Structural design of timber to BS 5268 –2:1996

The structural design of timber elements is based on permissible stresses and deflections

derived from elastic theory.

Flexural members – members subject to bending

Members subject to bending (i.e. beams) are assumed to behave in accordance with elastic

bending theory provided that the permissible material stresses are not exceeded. The bending

expression can be applied to timber design:

M/I =f/y =E/R

At any point across a section of a beam which is loca ted a distance y from the neutral axis of a

section, a stress f will be developed as a consequence of applying a bending moment M to the

section. The magnitude of the stress developed will vary with the second moment of area of

the section I.

In the timber design code, is the designation for stress, hence the above equation may be

written as:

M/I = /y

In timber design generally rectangular sections are used, therefore the maximum compressive

and tensile bending stress will occur at the extreme fibres. Thus y is equal to half the depth of

the section.

As both I and y are geometric properties of the section it is convenient to combine the two

terms in a single property which is referred to as the elastic modulus and denoted by the

symbol Z.

Z = I/y

Further, as rectangular sections are being considered, if b is the width of the section and h the

depth then I and y may be expressed as:

I = bh 3 /12 and y =h/2

Hence elastic modulus, Z = (bh 3 /12)/(h/2) = bh 2 /6

Considering, from the bending expression, M/I = /y and combining with the definition of

elastic modulus then:

M = Z

This can be rearranged to determine the maximum bending stress in the beam and then

compared with the permissible stress that the beam may carry.

Other design requirements

The other checks required to timber beams are shear, bearing, deflection and the maximum

depth to breadth ratio.

As the beams are simply supported, and generally carry uniformly distributed loads, shear will

be a maximum at the supports.

Maximum shear stress = –

3

Load

2

Cross-sectional area

The end bearing area is dependent on the contact area with the beam support.

Maximum bearing stress =

Load

Load

=

Contact area

width of beam bearing length

Both of these values can then be compared with the permissible values obtained from the

design code.

Deflection, as with other structural materials, is a serviceability requirement. Maximum

deflections are determined using the standard deflection formulae and compared with the

deflection limits given in the design code.

Timber as a structural material

Unlike other construction materials, timber cannot be mixed to a pre -determined formula. The

cut wood has to be inspected and graded by visual or mechanical means. The design code

allows for a number of strength classes based on the inspection of the timber, or alternatively,

if the species of timber is known it may be classified as given in Table 8 of the code according

to its standard name.

Appropriate grade stresses are assigned to the graded timber. For flexure the appropriate grade

stresses are:

•

•

•

Bending parallel to the grain

Compression perpendicular to the grain

Shear parallel to the grain

Account must also be taken of the loading and exposure conditions that the timber will be

subject to. The design code lists almost thirty factors that can be applied to the grade stresses.

Only a few will be of concern in this course.

Modification factors

Moisture content of timber related to service class.

It is difficult to artificially dry solid timber more than 100 mm thick, unless it is specially

dried. BS 5268 recognises three services classes that are related to the conditions of end use.

Service classes 1 and 2 generally require the timber to be art ificially dried and the dimensions

and properties of the dried timber can be taken as the grade values. Service class 3 timber is

used when the finished structure is fully exposed or if the timber is more than 100 mm thick. In

this case the grade values must be modified by a factor K 2 found in Table 13 which allows for

the differing load carrying mechanisms of wet and dry timber.

Service

class

Examples of end use of

timber

3

2

2

1

External & fully exposed

Covered and unheated

Covered and heated

Internal use and

continuously heated

Average

moisture

content

> 20 %

18 %

15 %

18%

12%

Moisture content in

each piece at time

each piece at time

24 %

20 %

24%

20%

Service classes 1 and 2 use unmodified stresses and moduli.

Service class 3 timber uses modified stresses and moduli.

i.e. K 2 =1

i.e. K 2 <1

Duration of loading K 3

The grade stresses based on the strength classes of the timber apply to long -term loading on the

structural element. Table 14 gives a modification factor for various load durations and l ist

values of K 3 varying from 1.0 to 1.75. K 3 is applied to the grade stresses only and does not

apply to the modulus of elasticity.

Load-sharing systems K 8

A load-sharing system may be considered as being, for example, a series of four or more floor

joists connected by flooring in such a way that act together – a standard timber floor. Provided

that the joists are no farther apart than 610 mm centres then the grade stresses should be

modified by the modification factor K 8 =1.1.

For all other systems K 8 may be taken as being equal to 1.0.

For load-sharing systems the mean modulus of elasticity should be used to calculate any

deflections except in circumstances where dynamic loads may occur, e.g. gymnasia, where the

minimum value should be used.

