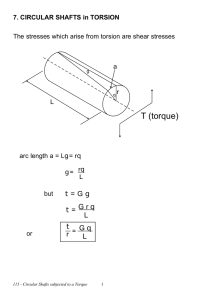

Seminar on TORSION OF PRISMATIC BARS Submitted by Mr. Birendra H Singh (Roll No. 192090022) Program: M.TECH (Mechanical Engineering) 2019-20 Under the guidance of Dr. S. G. JADHAV Department of Mechanical Engineering VEERMATA JIJABAI TECHNOLOGICAL INSTITUTE (Autonomous Institute Affiliated to University of Mumbai) MUMBAI-400019 i CERTIFICATE This is to certify that, Mr.Birendra H Singh, M.TECH. student has completed First Annual Progress Seminar report entitled "TORSION OF PRISMATIC BARS " is found to be satisfactory. Date: Dr. S. G. JADHAV (Supervisor) ii APPROVAL SHEET Seminar on “TORSION OF PRISMATIC BARS” submitted by Mr.Birendra H Singh (Roll No. 192090022) is approved as a partial fulfillment of the Dr. …………………… Dr. S. A. Mastud (Supervisor) (Head, Mech. Engg. Dept.) Date: Place: VJTI, Mumbai iii ABSTRACT Analysis of properties, states and behavior of technical objects is an important task of Engineering Mechanics. Strain-stress analysis of solid bodies ranks to these problems.Continuum mechanics and especially elasticity theory provides tools for this analysis.The strain-stress analysis passed through its development, analytic approaches predominating in the past are at present replaced by numerical tools as Finite Element Method,Finite Volume Method, Boundary Element Method etc. In comparison to the classical methodsthe numerical methods are universal in sense that their applicability is independent of geometry of the body, material characteristics, etc. This may indicate that the period of analytical elasticity ended. But it is not the case. There are reasons to keep on using both the analytical methods and the numerical methods in the strain-stress analysis. Torsion of the elastic bars is studied in several textbooks, see e.g. [3], [4], [2], [8], but the results are mostly introduced without proofs or circular cross-section only is considered, e.g. in monograph [1]. In this circular case the cross-sections remains planar, but in case of noncircular bar, the real cross-sections are deflected from the planar shape. The equationfor a non-circular bar is derived correctly in [7], but no solutions for particular profiles are introduced. iv TABLE OF CONTENT Sr. No. Content Page No. Abstract Table of content List of figures List of tables 1. Introduction 1 1.1 Assumptions in torsion of prismatic circular bars 1 1.2 torsion of prismatic non-circular bars 2 2. 3 Derivation 2.1 General Solution of any prismatic bar Torsion Problem 3. Numerical problems 11-15 4. Applications/case study 12 4.1 Application 12 4.1.1 Circular members 12 4.1.2 Rectangular members 13 4.1.3 Square members 13 4.1.4 Triangular profile 14 4.1.5 Elliptical profile 15 4.2 Case study 5. 6. 3-10 16-17 Conclusion 18 References 19 v LIST OF FIGURES Page Figure No Description No. 2.1 Deformation of a point ‘P’ due to torsion 2.2 Arbitrary cross section of a prismatic member in torsion. 2.3 Infinitesimal stress element 3.1 A tubular circular bar in torsion 4.1 Shear stress in circular members. Shear stress uniform distributed along circumferential lines. 4.2 St. Venant’s resulting stress zones from rectangular torsion members of b/t = 2, where b is the length of the long side and t is the height 4.3 stress zones from Square torsion members of (b/t = 1) (a) stress function Φ. 4.4 (b) modulus of the shear stress τ , the maximum values of |T| occur in the middle of the sides. (c) deflection of the cross-section (a) stress function Φ. 4.5 (b) modulus of the shear stress τ. (c) deflection of the cross-section 4.2.1 Experimental Setup. Torque versus Angle of Twist for Round and Square Torsion 4.2.2 Specimen vi 1 INTRODUCTION 1.1 • Torsion refers to the twisting of a structural member that is loaded by couples (torque) that produce rotation about the member’s longitudinal axis. • In other words, the member is