobility In Higher Education PIECE MODULE 14. “Life Cycle Assessment (LCA)” 4 steps of LCA, approaches, software, databases, subjectivity, sensitivity analysis, application to a classic example. NAMP PIECE Structure of Module 14 What is the structure of this module? Module 14 is intended to convey the basic aspects of Life Cycle Assessment (LCA) methods and tools, using a case study approach. This module is divided into 3 “tiers”, each with a specific goal: Tier I: Basic Concepts. Tier II: How to use computer tools. Tier III: How to Apply the Tool in a real world context. These tiers are intended to be completed in that particular order. Students are quizzed at various points to measure their degree of understanding, before proceeding to the next level. Module 14 – Life Cycle Assessment 2 NAMP PIECE Tier I Background Information Module 14 – Life Cycle Assessment 3 NAMP PIECE Purpose of Module 14 What is the purpose of this tier? Background Information. It will provide a general overview of life cycle assessment (LCA) and its potential applications Module 14 – Life Cycle Assessment 4 NAMP PIECE References 9Gaudreault, C., Samson, R., Stuart, P. (2004). “Survey of LCA Applications and Methodologies in the Pulp and Paper Industry”. Paper submitted to TAPPI Journal. 9Goedkoop and Oele. 2002. ”User Manual Introduction into LLCA methodology and practice with SimaPro 5.1“. 9 International Organization for Standardization.2000.“Environmental Management – Life Cycle Assessment – Principles and Framework”. Geneva, Switzerland. Notes: ISO 14040 9 International Organization for Standardization.2000 “Environmental Management – Life Cycle Assessment – Goal and Scope Definition and Inventory Analysis”. Geneva, Switzerland. Notes: ISO 14041 9 International Organization for Standardization.2000.“Environmental Management – Life Cycle Assessment – Life Cycle Impact Assessment”. Geneva, Switzerland. Notes: ISO 14042 9 International Organization for Standardization.2000.“Environmental Management – Life Cycle Assessment – Life Cycle Interpretation”. Geneva, Switzerland. Notes: ISO 14043 Module 14 – Life Cycle Assessment 5 NAMP PIECE References 9International Organization for Standardization.2000.“Environmental Management – Life Cycle Assessment – Life Cycle Interpretation”. Geneva, Switzerland. Notes: ISO 14043 9 Lopes, Dias, Arroja, Capela and Pereira, 2003 “Application of life cycle assessment to the Portuguese pulp and paper industry”. Journal of Cleaner Production. 9 Pollution Prevention – A Federal Strategy for Action, 1995 9 Svoboda S. (1995). “Note of Life Cycle Analysis”. National Pollution Prevention Center for Higher Education. 9 Society of Environmental Toxicology and Chemistry (SETAC), www.setac.org 9 United Nations Environment Programme (UNEP), http://www.unep.org Module 14 – Life Cycle Assessment 6 NAMP PIECE Tier I: Outline 1. Introduction and definition of the Life Cycle Assessment (LCA). 2. Overview of 4 stages of life cycle methodology. 3. Survey of life cycle applications in the pulp and paper industry. 4. Proposal of “life cycle thinking” concept: using LCA as a tool for practical applications in the operation of a facility. 5. Multiple choice questions. Module 14 – Life Cycle Assessment 7 NAMP PIECE Tier I: Outline 1. Introduction and definition of the Life Cycle Assessment (LCA). 1.1. The origin Module 14 – Life Cycle Assessment 8 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). 1.1. The origin LCA has its roots in the 1960’s, when scientists concerned about the rapid depletion of fossil fuels developed it as an approach to understanding the impacts of energy consumption. In the early 1970’s, LCA’s concentrated mainly on energy and raw materials but later air emissions, water emissions and solid waste were included in the calculation. Module 14 – Life Cycle Assessment 9 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). In the late 1970’s and early 1980’s, the environmental concern shifted to issues of hazardous waste management. The SETAC conference of 1990 in Vermont was the first to analyze LCA’s into three main stages. These stages are: Inventory – In which the data describing the system are collected and converted to a standard format to provide a description of the physical characteristics of the system of interest. Interpretation – In which the physical datas from the inventory are related to observable environmental problems. Improvement – In which the system is modified in some way to reduce or ameliorate the observed environmental impacts. Inventory Interpretation Module 14 – Life Cycle Assessment Improvement 10 NAMP PIECE Tier I: Outline 1. Introduction and definition of the Life Cycle Assessment (LCA). 1.1. The origin 1.2. Introduction Module 14 – Life Cycle Assessment 11 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). 1.2. Introduction A fundamental part in the application of the LCA is that a company that makes and uses a LCA -in the long run- is going to the same demand to its suppliers and clients within the commercial chain. Generally using a LCA causes a rain of ideas that can help to see the problem from an extensive point of view. The LCA is a tool of support for the decision making. ¾ For what kind of applications do we use the LCA ? A1 The potential applications of LCA include (ISO 1997): 9 Identification of improvement opportunities for environmental aspects. 9 As a decision making tool in strategic planning, priorities definition and product or process design. 9 Selection and evaluation of relevant environmental performance indicators. 9 Marketing programs. Module 14 – Life Cycle Assessment 12 Slide 12 A1 important vs potential applications ANTONIO; 06-janv.-05 NAMP PIECE Tier I: Outline 1. Introduction and definition of the Life Cycle Assessment (LCA). 1.1. The origin 1.2. Introduction 1.3. Definition Module 14 – Life Cycle Assessment 13 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). 1.3. Definition Life Cycle : Consecutive and interlinked stages of a product or a service system, from the extraction of natural resources to the final disposal. In this module, LCA is utilised as a quantitative process used to evaluate the associate environmental loads to a product, a process or an activity identifying the use of mass A2 and energy and the discharges to the surroundings; in order to determine it potential impact. Module 14 – Life Cycle Assessment 14 Slide 14 A2 not only environmental ANTONIO; 06-janv.-05 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). The study takes into account the stages of extraction and processing of raw materials; production, transportation and distribution of raw materials and products; use, reusability and/or recycling as well as the disposition of the remainder. Energy A3 Resource Recycled & Disposal of the remainder Extraction & Processing Use, reusability & maintenance Transport & Distribution Production Emissions Module 14 – Life Cycle Assessment 15 Slide 15 A3 too many "ands" ANTONIO; 06-janv.-05 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). The ISO 14040 standard defines LCA as a compilation and evaluation of the inputs and outputs and the potential environmental impacts of a product system through its life cycle. The Life-Cycle Assessment framework as laid down in this standard is shown below: Principles and Framework (ISO 14040) • Product development and improvement • Strategic planning • Public policy making • Marketing Goal and scope Definition (ISO 14041) Inventory Analysis (ISO 14041) Impact Assessment (ISO 14042) Module 14 – Life Cycle Assessment Direct application: Interpretation (ISO 14043) Other tools: ¾Techniques ¾Economic ¾Social (Based on ISO 14040 ) 16 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). The base of LCA consists of making a mass and energy balances of the studied system. In this way the inputs and outputs are identified, and later the potential environmental impacts are evaluated. A cradle-to-grave manner involves all the steps in the product production: from raw A4 material extraction and transport to production and consumption, until the re-use or the disposal. Module 14 – Life Cycle Assessment 17 Slide 17 A4 it is not - cradle to grave? ANTONIO; 06-janv.-05 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). Life Cycle Analysis must be used cautiously, and in the interpretation of the impact assessment, care must be taken with subjective judgments. When first conceived, it was predicted that LCA would enable definitive judgments to be made. That misplaced belief has now been discredited. In combination with the trend towards more open disclosure of environmental information by companies and the desire by consumers to be guided towards the least harmful purchases, LCA appears to be a vital tool. Module 14 – Life Cycle Assessment 18 NAMP PIECE Tier I: Outline 1. Introduction and definition of the Life Cycle Assessment (LCA). 1.1. The origin 1.2. Introduction 1.3. Definition 1.4. The ISO 14040 family Module 14 – Life Cycle Assessment 19 NAMP 1. PIECE Introduction and definition of the Life Cycle Assessment (LCA). 1.4. The ISO 14040 Family 9 ISO 14040 : Environmental Management - LCA – Principles and Framework 9 ISO 14041 : Environmental Management - LCA– Goal and Scope Definition & Inventory Analysis 9 ISO 14042 : Environmental Management - LCA– Life Cycle Impact Assessment 9 ISO 14043 : Environmental Management - LCA– Life Cycle Interpretation 9 ISO 14047 : Illustrative Examples on how to apply ISO 14042 - Life Cycle Assessment – Life Cycle Impact Assessment 9 ISO 14048 : Environmental Management - LCA– Data Documentation Format 9 ISO 14049 : Environmental Management - LCA– Examples of Application of ISO 14041 to Goal and Scope Definition and Inventory Analysis Module 14 – Life Cycle Assessment 20 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). ¾ ISO 14040 : Environmental Management - Life Cycle Assessment – Principles and Framework This international standard specifies the general framework, principles and requirements for conducting and reporting life cycle assessment studies. This international standard does not describe the life cycle assessment technique in details. In this definition, it is clear that impact assessment is an integral part of LCA. ISO 14040 is an excellent compromise between what makes up a Life Cycle Assessment and that what is to be achieved at all. Module 14 – Life Cycle Assessment 21 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). ¾ ISO 14041 : Environmental Management - Life Cycle Assessment – Goal and Scope Definition & Inventory Analysis This international standard in addition to ISO 14040 specifies the requirements and procedures necessary for the compilation and preparation of the definition of the goal and scope of a Life Cycle Assessment study and for performing, interpreting and reporting a Life Cycle Inventory analysis (LCI). This international standard does not describe the life cycle assessment technique in detail. Module 14 – Life Cycle Assessment 22 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). ¾ ISO 14042 : Environmental Management - Life Cycle Assessment – Life Cycle Impact Assessment ISO 14042 describes and gives guidance on a general framework for the Life Cycle Impact Assessment phase (LCIA) of LCA as well as its key features and inherent limitations. It specifies requirements for conducting LCIA and its relationship to other LCA phases. The standard is supported with a technical report illustrating examples on how to apply ISO 14042. In the ISO 14042 document a large range of issues are mentioned that need to be decided and described. Module 14 – Life Cycle Assessment 23 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). ¾ ISO 14043 : Environmental Management - Life Cycle Assessment – Life Cycle Interpretation This international standard provides requirements and recommendations for conducting the life cycle interpretation phase in LCA or LCI studies. This document is intended to provide guidance on the interpretation of LCA results in relation to the goal definition phase of the LCA study, involving review of the scope of the LCA. This international standard does not describe specific methodologies for the life cycle interpretation phase of LCA and LCI studies. This standard is short, clear and illustrated. The aim of the working group was to demonstrate that the LCA interpretation can be done simply, by referring essentially to common sense. Module 14 – Life Cycle Assessment 24 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). ¾ ISO/DTR 14047: Illustrative Examples on how to apply ISO 14042 - Life Cycle Assessment – Life Cycle Impact Assessment The purpose of this Technical Report is to provide examples to illustrate practice in carrying out a life cycle impact assessment according to ISO 14042. These examples are only a sample of the total possible examples that could satisfy the provisions of the standard. They should be read as offering “a way” or “ways” rather than the “unique way” of applying the standard. They reflect the key elements of the life cycle impact assessment (LCIA) phase of the LCA. It should be noted that the examples presented in this technical report are not exclusive and that other examples exist to illustrate the methodological issues described. Module 14 – Life Cycle Assessment 25 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). ¾ ISO/DTR 14048: Environmental Management - Life Cycle Assessment – Data Documentation Format This technical specification is applicable to the specification and structuring of questionnaire forms and information system. However, it can also be applied to other aspects of the management of the environmental data. The technical specification does not include requirements on completeness of data documentation. The data documentation format in independent of any software of database platform for implementation. The technical specification does not require any specific sequential, graphic or procedural solutions for the presentation or treatment of datas, nor does it describe specific modeling methodologies for LCA and LCI data. Module 14 – Life Cycle Assessment 26 NAMP PIECE 1. Introduction and definition of the Life Cycle Assessment (LCA). ¾ ISO/DTR 14049: Environmental Management - Life Cycle Assessment – Examples of Application of ISO 14041 to Goal and Scope Definition and Inventory Analysis This technical report provides examples about practices in carrying out a Life Cycle Inventory Analysis (LCI) as means of satisfying certain provisions of the standard. They should be read as offering a way or ways rather than the unique way of applying the standard. Also they reflect only certain portions of an LCI study. It should be noted that the examples presented in this technical Report are not exclusive and that many other examples exist illustrating the methodological issues described. The examples are only portions of complete LCI studies. Module 14 – Life Cycle Assessment 27 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology Module 14 – Life Cycle Assessment 28 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.1. Methodology The ISO 14040 general framework of an LCA study consists of four steps: 1. Defining the goal and scope of the study. 