Ships' Deck Fittings for Towage: Issues & Guidelines

advertisement

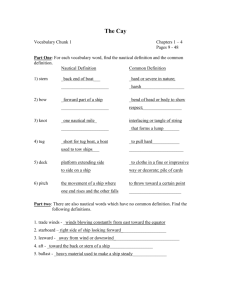

Day 1 Paper 6 ITS 2018 MARSEILLE Organised by The ABR Company Ltd Ships’ Deck Fittings Utilised for Towage Capt Arie Nygh (speaker/author), SeaWays Consultants, Australia SYNOPSIS There has been a move around the world to use high-powered escort tugs to ensure the safe passage of ships in restricted waterways. What has become apparent is that while these tugs can render significant assistance, there is an Achilles Heel – the ship’s fittings to which the towline is attached in many cases are unable to handle the forces generated by the tug (see Figures 1a1c). Investigation has found classification society regulations are confusing and lead to significant misunderstanding by pilots, tug masters and indeed ship owners. This potentially renders the whole exercise of escort towage a waste of time. This paper presents the issues, the underlying history of the situation, and comes up with some pragmatic guidelines to assist all concerned in making informed decisions. INTRODUCTION In January 2017, the author was undertaking annual competency assessments on a client’s tugs operating in an Australian port. When ordered in to connect the towline, the pilot informed the tug master that the safe working load (SWL) of the ship’s bitts the tug was to connect to was 50 tonnes. It was noted that throughout the towage operation the tug master endeavoured to keep the tug’s bollard pull to a maximum of 50 tonnes, which for that tug was only three-quarters power. The pilot service management was asked about the logic behind this procedure. The reply was that this was common in the port, and was designed to ensure there was no likelihood of damage or failure to the ship’s fittings. Mention was made at this point that the SWL of Figures 1a, 1b, 1c: Images of damaged ship’s fittings 1 mooring bitts on ships a ship’s bitts has nothing to do with the forces created by a tug’s towline during towage operations. Rather, the SWL is referencing the forces created by a ship’s mooring line when connected to the wharf. A classification society will assign a vessel an equipment number (EN) based on design criteria such as vessel dimensions, displacement and windage. These criteria are the main components that determine the tidal and wind forces that will act on the vessel and must be counteracted to moor the vessel safely. The EN is then used to determine the number, length and strength of mooring lines that must be supplied onboard the vessel. NB: The EN is also used to determine the strength of anchoring and emergency towage arrangements (see Table 1). Because the mooring line is belayed in figure-ofeight turns around the legs of the bitts, the SWL is a calculation based on the collapsing force of the vertical levers created by the figure-of-eight turns nearing the top of the bitt’s legs. With this in mind, it is accepted practice in the towage industry, though little known, to effectively double whatever the SWL of the bitts is when placing the towline at the base of one of the ship bitt’s legs. For example, if the bitts are rated at a SWL of 50 tonnes, from a tug’s perspective this can be read as 50 tonnes x 2, giving the tug a SWL of 100 tonnes. Strength requirements: mooring line IACS MBL as determined by EN OCIMF MBL as determined by Class EN Table 1: Mooring line strength requirements Subsequently the author contacted colleagues in the Brisbane Pilot Service and suggested undertaking work to investigate the subject of ships’ fittings utilised in towage operations. At that stage we had no idea where the research programme was to lead us, and the issues we were to uncover. Ship fittings are marked with a safe working load (SWL). This is the maximum load that can be applied to a line attached to or passing around the fitting for mooring purposes. Note that the resultant load on the fitting may exceed the load on the line (see Table 2). Joining us in this research was a small team of exemplary industry professionals: Capt Henk Hensen, author of publications such as Tug Use in Port: A Practical Guide and Tug Stability: A Practical Guide to Safe Operations; Capt Brenton Winn, senior pilot at Brisbane Marine Pilots, and Gijsbert de Jong, of classification society Bureau Veritas. Strength requirements: bitts IACS 2 x MBL SWL = MBL OCIMF 2 x MBL Table 2: Bitts’ strength requirements For mooring purposes, it is assumed that the mooring line is attached to the ship’s bitts in a figure-of-eight fashion. Turns are taken around each post in turn to secure the line. The load imposed on each post by a line attached in this manner is twice the load on the line (see Figures 2 and 3). DeSIgN AND CONSTRUCTION STANDARDS OF ShIPS’ BITTS AND FAIRleADS It is important to clearly understand that ship deck fittings are primarily provided for mooring the ship to the wharf, not towage operations. Their