loaded in such a way that the stress resultant is a couple about the longitudinal axis and the response is a twisting motion about that axis. • Different materials have different ways to respond to the torsion some will crack even break depending upon the type of material. • In many engineering applications, members are required to carry torsional loads. • Torsion of a uniform bar of homogeneous isotropic material means twisting deformation produced by equal and opposite twisting moments applied to the ends of the bar. • In this chapter, consideration is given to stresses and deformations in prismatic members subject to equal and opposite end torques. • In general, these bars are assumed free of end constraint. Usually, members that transmit torque, such as propeller shafts and torque tubes of power equipment, are circular or tubular in cross section. • For circular cylindrical bars, the torsion formulas are readily derived employing the method of mechanics of materials, as illustrated in the next section. • We shall observe that a shaft having a circular cross section is most efficient compared to a shaft having an arbitrary cross section. ASSUMPTIONS IN TORSION OF PRISMATIC CIRCULAR BARS In the development of a torsion formula for a circular bars, the following assumptions are 1. Material of the BARS is homogeneous throughout the length of the BARS. 2. BARS is straight and of uniform circular cross section over its length. 3. Torsion is constant along the length of the BARS. 4. Cross section of the BARS which are plane before torsion remain plane after torsion. 5. Radial lines remain radial during torsion. 1 6. Stresses induced during torsion are within the elastic limit. 2 1.2 TORSION OF PRISMATIC NON-CIRCULAR BARS • Previous torsion formulas are valid for axis-symmetric or circular BARS • Planar cross-sections of noncircular bars do not remain planar and stress and strain distribution do not vary linearly. • For non-circular BAR under torsion, the plane cross-sections perpendicular to the BARS axis do not remain plane after twisting, and deformation takes place in the axial direction which is called warping. • The shear stress is actually zero at the corners for square cross-section bar. • The governing differential equations derived using this method are applicable to both the linear elastic and the fully plastic torsion problems. 3 2 DERIVATION 2.1 General Solution of any prismatic bar Torsion Problem Consider a prismatic bar of constant arbitrary cross section subjected to equal and opposite twisting moments applied at the ends, as in Fig. 1. The origin of x, y, and z in the figure is located at the center of twist of the cross section, about which the cross section rotates during twisting. It is sometimes defined as the point at rest in every cross section of a bar in which one end is fixed and the other twisted by a couple. At this point, u and v, the x and y displacements, are thus zero. The location of the center of twist is a function of the shape of the cross section. The z passes through the centers of twist of all cross sections. Fig. 2.1--Deformation of a point ‘P’ due to torsion [2] Geometry of Deformation • In general, the cross sections warp, as already noted. We now explore the problem of torsion with free warping, applying the Saint-Venant semi-inverse method. • As a fundamental assumption, the warping deformation is taken to be independent of axial location, that is, identical for any cross section: • W=f(x,y) a) It is also assumed that the projection on the xy plane of any warped cross section rotates as a rigid body and that the angle o f twist per unit length of the bar, θ, is constant.We refer now to Fig.1b, 4 which shows the partial end view of the bar (and could represent any section). An arbitrary point on the cross section, point P(x, y), located a distance r from center of twist A, has