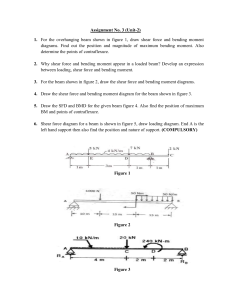

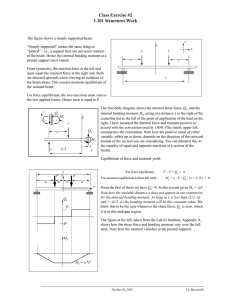

ENGG1400 Statics Prac S2 2020 Introduction This guide describes how to set up and perform experimental tests to obtain the bending moments and shear forces in beams. It clearly demonstrates the principals involved and gives practical support to your studies on internal shear forces and bending moments in beams. Part 1: Bending Moments in a Beam In Part 1 of the experiment, we shall focus our attention in determining the bending moments in beams. Figure 1 shows the set up for this part of the experiment. It consists of a beam, which is ‘cut’ by a pivot. In order to stop the beam from collapsing, a moment arm bridges the cut onto a load cell; the measured force is then converted to the bending moment by multiplying the force A diagram on the left-hand support of the beam shows the beam geometry and hanger positions. Hanger supports are 20mm apart, and have a centre slot, which positions the hangers. The moment arm is 125mm long. with the lever arm. A digital display shows the force from the load cell. Figure 1: Experimental set up for determining bending moment in beam 1 ENGG1400 Statics Prac S2 2020 How to set up the equipment The beam bending experiment fits into a test frame as shown in Figure 2. Never apply excessive loads to any part of the equipment. Figure 2: Beam bending experiment in a structural frame Steps l to 4 of the following instructions have already have been completed for you. 1. Place assembled Test Frame (refer to the separate instructions supplied with the Test Frame if necessary) on a workbench. Make sure the ‘window’ of the Test Frame is easily accessible. 2. There are four securing nuts in the top member of the frame. Slide them to approximately the positions shown in Figure 3. 3. With the right-hand and of the experiment resting on the bottom member of the Test Frame, fit the left-hand support to the top member of the frame. Push the support on the frame to squarely. Tighten the support in position by screwing two of the thumbscrews provided into the securing nuts (on the front of the support only). 4. Lift the right-hand support into position and locate the two remaining thumbscrews into the securing nuts. Push the support on to the frame to ensure the internal bars are sitting on the frame squarely. Position the support horizontally to the rolling pivot is in the middle of its travel. Tighten the thumbscrews. 5. Make sure the digital force display is ‘on’. Connect the mini DIN lead from ‘Force Input 1’ on the Digital Force Display to the socket marked ‘Force Output’ on the left-hand support of the experiment. Ensure the lead does not touch the beam. 2 ENGG1400 Statics Prac S2 2020 6. Carefully zero the force meter using the dial on the left-hand beam of the experiment. Gently apply a small load with a finger to the centre of the beam and release. Zero the meter again if necessary. Repeat to ensure the meter returns to zero. Note: if the meter is only ±0.1N, lightly tap the frame (there may be a little suction and this should overcome it). Experiments Experiment 1: Bending Moment Variation at the Point of Loading This experiment examines how bending moment varies at the point of loading. Figure 3 shows the free body diagram of the beam with the load W and the reaction forces RA and RB. From statics consideration, RA= W(l-a)/l and RB=Wa/l. 300mm 440mm Figure 3: Free body diagram of beam The bending moment (BM) at the cut is given by BM (at cut) = 𝑊𝑎 (𝑙 − 𝑎) 𝑙 You may find Table 1 useful in converting the masses used in the experiments to loads. Table 1 Grams to Newtons conversion table Mass (Grams) Load (Newtons) 100 0.98 200 1.96 300 2.94 400 3.92 500 4.90 (a) Check that the Digital Force Display meter reads zero with no load. (b) Place a hanger with a 100 gm mass at the ‘cut’. Record the digital force display reading in a table as in Table 1. Repeat using masses of 200 gm, 300 gm, 400 gm and 500 