required strength is determined by the breaking strain of the mooring lines deemed necessary by classification societies. Ships’ mooring fittings and their foundations should be designed to carry at least the force imposed on the fitting and foundation by an attached mooring line to the wharf at the line’s minimum breaking load (MBL). OCIMF guidelines state that: “Belaying figure-of-eight tends to pull the two posts together inducing a higher stress in each barrel than that produced by an eye laid around a single post.” The design load of the bitts must be twice the maximum expected load of an attached line. Remembering that the SWL of a fitting is defined as the maximum load of a line attached to the fitting, then the design load of the bitts must be 2 x SWL. Gaining an understanding regarding ship deck fittings used for towage requires an understanding of ships’ mooring fittings design regulations. Reference throughout this paper is made to the following documents: • • Requirement Concerning Mooring, Anchoring and Towing, International Association of Classification Societies (IACS), 2017 Mooring Equipment Guidelines, 3rd ed, Oil Companies International Marine Forum (OCIMF), 2008 This paper does not include detailed consideration of safety factors when discussing design or breaking loads. In general terms, the safety factor allowed is around 15-25 per cent. Figure 2: SWL when belaying a mooring line 2 Figure 4: Prefabricated deck fittings SWL of the associated bitts, but caution should be exercised, as this is not always the case. Towing The load calculation on the fairlead is the same, irrespective of whether the line is being used for mooring or towing (notwithstanding the additional dynamic loads that may occur on a towing line) (see Table 3, Figures 5a and 5b). Figure 3: Figure-of-eight belaying a mooring line to the wharf Strength requirement: fairlead Bitts are an attachment to the vessel and are often provided ‘off the shelf’. Manufacturers produce bitts complying with relevant international or national industry standards (ie, ISO 13795, DIN, JMSA), Type-tested to demonstrate compliance to strength requirements. (Note that the standards of design differ between the various industry standards.) IACS Up to 2 x MBL OCIMF 2 x MBL Dependent on wrap angle, as shown on the Mooring Arrangement Plan. SWL = MBL Worst case: wrap angle 180 degrees MBL = Minimum Breaking Load Table 3: Fairlead strength requirements Fairleads on ships A fairlead redirects a line passing through it from the wharf or tug to the ship’s bitts. The angle of the line inboard of the fairlead is determined by the layout of the fittings on the deck that the line may pass around or be secured to. These working angles are shown on the ship’s mooring arrangement plan. Outboard of the fairlead, the line will pass to a bollard on a quay to moor the ship, or, in the case of towing, will be secured to a tug. The angle of the line is variable, depending on the freeboard of the ship and the position of the shore bollard or positioning of the tug assisting the ship. The external angle is likely to have a horizontal and vertical component, and, as it cannot be determined, a worst-case scenario should be assumed (ie, ≈90 degrees). Figure 5a: Line force is doubled due to the angle around the fairlead The load on the fairlead will depend on the load on and angle of the line passing through it (the wrap angle). The worst-case scenario is where the wrap angle is 180 degrees, whereby the maximum load on the fairlead and its foundation structures will be twice the load on a line passing through the lead. Fairleads are an attachment to the vessel and are also often provided ‘off the shelf’ and made to a Typetested design (Figure 4). It is common to see the marked SWL of the fairleads being the same as the Figure 5b: Line force is doubled due to the angle around the fairlead 3 Towage fittings on ships The ship deck fittings will also routinely be used to secure a towline for harbour towage, and in some ports for escort towage, either in the ship’s bow or through its centre lead aft (CLA). Unlike the calculation for mooring line strength, the rules do not specify the forces that may be required on the towline to safely manoeuvre the vessel. IACS requires the fittings to meet the “intended maximum towing load (eg, tug’s ‘static’ bollard pull) as indicated on the towing and mooring arrangements plan” (Table 4). Strength requirements: towline IACS Intended maximum towing load OCIMF Not specified Table 4: Towline strength requirements Figure 6: TOW SWL designed for tug towline forces The ship has no control over the power of tugs, or the breaking strain of the towline provided. The power applied by the tug may have to be limited if the bollard pull/load on the towline is likely to exceed the load limits of the ship’s fittings. In calculating towing loads, it is assumed that the towline is secured to the bitts