moved to P′ = (x – u, y + v) as a result of torsion. Assuming that no rotation occurs at end z = 0 and that θ is small, the x and y displacements of P are, respectively, � = −(���) sin � = −��� y=r*sinα; � = (���) cos � = ��� x=r*cosα; b) where the angular displacement of AP at a distance z from the left end is θz; then x, y, and z are the coordinates of point P, and α is the angle between AP and the x axis. Clearly, Eqs. (b) specify the rigid body rotation of any cross section through a small angle θz. x y z w –y x w zx 0 xy x y zy c) Equation (2.36) together with this expression leads to the following: �X = �F = �Z = �XF = 0 d) w G zx zy y x w G x y e) Equations of Equilibrium By now substituting Eq. (d) into the equations of equilibrium , x y x zy y Y z z z y y 0 B y z x X z yx x xz xy x 0 B Z 0 B z 5 assuming negligible body forces, zy zx zx 0 z zx 2 G yz G w xz y w z xz y w u 2 G X 2 0 y x z G v yz 0 x z– y w 2 x G w Substituting the values in eq 1, we obtain G yz w xz X y 62 M 6y2 y Y y 2 x x 2 x 62M 6s2 - (2) Where W can be recalled as wrapping function, whole stress in system depends on wrapping function, the solution can be found out by analyzing the equation as Laplace equation. Let us, look into, how to get the solution for the warping function. This warping function was introduced by saint venant. And later on, a function was introduced by Prandtl, which is convenient for obtaining solutions to different geometries. So, we would like to consider, this channel stress function approach. 1. Prandtl’s Stress Function As in the case of beams, the torsion problem formulated in the preceding is commonly solved by introducing a single stress function. If a function Φ(x, y), the Prandtl stress function, is assumed to exist, such that zx y zy x 6 G w Y x 2 y G – w X x 2 y Equations of Compatibility Again Differentiating the first equation of with respect to y and the second with respect to x and adding the second and first, we obtain an equation of compatibility: 2 y • • 2 2 x G 2 2 2 W – W – G x y – 2G x y This is an important equation of torsion. So therefore, the Prandtl’s stress function is such that, it satisfies the Poisson type equation. The stress function Φ must therefore satisfy Poisson’s equation if the compatibility requirement is to be satisfied. Boundary Conditions We are now prepared to consider the boundary conditions, treating first the load-free lateral surface. τxz is a z-directed shearing stress acting on a plane whose normal is parallel to the x axis, that is, the yz plane. Similarly, τzx acts on the xy plane and is x-directed. By virtue of the symmetry of the stress tensor, we have τxz = τzx and τyz = τzy. Therefore, the stresses given by Eq. (e) may be indicated on the xy plane near the boundary, as shown in Fig. 2. The boundary element is associated with arc length ds. Note that ds increases in the counterclockwise direction. When ds is zero, the element represents a point at the.Noting that the cosine of the angle between z and a unit normal n to the surface is zero [that is, cos(n, z) = 0], we have n=(l,m,0) 7 Figure 2.2-Arbitrary cross section of a prismatic member in torsion.[3] l zx zy zs m Zr --(a) zy According to Eq. (a), the resultant shear stress τ must be tangent to the boundary (Fig. 6.9). From the figure, it is clear that � = cos(�, dy �) = � = cos(�, �) = − �� � � dc (b) Note that as we proceed in the direction of increasing s, x decreases and y increases. This accounts for the algebraic sign in front of dx and dy in F ig. 2. Substitution of Eqs. (3) and (b) into Eq. (a) yields zs zx zy y zy dy y ds x x -- (3) dx d ds ds 0 (on the Boundary)- -- (4) • This expression states that the directional deviation along a boundary curve is zero. Thus, the function Φ(x, y) must be an arbitrary constant on the lateral surface of the prism. Examination of Eq. (6.8) indicates that the stresses remain the same regardless of additive constants; that is, if Φ + constant is substituted for Φ, the stresses will not change. 