Depth factor K 7

The grade stresses based on the strength classes of the timber apply to materials having a depth

(h) of 300 mm. A modification factor K 7 is applied to the grade bending stress of beams

having a depth other than 300 mm.

For solid timber beams:

Depth of beam (h) mm

72 mm or less

72 > h < 300

h > 300

K 7 value

1.17

(300/h) 0.11

0.81(h 2 + 92300)

(h 2 + 56200)

Notching of beams K 5

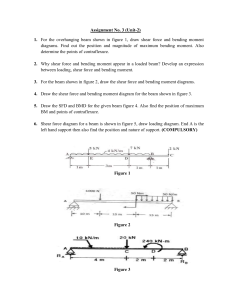

Figure 2

Notching the end of a beam for construction purposes causes stress concentrations that must be

allowed for in the shear calculation. The shear stress should be calculated by using the

effective depth (h e ) shown in Figure 2. The grade shear stress should be multiplied by a

modification factor K 5 to obtain the permissible stress.

For beams notched on the underside K 5 = h e /h

Note: Beams with notches on the top edge are not considered in this unit.

Deflection

The deflection is acceptable if the deflection of the fully loaded beam does not exceed 0.003

times the span of the member or 14mm whichever is the lesser.

Timber flexural members design examples

Boarding

Check the suitability of 20mm tongued and grooved floor boarding spanning between 50mm

250mm timber joists at 600mm centres. The boards are of strength class C14.

Note that boarding is normally provided in lengths up to 3m long. Each board spans over a

number of joists and for analysis purposes may be treated as a continuous beam.

The maximum moment occurs at an internal support and may be found using M = wL 2 /10. The

maximum shear force (reaction) occurs at the outside support and may be taken as V= 0.4wL.

Additional data:

Dead load inclusive of self-weight of boards

Imposed load

0.15 kN/m 2

1.5 kN/m 2

Solution

Consider a width of boarding (b) = 1m

b=1000 mm

(Actual width of floor is immaterial if width of one metre is assumed)

Length between supports

L = 600mm = 0.6m

Load on boarding

w =dead + imposed = 0.15 + 1.5 = 1.65 kN/m 2

Considering a typical 1m width of board b=1.65 1 = 1.65 kN/m

Bending

Maximum moment M = wL 2 /10 = 1.65 0.6 2 /10 = 0.06 kNm

Elastic modulus of board Z = bh 2 /6 = 1000 20 2 /6 = 66667 mm 3

Actual bending stress, s = M/Z = 0.06 10 6 /66667 = 0.9 N/mm 2

Permissible stress =

grade bending stress parallel to the grain K 2 K 3 K 7 K 8

Grade stress from Table 7 – C14 = 4.1 N/mm 2

K 2 – wet stresses modification factor – material 20 mm

thick – service class 1

K 3 – duration of loading – on floor this may be taken

as long term

K 7 – depth factor – less than 72 mm

K 8 – load-sharing – boards are load-sharing

K2 = 1

K3 = 1

K 7 = 1.17

K 8 = 1.1

Permissible stress = 4.1 1.0 1.0 1.17 1.1

= 5.28 N/mm 2 > 0.9 N/mm 2 boards suitable in bending

Shear

Maximum shear force V = 0.4wL = 0.4 1.65 0.6 = 0.4 kN

Maximum shear stress v =

3V

3 0.4 103

=

= 0.03 N/mm 2

2bh

2 1000 20

Permissible stress =

grade shear stress parallel to the grain K 2 K 3 K 8

Grade stress from Table 7 – C14 = 0.6 N/mm 2

The modification factors used for bending are still applicable – except K 7 that is applied to

bending only.

Permissible stress = 0.6 1.0 1.0 1.1

= 0.66 N/mm 2 > 0.03 N/mm 2 boards suitable in shear

Deflection

Considering the beam as continuous, = wL 4 /384EI

E mean from Table 7 – C14 (one board cannot act on its own) E = 6800 N/mm 2

I =bh 3 /12 = 1000 20 3 /12 = 666667 mm 4

= wL 4 /384EI = 1.65 600 4 /(384 6800 666667) = 0.13 mm

Permissible deflection (clause 2.10.7) = 0.003 span = 0.003 600 = 1.8 mm

Actual deflection less than permissible – beam is suitable.

Floor joists

The floor joists for the boarding example above also require to be checked. It may be assumed

that the joists are simply supported over a span of 3.6 m and bear on to blockwork supports

100 mm wide. The revised dead load to include for the self -weight of the beam may be taken

as 0.34 kN/m 2 . The joists are strength class C16.