by passing an eye over a single post of the ship’s bitts. towline can be controlled by limiting the power applied by the tug, in some circumstances (dynamic loads, transverse arrest, indirect towing) the load on the line can be excessive, comfortably surpassing the rated bollard pull of the tug. In these cases, the basic IACS design principle requiring the line to be the weakest link in the system may be negated, resulting in overloading of ship fittings or underpinning structure before the towline MBL is reached. It is generally accepted that the strength of the ship’s fittings and foundation structures required for mooring purposes will provide sufficient strength for towage purposes. A problem arises as the loads applied on some parts of the system during towage are different to the loads applied for mooring. This is primarily due to the different methods of attaching a mooring line (figure-of-eight) and a towline (single eye) to the bitts, plus the various towline angles, both in the horizontal and vertical planes, that a tug in a dynamic environment can generate. This is explained in more detail below. Furthermore, it also must be acknowledged that many ships were built years ago when no one had envisaged harbour tugs of 70 or 80 tonnes BP, or high-performance escort tugs with hydrodynamic keels/ skegs that can produce twice the tug’s rated bollard pull (commonly ≈120 tonnes BP). For towing purposes, it is assumed that the towline is attached to the bitts by a single eye placed over one of the posts. The load imposed on the bitts by a line attached in this manner is equal to the load on the line. As the design load of the bitts is 2 x SWL, the load on a line attached by a single eye can also be 2 x SWL (see Figure 7). Ship fittings can be marked with a safe towing load (TOW) that pertains to the forces relating to a tug. This is the maximum load that can be applied to a line attached to or passing around the fitting for towage purposes. Note that this marking is rarely seen in practice, and frankly is too simplistic to be useful (Figure 6). Furthermore, there is a lack of awareness among many tug masters and pilots of how the tug’s towline forces on the ship’s deck fittings can be multiplied many times over by a combination of towline angles and the operating mode the tug is using (direct, indirect, combination arrest, transverse arrest, etc). As an example, in a worst-case scenario it is possible that there can be a 600 per cent multiple factor applied to the tug’s rated (published) bollard pull, meaning a 60-tonne BP tug can produced a 360-tonne force on to the ship’s deck fittings. (Note: the above is not including spike (shock) loadings caused by rough tug driving or sea state.) Consequently, the bollard pull of a tug and the MBL of a towline supplied from a tug may significantly exceed the SWL of the ship’s fittings. While the load on the Figure 7: Force on post of bitts 4 Foundation structure of deck fittings on ships Basic understanding for fairleads Any force on the fairlead is transferred to the attachment and foundation structure. The foundation structure must be able to withstand the loads imposed on the fairleads at various wrap angles. Strengthening required in way of the fairleads will normally be determined by calculation and incorporated in the vessel construction at time of building. Basic understanding for bitts The loads imparted on to the bitts by the line are withstood by the structure of the bitts, and are not transferred to the foundation structure. The bitts can be considered as a single box mounted to the deck, with an external force acting on the box equal to the load on the line. The external force is transferred through the box to the foundation structure. The load that the foundation structure must withstand is equal to the load on the line. The foundation structure is an integral part of the ship’s design. Strengthening required in way of the bitts will normally be determined by calculation, and incorporated in the vessel construction at time of building (see Figure 8 and Table 5). Summary of system loads and strength requirements In the above reference, the strength of a ship’s deck fittings is relevant to the MBL of the mooring in use. Where commonly a ship’s mooring line may be in the order of 150 tonnes MBL, a modern high-performance tug can have towlines with an MBL greater than 300 tonnes. Hence the IACS and OCIMF reference data above is not appropriate for towage operations (see Tables 6 and 7). Investigation results Key points • Figure 8: Force on the bitts’ foundation We found the rules for design and construction for ship’s deck fittings from one industry entity to another to be not only confusing, but in some cases contradictory. Even industry experts we consulted were at times confused by them. Strength requirements: bitt foundation structure IACS MBL = SWL bitts Sufficient to meet mooring load OCIMF 2 x MBL