8 • For solid cross sections, we are therefore free to set Φ equal to zero at the boundary. In the case of multiply connected cross sections, such as hollow or tubular members, an arbitrary value may be assigned at the boundary of only one of the contours s0, s1,..., sn. For such members it is necessary to extend the mathematical formulation presented in this section. • Thus the determination of stress distribution over a cross sectionof a twisted bar consists in finding the function Φ ,that satisfies the equation (A).and is zero at boundaries f) CALCULATION OF TORSION Returning to the member of solid cross section, we complete discussion of the boundary conditions by considering the ends, at which the normals are parallel to the z axis and therefore cos(n, z) = n = ± 1, l = m = 0. & pz = 0, Fig 2.3-: Infinitesimal stress element [3] Where, p zx x ; p y zy where the algebraic sign depends on the relationship between the outer normal and the positive z direction. For example, it is negative for the end face at the origin in Fig. a. We now confirm that the summation of forces over the ends of the bar is zero: ∑�� = 0; p dxdy zx x y2 dx = y y 1 d y dxdy y dxdy y y 2 dx ( 1 9 2 1 ) Here y1 and y2 represent the y coordinates of points located on the surface. as Φ = constant on the surface of the bar, the values of Φ corresponding to y1 and y2 must be equal to a constant, Φ1 = Φ2 = constant. Similarly it may be shown that ∑�y= 0; zy dxdy 0 ; ∑� = �; T x dy y ZY x ZY dxdy d x dxdy x – x dx y x y dxdy y dy y Integrating by parts, T x x2 dy x1 dxdy – y y2 y 1 dx dxdy Since Φ = constant at the boundary and x1, x2, y1, and y2 denote points on the lateral surface, it follows that T 2 dxdy --- (5) • As Φ(x, y) has a value at each point on the cross section, it is clear that Eq. (4) represents twice the volume beneath the Φ surface. • What has resulted from the foregoing development is a set of equations satisfying all the conditions of the prescribed torsion problem. Equilibrium is governed by Eqs. ), compatibility by Eq. (A), and the boundary condition by Eq. (4). Torque is related to stress by Eq. (5). To ascertain the distribution of stress, it is necessary to determine a stress function that satisfies Eqs. (4) and (A). 1 0 3 EXAMPLE 1) Solve Torsion equation of Elliptical BARS Using Prandtl’s Method SolutionConsider a bar with elliptical cross section as shown in the figure subject to a torque at its ends. The boundary is described by the implicit equation �2 �2 ∅ =( 2+ − 1) � �2 The torsion equation and boundary condition Φ = 0 are satisfied by given stress fuction. Where m is constant whose value has to be determined ∆ 2∅ = �2 ∅ �2 � 2 ∅ ∅ = −2�� � � �2 � 2 + 2 � = �� 2 �2 � 2 2� ∅ �2 � �2 = Substituting in the torsion equation we get 1 1 2� ( + ) = −2�� �2 � 2 �2�2 �=−( 2 )∗ � + �2 �� � 2� 2 �2 �2 ∅ =−( 2 ) ] + − 1] �� � + � 2 �2 �2 The shear stress components are; a2b2= � 6∅ = −( ∗ 2y ∗� 2 = ( � a=2b6∅ 1 0 2s ∗ ∗ �� zs 6y a2+b2 ) (b2 ) zy Resultant stress is given by: 1 0 6s a2+b2 ) (b2) Equating the moment due to shear stress to the external torque 2�2 2 2� 2 � = fl �(�zs − �zy )�� = ) ��� + ) � ( ��� 2 )� � = fl(( 2 + �2 �2 + �2 � = 2 � fl �(� 2 � 2 + �2 � 2 )�� � �2 + �2 We know that, nba3 = � =∬ 4 yy �(� 2 ��) ��� 3 � yy �ss = fl �(� 2 ��) �yy = 4 2) A hollow aluminum alloy 6061-T6 shaft of outer radius c = 40 mm, inner radius b = 30 mm, and length L = 1.2 m is fixed at one end and subjected to a torque T at the other end, as shown in Fig.1. If the shearing stress is limited to τmax = 140 MPa, determine (a) the largest value of the torque; (b) the corresponding minimum value of shear stress; (c) the angle of twist that will create a shear stress τmin = 100 MPa on the inner