2. Making a model of the product life cycle with all the environmental inflows and outflows. This is usually referred to as the life cycle inventory (LCI) stages. 3. Understanding the environmental relevance of all the inflows and outflows, this is referred to as the life cycle impact assessment (LCIA) phase. 4. The interpretation of the study. Module 14 – Life Cycle Assessment 29 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Principles and Framework (ISO 14040) Goal and scope Definition (ISO 14041) Inventory Analysis (ISO 14041) Impact Assessment (ISO 14042) Module 14 – Life Cycle Assessment Life Cycle Interpretation Direct application: • Product development and improvement • Strategic planning • Public policy making • Marketing • Other (ISO 14043) Other tools: ¾Techniques ¾Economic ¾Social 30 NAMP PIECE 2. Overview of 4 stages of life cycle methodology The challenge for the LCA practitioner is to develop the models in such a way that the simplifications and thus uncertainties do not influence the results too much. The best way to deal with this problem is to carefully define a goal and scope of the LCA study before starting. The goal and scope definition is a guide that helps you to ensure the consistency of the LCA you perform. Example : LCA methodology was applied to Portuguese production of printing and writing paper in order to evaluate its environmental performance and also to make a comparative, environmental assessment of fuel oil and natural gas, respectively, as energy sources in the manufacturing process. (Lopes et al. 2003) Module 14 – Life Cycle Assessment 31 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope Module 14 – Life Cycle Assessment 32 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.2. Goal and scope Goal & Scope Definition (ISO 14041). That is to state, the reasons of the study, the information that is expected to obtain, how it is going to be used, the intended audience of the report, the analysis of the scope and the limits of the system. 1. Defining the goal: The goal of any study shall unambiguously state the intended application, the reasons for carrying out the study and the intended audience, I.e. to whom the results of the study are intended to be communicated. Some LCA studies serve more than one purpose. The results may be both used internally and externally. In that case, consequences of such double use should be clearly described. (Goedkoop and Oele. 2002) Module 14 – Life Cycle Assessment 33 NAMP PIECE 2. Overview of 4 stages of life cycle methodology It is obvious that an LCA should have goal. However, in ISO there are some particular requirements for the goal definition: 9 The application and intended audiences shall be described unambiguously. This is important, as a study that aims to provide data that is applied internally can be quite differently structured than a study that aims at making public comparisons between two products. 9 The reasons for carrying out the study should be clearly described. Is the commissioner or practitioner trying to prove something, is the commissioner intending to provide A5 information only, etc. 2. Defining the scope: The scope of the study describes the most important methodological choices, assumptions and limitations. One starts with initial system boundaries and initial data quality requirements that can be adapted later if more information becomes available or necessary. Module 14 – Life Cycle Assessment 34 Slide 34 A5 alignment... ANTONIO; 06-janv.-05 NAMP PIECE 2. Overview of 4 stages of life cycle methodology The scope of any LCA study should be efficiently well defined to ensure that the breadth and the inherent details in which the study is conducted are both compatibles with and A6 sufficientes to address the stated study goal. (Goedkoop and Oele. 2002) Factors that should be considered and stated clearly in the Scope of Study include: 9 9 9 9 9 9 9 9 The function(s) of the system to be analyzed The functional unit on which the study will be based The system boundaries Allocation procedures adopted Data quality requirements Any assumptions made Study limitations The type and format of the study reports Module 14 – Life Cycle Assessment 35 Slide 35 A6 "s" twice ANTONIO; 06-janv.-05 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Function, functional unit and reference flow A particularly important issue in product comparisons is the functional unit or comparison basis. In many cases, one cannot simply compare product A and B, as they may have different performance characteristics. Defining a functional unit can be quite difficult, as the performance of products is not always easy to describe. For instance, if the objective of the study is to compare paper towels with hand dryers, the function of these products is to dry hands and the functional unit can be defined as x pair of dried hands. Initial System Boundaries Product systems tend to be interrelated in a very complex way. It is helpful to draw a diagram of the system and to identify the boundaries in this diagram. Important choices in this area are: 9 What is the boundary with nature? For example, in an LCA on paper it is important to decide if the growing of a tree is included. If it is, one can include the CO2 uptake and the land use effect. Module 14 – Life Cycle Assessment 36 NAMP PIECE 2. 9 • • • Overview of 4 stages of life cycle methodology Will the production and disposal of capital goods be included? One can distinguish three orders: First Order : Only the production of materials and transport are included. Second Order : All processes during the life cycle are included, but the capital goods are left out. Third Order : Now the capital goods are included. Criteria for inclusion of inputs and outputs Apart from the criteria for system boundaries, one can also use a certain threshold below which you consider it is useless to collect data for an inflow or an outflow. ISO recommends using one or more of the following bases for such a threshold: 9 If the mass of the inflow is lower than a certain percentage. 9 If the economic value of an inflow is lower than a certain percentage of the total value of the product system. 9 If the contribution from an inflow to the environmental load is below a certain percentage. Module 14 – Life Cycle Assessment 37 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Data Categories It defines the kind of data necessary for the study. They can be collected at the production sites (i.e. primary data) or be obtained or calculated from published references or databases (i.e. secondary data). ISO recommends the use of primary data for those processes that contribute with most of the mass and energy flows or processes with significant environmental emissions (ISO 1999). Data Quality Requirements The quality of the data used in the life cycle inventory is naturally reflected in the quality of the final LCA. The data quality can be described and assessed in different ways. It is important that the data quality is described and assessed in a systematic way that allows others to understand and control the actual data quality. Initial data quality requirements shall be established which define that following parameters: 9 Time-related coverage. 9 Geographical coverage. 9 Technology coverage. Module 14 – Life Cycle Assessment 38 NAMP PIECE 2. Overview of 4 stages of life cycle methodology In all studies, the following additional data quality indicators shall be taken into consideration in a level of detail depending on goal and scope definition: 9 9 9 9 9 Precision Completeness Representativeness Consistency Reproducibility 12 10 8 6 4 2 0 1 Module 14 – Life Cycle Assessment 2 3 4 5 6 7 39 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Allocation ISO recommends the following procedure in order to deal with allocation issues: 9 Avoid allocation, by splitting the processes in such a way that can be described as two separated processes that each has a single output. 9 Another way to avoid allocation is to extend the system boundaries, and by including process is that would be needed to make a similar output. 9 If it is not possible to avoid allocation in either way, the ISO standard suggest allocating the environmental load based on a physical causality, such as mass or energy content of the outputs. If this procedure cannot be applied, ISO suggests using socio-economic allocation basis, such as the economic value. Although ISO mentions the socio-economic basis as a last resource, it is used very often. The advantage is that economic value is a good way to distinguish waste from an output, and it expresses the relative importance of an output. Module 14 – Life Cycle Assessment 40 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example Module 14 – Life Cycle Assessment 41 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.3. Goal and scope: Example The purpose of this study is the identification and assessment of the environmental impacts associated with the production, use and final disposal of printing and writing paper produced in Portugal from Eucalyptus globulus and consumed in Portugal. The schema below shows the system boudaries. Eucalyp tus forest Eucalyptus forest Eucalyptus Eucalyptus pulp p ulp production production Paper Paper production prod uction Com Com posting posting C onsum ers Consum S Softw oftwood ood pulp pulp production production Land filling Landfilling R Recycling ecycling S oftw ood Softw ood forest forest Chem Chemical ical Production Production Electricity Electricity Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Transports Transports Fuel roduction Fuel p prod uction 42 NAMP PIECE 2. Overview of 4 stages of life cycle methodology In this example, the functional unit was defined as 1 tonne of white printing and writing paper, with a standard weight of 80 g/m2, produced from Portuguese Eucalyptus globulus kraft pulp and consumed in Portugal. The impact assessment conducted in this study considers the following impact categories: 9 9 9 9 9 Global Warming potential for 100 years Acidification Eutrophication Non-renewable resource depletion Photochemical oxidant formation Module 14 – Life Cycle Assessment 43 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis Module 14 – Life Cycle Assessment 44 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.4. ISO guidelines; Inventory Analysis Phase of Life Cycle Assessment involving the compilation and quantification of inputs and outputs, for a given product system throughout its life cycle. (International Organization for Standardization 1997) Module 14 – Life Cycle Assessment 45 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Inventory Analysis Inventory analysis is the stage in which data are collected and where calculations are performed in order to quantify the relevant inputs and outputs of the system as a whole. Typically, inventory data include raw materials and energy consumption, and the emission of solid, liquid and gaseous wastes. Inventory data may be provided for full life cycles or for partial life cycles. (Susan Svoboda, 1995) Inputs Outputs Raw Materials Energy Water Module 14 – Life Cycle Assessment System Emissions to Air Releases to Water Solid Waste Usable Products Other Environmental Releases 46 NAMP PIECE 2. Overview of 4 stages of life cycle methodology An important step in the inventory is the creation of a process flow diagram that will serve as the “blueprint” for the data to be collected. Each step in the system should be represented in the diagram, including the steps of the production of ancillary products such as chemicals and packaging. This step is important because it clearly depicts the relative contribution of each subsystem to the entire production system and the final product. The following is a synopsis of the various issues that can be analyzed in an inventory analysis: 9 9 9 9 9 9 Data Collection Refining System Boundaries Calculation Validation of Data Relating data to the specific system Allocation and Recycling Module 14 – Life Cycle Assessment 47 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 1. Data Collection Inventory Analysis involves data collection and calculation procedures to quantify relevant inputs and outputs of a product system. These inputs and outputs may include the use of resources and releases to air, water and land associated with the system. Interpretation may be draw from these data, depending on the goals and scope of the LCA. These data also constitute the input to the life cycle impact assessment. The qualitative and quantitative data for inclusion in the inventory shall be collected for each unit process that is included within the system boundaries. The procedures used for data collection may vary depending on the scope, unit process or intended application of the study. The technical specification provides comprehensive formats for data collection and treatment and the following concept can be used, 9 9 9 Description of the process as well as description of inputs and outputs. Description of modeling and validation Description of administrative information Module 14 – Life Cycle Assessment 48 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2. Refining System Boundaries The system boundaries are defined as a part of the scope definition procedure. After the initial data collection, the system boundaries can be refined e.g. as a result of decisions of exclusion life stages or sub-systems, exclusion of material flows or inclusion of new unit processes shown to be significant according to the sensitivity analysis. The following is a synopsis of the various subsystems that can be analyzed in an inventory analysis: Inputs Raw Material Acquisition Raw Materials Material Manufacture Energy Water Final Product Assembly Transportation/Distribution Consumer Use and Disposal Outputs Emissions to Air Releases to Water Solid Waste Usable Products Other Environmental Releases System Boundary Module 14 – Life Cycle Assessment 49 NAMP PIECE 2. Overview of 4 stages of life cycle methodology ¾ Raw Materials Acquisition. Data are collected for this subsystems an all activities required to obtain raw materials, including transportation of the materials to the