Sufficient strength to accommodate line attached to bitt by single eye over one post at a load of 2 x SWL Table 5: Bitt foundation strength requirements Loads on system Figure-of-eight (mooring) Single eye (towage) Doubling load on single eye T T 2T Fitting and foundation Up to 2 x T (depending on wrap angle) Up to 2 x T (depending on wrap angle) Up to 4 x T (depending on wrap angle) Fitting 2xT T 2xT Foundation T T 2xT Line Fairlead Bitts Table 6: Summary of system loads Strength requirements Line IACS OCIMF MBL MBL Fairlead Fitting and foundation Up to 2 x MBL dependent on 2 x MBL wrap angle (worst case wrap angle (Marked SWL = MBL) 180o) Bitts Fitting 2 x MBL (Marked SWL = MBL) 2 x MBL Foundation MBL 2 x MBL Table 7: Summary of strength requirements 5 Towing To meet expected maximum towing load • Regarding the foundation structures and attachment to the vessel of the fittings, it should be understood these are not integral parts of the ship’s structure, and must be attached to the ship. The strength of the attachment and underlying structure are an important part of the system but this is often underestimated during the design and construction of the ship. Age matters • • For ships constructed prior to 2007, there is no guarantee that class rules adequately cover the design of the ship’s deck fittings. For ships constructed prior to 2012, there is no guarantee that class rules adequately cover the underpinning deck structure the ship’s deck fittings are connected to. Figure 9: Force on CLA Findings pertaining to ship’s bitts and leads failure, and deck fitting failure before hull or foundation failure. During towage operations this is usually far from the reality (see Figure 10, opposite). While it is all well and good to focus on the SWL of the ship’s bitts the tug’s towline is connected to, what must also be taken into account is the ship’s fairleads that the tug’s towline runs through. It is important for a tug master to know when to focus on the SWL of one over the other. Towline angles To further complicate things, the angle of the tug’s towline from the horizontal applies a significant multiplication factor to the forces the tug is creating into its towline and on to the ship’s deck fittings. As an example, with the tug’s towline angled up to the ship at 60 degrees from the horizonal, there is a multiplication factor of x2 (200 per cent) into the towline and a factor of x1.8 (180 per cent) on to the ship’s fittings. As pointed out above, we can double the SWL of a set of ship’s bitts by placing the eye of the tug’s towline at the base of one leg of the ship’s bitts, but this does not apply to the ship’s fairleads, be they roller, cotton reel or panama types. At a 75 degree towline angle, this multiplication factor increases to x3.8 force into the towline and a x3.3 factor on to the ship’s deck fittings. For example, a tug producing 85 tonnes BP into the water with a vertical towline angle of 70 degrees can have 248 tonnes force in its towline and 223 tonnes force on to the ship’s deck fittings (see Table 8). Generally for tugs working in a push/pull mode on the ship’s sides or directly astern when centre lead aft (CLA), there is not a significant force being brought to bear on the ship’s fairleads. Often what force is created is in fact a downward force that tends to press the ship’s fairlead into the deck, rather than trying to pull it off its connection to the ship’s deck foundation. The situation changes significantly when the tug’s towline forces are at an obtuse angle to the fairleads, which in turn can create a tearing/ripping sideways force on to the fairleads (in this case, the CLA). The worst case scenario is when the towline is near horizonal to the water and at an angle of near 90 degrees to the ship’s fairlead, and the angle from where the towline enters the fairlead (in this case CLA) to where it leads to the ship’s bitts is greater than 90 degrees. This combination can create a destructive force on to the ship’s fairlead (CLA) of up to ≈2x the towline force the tug is creating (Figure 9). Table 8: Force multiples due to towline angles General design strength principle of deck fittings A possible worst case As a general principle, the ship’s mooring fittings and foundations should be designed to carry the force imposed by an attached mooring line. The requirements concerning the strength of the ship’s mooring fittings are based on the principle of rope failure before deck fitting A tug out square to the ship is producing (say) 65 tonnes BP into the water with a vertical towline angle of 75 degrees, hence producing 251 tonnes towline force and 217 tonnes force on to the ship’s fittings. Now lead the towline through the ship’s fairlead and back to the 6 Figure 10: Towline force on ship’s fittings ship’s bitts at an angle of near 180 degrees and there is another multiple factor of x2, hence the 217 tonnes now becomes a 434 tonne force on