surface. G = 72 GPa and τyp = 220 MPa Solution- Fig.3.1-A tubular circular bar in torsion. �=� c ∗ Nax --b c the polar moment of inertia of the hollow circular tube is � � (� 4 − � 4 ) = (404 − 304 ) = 2.749 ∗ 106 �� 4 �= 11 2 2 Inserting J and τmax into Eq. (b) results in 12 The smallest value of the shear stress takes place on the inner surface of the shaft, and τmin and τmax are respectively proportional to b and c. Therefore, Through the use of Eq. (2.27), the shear strain on the inner surface of the shaft is equal to or φ = 3.19° 3) The shaft in Fig. (a) consists of a 3-in. -diameter aluminum segment that is rigidly joined to a 2-in. -diameter steel segment. The ends of the shaft are attached to rigid supports, Calculate the maximum shear stress developed in each segment when the torque T = 10 kip in. is applied. Use G = 4×106 psi for aluminum and G = 12×106 psi for steel. Solution Equilibrium ΣMx = 0 , ( 10 × 103 ) —Tst —Tal =0---- (a) 13 (a) This problem is statically indeterminate. Compatibility the two segments must have the same angle of twist; that is, θst = θal From Eq. (3.4b), this condition between. � �� � =( ) �� ÆL ( ) � � ST �ct ∗ 3 ∗ 12 �aS ∗ 6 ∗ 12 ( ) = ( 4 ∗ 34 ) 12 ∗ 24 Tst = 1.1852 Tal (b) Solving Eqs. (a) and (b), we obtain Tal = 4576 lb‧ in. Tst = 5424 lb‧ in the maximum shear stresses are 16∗ T 16∗ 4756 )�� = = = 863 ��� (� Nas n∗ d 3 (� Nas )�� = n∗ d n∗ 33 16∗ T 16∗ 5424 = = 3450 ��� n∗ 23 3 4) An aluminum tube of rectangular cross section (Fig. 6.19a) is subjected to a torque of 56.5 kN · m along its longitudinal axis. Determine the shearing stresses and the angle of twist. Assume G = 28 GPa. Solution- the applied torque is, T = 2Ah = 2(0.125h) = 56,500 N · m from which h = 226,000 N/m. The shearing stresses are found from Eq. (a) as follows: 14 the angle of twist per unit length is 5) Find the shear stress due to torsion on a triangular profile? Solution Third order polynomials enable to solve the case of a triangle profile. Let us consider a general triangle Ω with one side being parallel to the axisy, i.e. a subset of the linez=−c.Let the other sides lie on the linesz=a1y+b1andz=a2y+b2,wherea1,a2,b1,b2 P3(y, z)=k(a1y+b1−z)(a2y+b2−z)(z+c) With k= 0 bounds the triangle Ω. Simple calculation yields ΔP3(y, z)=−2k(a1+a2)y+2k(a1a2+3)z+2k(a1a2c−b1−b2+c) The right-hand side is constant if the coefficients by terms y and z are zero, i.e. ifa1+a2=0 and a1a2+ 3 = 0, which impliesa1=−a2=±√3. Thus the triangle Ω must be equilateral. Choosingb1=b2=b and b=2cthe triangle has vertices [−√3c,−c], [√3c,−c], [0,2c]with its center of gravity in [0,0].The polynomialP3is a solution to the problem (11) if the righthand constant equalsto−2, i.e.−k(a1a2c−b1−b2+c)=k6c= 1 which yieldsk=(6c)−1. We obtained the Airy stress function Φ(y, z) = 1 (3y + 2c − z)(−√3y + 2c − z)(z + c) 6 � The moment J of the cross-section can be computed using 15 �= 2∗ 1 2c ƒ (Φ(y, z)dy) dz = 9√35�4 6 –c � The only non-zero components of the stress tensor are τxy = −αμ ∗ z2+2c y2– τxz = −αμ ∗ y(z+c) c 2c The modulus of the shear stress 2 |τ|=J(� ) + sy (�sz )2= αμ 1 ƒ(� 2 − z 2 + 2cz)2 + 4y 2 (z + c)2 2c 16 4 APPLICATIONS/CASE STUDY 4.1 APPLICATION 4.1.1 • Circular members In circular members, central geometry greatly enhances the understanding of torsion’s effects. Shear stresses are equivalent along circumfrential lines about the centre (see Figure 3). Fig. 3- Shear stress in circular members. Shear stress uniform distributed along circumfrential lines.[2] 4.1.2 Rectangular members Fig-4.1- St. Venant’s resulting stress zones from rectangular torsion members of b/t = 2, where b is the length of the long side and t is the height [2] 17 4.1.3 Square members Fig-4.2-stress zones from Square torsion members of (b/t = 1)-[2] • • • 4.1.4 Applicable statements from the theory of elasticity: The maximum shear strain and stress occur at the centerline of the long sides of the rectangular cross section The shear strain and stress at the corners and center of the rectangular cross section are zero The strain and stress variations on the cross section are primarily nonlinear Triangular profile Fig.4.3- (a) stress function Φ. (b) modulus of the shear stress τ , the maximum values of |T| occur in the middle of the sides.