point of manufacture. The inventory should also include all inputs of energy, materials, and equipment necessary for acquiring each raw material. Because this dramatically increases the complexity of the analysis, criteria must be determined to eliminate insignificant contributions (usually any component contributing less than five percent of inputs might be ignored). Inputs Energy Materials Outputs Infrastructure and Capital Equipment Inputs Exploration and Extraction Cultivation, Harvest, and Replenishment Outputs Handling and Transportation Module 14 – Life Cycle Assessment 50 NAMP PIECE 2. Overview of 4 stages of life cycle methodology ¾ Product System. Data collected for this subsystem includes all energy, material, or water inputs and environmental releases that occur during the manufacturing processes required to convert each raw materials input into intermediate materials ready for fabrication. If industrial scrap is used in another subsystem, it is considered to the same consumption and emission rates required to produce that primary material. Fuel Production Producing Of Ancillary Industries Materials Raw Materials Acquisition Module 14 – Life Cycle Assessment Main Productions System Emissions to Air Releases to Water Solid Waste Usable Product Co-Products 51 NAMP PIECE 2. Overview of 4 stages of life cycle methodology ¾ Transportation/Distribution. An inventory of the related transportation activities of the product to warehouses and end-users maybe simplified by using standards for the average distance transported and the typical mode of transportation used. As in previous stages, clear boundaries must be established to define the extent to which issues such as building and maintaining transportation and distribution equipment will be included into the inventory results. Module 14 – Life Cycle Assessment 52 NAMP PIECE 2. Overview of 4 stages of life cycle methodology ¾ Consumer Use/Disposal. Data collected for this subsystem cover consumer activities including use (product consumption, storage, preparation, or operation), maintenance (repair) and reuse. Issues to consider when defining the scope of the subsystem include: 9 9 9 9 Time of product use before it is discarded Inputs used in the maintenance process The typical frequency of repair Potential product reuse and recycling options Use Transportation /Distribution Point Of Use Maintenance Disposal Waste Management Re-Use Recycle Module 14 – Life Cycle Assessment 53 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 3. Calculation procedures No formal demands exist for calculation in life cycle assessment except the described demands for allocation procedures. Due to the amount of data it is recommended as a minimum to develop a spreadsheet for the specific purpose. A number of general PC-programs/software for calculation are available e.g. spreadsheets/spreadsheet applications (EXCEL/Lotus etc), together with many software programs developed specially for life cycle assessment. The appropriate program can be chosen depending on the kind and amount of data to be handled. 4. Validation of Data The validation of data has to be conducted during the data collection process in order to improve the overall data quality. Systematic data validation may point out areas where data quality must be improved or data must be found in similar processes or unit processes. For each data category and for each reporting location where missing data are identified, the treatment of the missing data should result in: 9 An acceptable reported data value; 9 A “zero” data value of justifies; or 9 A calculated value based on the reported values from unit processes employing similar technology. Module 14 – Life Cycle Assessment 54 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 5. Relating data to the specific system The fundamental inputs and outputs data are often delivered from industry in arbitrary units e.g. energy consumption as MJ/machine/week or emissions to the sewage system as mg metals/liter wastewater. For each unit process, an appropriate reference flow shall be determine (e.g. one kilogram of material or one mega joule for energy). The quantitative input and output data of the unit process shall be calculated in relation to this reference flow. Based on the refined chart and system’s boundaries, unit processes are interconnected to allow calculations of the complete system. 6. Allocation and Recycling When performing a life cycle assessment of a complex system, it may not be possible to handle all the impacts and outputs inside the system boundaries. This problem can be solved either by: 1. Expanding the system boundaries to include all the inputs and outputs, or by 2. Allocating the relevant environmental impacts to the studied system. Since the inventory is intrinsically based on material balances between inputs and outputs, allocation procedures should approximate as much as possible such fundamental inputoutput relationships and characteristics. Some principles should be kept in mind when allocating loadings. Module 14 – Life Cycle Assessment 55 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Allocation can be necessary when dealing with: Multi-output “black box” processes, i.e. when more than one product is produced and some of those product flows are crossing the system boundaries. 9 Multi-input processes, such as waste treatment, where a strict quantitative causality between inputs and emissions etc. seldom exists. 9 Open-loop recycling, where a waste material leaving the system boundaries is used as a raw material by another system, outside the boundaries of the studied system. 9 Recycling technology is expected to improve greatly in the future. Therefore, content levels and recycling rates should always be reported at current rates with documentation of study dates. Advances in technology will both increase rates and the number of products that are recyclable, altering both open-loop and closed-loop recycling options. P ro d u c e V irg in M a te ria l P ro d u c e V irg in M a te ria l Re c y c lin g Su b sy s t e m Closed- lop Open- lop Module 14 – Life Cycle Assessment C o n v e rt to P ro d u c t 1 W a s te M anagem ent R e c y c lin g C o n v e rt to P ro d u c t 1 W a s te M anagem ent 56 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis 2.5. Inventory Analysis: Example Module 14 – Life Cycle Assessment 57 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.5. Inventory Analysis: Example Eucalyptus Eucalyptus forest forest Eucalyptus Eucalyptus pulp pulp production production Com Com posting posting The production of Eucalyptus forest installation, forest Landfilling Paper Consum ers Paper production productionincludes Landfilling growth and wood harvesting. Forest Softw Softwood ood pulp pulp installation and growth comprises production production R Recycling ecycling path opening, land preparation, soil Softw Softwood ood forest forest preparation, deep fertilization, plantation, pest control, soil Chem Chem ical ical Production Production mobilization and soil fertilization. Electricity Electricity Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Transports Transports Fuel Fuel production production 58 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Eucalyptus Eucalyptus forest forest Eucalyptus Eucalyptus pulp pulp production production Paper Paper production production Softw Softwood ood pulp pulp production production Com posting posting This subsystem includes pineCom growth and pine harvesting, Consum ers 75% of which is done by Landfilling Landfilling regeneration felling and 25% byR Recycling ecycling thinking. Softw Softwood ood forest forest Chem Chem ical ical Production Production Electricity Electricity Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Transports Transports Fuel Fuel production production 59 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Eucalyptus Eucalyptus forest forest Eucalyptus Eucalyptus pulp pulp production production Paper Paper production production Data on the production of softwood pulp include the Consum ers pulping process. Softw Softwood ood pulp pulp production production Com Com posting posting Landfilling Landfilling R Recycling ecycling Softw Softwood ood forest forest Chem Chem ical ical Production Production Electricity Electricity Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Transports Transports Fuel Fuel production production 60 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Eucalyptus Eucalyptus forest forest Eucalyptus Eucalyptus pulp pulp production production To perform this study, two scenarios were defined: Paper Consum ers (AS): Paper production production • Actual scenario Eucalyptus pulp and paper Softw Softwood ood pulp pulp integrated production using production production heavy fuel oil. • Natural gas scenario (NGS): Softw Softwood ood forest forest Eucalyptus pulp and paper integrated production using Chem Electricity natural gas. Electricity Chem ical ical Production Production Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Com Com posting posting Landfilling Landfilling R Recycling ecycling Transports Transports Fuel Fuel production production 61 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Eucalyptus Eucalyptus forest forest Eucalyptus Eucalyptus pulp pulpThe production production printing and writing paper Com Com posting posting production include eucalyptus softwood pulp Landfilling Paper Consum ers Paper production productionpulp transfer, Landfilling bales pulping, pulp refining, Softw Softwood ood pulp pulpcleaning, and screening, broke R Recycling ecycling production production recovery, paper machine, finishing, wastewater treatment Softw Softwood ood forest forest in an activated sludge plant and on site energy production. Chem Chem ical ical Production Production Electricity Electricity Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Transports Transports Fuel Fuel production production 62 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Eucalyptus Eucalyptus forest forest Eucalyptus Eucalyptus pulp pulp production production Com Com posting posting Paper Paper production production Consum ers Landfilling Landfilling Final disposal alternatives in Softw Softwood ood pulp pulp Portugal for printing production production R Recycling ecycling and writing wastepaper are recycling (11%), Softw Softwood ood forest forest landfilling (84%) and composting (5%). Chem Chem ical ical Production Production Electricity Electricity Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Transports Transports Fuel Fuel production production 63 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Eucalyptus Eucalyptus forest forest Eucalyptus The production of pulp Eucalyptus pulp production production hydrogen peroxide and sodium chlorate was Paper Paper production production included because, they are energy-insensitive Softw Softwood ood pulp pulp production process. production Com Com posting posting Consum ers Landfilling Landfilling R Recycling ecycling Softw Softwood ood forest forest Chem Chem ical ical Production Production Electricity Electricity Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Transports Transports Fuel Fuel production production 64 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Eucalyptus Eucalyptus forest forest Eucalyptus Eucalyptus pulp pulp production production Some subsystems purchase electricity from national grid, while Paper ers Paper production production theConsum others have a surplus of Softw electricity production. Softwood ood pulp pulp production production Com Com posting posting Landfilling Landfilling R Recycling ecycling Softw Softwood ood forest forest Chem Chem ical ical Production Production Electricity Electricity Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Transports Transports Fuel Fuel production production 65 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Eucalyptus Eucalyptus forest forest Eucalyptus Eucalyptus pulp pulp production production Paper Paper production production Consum ers Softw Softwood ood pulp pulp production production This subsystem includes the circulation, between subsystems, of wood, Com Com posting posting softwood pulp, paper, wastepaper, chemicals and Landfilling fuels by 16 tonne, 28 Landfilling tonne and garbage trucks, ocean ships and electric R Recycling ecycling trains. Softw Softwood ood forest forest Chem Chem ical ical Production Production Electricity Electricity Production Production O Other ther system system ss Module 14 – Life Cycle Assessment Transports Transports Fuel Fuel production production 66 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Eucalyptus Eucalyptus forest forest Eucalyptus Eucalyptus pulp pulp production production Paper Paper production production Softw Softwood ood pulp pulp production production Com Com posting posting Consum ers Landfilling Landfilling R Recycling ecycling Softw Softwood ood forest forest The fuels considered are Chem ical Electricity Electricity Chem ical heavy fuel oil, light fuel Transports Transports Production Production Production Production oil, diesel oil and natural gas.O Fuel Other ther system system ss Fuel production production Module 14 – Life Cycle Assessment 67 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis 2.5. Inventory Analysis: Example 2.6. Impact Assessment Module 14 – Life Cycle Assessment 68 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.6. Impact Assessment The purpose of Life Cycle Impact Assessment (LCIA) is to assess a system’s Life Cycle Inventory results with the aim of improving understanding with regard to their potential environmental significance. LCIA specifically uses impact categories and associated indicators to simplify LCI results with regard to one or more environmental issues. An LCA shall include LCIA to help identify potential environmental problems associated with various man-made activities. Life Cycle Impact Assessment is defined as the phase in the LCA aimed at understanding and evaluating the magnitude and significance of the potential environmental impacts of a product systems. Module 14 – Life Cycle Assessment 69 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.6. Impact Assessment Life Cycle Impact Assessment (LCIA) is the third phase in a life cycle assessment containing the following main issues: Mandatory Elements 9 Selection of impact categories and category indicators 9 Assignment of LCI results (Classification) 9 Characterization Optional Elements 9 Normalization 9 Grouping 9 Weighting 9 Data Quality Analysis Module 14 – Life Cycle Assessment 70 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Selection of Impact Categories An important step in an LCIA is the selection of