to the ship’s fittings! While we are giving a worst case scenario here to make the point, it is fair to say that this scenario is theoretically possible, and should the planets ever align in this way then something in the system will fail, whether it be the tug’s winch brake slipping, the towline parting, or (more likely) the ship’s deck fittings being ripped from the deck. If the 85-tonne BP tug is a high performance escort tug (say, a RAstar85) with a keel/skeg that creates hydrodynamic lift, it can produce up to x2 its rated bollard pull: 170 tonnes BP. Needless to say, this is not the real cost. Generally, tugs only operate at maximum power due to the ship being in a situation that demands it. When there is an equipment failure, there is little to no time for the pilot to save the ship from being involved in a serious incident, due to not having the tug generating the required forces. Hence, in broad terms: • 85 tonnes BP x 2 = 170 tonne towline force, created due to indirect type towage assist • 170 tonnes x 2.92 = 496 tonnes into the towline due to a towline angle up to the ship of 70 degrees • 496 tonnes x 2 = 992 tonnes on to the fairlead, due to the towline angle around the fairlead being ≈180 degrees Active escort operations While the issue of ships’ deck fittings being adequate for general harbour towage is serious and indeed real, the issue goes to another level when it comes to active escort towage operations. Modern high performance (Note that the actual steering created by the tug on to the ship is still only 170 tonnes.) 7 Table 9: Force created by rudder angles Basically, the rudder design is best described as an aeroplane wing that, instead of being horizontal in the air, is vertical in the water. As with a plane accelerating down the runway, the faster the ship goes, the more lift (or steering force) the rudder creates. This is required because the faster the ship goes the more steering force is required to control and steer it. These forces are further exaggerated by environmental influences such as narrow waterways and low underkeel clearances. escort tugs are sophisticated designs with rated bollard pulls commonly of 80-100 tonnes. They are able to generate huge towline forces via their specially designed keels or skegs. There are good reasons to require escort tugs to be able to produce these high tonnages. For example: • • • When a ship of, say, 100,000dwt is steaming ahead at 8 knots, its rudder can produce steering forces in the order of ≈70 tonnes steering force. Increase the same ship’s speed to 10 knots, and its rudder can produce ≈100 tonnes steering force. Now consider a CapeSize or VLCC-type ship of 200,000dwt. At 8 knots, its rudder produces ≈100 tonnes steering force, and at 10 knots this increases to ≈150 tonnes (see Table 9). Modern high performance escort tugs (ASD, ATD and VSP designs) have either keels or skegs of a similar design to the ship’s rudder, so also create hydrodynamic lift. Consequently, the faster the ship steams ahead, the greater towline forces the escort tug can create. This is needed in order to overpower the ship’s steering forces in the event of a rudder failure (Figure 11). When a ship is in a narrow waterway such as a shipping channel, and/or there is low under keel The reason for this is that a ship’s rudder is designed to create hydrodynamic lift. What does this mean? Figure 11: Hydrodynamic lift rudders 8 Given that a ship of ≈200,000dwt can produce >100 tonnes steering force via its rudder, it can be seen there is an immediate issue, given the escort tug must produce considerably more counter force via its towline running through the ship’s fairleads to its bitts (see Figure 12). clearance, the towline forces required from the tug increase quite dramatically. Furthermore, in the event of a failure of the ship’s rudder these forces from the tug must be applied very quickly to avoid the ship sheering off course. In this type of scenario we are talking about a counter steering force from the escort tug being applied within ≈30 seconds. With modern tug designs, high performance synthetic towlines and elite training of the tug’s crew, this is now all possible. But the Achilles Heel we have only recently come to understand fully is the ship’s deck fittings. Reality check The reality, when holistically reviewing this topic, is that most of these types of ships when transiting a narrow waterway cannot in the event of a rudder failure likely be saved by their escort tugs, given the steering forces required being accentuated by the physics of towline angles, regardless of the question marks over the quality of the ship’s deck fittings and underpinning support structure. Inadequency of ship’s deck fittings Earlier in this paper we alluded to there being potential issues with ship’s deck fittings on ships older than 2007, due to them not necessarily being covered by class rules, and ships older than 2012 