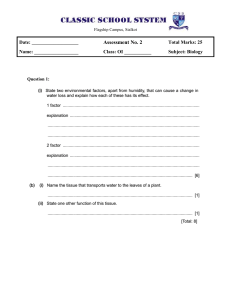

Natural Gas Dehydration: Molecular Sieve Study in Iraq

advertisement