the appropriate impact categories. The choice is guided by the goal of the study. It requires some expert judgment to make such a list, and to understand which impact categories should be defined to cover all these issues. An important help in the process of selecting impact categories is the definition of socalled endpoint. Endpoints are to be understood as issues of environmental concern, like human health, extinction of species, availability of resources for future generation. Endpoints can be selected by the practitioner, as long as the reasons for including or excluding endpoints are clearly documented. Category endpoints are variables which are of direct social concern, such as human life span, natural resources, valuable ecosystems or species, etc. The level of the endpoints is also called “damage level”. Category midpoints are variables in the environmental mechanism of an impact category between the environmental interventions and the category endpoints, like the concentration of toxic substances, the deposition of acidifying substances, etc. Module 14 – Life Cycle Assessment 71 NAMP PIECE 2. Overview of 4 stages of life cycle methodology The level of the endpoints is also called “damage level”. Category midpoints are variables in the environmental mechanism of an impact category between the environmental interventions and the category endpoints, like the concentration of toxic substances, the deposition of acidifying substances, etc. The level of midpoints is also called “problem level” (Udo de Haes et al. 1999a). According to ISO, the category indicator can be defined at any level of the environmental mechanism (ISO 2001a). The inventory results of an LCA usually contains hundreds of different emissions and resource extraction parameters. Once the relevant impact categories are determined, these LCI results must be assigned to these impact categories. Once the impact categories are defined and the LCI results are assigned to these impact categories, it is necessary to define characterization factors. These factors should reflect the relative contribution of an LCI result to the impact category indicator result. Module 14 – Life Cycle Assessment 72 NAMP PIECE 2. Overview of 4 stages of life cycle methodology General overview of the structure of an impact assessment method. The LCI result are characterized to produce a number of impact categories indicators. According to ISO, one must document the environmental relevance of each indicator by describing the link to the endpoints. Module 14 – Life Cycle Assessment LCI LCI results results Ecotoxicity Ecotoxicity Minerals Minerals Fossil fuel fuel Fossil Land-use Land-use Nutriphication Nutriphication Ozone layer layer Ozone Acidification Acidification Extinction Extinction of of species species Dieing Reduced Dieing Reduced forest forest resource resource Cancer Cancer base base Carcinogen Carcinogen Climate Climate Seawater Seawar level level Radiation Radiation Smog Smog Environmental Mechanism Mechanism Environmental Respiratory Respiratory deceases deceases Endpoints Endpoints Midpoints Midpoints Inventory Inventory 73 NAMP PIECE 2. Overview of 4 stages of life cycle methodology The impact category “human toxicological impacts” is one of the most difficult categories to handle. The potential effect on humans depends as for ecotoxicological impacts an the actual emission and fate of the specific substances emitted to the environment. The human toxicological effects can be: 9 Acute toxicological effects 9 Irritation 9 Allergenic reactions 9 Genotoxicity 9 Cecinogenicity 9 Neurotoxicity 9 Teratogenicity Module 14 – Life Cycle Assessment 74 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Implementation Implementation plan plan for of LCA for of LCA Goal: Goal: Why Why use use LCA LCA Scope: Scope: •Which •Which applications? applications? •How ar •How aree rresults esults rrepor eported, ted, and and to to who? who? •Who •Who will will do do itit Interface face with with your your or organization ganization Inter The choice of the impact assessment method depends largely on the addressed audience. Module 14 – Life Cycle Assessment Ecodesign Ecodesign Str Strategy ategy development development Pr Product oduct declar declaration ation Benchmar Benchmarking king EMS, EMS, pr process ocess impr ovement impr ovement Designer Designerss Ecoindicator s LCA LCA ex exper perts ts All details Pr Product oduct manager managerss Aggr egated scor es and some details EMS EMS specialist specialist LCC LCC 75 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Assignment of LCI results (Classification) Assignment of LCI results to impact categories should consider the following, unless otherwise required by the goal and scope: 9 Assignment if LCI results which are exclusive to one impact category; 9 Identification of LCI results which relate to more than one impact category, including impact categories of human and acidification and 9 Allocation among serial mechanism, e.g. NOX may be assigned to ground level ozone formation and acidification. Classification is a qualitative step based on scientific analysis of relevant environmental processes. The classification has to assign the inventory input and output data to potential environmental impacts i.e. impact categories. Some outputs contribute to different impact categories and therefore, they have to be mentioned twice. Module 14 – Life Cycle Assessment 76 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Characterization The method of calculating indicators results shall be identified and documented, including the value-choices and assumptions used. The usefulness of the indicator results for a given goal and scope depends on the accuracy, validity and characteristic of the models and characterization factors. The number and kind of simplifying assumptions and value-choices used in the characterization model for the category indicator will also vary between impact categories. A trade off often exist between characterization model simplicity and accuracy. Variation in the quality of indicators among impact categories may influence the overall accuracy of the LCA study, for example: 9 The complexity of the environmental mechanism between the system boundary and the category endpoint, Module 14 – Life Cycle Assessment 77 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 9 The spatial and temporal characteristics, for example the persistence of a substance in the environment, and 9 The dose-response characteristics Calculation of indicator results occur in two steps: a. Selection and use a characterization factor to convert the assigned LCI results to common units; b. Aggregation of the converted LCI results into the indicator results. Module 14 – Life Cycle Assessment 78 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Normalization This procedure transform an indicator result by diving with a selected value. Some examples of reference values are 9 The total emissions or resource use for a given area which may be global, regional, national or local 9 The total emissions or resource use for a given area on per capita basis 9 A baseline scenario such as the indicator result under consideration divided by the calculated indicator result of a given alternative product system. The selection of the reference system should consider the consistency of the spatial and temporal scales of the environmental mechanism and the reference value. Module 14 – Life Cycle Assessment 79 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Grouping Grouping is assigning impact categories into one or more sets, sets are predefined in the goal and scope, and it may involve sorting and/or ranking. Grouping is an optional element with two possible procedures: 9 To sort the impact categories on a nominal basis e.g. by characteristics such as emissions and resources or global, regional spatial scales; 9 To rank the indicators in a given order or hierarchy, e.g. medium and low priority. Ranking is based on value choices. Module 14 – Life Cycle Assessment 80 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Weighting Weighting is the process of converting indicator results of different impact categories by using numerical factors based on values-choices. It may include aggregation of the weighted indicator results. Weighting is an optional element with two possible procedures: 9 To convert the indicator results or normalized results with selected weighting factors; 9 To possibly aggregate these converted indicator results or normalized across impact categories. Weighting steps are based on value-choices and are not based on natural science. The application and use of weighting methods shall be consistent with the goal and scope of the LCA study and it shall be fully transparent. Different individuals, organizations and societies may have different preferences, therefore it is possible that different parties will reach different weighting results based on the same indicator results or normalized indicator results. Module 14 – Life Cycle Assessment 81 NAMP PIECE 2. Overview of 4 stages of life cycle methodology In an LCA study it may be desirable to use several different weighting methods and to conduct sensitivity analysis to assess the consequences on the LCIA results of different value-choices and weighting methods. Obligatory Elements Selection of impact categories, category indicators and characterization models Classification: Assignment of LCI results to selected impact categories Characterization: Calculation of category indicator (CI) results for each impact category Category indicator results (LCIA profile) Optional Elements Normalization: Calculation of magnitude of CI results relative to reference information Grouping: Assignment of impact categories to groups or ranking categories Weighting: Conversion and possible aggregation of CI results through impact categories using numerical factors based on value choices Data Quality Analysis Elements of LCIA phase according to ISO 14042 Module 14 – Life Cycle Assessment 82 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis 2.5. Inventory Analysis: Example 2.6. Impact Assessment 2.7. ISO guidelines; Impact Assessment Module 14 – Life Cycle Assessment 83 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.7. ISO guidelines; Impact Assessment LCIA – Mandatory Elements Impact Categories Class representing environmental issues of concern to which LCI results may be assigned. (International Organization for Standardization 2000) Classification Assignment of LCI results. (International Organization for Standardization 2000) Characterization Calculation of category indicator results. (International Organization for Standardization 2000) LCIA – Optional Elements Normalization Calculation of the magnitude of category indicator relative to reference information. (International Organization for Standardization 2000) Grouping Sorting and possibly ranking of the impact categories. (International Organization for Standardization 2000) Weighting Convert and possibly aggregating indicator results across impact categories using numerical factors based on values-choice. (International Organization for Standardization 2000) Data quality analysis Better understanding the reliability of the collection of indicator results, the LCA profile. (International Organization for Standardization 2000) Module 14 – Life Cycle Assessment 84 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis 2.5. Inventory Analysis: Example 2.6. Impact Assessment 2.7. ISO guidelines; Impact Assessment 2.8. Impact Assessment : Example Module 14 – Life Cycle Assessment 85 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.8. Impact Assessment : Example The next table shows the inventory parameters considered in this study and the impact categories selected for analysis. Impact categories and corresponding parameters. Impact Category Parameters Global Warming, 100 years (GW) Acidification (A) Eutrophication (E) Non-renewable CO2, CH4, N2O SO2, NOx, HCL, NH3, HF, H2S NOx air, NH3 air, N water, NO3- water, NH4+ water, P water, PO43- water COD water Crude oil, Natural gas, Coal CH4, Halogenated hydrocarbons, Aromatic hydrocarbons. Non-renewable resource depletion (NRRD) Photochemical oxidant formation (POF) In the next step of impact assessment (characterization), the total potential contribution from all inputs and outputs to the different impact categories is calculated using characterization factors. Module 14 – Life Cycle Assessment 86 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis 2.5. Inventory Analysis: Example 2.6. Impact Assessment 2.7. ISO guidelines; Impact Assessment 2.8. Impact Assessment : Example 2.9. Interpretation Module 14 – Life Cycle Assessment 87 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.9. Interpretation Interpretation (ISO 14043). Is a systematic procedure to identify, qualify, check and evaluate information from the conclusions of the inventory analysis and/or impact assessment of a system and present them in order to meet the requirements of the application as described in the goal and scope of the study. Interpretation is performed in interaction with the three other phases of the life cycle assessment. If the results of the inventory analysis or the impact assessment is found not to fulfill the requirements defined in the goal and scoping phase, the inventory analysis must be improved by e.g. revising the system boundaries, further data collection etc. followed by an improved impact assessment. This iterative process must be repeated until the requirements id the goal and scoping phase are fulfilled as can be described by the following steps (Goedcoop and Oele. 2002): 1. Identify the significant environmental issues. Evaluate the methodology and results for completeness, sensitivity and consistency. Module 14 – Life Cycle Assessment 88 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2. Check that conclusions are consistent with the requirements of the goal and scope of the values and application oriented requirements. 3. If so, report as final conclusions. If not, return to step 1 or 2. 4. This procedure has to be repeated until 3 is fulfilled. Interpretation is the fourth in life cycle assessment containing the following main issues: 9 9 9 Identification of significant environmental issues. Evaluation which considers completeness, sensitivity and consistency checks Conclusions, recommendations and reporting Module 14 – Life Cycle Assessment 89 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Identification of significant environmental issues The objective of this step is to structure the information from the inventory analysis and – if additionally conducted – from the life cycle impact assessment phase in order to determine the significant environmental issues in accordance with the goal and scope definition. The identification step include structuring and presentation of relevant information: 9 Results from the different phases i.e. presentation of e.g. data from inventory analysis in tables, figures or diagrams etc. or presentation of results of the impact assessment . 