(c) deflection of the cross-section [6] 4.1.5 Elliptical profile 18 Fig.4.4- (a) stress function Φ.(b) modulus of the shear stress τ.(c) deflection of the cross-section [6] The applied torsion on the twisted bar is proportional to twice the volume included between the deflected membrane and plane through the supporting edges 19 4.2 CASE STUDY 4.2.1.1 TORSION EXPERIMENTS Tinius Olsen torsion tester along with a reaction torque sensor were used.to perform torsion tests on 6061extruded aluminum bars of circular (0.25 inch in diameter) as well as square section (0.25 inch to a side). The best fit lines were drawn for the torque-twist curves for the square and round torsion specimens and are shown in Figure 4.2.2, The torque-twist diagram for the round (circular) specimen was used to calculate the shear modulus of the material. This value was subsequently used to verify the analytical value for the torque-twist relationship for the square section. The torsional stiffnesses (k) of the round and square specimens for a typical case were obtained experimentally (from the slopes of the lines in Figure 4.2.1) as 84 lb-in/rad and 118 lb-in/rad respectively. Figure 4.2.1: Experimental Setup Figure 4.2.2 Torque versus Angle of Twist for Round and Square Torsion Specimen 11 0 For the round specimen, from any text on Mechanics of Materials, such as, Reference [3] Which gives G = 3.94 x 106 psi For the square cross section, the determination of torsional stiffness requires consideration of warping which is available only in advanced texts on Mechanics of Materials. Stiffness for the square specimen, This gives α = 0.138 which compares favorably with the analytical value of 0.1406 2 0 5 OUTCOMES • • • • • Warping has been demonstrated using (a) twisting Styrofoam specimens, (b) Membrane Analogy, and (c) Torsion experiments involving shafts of circular and square sections. Membrane analogy provides a mental picture of the state of stress. The membrane for a square shaft has been shown to have the greatest slope at the midpoint of the edges and not at the corners as is sometimes supposed. In the corner the membrane has a zero slope along both edges indicating zero stress. Experimental investigation on the torsion of square shaft provides a basis of comparison of its torsional stiffness with the analytical values that take warping into consideration. Future efforts in this area would be to measure strains using strain gages to compare with the analytical expressions for shear stresses, and also developing electrical analogy experiments similar to what has been reported. 21 6 REFERENCES [1]-Basler, K, and C.F. Kollbrunner. Torsion in Structures. New York: SpringerVerlag,1969. [2]-Torsion of members with rectangular cross-sections-Jeremy Elder, April 23rd, 1999 [3]-http://ocw.snu.ac.kr/sites/default/files/NOTE/Chapter%206_1.pdf-Professor Youn, Byeng Dong [4]-A Study of Warping of Non-circular BARSs in Torsion Prof. Somnath Chattopadhyay, Georgia Southern University-American Society for Engineering Education, 2013 [5]-Hearn E.J.: Mechanics of Materials 2 : An Introduction to the Mechanics of Elastic and Plastic Deformation of Solids and Structural Materials,ButterworthHeinemann, Oxford, 3rd edition, 1997 [6] -www.kmp.tul.cz/system/files/krouceni_nekruhoveho_hridele_francu.pdf [7]- Strength of Materials- Torsion of Non Circular Section- Hani Aziz Ameen [8]- R. Bredt, Critical observations on elastic torsion (in German), Z. Ver. Deut. Ingenieure 40,785 (1896). 22