Solution

Centres of joists

Load/joist

600mm = 0.6m

w = (dead + imposed) centres

= (0.34 + 1.5) 0.6 = 1.1 kN/m

Bending

For a simply supported beam

Maximum moment M = wL 2 /8 = 1.1 3.6 2 /8 = 1.78 kNm

Elastic modulus of board Z = bh 2 /6 = 50 250 2 /6 = 520833 mm 3

Actual bending stress, = M/Z = 1.78 10 6 /520833 = 3.42 N/mm 2

Permissible stress = grade bending stress parallel to the grain K 2 K 3 K 7 K 8

Grade stress from Table 7 – C16 = 5.3 N/mm 2

K 2 – wet stresses modification factor – material 20 mm

thick – service class 1

K 3 – duration of loading – on domestic floor this may be

taken as long term

K 7 – depth factor (clause 2.10.5)

K 7 = (300/h) 0.11 = 300/250) 0.1 = 1.02

K 8 – load-sharing – boards are load-sharing

K 2 =1

K 3 =1

K 7 =1.02

K 8 =1.1

The assumption is that the floor boards are of sufficient length to distribute the load over at

least four joists.

Permissible bending stress

= 5.3 1.0 1.0 1.02 1.1

= 5.95 N/mm 2 < 3.42 N/mm 2

Beam satisfactory in bending.

Shear

Maximum shear force V = wL/2 = 1.1 3.6/2 = 1.98 kN

3V

3 1.98 103

Maximum shear stress v =

=

= 0.24 N/mm 2

2bh

2 50 250

Permissible stress = grade shear stress parallel to the grain K 2 K 3 K 8

Grade stress from Table 7 – C16 = 0.67 N/mm 2

The modification factors used for bending are still applicable

(K 7 is only applicable to bending)

Permissible stress = 0.67 1.0 1.0 1.1

= 0.74 N/mm 2 > 0.24 N/mm 2

joist suitable in shear

Bearing

Value of reaction = wL/2 = 1.1 3.6/2 = 1.98 kN

Joist bears on to a 100mm wide support and width of joist is 50mm

Reaction

1.98 103

Actual bearing stress =

=

= 0.39 N/mm2

Bearing length width

100 50

Permissible stress = compression perpendicular to the grain K 2 K 3 K 8

Grade stress from Table 7 – compression perpendicular to the grain – 2.2 N/mm 2

Two values of compression perpendicular to the grain are given in Table 7. Which value

should be used? Reference should be made to Note 1 of the table.

The modification factors used for shear are still applicable

Permissible stress = 2.2 1.0 1.0 1.1

= 2.42 N/mm 2 > 0.39 N/mm 2 bearing length is suitable

Deflection

As the beam is simply supported, = 5wL 4 /384EI

E mean from Table 7 – C14 (one board cannot act on its own) E = 8800 N/mm 2

I =bh 3 /12 = 50 250 3 /12 = 65.1 10 6 mm4

= 5wL 4 /384EI = 5 1.1 3600 4 /(384 8800 65.1 10 6 ) = 4.2 mm

Permissible deflection (clause 2.10.7) = 0.003 span £ 14 mm = 0.003 3600 = 10.8 mm

Actual deflection less than permissible – beam suitable.

Notches

If the beam is notched at the support, then the shear cross -sectional area is reduced and the

modification factor K 5 applies (see clause 2.10.4).

Consider the above beam with a 75mm notch on the underside.

Dimension h e = h – 75 = 250 –75 = 175 mm

Maximum shear stress v =

K5 = he/h = 175/250 = 0.7

3V

3 1.98 103

=

= 0.34 N/mm 2

2bh

2 50 174

Permissible stress = grade shear stress parallel to the grain K 2 K 3 K 8 K 5

Permissible stress = 0.67 1.0 1.0 1.1 0.7

= 0.52 N/mm 2 > 0.34 N/mm 2

Joist is still suitable in shear.

Timber compression members

As with all structural materials, the design of compression members is dependent on the

slenderness ratio.

Where the slenderness ratio, = L e /i

L e = effective length is found using Table 18, which lists for conditions of end restraint, the

ratio of L e /L, where L is the actual length.