9 Methodological choices 9 Valuation methods used 9 Role and responsibility if different interested parties. Module 14 – Life Cycle Assessment 90 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Evaluation The objective of this step is to establish confidence in the result of the study, based on the preceding LCA phases, and on the significant environmental issues identified in the first step of the interpretation. The results should be presented in such a form as to give the commissioner or any interested party a clear and understandable view of the outcome of the study. The interpretation made at this stage shall be reinforced by the facts and calculations bought forward in at least the three following elements: 9 Uncertainty Analysis 9 Sensitivity Analysis 9 Contribution Analysis 9 Gravity Analysis Module 14 – Life Cycle Assessment 91 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Types of Uncertainties in LCA and Existent Frameworks for their Assessment The objective of this step is to establish confidence in the result of the study, based on the preceding LCA phases, and on the significant environmental issues identified in the first step of the interpretation. The results should be presented in such a form as to give the commissioner or any interested party a clear and understandable view of the outcome of the study. The interpretation made at this stage shall be reinforced by the facts and calculations bought forward in at least the three following elements: 9 Uncertainty Analysis 9 Sensitivity Analysis 9 Contribution Analysis 9 Gravity Analysis Module 14 – Life Cycle Assessment 92 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 1. Parameter Uncertainty It includes the uncertainty on the inventory data and the data used for the calculation of impact assessment factors (i.e. characterization, normalization and weighting). Sources of parameter uncertainties are (Huijbregts 1998a): lack of data, inaccuracy and unrepresentativity. LCA practitioners mostly have to deal with parameter uncertainties on inventory data that they collect and model in order to study a system. For such purposes several frameworks have been proposed (Huijbregts 2001b, Maurice 2000, Huijbregts 1998b, Weidema 1996). To fill data gaps in life cycle inventories, it has been recommended the use of mass and energy balances or models that calculate direct and indirect emissions and resources using the estimated price of missing flows as input. Missing data can also be estimated by using information for the most similar process or product for which data are available or for the main ingredients of the product. This kind of sources may also be used to further specify sum parameters (e.g. hydrocarbon emissions) (Huijbregts et al 2001b). Module 14 – Life Cycle Assessment 93 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Monte Carlo simulation is usually recommended to assess the inaccuracy and representativity of the inventory data (Huijbregts et al 2001b, Maurice et al 2000, Huijbregts 1998b). However, in practice it is be very difficult to obtain the uncertainty distributions for the large amount of parameters included in the inventory analysis. Therefore, a prior identification of key parameter is proposed by means of a broad sensitivity analysis using standard uncertainty estimates (Sakai et al 2002, Heijungs 2001, Heijungs 1996). However, a disadvantage of using a standard sensitivity range is that parameters with a minor contribution to LCA outcomes but with a large unknown uncertainty range are eliminated from the analysis (Huijbregts 1998b). An alternative approach is to identify the key input parameters based on the contribution of input data to the results and a qualitative assessment of the data uncertainty (Maurice et al 2000). Contributions can be calculated from current LCA software and uncertainty can qualitatively be assessed using data quality indicators (i.e. ordinal scale with numbers ranging from 1 to 5) (Weidema 1998). Module 14 – Life Cycle Assessment 94 NAMP PIECE 2. Overview of 4 stages of life cycle methodology After the key input parameters have been identified, a quantitative uncertainty analysis can still remain complicated because of lack of knowledge about actual uncertainty of input data. One alternative can be the use of expert judgement to estimate uncertainty ranges (Huijbregts 2001) or different proposed guidelines for parameters extensively measured and data based on little information (Maurice 2000, Finnveden 1998, Hanssen et al 1996). The assessment of the uncertainty of characterization factor on the LCA study outcomes has been illustrated for the comparison of insulation thickness in buildings (Huijbregts 2001a), but there is no evidence of its inclusion in real studies because uncertainty of characterisation factors is generally unknown. Model developers generally do not provide quantitative information about parameter uncertainty, except for some references about midpoint modeling of toxicity potentials (Hertwich et al 2000, Huijbregts et al 2000, Hertwich et al 1999). Because normalization and weighting are optional steps and the methodological choices involved in their application are supposed to have a stronger effect on the study results, parameter uncertainty of the normalization and weighting factors are not covered on the literature. Module 14 – Life Cycle Assessment 95 NAMP PIECE 2. ¾ Overview of 4 stages of life cycle methodology Uncertainty due to Choices Several choices are made when performing LCA studies (e.g. system boundaries, allocation rules, characterization models, weighting factors, etc.). The use of guidelines such as SETAC Best Available Practices (Udo de Haes et al 2002) and ISO standards (ISO 1997, ISO 1999, ISO 2001a, ISO 2001b) as well as the peerreview processes are useful practices to reduce uncertainty due to choices (Huijbregts 1998a). Uncertainties due to choices can be quantitatively assessed as it has been illustrated for the comparison of two types of roof gutter, where the combined effect of parameter uncertainty and uncertainty due to choices in inventory data and characterization factors were calculated (Huijbregts 1998b). ¾ Model Uncertainty There are model uncertainties in LCA studies due to the lack of temporal and spatial variability as well as the linearity in the assessment, model uncertainties on the simplified environmental models used to calculate characterization factors, etc. At present, model uncertainty assessment has not been made operational in LCA case studies (Huijbregts 1998b). Module 14 – Life Cycle Assessment 96 NAMP PIECE 2. Overview of 4 stages of life cycle methodology All these factors can have very significant impacts on the result. The only way to deal with them is in the uncertainty analysis. Uncertainty caused by incompleteness refers to the unavoidable data gaps. Important issues are: 9 System Boundaries, as we have discussed above it is not easy to apply consistent boundaries and cut of criteria. 9 Incomplete data sheets and insufficiently specified data. In many cases, data is gathered from interviews and through questionnaires, and often data will be partially available. A particular problem is that often data is gathered in sum parameters. 9 Mismatch between inventory and impact assessment. In many cases, inventory data that is collected does not have a characterization factor, and therefore this finding is ignored in the rest of the LCA. Module 14 – Life Cycle Assessment 97 NAMP PIECE 2. 2. Overview of 4 stages of life cycle methodology Sensitivity Analysis The ISO 14043 prescribes that sensitivity analysis should focus on the most significant issues, to determine the influence on variations in techniques, methods and data. Tornado diagrams illustrate the changes in output parameter values for equal levels of change in input parameters. The model is run with low and high values for each parameter while all other parameters are held constant. The result are presented in lying bar graphs, the top bar representing the output range of the most sensitive parameter, and the bottom bar representing the least sensitive parameter, giving a graph shaped like an upside down triangle, hence the simile to a tornado. One-way sensitivity analysis determines the amount an individual input parameter value needs to change, all other parameters held constants, in order for output parameter values to change by a certain percentage. Module 14 – Life Cycle Assessment 98 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Scenario analysis. Scenarios in LCA studies are descriptions of possible future situations, based on specific assumptions about the future, and are characterized by choice of system boundaries, allocation methods, technology, time, space, characterization methods, and weighting methods. In Ratio sensitivity analysis, which is applicable only in comparative studies, a ratio is calculated to determine the percentage an input parameter value need to change in order to reverse rankings between two alternatives. The sensitivity is expressed as the ratio of the difference between alternatives over individual process component. The Critical error factor (CEF) is a measure of the sensitivity of a priority between two alternatives to an input parameter value x. It is calculated as the ratio of the critical error Δx, i.e. variation in x required to bring about a change in priority, over the value of x, i.e. CEF=Δx/x. Module 14 – Life Cycle Assessment 99 NAMP PIECE 2. 3. Overview of 4 stages of life cycle methodology Contribution Analysis An important tool in understanding the contribution of your results is the use of the contribution analysis. With such analysis, you determine which processes are playing a significant role in your results. With the information you can focus your attention on these processes, and analyze if these processes are sufficiently representative, complete and if there are important assumptions within these processes. 4. Gravity Analysis Contribution analysis shows which processes create high environmental load. However this does not reveal the cause of the load. In gravity analysis we can look at the interrelations between the processes and show which processes are in fact responsible for the load, while these processes in themselves may have low emissions. . Module 14 – Life Cycle Assessment 100 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Conclusions and Recommendations The final step of the interpretation is more or less similar to the traditional concluding and recommending part of a scientific and technical assessment, investigation or alike. The aim of this third step of the interpretation is to reach conclusions and recommendations for the report of the LCA study or life cycle inventory study. This step is important to improve the reporting and the transparency of the study. Both are essential for the readers of the LCA report. Module 14 – Life Cycle Assessment 101 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis 2.5. Inventory Analysis: Example 2.6. Impact Assessment 2.7. ISO guidelines; Impact Assessment 2.8. Impact Assessment : Example 2.9. Interpretation 2.10. ISO guideline; Interpretation Module 14 – Life Cycle Assessment 102 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.10. ISO guideline; Interpretation Significant points identification To structure the results from the LCI or LCIA phases in order to determine the significant issues, in accordance with the goal and scope definition and interactively with the evaluation element. (International Organization for standardization 2000) Completeness study Process of verifying whether information for the preceding phases on an LCA or an LCI study id sufficient for reaching conclusions in accordance with the goal and scope definition. (International Organization for standardization 2000) Consistency study Process of verifying that the assumptions , methods and data are consistently applied throughout the study and in accordance with the goal and scope definition. (International Organization for standardization 2000) Sensitivity analysis Process of verifying that the information obtained from a sensitivity analysis is relevant for reaching the conclusion and giving recommendations. (International Organization for standardization 2000) Conclusion and recommendations The objective of this third element of the life cycle interpretation is to draw conclusions and make recommendations for the intended audience of the LCA or LCI study. (International Organization for standardization 2000) Module 14 – Life Cycle Assessment 103 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis 2.5. Inventory Analysis: Example 2.6. Impact Assessment 2.7. ISO guidelines; Impact Assessment 2.8. Impact Assessment : Example 2.9. Interpretation 2.10. ISO guideline; Interpretation 2.11. Interpretation: Example Module 14 – Life Cycle Assessment 104 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.11. Interpretation : Example It is possible to make a first interpretation at the inventory analysis level based on individual parameters. The next figures show the energy consumptions, the air emissions and the water emissions at the different stages of the paper life cycle, for the actual scenario and for the natural gas scenario. It important to note that only the CO2 originated during the combustion of non-renewable fuels (non-renewable CO2) was considered, since one of the assumptions of this study is that the CO2 released from renewable sources (renewable CO2) is balanced by CO2 absorption in the forest. Module 14 – Life Cycle Assessment 105 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Module 14 – Life Cycle Assessment 106 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Module 14 – Life Cycle Assessment 107 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Module 14 – Life Cycle Assessment 108 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Based on the inventory analysis and impact assessment results: The printing and writing paper production is the most important contributor to non-renewable CO2 emissions due to on-site energy production. Although the eucalyptus pulp production is the largest consumer of energy throughout the paper life cycle, its contribution to air emissions is not predominant. The final disposal stage