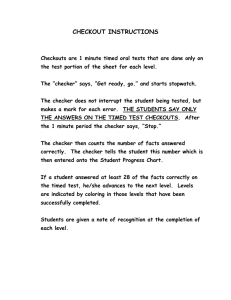

Development of Checker Training Module, Skill Matrix & Upgradation of Quality Manual – SSAL-2 Sayantan Raha, MFT Background Global business in apparel sector is dependent on quality characterization as major buyers want to ensure about the quality of the merchandise prior to the delivery to the consumers. This project has been selected for every quality related activities in our organization. Upgrading & improvement of the same will be a challenging job nowadays. Objectives: Review of old process & quality manual Process smoothening of internal & buyer or third party audits. Defect analysis & making of defect libraries. Total defects will be reduced. Development of Checker’s skill matrix. Process sheet upgradation will helps the confidence of the quality checker. Reworks will be reduced Online & Offline implementation of training manual. Research Methodology: 1 • Study of the functioning and activities performed in quality department 2 • Collect information regarding existing training manuel & quality manual from the quality department. 3 • Analyse the data based on internation quality standards • Soft Skill & other criteria analysis. • Descriptive analysis was done to identify critical operations for better quality control by identifying the major source of defects/rework. • OQL reports analysis, DHU analysis for defect minimization as well as Skill matrix development. 4 Findings & Conclusion: • Developing checker training manuel & Skill matrix by try & test (pilot run) • And upgradation of Quality manual 5 • .Collect feedback Keywords 6 Quality Manual, OQL, DHU, Quality Tools, Digital Quality reports, Sig sigma, DMAIC, PDCA cycle, Poka Yoke; • Final implementation of the checker's training module & Skill Matrix in the Dept. Research Tool: Questionnaires, interviews, Informal enquiries, MS Excel, 7 QC Tool, Six Sigma DMAIC tool. Analysis: Descriptive analysis was done with DHU & RAM reports with various general format and list out of all defects in trs & jkt line. Development of quality checker’s rating & grading chart. Creation of operator’s confidence & motivation. Improving quality training manual by local languages along with pictures. Reduction of reworks can profitable for our organization. It will be helpful for proper quality auditing requirements.