Values given for L e are 0.7L, 0.85L, 1.0L, 1.5L and 2 L.

i is the radius of gyration of the section. As only solid rectangular sections will be dealt with,

there are two possible axes of buckling, x–x and the y–y. Hence there are two values of

slenderness ratio:

x = L ex /i x

The radius of gyration i x = I x /A

y = L ey /i y

i y = I y /A

Where I (for a rectangular section) = bh 3 /12 I x =bh 3 /12 and I y =hb 3 /12

Area A = bh

considering x–x axis

considering y–y axis

The critical slenderness ratio is the larger of the two

In no case should the slenderness ratio exceed 180 (see clause 2.11.4)

The permissible stress is based on the comments of clause 2.11.5 which gives two design

procedures:

1.

2.

Compression members with slenderness ratios less than 5 (short columns)

Compression members with slenderness ratios greater than 5 (slender columns)

In both cases the permissible stress is taken as the grade compression stress parallel to the

grain multiplied by the modification factors for moisture content, duration of loading and load

sharing.

Permissible stress = grade stress parallel to the grain K 2 K 3 K 8

In addition for members with a slenderness greater than 5, the above formula is multiplied by

K 12 given in Table 19.

Factor K 12 varies with slenderness ratio as calculated above and with

E/ c ,

where E = minimum modulus of elasticity of the material, and

c ,= compression parallel to the grain.

Example

Single column

A timber column 200mm 200mm is required to carry a load of 210 kN. The load has been

transferred to the column by timber joists such that the end restraint conditions top and bottom

may be taken as restrained in position but not in direction. The height of column is 2.8 m and

the timber may be taken as strength class C27. The load may be considered as short term.

Solution

As timber is greater than 100mm thick it would be difficult to dry the section, so use wet

stresses. Values found in Table 7 are modified by factor K 2 found in Table 13

From Table 7

c ,= compression parallel to the grain = 8.2 N/mm 2

E min = 8200 N/mm 2

L e =1.0L = 2800 mm

K 2 = 0.6

K 2 = 0.8

I = bh 3 /12 = 200 200 3 /12 = 1.333 10 8 mm4

A = bh = 200 ´ 200 = 40000 mm 2

i= I/A = 57.7 mm

l = L e /i = 2800/57.7 = 48.5 (for both axes) < 180 suitable

Ratio E/c ,= (8200 0.8)/(8.2 0.6) = 1333.3 {modified by factor K 2 }

From Table 19:

1300

1400

40

0.809

0.811

50

0.757

0.760

Modification factor K 12 for = 48.5 and E/c ,=1333.3

K 12 = 0.767

Alternatively for Table 19 an equivalent slenderness L e /b may be used for rectangular sections,

in this example 2800/200 = 14

From Table 19:

1300

1400

as before.

11.6

0.809

0.811

14.5

0.757

0.760

K 3 for short term loading = 1.5

K 8 for non load-sharing member = 1.0

Permissible stress = grade stress parallel to the grain K 2 K 3 K 8 K 12

= 8.2 0.6 1.5 1 0.767

= 5.66 N/mm 2

Actual compressive stress = Load/Area = 210 10 3 /40000 = 5.25 N/mm 2

As this is less than 5.66 N/mm 2 the column is suitable.

Example

Column forming part of a partition wall

A timber column of 72mm 168mm cross-section supports a medium term axial load of 24 kN.

The column forms part of a partition wall that is 3.9 m high and the columns are arranged such

that there is no load sharing. The column i s restrained in position only top and bottom and is

provided with restraining side rails at the third points about the weaker axis. Check the

suitability of strength class C22 to carry the load.

Solution

As there are two differing effective lengths and h ence two different slenderness ratios, the

critical axis must be identified

L e = 3.9m

L e =1.3m

72 168

12

3

I = bh 3 /12

i= I/A

l = L e /I

Ix =

Iy =

168 723

12

28.45 10 6 mm 4

5.23 10 6 mm 4

28.45 10 6 /(168 72)

5.23 10 6 /(168 72)

48.5 mm

20.8 mm

3900

= 80.4

48.5

1300

= 62.5

20.8

Critical axis for buckling is the x–x axis

Section is less than 100mm thick so service class 1 or 2 applies (K 2 = 1.0)

From Table 7

c ,= compression parallel to the grain = 7.5 N/mm 2

E min = 6500 N/mm 2

Ratio E/c ,= 6500/7.5 = 867

From Table 19 for the ratio value of 867 and l = 80.4

K 12 = 0.51

K 3 for medium term loading = 1.25

K 8 for non-load sharing member = 1.0

Permissible stress = grade stress parallel to the grain K 2 K 3 K 8 K 12

= 7.5 1.0 1.25 1 0.51

= 4.78 N/mm 2

Actual compressive stress

= Load/Area = 24 10 3 /(72 168)

= 1.98 N/mm 2

As this is less than 4.78 N/mm 2 the column is suitable.