gm. (c) Convert the mass into a load (in N) and the force reading into a bending moment (Nm). Remember: Bending moment at the cut (in Nm) = displayed force × 0.125 (d) Calculate the theoretical bending moment at the cut and complete Table 2. (e) Calculate the percentage error 3 ENGG1400 Statics Prac S2 2020 Table 2 Results for Experiment 1 Mass (gm) Load (N) Displayed Force (N) Experimental bending moment (Nm) Theoretical bending moment (Nm) Percentage difference between experimental and theoretical bending moments 0 0 0 0 0.000 0% 100 0.98 0.8 0.1 0.094 6.45% 200 1.96 1.6 0.2 0.187 6.45% 300 2.94 2.3 0.2875 0.281 2.39% 400 3.92 3.1 0.3875 0.374 3.44% 500 4.90 3.8 0.475 0.468 1.53% What does it tell us about how bending moment varies at the point of loading? The bending moment is directly proportional to the load applied (theoretically, newton of applied in this case). 21 220 increase per Does the equation we used accurately predict the behaviour of the beam? The equation somewhat accurately predict the behaviours of beams (greatest deviation being of 6.45%). Graph next page 4 ENGG1400 Statics Prac S2 2020 Plot a graph which compares your experimental results to those you calculated by using the theory. Comment on the shape of the graph. Load vs Bending Moment 6 5 Load (N) 4 Experimental 3 Theoretical 2 Linear (Experimental ) Linear (Theoretical) 1 0 0 0.1 0.2 0.3 0.4 0.5 Bending Moment (Nm) Comment: The Load applied increases linearly with the bending moment. The trendline shows this linearity. 5 ENGG1400 Statics Prac S2 2020 Experiment 2:Bending Moment Variation away from the Point of Loading This experiment examines how bending moment varies at the cut position of the beam for various loading conditions. Figures 4, 5 and 6 show the free body diagrams for various loading positions considered. Figure 4: Free body diagram of beam with load at 140 mm to the left of support A Figure 5: Free body diagram of beam with two loads W1 and W2 at 220mm and 260mm to the right of support A 6 ENGG1400 Statics Prac S2 2020 Figure 6: Free body diagram of beam with two loads W1 and W2 at 240mm and 400mm to the right of support A “The Bending Moment at the ‘cut’ is equal to the algebraic sum of the moments caused by the forces acting to the left or right of the cut.” (a) Check the Digital Force Display meter reads zero with no load. (b) Carefully load the beam with the hangers in the positions shown in Figure 4, using the loads indicated in Table 3. Record the Digital Force Display reading in a table as in Table 2. (c) Convert the force reading into a bending moment (in Nm). Remember: Bending moment at the cut (in Nm) = displayed force × 0.125 (d) Calculate the support reactions (𝑅𝐴 and 𝑅𝐵 ) and calculate the theoretical bending moment at the cut. (e) Repeat the procedure with the beam loaded as in Figure 5 and Figure 6. (f) Comment on how the results of the experiments compare with those calculated using the theory. 7 ENGG1400 Statics Prac S2 2020 Table 3 Results for Experiment 2 -1.5 Experimental bending moment (Nm) -0.1875 3.92 3.7 3.92 4.0 𝑊1 𝑊2 (N) (N) Displayed Force (N) 4 3.92 0 5 1.96 6 4.91 Figure 𝑅𝐴 𝑅𝐵 (N) (N) 5.167 -1.247 Theoretical bending moment (Nm) -0.175 0.4625 2.584 3.296 0.462 0.5 2.588 6.242 0.482 The experimental results closely resemble those found by the theory. 8 ENGG1400 Statics Prac S2 2020 Part 2: Shear Forces in a Beam In Part 2 of the experiment, we will look at determining the shear forces in beams. Figure 7 shows the set up for this part of the experiment. It consists of a beam which is ‘cut’. To stop the beam collapsing a mechanism, (which allows movement in the shear direction only) bridges the cut on to a load cell thus activating (and measuring) the shear force. A digital display shows the force from the load cell. A diagram on the left-hand support of the beam shows the beam geometry and hanger positions. Hanger supports are 20 mm apart, and have a central groove which positions the hangers. Figure 8 shows the experimental set up assembled in the Frame. Figure 7: Experimental set up for determining shear forces in beam . 