due to the underpinning deck structure not necessarily being covered by class. What to do? Having gained an understanding of the issues, SeaWays has been involved in extensive live escort trials with one of its clients, their port authority and the port’s pilot service. The results of the first stage of these trials supported the findings of our research. In addition to this, in many cases the actual SWL rating of ship’s deck fittings utilised in towage operations has proven to be of serious concern. As an example, our research into CapeSize bulkers has shown more than half of these ships have deck fittings that are required to be used in escort towage of 50-80 tonnes SWL. This is assuming that their SWL ratings are actuals, taking into account the points we have raised within this paper. Of course, the next question is: what to do? The whole point of investing in high performance escort tugs, as well as an extensive training programme for pilots and tug masters, is to to ensure the operational Figure 12: Rudder forces on a CapeSize or VLCC-type ship 9 Figure 13: Dual escort towage integrity of the shipping channel. A channel blockage due to a ship running aground in the port where we conducted our trials would cause an estimated cost running into billions of dollars, due to lost trade over the likely period before the channel could be cleared. each tug could easily produce, say, 80 tonnes towline force (80 tonnes x 2 = 160 tonnes required steering force) spread over two sets of ship’s fittings. Dual escort towage also allows the pilots to have numerous initial response scenarios and ongoing control over the ship, as well as redundancy in the case of mechanical failure of a tug or its towline (Figure 13). Interim fix – dual towage (T2) The second stage of our trials involved undertaking dual escort towage operations. This concept, also known as T2, was originally developed by Capt Greg Brooks from Towage Solutions. It involves using two escort tugs connected either side of a ship’s transom. Naturally, this type of activity comes at a significant cost, though when considering the cost of a channel blockage it can be argued that it is a small investment. Note that it is important to understand that while there can be towline forces in the hundreds of tonnes, this is not related to the actual steering force the tug is creating on to the ship. The actual steering force is the same as the force the tug is generating into the water (its bollard pull), not into its towline. There are other towage techniques that can also be utilised, depending of the circumstance and attending tug, but this is beyond the scope of this presentation, and will have to wait for when we have another opportunity to present to industry. Using dual escort towage in this manner can have the benefit of doubling the overall steering forces the tugs can create, but this was not our motivation. Instead, we wanted to be able to generate the required steering forces without the risk of the ship’s deck fittings failing. Hence, while (in this case) one of the Robert Allan Ltd RAstar85 escort tugs we were using in our trials could produce upwards of 160 tonnes towline force, using two of these tugs in a dual escort configuration meant that 10 Long-term fix Pragmatic information guide The client involved in our escort and dual escort trials has placed its charterers on notice that they have two years to ensure their ships have adequately rated fairleads and bitts, so that in an emergency the escort tug can produce the required towline steering force to overpower the ship’s rudder lock. The diagram (see Figure 14, overleaf) is a free gift to the industry from SeaWays. It has been produced in an A3 landscape format ready for printing, and can be obtained either here at the ITS 2018 conference from our SeaWays desk in the exhibition hall or by going to our websites www.seaways.net.au or www. seawaysglobal.com and downloading it. In our opinion, now that the research group has undertaken this work, there is an onus, indeed a responsibility, on ship owners, designers and classification societies to ensure that all newbuilds have deck fittings, particularly in the bow and stern of ships, that are of a rating to be able to sustain the forces an escort tug has to generate in order to save the ship in a rudder steering failure-type emergency. These deck fitting ratings must also acknowledge the physical forces in play due to towline angles. To assist industry, particularly tug masters and pilots, SeaWays has developed a diagram that provides insight into the issues identified in this paper and some practical ‘rule of thumb’ operational guidelines. The challenge was to condense a significant amount of research material into a one-page diagram that can be understood by mariners whose first language is not necessarily English. Hopefully we have had some success with this. 11 Figure 14: Operational guidelines 12