assumes a predominant role in global warming and photochemical oxidants formation impact categories, as a result of the CH4 emissions in landfilling. Transport is the main source of NOx emissions, resulting in an important contribution to the eutrophication and acidification impact categories. The contribution of the remaining stages of the paper life cycle to the impact categories is not relevant. Module 14 – Life Cycle Assessment 109 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis 2.5. Inventory Analysis: Example 2.6. Impact Assessment 2.7. ISO guidelines; Impact Assessment 2.8. Impact Assessment : Example 2.9. Interpretation 2.10. ISO guideline; Interpretation 2.11. Interpretation: Example 2.12. Benefits and limits of LCA Methodology Module 14 – Life Cycle Assessment 110 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.12. Benefits and limits of LCA Methodology LCA is the only tool that can be used for product comparisons over the whole life cycle (Finnveden 2000). The main benefits from using this methodology have been highlighted by ISO and SETAC as (Owens 1999): 9 9 9 9 Quantifying material and energy efficiency for a system. Identifying improvement opportunities and trade-offs. Illuminating hidden or unrecognized issues. Promoting a wider communication about how to compare and improve highly complex and difficult to analyze industrial systems. However, LCIA addresses only the environmental issues that are identified in the goal and scope, therefore, is not a complete assessment of all environmental issues. Furthermore, LCIA is fundamentally an analysis of inputs from and outputs to the environment rather than an analysis of the actual environmental consequences or effects from a system. Impact Assessment modeling in LCA involve in some cases highly simplified assumptions about complex environmental processes (e.g. eco-toxicity) and there are also difficulties in dealing with spatial, temporal and dose-response issues (Owens 1999). Module 14 – Life Cycle Assessment 111 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Therefore, even for comparisons it has been suggested complementing LCA results with absolute approaches of other techniques, (e.g. risk assessment). The system-wide, relative LCA approach can be seen to identify and analyse possible system issues and trade-offs, where absolute tools would analyse in detail the issues raised by LCA (Owens 1999). Others limitations of the methodology include the uncertainty of the results due to data gaps, data uncertainties, methodological choices and values. However, these are relevant also for other environmental tools (Finnveden 2000). Module 14 – Life Cycle Assessment 112 NAMP PIECE Tier I: Outline 1. 2. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. 2.1. Methodology 2.2. Goal and Scope 2.3. Goal and Scope : Example 2.4. ISO guidelines; Inventory Analysis 2.5. Inventory Analysis: Example 2.6. Impact Assessment 2.7. ISO guidelines; Impact Assessment 2.8. Impact Assessment : Example 2.9. Interpretation 2.10. ISO guideline; Interpretation 2.11. Interpretation: Example 2.12. Benefits and limits of LCA Methodology 2.13. Interaction (Value) of LCA with other PI tools Module 14 – Life Cycle Assessment 113 NAMP PIECE 2. Overview of 4 stages of life cycle methodology 2.13. Interaction (Value) of LCA with other PI tools Heat & Mass Exchange Networks Capital Effectiveness Analysis Integrated Process Design & Control Business Modeling Supply Chain Process Simulation Validation Data Driven Process Modeling On-line Data Collection/Analysis Module 14 – Life Cycle Assessment Process Data Process Models 114 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Heat & Mass Exchange Networks Capital Effectiveness Analysis Process simulation Integrated data can Process be used Design & Control into a LCA model in order to assess environmental impacts. Business Modeling Supply Chain Process Simulation Validation Data Driven Process Modeling On-line Data Collection/Analysis Module 14 – Life Cycle Assessment Process Data Process Models 115 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Heat & Mass Exchange Networks Capital Effectiveness Analysis Business Modeling Supply Chain Integrated Process Design & Control LCA results can be used as a complement to capital effectiveness Process analysis in order to show Simulation the impact of a project on the environment. Validation Data Driven Process Modeling On-line Data Collection/Analysis Module 14 – Life Cycle Assessment Process Data Process Models 116 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Heat & Mass Exchange Networks Capital Effectiveness Analysis Data Driven Process Modeling On-line Data Collection/Analysis Module 14 – Life Cycle Assessment Business Modeling Supply Chain Integrated Process Design & Control Heat and mass integration will identify the optimal pollution Process prevention strategies from a Simulation process perspective. The utilization of LCA will demonstrate if the improvements are beneficial from a product perspective. It can also be used to communicate these Processto the public. Process improvements Data Models Validation 117 NAMP PIECE 2. Overview of 4 stages of life cycle methodology Heat & Mass Exchange Networks Capital Effectiveness Analysis Data Driven Process Modeling On-line Data Collection/Analysis Module 14 – Life Cycle Assessment Business Modeling Supply Chain Integrated Process Design & Control Business modeling look simultaneously at the process, Process economic and environmental Simulation dimension. LCA can be used as a framework to modelize the environmental dimension. Both LCA and Supply Chain Management are going beyonfd the firm boundaries, so there are a lot of opportunities to use them together. Process Process Data Models Validation 118 NAMP PIECE Tier I: Outline 1. 2. 3. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. 3.1. Pulp & Paper Industry Module 14 – Life Cycle Assessment 119 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. 3.1. Pulp & Paper Industry LCA is a potentially a powerful tool for evaluating the environmental performance of pulp and paper products. This work show the range applications of LCA in the pulp and paper industry and the methodologies used by analysis of the literature. The authors highlight certain of the limitations of LCA, and identify its potential as a tool for demonstrating continuous improvement at mills. Module 14 – Life Cycle Assessment 120 NAMP PIECE Tier I: Outline 1. 2. 3. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. 3.1. Pulp & Paper Industry 3.2. Survey of applications Module 14 – Life Cycle Assessment 121 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. 3.2. Survey of applications 33 studies have been investigated in order to draw a picture of LCA applications in the pulp and paper industries. These applications were divided in the followings fields: 9 Product comparisons 9 Process analysis and benchmarking 9 Comparison of improvement options for a given product or process 9 Evaluation of new products 9 Strategic evaluation The next figure shows the repartition of the studies between those fields. The sum is higher of 34 because some of the studies cover more than one field of application. It also shows that, even if product comparisons were the primary purpose of LCA, this methodology is more and more used for environmental process analysis and comparison of process options. Since pulp and paper is an old industry that reaches “steady state” regime, it is not a lot involved with Greenfield design. For this reason, LCA has not been integrated in the design phase of this industry. LCA begins to be utilized to performed strategic evaluation like environmental assessment en EMS. All these applications will be discussed later. Module 14 – Life Cycle Assessment 122 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Number of studies 12 10 8 6 4 2 0 Product comparison Process analysis Process Evaluation of Strategic options new product evaluation comparison Application Breakdown of Studies by Field of Application Module 14 – Life Cycle Assessment 123 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. It also possible to classify these studies by the type of publications, such as: case studies, methodological approaches, methodology illustrated by a case study, review of previous work and industrial experience with LCA. Papers or conference proceedings presenting an individual company’s experiences with the utilization of LCA are classified in this last category. The classifications are show in the next figure. Survey 3% Industrial experience 9% Methodology and case study 15% Methodological approach 15% Case study 58% Some countries are more advanced than others concerning the development of LCA methodology and its application. In fact, even of some studies were applied to some specific countries, it is the countries from where the study was performed that is considered here. Module 14 – Life Cycle Assessment 124 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Japan studies had not been considered here but they would represent a high percentage if they were. In fact, Japan is far more advanced in terms of general LCA development and utilization in comparison to other countries European ones. Japan’s Ministry of Economy, Trade and Industry (METI) has launched in 1998 a national project, “Development of Assessment Technology of Life Cycle Environment Impacts of Products”. The objective of the LCA Project is to develop a highly reliable LCA could be due to the fact that greater concern has arisen from demographic and natural resources issues, than say in North America. France 9% Australia 12% UK 9% Greece 3% USA 19% Portugal 6% Europe 58% N etherlands 3% 27% Canada 6% Sw eden 12% Finland 12% Sw itzerland 3% India 3% South Africa 3% Country of Origin of LCA studies Module 14 – Life Cycle Assessment 125 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. It is also possible to classify LCA studies by the type of organizations they come from. The classification is show in the next figure. The figure shows that most of the studies come from the university sector, This could be explained by the fact LCA is still a methodology under development. Consulting company 12% Industrial association and/or Industry 27% University 43% 18% Government Groups performing LCA studies Module 14 – Life Cycle Assessment 126 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. The next figure illustrates who did what. We can see that consulting companies have mostly implied in product comparison. The interest of industrial side is more related to the processes and the strategic evaluation because they have to meet regulations and want to have a better concurrent position on the market. Government touches to all preceding categories. Consulting Company Industrial association Government University 12 10 8 6 4 2 0 Product comparison Process analysis Process improvement New product Strategic evaluation Work Breakdown Module 14 – Life Cycle Assessment 127 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. The next figure shows that the application of each study, and its conclusions, are generally well defined. Yes Not done No info 100% Suggested elements 80% 60% Goal and scope Module 14 – Life Cycle Assessment LCIA Conclusions Consistency Sensitivity Completeness Sign. Points Data quality Weighting Grouping Normalization Characterization Impact cat. Inventory LCI Classification the activity in the publication Peer review No info: There is no info about Data source activity has not been done Boundaries Not done: It is clear that the Required elements 0% Functional unit the publication 20% Public Yes: Activity is defined in Application Legend 40% Interpretation 128 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. LCA General application in the Pulp and Paper Industry 9 Products Comparison 9 Analysis of the origins of environmental impacts related to a particular product LCA 9 Comparison of improvement variants of a given product or process, or alternative process technologies 9 Evaluation of new products and product management (Product Stewardship) 9 Strategic policy development Module 14 – Life Cycle Assessment 129 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Comparison of Products with the Same Function LCA is used for the comparison of paper products with alternatives. This section intended to highlight problems encountered when using LCA to compare different products with the same function. Examples of product comparison are presented in the next tables. Product Comparison : Paper vs. Polyethylene (PE) Bags References Franklin Associates (1990) USA Eurosac (1993) France Objectives At the time this study were performed, there was no well-accepted methodology. Main Conclusions Comparison of paper and PE PE is worse concerning: NonNon-renewable energy; abiotic resource check out bags in United States depletion; GW; photoquemical oxidant; acidification; air and water water using a resource andThree profile companies emissions; pollution of aquatic system. were analysis (REPA) orrespectively LCI. Paper is worse responsible for concerning: Eutrophication. the inventory, the impact Comparison of industrial paper Paper is worse concerning: Climate change: ozone depletion; assessment and the critical and PE sacks. ecotoxicity: land use; mineral depletion. analysis. Plastic is worse concerning: Fossil fuel depletion at high use ratios. Module 14 – Life Cycle Assessment 130 NAMP PIECE 3. Survey of life cycle applications in that thethepulp and results from this study were applicable only for the case defined by paper industry. assumptions. The authors emphasise Product Comparison : Towels vs. Air Driers References Objectives Environment al resources Management (2001) UK Comparison of paper towel and air dryers in United Kingdom (UK) Main Conclusions Environmental footprint for air driers is smaller than the paper towels. Use of dries results in lower GW, acidification ecotoxicity, ecotoxicity, human toxicity, nutrification, ozone depletion and photoquemical smog burdens. Product Comparison : Disposable vs. Cloth Diaper References Sauer et al. (1994) USA Miljö Miljökonsult and Svensson (1993) Sweden The authors stresses that REPA (LCI)Objectives should not be used to find winner or awater Assessment of the aenergy usage, loosersolid but waste, to identify requirement, atmospheric possible improvements. emission and water emissions generated by disposable and cloth diapers. Comparison of disposable and cloth diapers. Module 14 – Life Cycle Assessment Main Conclusions Cloth and disposable diapers Cloth diapers use more energy and water than are difficult to compare disposable. Disposable diapers