9 ENGG1400 Statics Prac S2 2020 Figure 8: Shear force of a beam experiment in the structures frame Experiment 3: Shear force Variation at the Point of Loading This experiment examines how the shear force varies at the point of loading. Figure 9 shows the free body diagram for the beam with the applied load W. 260m m Figure 9: Free body diagram The following equation will be used in this experiment Shear force at cut, 𝑆𝑐 = 𝑊𝑎 𝑙 where 𝑎 is the distance to the load (not the cut), 𝑎 = 260 mm 10 ENGG1400 Statics Prac S2 2020 (a) Check the digital force display meter reads zero with no load. (b) Place a hanger with a 100 gm mass to the left of the ‘cut’ (40mm away). Record the Digital Force Display reading in a table as in Table 2. Repeat using masses of 200 gm, 300 gm, 400 gm and 500 gm. Convert the mass into a load (in N) Remember: Shear force at the cut = Displayed force (c) Calculate the theoretical shear force at the cut and complete Table 4. Table 4 Results for Experiment 3 Theoretical shear force (N) Percentage difference between experimental and theoretical shear force Mass (gm) Load (N) Experimental shear force (N) 0 0 0 0.000 0% 100 0.98 0.6 0.579 3.485% 200 1.96 1.1 1.158 5.289% 300 2.94 1.8 1.737 3.485% 400 3.92 2.3 2.316 0.711% 500 4.90 2.7 2.895 7.239% What does it tell us about how shear force varies due to an increased load? The shear force increases proportionally to the load applied (in this case 13 𝑊) 22 Does the equation we used accurately predict the behaviour of the beam? Yes, although a little divergence at a greater load could be seen in the Plot. Greatest deviation is 5.389%. 11 ENGG1400 Statics Prac S2 2020 Plot a graph which compares your experimental results to those you calculated using the theory. Comment on the shape of the graph. Load vs Shear Force 6 5 Load (N) 4 Experimental 3 Theoretical Linear (Experimental) 2 Linear (Theoretical) 1 0 0 0.5 1 1.5 2 2.5 3 3.5 Shear Force (N) Comment: A linear trend between the Load and Shear Force can be seen. As the load was increased, so did the shear force. 12 ENGG1400 Statics Prac S2 2020 Experiment 4: Shear Force Variation for Various Loading Conditions This experiment examines how shear force varies at the cut position of the beam for various loading conditions. Figure 10, Figure 11 and Figure 12 show the positions of the various loading positions considered. Figure 10: Loading W1 on the beam at 140mm to the left of support A Figure 11: Loadings W1 and W2 on the beam at 220mm and 260mm to the right of support A 13 ENGG1400 Statics Prac S2 2020 Figure 12: Loadings W1 and W2 on the beam at 240mm and 400mm to the right of support A “The Shear force at the ‘cut’ is equal to the algebraic sum of the forces acting to the left or right of the cut.” (a) Check the Digital Force Display meter reads zero with no load. (b) Carefully load the beam with the hangers in the positions shown in Figure 10, using the loads indicated in Table 5. Record the Digital Force Display reading in a table as in Table 2. (c) Record the Digital Force Display reading as in Table 3. Remember, Shear force at the cut (N) = Displayed force (d) Calculate the support reactions (𝑅𝐴 and 𝑅𝐵 ) and calculate the theoretical shear force at the cut. (e) Repeat the procedure with the beam loaded as in Figure 11 and Figure 12. 14 ENGG1400 Statics Prac S2 2020 Table 5 Result for Experiment 4 Figure 𝑊1 (N) 𝑊2 (N) Experimental shear force (N) 𝑅𝐴 (N) 𝑅𝐵 (N) Theoretical shear force (N) 4 3.92 0.0 -1.3 5.167 -1.247 1.247 5 1.96 3.92 3.2 2.584 3.296 -3.296 6 4.91 3.92 2.3 2.588 6.242 -2.322 Comment on how the results of the experiments compare with those calculated using the theory. The results gave the opposite signs. The magnitudes were very similar. This could be due to a different sign convention being used. Theoretical calculations on following pages 15