generateddue moretosolid the incompleteness of the wastes. Air and water emissions are considered information and the inability to equivalent for both product. weight environmental effects against each other. With good laundry practices, cloth diapers contribute less to GW and acid rain and use less energy. Phosphorus and other discharges are higher for cloth diapers, and cotton cultivation may no be sustainable. Disposable diaper consumes a lot of fossil fuel. 131 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. The authors recognize the importance of the accuracy of the input data. Product Comparison : Paper vs. Polystyrene Egg Packaging References Objectives Zabanioyou and Kassisi (2003) Greece Comparison of paper and polystyrene for egg packaging. Main Conclusions The application of the LCA procedure to polystyrene and recycled paper egg packaging does not provide a clearclear-cut answer for defining the friendlier product, but it seems that the polystyrene carton has a higher environmental impact. Product comparison is undoubtedly the application that is the most sensitive to LCA’s limitations. The results to two different studies on the same products could seem to have contradictory results. The result from an LCA cannot be generalized, and are very specific to the defined goal and scope. For this reason, some authors recommend that LCA should not been used perform product comparison but only to improve the processes. Module 14 – Life Cycle Assessment 132 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Process Analysis and Benchmarking Process analysis and benchmarking consist in the determination of the contribution of each stage to different impact categories, to the utilization of LCA as an environmental benchmark method, and to the optimization of resources and energy. Examples of these are presented in the next tables. As a result of this study, LCA became part of their environmental program. Process Analysis and Benchmarking : Overall Process Evaluation References Wiegard (2001) Australia Objectives Illustration of how LCA could be used to find opportunities for environmental improvement, more specifically for reducing GHG emissions. Module 14 – Life Cycle Assessment Main Conclusions Performing LCA on the virgin and recycled paper gave the Visy company a true picture of its mills in terms of GHG emissions. 133 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Modeling techniques and scenario-type sensitivity analysis are helpful to Process Analysis and Benchmarking : Resources and Energy Optimization Optimization answer questions with a high level of complexity and uncertainty. References Objectives Main Conclusions Sundin et al. (2002) UK LifeLife-Cycle material and energy analysis for the pulp and paper cycle in the United Kingdom for the period between 1987 and 1996, and modelisation of future trends in material and energy flows until 2010. Environmental benefits of reducing consumption of paper and improving technology is greater than increasing recycling. Process Analysis and Benchmarking : Evaluation of Emissions along along the Paper Cycle References Objectives Main Conclusions Pajula, Kutinlahti, and Wessman (2001) Evaluation of the contribution of transportation to the overall environmental impact of the paper chain. Fossil CO2, SO2 and NOx are the emissions that are the most influenced by transport. The vehicle used has more impact than the distance (except for longlong-sea trip). Paper production is the major contributor to CO2 and SOx. The result can change if clean energy is used in the process. Module 14 – Life Cycle Assessment 134 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Process Analysis and Benchmarking : Asset Evaluation References Vasara and Jallinoja (1997) Finland Objectives Evaluation of different scenarios over time concerning the life cycle of a paper machine. Incorporation of time dimension in LCA increases its utility as decisionmaking tool. Main Conclusions Life cycle of equipment must be considered over its entire lifetime and that its environmental impacts could change in time. Many examples show that LCA is a useful tool for investigating environmental strengths and weaknesses along the life cycle of a process or product and identifying stages of production which cause the most impacts. LCA is useful for identifying and assessing the environmental impacts of a product and to improve the management control of the plant. Module 14 – Life Cycle Assessment 135 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Comparison of Improvement Options for Given Product or Process Once processes are benchmarked, LCA can be use for the evaluation of improvement variants. The comparison of these with the benchmark and with each other shows the best opportunities for improvement. The example below shows that LCA can give a clear answer to a defined problem, but under certain conditions. Because of the uncertainty in the data, results were only indicative. Comparison of Waste Management Scenarios References Pickin, Yuen and Hennings (2002) Australia Objectives Investigation of various waste management options in order to reduce GHG emissions from paper. Module 14 – Life Cycle Assessment Main Conclusions Options other than landfill reduce GHG emissions. WasteWaste-toto-energy recovery is the most effective. 136 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Results from LCA should Comparison of Waste Management Scenarios References Grant et al. (2001) Australia Objectives Determination or the Environmental benefits of recycling. not be used alone for decision-making. Technical, operational and economic reliability should be taken into consideration. Main Conclusions Recycling avoid virgin material use and impacts related to landfills. LCA methodology alone is not enough to compare these two process Comparison of Improvement optionsThe for a given product or process : Bleaching Processes alternatives. outcomes of combined LCA, risk References Objectives Main Conclusions assessment and exposurebased of assessment provide FWA production uses less energy and causes Sheringer, Halder Comparison environmental a better picture. lower air and COD emissions but higher AOX and Hungerbü performance of fluorescent Hungerbüler emissions. (2000) Switzerland whitening agents (FWAs) with peroxide bleaching of mechanical pulp using LCA Module 14 – Life Cycle Assessment 137 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Recycling problems are quite complex to analyze using LCA. For this reason, several authors tried to develop LCA methodologies that are specific to recycling characteristics. LCA is not sufficient to answer complex question related to process alternatives, because some impacts are not well addressed. The author recommends to combine LCA with risk assessment and exposure-based assessment. LCA is the most appropriate tool to evaluate the global impact of process modifications. Comparison of Improvement options for a given product or process : Energy Alternatives References Lopes et al. (2003) Portugal Objectives Main Conclusions Assessment of the replacement of heavy fuel oil (HFO) by natural gas and cogeneration in the manufacturing process of paper made from Eucalyptus globulus pulp. Substituting HFO by natural gas in the pulp and paper production process is a good environmental solution when combined with cogeneration. Module 14 – Life Cycle Assessment 138 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. LCA only guides decision-makers in the assessment and selection of technologies based on environmental performance. The methodologies used and their advantages are presented in the next table. Methodology Advantage Ranking of scenarios in term of environmental impact categories. Enables the decision-maker too chose the best option based on this environmental priorities. Normalization to national or global impact categories totals. Gives the relative significance of this system to the overall loads. Environmental-economic valuation model. Integrates economic considerations in the decision. Sensitivity analysis. Enables to test the impact of assumptions, condition and data that have the ability to affect the results and conclusions of the study. Data quality analysis. Enables the identification and management of data gaps, inconsistencies and errors. Consistency analysis. Ensures the consistency with defined boundary conditions throughout the study. Module 14 – Life Cycle Assessment 139 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Evaluation of New Products The environmental aspect should be considered in each stage of the life cycle of a product beginning with its design. This practice allows a better selection of materials and processes. Pulp and Paper industry is not using LCA a lot of the assessment of new products. Nevertheless, it could be predicted that it will be more used for this purpose in the future due to the notion of product stewardship. The notion means that the manufacturer is liable for its product during the course of its entire life cycle, from the design stage through raw material extraction and on the final disposition of the product. Module 14 – Life Cycle Assessment 140 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Strategic Evaluation LCA applications can go farther than the comparison of products, process benchmarking, choice of improvement alternatives, or green design. It can provide an organization with helpful information for strategic choices and marketing. A few examples of how LCA has been used to accomplish this objective are presented in the next table. Like mentioned before, LCA has only just begun to be used for strategic evaluations other than process analysis and comparison of improvement variants. Up today, the main applications in this field were the structuring of supply chains and marketing. Module 14 – Life Cycle Assessment 141 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. Strategic Evaluation : Structuring of Supply Chains Reference Bradley (1999) Canada Application Canfor sees benefits of using LCA within the supply chain. There is an enhancement of the partner's knowledge about the potential environmental impact of the paper chain. This experience makes opportunities for improvement more obvious. Because both economic economic and environmental performance can be optimized, there are clear benefits from having having suppliers and customers working closely and studying the process chain. Strategic Evaluation : Strategic Policy Development and Marketing Marketing Reference Côté Côté (1996) USA Application International paper uses LCA in order to satisfy their customers’ customers’ concerns about the environment. Strategic Evaluation : LCA and EMS Reference Zobel at al. (2002) Sweden Application Proposition of a transparent and stringent methodology to identify identify and assess environmental aspect in EMS based on LCA Module 14 – Life Cycle Assessment 142 NAMP PIECE 3. Survey of life cycle applications in the pulp and paper industry. The LCA methodologies presented in the publications were almost always incomplete. The major criticisms concern adherence to life cycle assessment stages related to the quality of the studies i.e. data quality sensitivity, completeness and coherence studies. Product comparison is the most sensitive application to LCA limitations because dealing with two products with the difference in system of product compared has a consequence that there is more subjective choice to do this application compared to the others. The most obvious application of LCA is process analysis, as it was created for this. However, the comparison of process alternatives will have more value if supported by techno-economic analysis. Module 14 – Life Cycle Assessment 143 NAMP PIECE Tier I: Outline 1. 2. 3. 4. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. Proposal of “life cycle thinking” concept: using LCA as a tool for practical applications in the operation of a facility. Module 14 – Life Cycle Assessment 144 NAMP PIECE 4. Life Cycle Thinking Life Cycle thinking implies that everyone in the whole chain of a product’s life cycle, from cradle to grave, has a responsibility and a role to play, taking into account all the relevant external effects. The impacts of all life cycle stages need to be considered comprehensively when taking informed decisions on production and consumption patterns, policies and managements strategies. Module 14 – Life Cycle Assessment 145 NAMP PIECE 4. Life Cycle Thinking Disposal Scope of Environmental Concern In the UK, Professor Roland Clift argued that “it is key that life-cycle thinking be fostered throughout organizations, and be adopted as part and parcel of the S o c ie ty S u s ta in a b le D e v e lo p m e n t organization’s philosophy, mission and day-to-day operations. This makes it essential that life-cycle thinking also be applied corporate educational processes”. M uthinking ltip le I n d u squantitative tr ia l E c o lo g y Life cycle is a mostly discussion to identify stages of the life cycle M a n u fa c tu r e rs and/or the potential environmental impacts of greatest significance e.g. for use and design brief or in an introductory L ife C y c le discussion T h in k in g of policy measures. The greatest benefit is that it helps focus consideration of the full life cycle of the product or system. D fE Production Use E n v ir o n m e n ta l C o n s c io u s AppliedSto product design, manufacturing processes and as a decision-making tool for in g le D e s ig n & M a n u fa c tu r in g Pro d u ct environmental policies, life cycle thinking is an essential element for the L ife tim e implementation of sustainable development. PP P ro d u c tio n CP P r o d u c t L ife tim e U se D is p o s a l H u m a n C iv iliz a tio n L ife tim e span S co p e o f T e m p o ra l C o n ce rn Moving toward sustainability Module 14 – Life Cycle Assessment 146 NAMP PIECE Tier I: Outline 1. 2. 3. 4. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. Proposal of “life cycle thinking” concept: using LCA as a tool for practical applications in the operation of a facility. 4.1. Sustainable Development (SD) Module 14 – Life Cycle Assessment 147 NAMP PIECE 4. Life Cycle Thinking 4.1. Sustainable Development (SD) It is defined as a development that meets the needs of the present without compromising the ability of future generations to meet their own needs. Schematic representation of the notion of sustainable development. Module 14 – Life Cycle Assessment 148 NAMP PIECE Tier I: Outline 1. 2. 3. 4. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. Proposal of “life cycle thinking” concept: using LCA as a tool for practical applications in the operation of a facility. 4.1. Sustainable Development (SD) 4.2. Industrial Ecology (IE) Module 14 – Life Cycle Assessment 149 NAMP PIECE 4. Life Cycle Thinking 4.2. Industrial Ecology (IE) The journal of Industrial Ecology, defines IE as: a rapidly growing field that systematically examines local, regional, and global uses and flows of materials and energy in products, processes, industrial sectors, and economies. It focuses on the potential role of industry in reducing environmental burdens throughout the product life cycle from the extraction of raw materials to the production of goods, to the use of those goods and to the management of the resulting wastes. Module 14 – Life Cycle Assessment 150 NAMP PIECE Tier I: Outline 1. 2. 3. 4. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. Proposal of “life cycle thinking” concept: using LCA as a tool for practical applications in the operation of a facility. 4.1. Sustainable Development (SD) 4.2. Industrial Ecology (IE) 4.3. Design for the Environment (DfE) Module 14 – Life Cycle Assessment 151 NAMP PIECE 4. Life Cycle Thinking 4.3. Design for the Environment (DfE) Design for the environment approach is grounded in comparing performance, costs, and the risks associated with alternatives. It uses cleaner technologies, substitute assessments (CTSAs) and life cycle tools to evaluate the performance, cost, and environmental and human health impacts of competing technologies. A goal of DfE is to encourage pollution prevention, front-end, innovations through redesign rather than relying in end-of-pipe controls to reducing potential risks to human health and the environment. Module 14 – Life Cycle Assessment 152 NAMP PIECE Tier I: Outline 1. 2. 3. 4. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. Proposal of “life cycle thinking” concept: using LCA as a tool for practical applications in the operation of a facility. 4.1. Sustainable Development (SD) 4.2. Industrial Ecology (IE) 4.3. Design for Environment (DfE) 4.4. Pollution Prevention (PP) Module 14 – Life Cycle Assessment 153 NAMP PIECE 4. Life Cycle Thinking 4.4. Pollution Prevention (PP) Design for the environment approach is grounded in comparing performance, costs, and the risks associated with alternatives. It uses cleaner technologies, substitute assessments (CTSAs) and life cycle tools to evaluate the performance, cost, and environmental and human health impacts of competing technologies. A goal of DfE is to encourage pollution prevention, front-end, innovations through redesign rather than relying in end-of-pipe controls to reducing potential risks to human health and the environment. Module 14 – Life Cycle Assessment 154 NAMP PIECE Tier I: Outline 1. 2. 3. 4. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. Proposal of “life cycle thinking” concept: using LCA as a tool for practical applications in the operation of a facility. 4.1. Sustainable Development (SD) 4.2. Industrial Ecology (IE) 4.3. Design for Environment (DfE) 4.4. Pollution Prevention (PP) 4.5. Cleaner Production (CP) Module 14 – Life Cycle Assessment 155 NAMP PIECE 4. Life Cycle Thinking 4.5. Cleaner Production (CP) The continuous application of an integrated preventive environmental strategy applied to processes, products, and services to increase overall efficiency and reduce risks to humans and the environment. For production processes, cleaner production includes conserving raw materials and energy, eliminating toxic raw materials, and reducing the quantity and toxicity of all emissions and wastes. For products is involves reducing the negative impacts along the life cycle of a product, from raw materials extraction to its ultimate disposal. For services the strategy focuses on incorporating environmental concerns into designing and delivering services. Module 14 – Life Cycle Assessment 156 NAMP PIECE Tier I: Outline 1. 2. 3. 4. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. Proposal of “life cycle thinking” concept: using LCA as a tool for practical applications in the operation of a facility. 4.1. Sustainable Development (SD) 4.2. Industrial Ecology (IE) 4.3. Design for Environment (DfE) 4.4. Pollution Prevention (PP) 4.5. Cleaner Production (CP) 4.6. Life Cycle Management Module 14 – Life Cycle Assessment 157 NAMP PIECE 4. Life Cycle Thinking 4.6. Life Cycle Management The basic idea in life cycle management is to establish a thorough knowledge of the environmental burdens of the products manufactured by the company and use this for improvement actions. The process includes employees at most levels of the company and starts with an identification of all processes at the production site and an analysis of the related in-and outputs. The result from the process can be used to establish an LCA, but it is more important that the results are used to minimize the environmental burdens. This one by using a set of tools tailored to meet the needs of a given company, e.g. design for the environment, pollution prevention strategies, waste audits, green procurement etc. Module 14 – Life Cycle Assessment 158 NAMP PIECE Tier I: Outline 1. 2. 3. 4. 5. Introduction and definition of the Life Cycle Assessment (LCA). Overview of 4 stages of life cycle methodology. Survey of life cycle applications in the pulp and paper industry. Proposal of “life cycle thinking” concept: using LCA as a tool for practical applications in the operation of a facility. Multiple choice questions. Module 14 – Life Cycle Assessment 159 NAMP PIECE 5. Multiple choice questions Question 1: What parts imply the cradle-to-grave concept? a) Extraction and transport of raw materials b) Production c) Consumption d) Re-use or disposal e) All of the above. Module 14 – Life Cycle Assessment 160 NAMP PIECE 5. Multiple choice questions Question 2: Which parts according SETAC conform an LCA study ? a) Life Cycle Inventory (LCI), Life Cycle Impact Assessment (LCIA), the Interpretation of the study. b) Defining the goal and scope of the study, Life Cycle Inventory (LCI), Life Cycle Impact Assessment (LCIA), the Interpretation of the study. c) Defining the goal and scope of the study, Life Cycle Inventory (LCI), Life Cycle Impact Assessment (LCIA). Module 14 – Life Cycle Assessment 161 NAMP PIECE 5. Multiple choice questions Question 3: Principal factors that should be considered and stated clearly in the Scope of Study include: a) The function(s) of the system to be analyzed b) The system boundaries c) Data requirements d) Any assumptions made e) Study limitations f) All of the above Module 14 – Life Cycle Assessment 162 NAMP PIECE 5. Multiple choice questions Question 4: What is the most sensitive to LCA’s limitations ? a) Money b) Information c) Society d) Product Comparison e) Goal and Scope Module 14 – Life Cycle Assessment 163 NAMP PIECE 5. Multiple choice questions Question 5: It consist in the determination of the contribution of each stage to different impact categories? a) Process analysis and benchmarking b) Life Cycle Assessment c) Inventory Analysis d) Sustainability Module 14 – Life Cycle Assessment 164 NAMP PIECE 5. Multiple choice questions Question 6: What implies Life Cycle thinking ? a) Consecutive and interlinked stages of a product or service system, from the extraction of natural resources to the final disposal b) That everyone in the whole chain of a product’s life cycle, from cradle to grave, has a responsibility and a role to play, taking into account all the relevant external effects c) Defining a functional unit can be quite difficult, as the performance of products is not always easy to describe Module 14 – Life Cycle Assessment 165 NAMP PIECE 5. Multiple choice questions Question 7: It is defined as a development that meets the needs of the present without compromising the ability of future generations to meet their own needs: a) Cleaner Production b) Sustainable Development c) Industrial Ecology d) Inventory Analysis Module 14 – Life Cycle Assessment 166 NAMP PIECE 5. Multiple choice questions Question 8: The goal and scope definition is a guide that helps you to ensure the consistency of the LCA you perform. a) True b) False Module 14 – Life Cycle Assessment 167 NAMP PIECE 5. Multiple choice questions Question 9: Most of the study about LCA studies come from the university sector because : a) They like it b) It is easy c) LCA methodology is still under development d) It is difficult Module 14 – Life Cycle Assessment 168 NAMP PIECE End of Tier I End Of Tier 1 Congr atulations Assuming that you have done all the reading, this is the end of Tier 1. No doubt much of this information seems confusing, but things will become more clear when we’ll look at examples in Tier 2. Module 14 – Life Cycle Assessment 169 NAMP PIECE Tier I Definitions Module 14 – Life Cycle Assessment 170 NAMP PIECE Terminology Allocation. Material input that is used by the unit process producing the product, but does not constitute a part of the product – e.g. a catalyst. Category endpoint. Attribute or aspect of natural environment, human health or resources identifying an environmental issue of concern. Characterization. Second element within impact assessment succeeding the classification element and preceding valuation, in which analysis/quantification, and aggregation of the impacts within the chosen impact categories takes place. Classification. First element within impact assessment, which attributes the environmental inventions listed in the inventory table to a number of selected impact categories. Completeness. Percentage of locations reporting primary data from the potential number in existence for each data category in a input process. Consistency. Qualitative assessment of how uniformly the study methodology is applied to the various components of the analysis. Module 14 – Life Cycle Assessment 171 NAMP PIECE Terminology Data quality. Characteristics of data that bears on their ability to satisfy stated requirements. Functional Unit. Quantified performance of a product system for use as a reference unit in a life cycle assessment study. Geographical coverage. Geographic area from which data for unit processes should be collected to satisfy the goal of the study (e.g. local, regional, national, continental, global). Impact. The consequences for health, for the well-being of flora and fauna or for the future availability of natural resources, attributable to the input and output streams of a system. Impact Category. Class representing environmental issue of concern into which LCI results may be assigned. Module 14 – Life Cycle Assessment 172 NAMP PIECE Terminology Marketing. Traditional way to communicating product properties and capabilities which are consistent with the consumer’s expectations and demands. As the level of environmental consciousness is increasing, more attention is being paid by the consumer to the environmental properties of goods and services. This is being used (and misused) by many companies to attempt to increase their market share, and development of criteria and guidelines for environmental marketing has a high priority. Normalization. An optional element within impact assessment which involves relating all impact scores of a functional unit in the impact score profile to a reference situation. Normalization results in a normalized impact score profile which consist of normalized impact scores. Precision. Measure of the variability of the data values for each data category expressed (e.g. variance). Module 14 – Life Cycle Assessment 173 NAMP PIECE Terminology Process Flow Diagram. Chart containing labelled boxes connected by lines with directional arrows to illustrate the unit processes or sub-systems included in the product system and the interrelationships between those unit processes. Product System. Collection of materially and energetically connected unit processes which perform one or more defined functions – in the international ISO Standard, the term “product” used alone includes not only product systems but also can include service systems. Recycling. Recycling of products implies that the environmental inputs and outputs associated with the manufacturing of a product and its recycling are to be shared by more than one product system. Recycling, closed-loop. Recovery of material on the same factory that produced the material. This kind of recovery requires a “take back” arrangement. Recycling, open-loop. Recovery of material – but not on the same factory that produced the material. This kind of recovery requires a central collection of used material. Module 14 – Life Cycle Assessment 174 NAMP PIECE Terminology Reference Flow. Measure of the needed outputs from processing a given product system required to fulfill the function expressed by the functional unit. Representativeness. Qualitative assessment of the degree to which the data set reflects the true population of interest (i.e. geographic and time period and technology coverage). Reproducibility. Qualitative assessment of the extent to which information about the methodology and data values allows an independent practitioner to reproduce the results reported in the study. Risk Assessment. A tool developed to investigate the potential risk to human health or the environment from specific situations like transport of dangerous goods or the use of specific substances. System Boundary. Interface between a product system and the environmental or other product system. Technology coverage. Nature of the technology mix (e.g. weighted average of the actual process mix, best available technology or worst operating unit). Module 14 – Life Cycle Assessment 175 NAMP PIECE Terminology Time-related coverage. The desired age (e.g. within last 5 years) and the minimum length of time (e.g. annual). Unit – process. Smallest portion of a product system for which data are collected when performing a life cycle assessment. Valuation/weighting. Last element within impact assessment following the characterization/normalization element, in which results of the characterization/normalization, in particular the (normalized) impact scores, are weighted against each other an a quantitative and/or qualitative way order to be able to make the impact information more decision-friendly. This is an element which necessarily involves qualitative or quantitative valuations which are not only based on natural sciences. For instance, political and/or ethical values can be used in this element. The valuation can result in an environmental index. Waste. Any output from the product system which is disposed of. Weighting. Conversion of category indicator results by using numerical factors based on value choices – weighting may include aggregation of the weighted category indicator results. Module 14 – Life Cycle Assessment 176