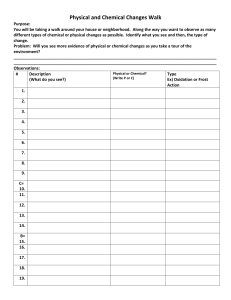

Materials Science for Energy Technologies 2 (2019) 607–623 Contents lists available at ScienceDirect Materials Science for Energy Technologies CHINESE ROOTS GLOBAL IMPACT journal homepage: www.keaipublishing.com/en/journals/materials-science-for-energy-technologies Materials progress in the control of CO and CO2 emission at ambient conditions: An overview Subhashish Dey ⇑, Ganesh Chandra Dhal Department of Civil Engineering, IIT (BHU), Varanasi, India a r t i c l e i n f o Article history: Received 31 May 2019 Revised 21 June 2019 Accepted 22 June 2019 Available online 24 June 2019 Keywords: Carbon monoxide Poisonous Source Catalyst Parameters and applications a b s t r a c t Catalytic conversion of carbon monoxide (CO) is one of the most important process for human health protection. CO is also called the unnoticed poisons and silent killer of 21st century. The effect of inhaling CO can cause of hypoxic injury, neurological break and even death. Due to CO poisoning decay vegetation life and increases in global warming and ozone layer depletion. CO is produced into the environment by partial oxidation of carbon containing compounds. The main source of CO emission is the transportation sector. Thus, the oxidation of poisonous CO to nonpoisonous CO2 at ambient conditions is crucial for life conservation in many applications. Further, low-temperature CO oxidation is vital in minimizing emissions at the cold start of an internal combustion engine. A variety of CO oxidation catalysts are investigated in this era, but a maximum of them have problems associated with the deactivation in presence of moisture, cost-effective, lower stability, poison resistance, availability in the world. These accelerate the investigation of CO oxidation over various catalysts. Although there are numerous research articles present on this topic until now no one review are present for this demanding issue. So there is a space in this area, it has been made an attempt to seal this hole by this review. Ó 2019 The Authors. Production and hosting by Elsevier B.V. on behalf of KeAi Communications Co., Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-ncnd/4.0/). Contents 1. 2. 3. 4. 5. 6. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sources of CO emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1. Natural sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2. Anthropogenic sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . An adverse effect of CO emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1. Impact of CO on health . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2. Impact of CO on vegetation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3. Impact of CO exposure on global warming and ozone-layer depletion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Control of CO emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1. Regulations of CO emissions and recommended limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1.1. Motor vehicle emission standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1.2. Recommended exposure limits (REL) for CO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Formation of CO in internal combustion (IC) engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Control of CO emission by application of catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ⇑ Corresponding author. E-mail address: subhasdey633@gmail.com (S. Dey). Peer review under responsibility of KeAi Communications Co., Ltd. Production and hosting by Elsevier https://doi.org/10.1016/j.mset.2019.06.004 2589-2991/Ó 2019 The Authors. Production and hosting by Elsevier B.V. on behalf of KeAi Communications Co., Ltd. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/). 608 609 609 609 612 612 612 613 614 614 614 615 615 616 608 7. 8. S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 Catalysts for CO oxidation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1. Noble metal catalysts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2. Base metal catalysts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3. Groups of catalysts for CO oxidation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3.1. Hopcalite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3.2. Perovskites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3.3. Spinel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3.4. Monel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4. Preparation of catalysts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4.1. Co-precipitation method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4.2. Sol-gel method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4.3. Impregnation method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4.4. Reactive grinding method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4.5. Hydrothermal method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4.6. Pyrolysis method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5. Metals promoted on catalysts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.6. Mechanism and kinetics study of catalyst . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.7. Use of catalysts at cold start emission conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Conclusions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Declaration of Competing Interest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1. Introduction Carbon monoxide (CO) is also called carbonous oxide, is a colorless, odorless and tasteless gas, which creates very difficult for humans to perceive [1,2]. CO has been called ‘‘the unnoticed poison of the 21st century” and ‘‘the silent killer”, because it gives no clear warning to its victims that they were at risk [3,4]. The small amount of CO poisoning causes hypoxic injury and neurological damage of humans. Due to CO exposure the plant respiration and nitrogen fixation are failures [6,7]. The presence of CO on earth’s atmosphere effects the atmospheric chemistry as well as the environment [5,8]. When CO enter into the ground level ozone, it can creates serious respiratory problems and also increases the global warming level. Therefore, CO levels in the atmosphere play a significant role in influential the air quality of region. Carbon monoxide is produced into the environment by partial oxidation of carbon-containing compounds and also produced by the catalytic cycle of heme degradation and approved by the enzyme heme 616 616 617 617 617 617 617 618 618 618 618 618 618 618 618 619 619 620 620 620 620 oxygenase (HO-1) within the human body [11,12]. Endogenously produced CO take part in a role of cytoprotection against damage of body tissues. However, with outside exposure of CO formation of carboxy-hemoglobin (COHb), which reduces the oxygen percentages (Fig. 1) in the blood [13,14]. Thus, depending on the concentration, the role of CO exposures depending on the range from cyto-protective to cyto-toxic [15]. The main sources of CO produces into the environments are transport, power plants and industrial activities [16]. The transportation sector contributes 64% of the CO contamination in the urban area. Forest fires and building fires also release a large quantity of CO in the atmosphere [17,18]. Carbon monoxide is a molecule with three resonance structures or Lewis structures. CO is one of the strongest diatomic molecules and a weak electron donor. Due to the poisoning of CO and its negative impacts on public health and natural environment, the standards in legislation focus on regulating pollutants from different sources [19,20]. For diesel passenger cars, Legislation is progressively improved year by year Fig. 1. Current and future therapeutic targets of CO poisoning. S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 to maintain the air quality and reducing CO such as: for Euro1/2, medium HC & CO conversion, for Euro 3/4, medium HC conversion and high CO conversion and for Euro 4/5, very high HC & CO conversion by improving engines and three way converters (TWC) [21–23]. Many organizations such as WHOM, OSHA, NIOSHA, ACGIH, ASHRAE etc., have its own terms to depict the type of limit or level [24]. To control the automobile pollution was done by the 1970 Clean Air Act, for reduction in CO, HC and NOx productions from automobiles [25]. Catalytic oxidation at lower or ambient temperatures has stimulated a lot of research interest for its abatement. The catalyst converts toxic CO into nontoxic product CO2 form in the environment which was used for the photosynthesis by vegetation [26]. Low temperature CO oxidation has been broadly studied over various types of catalysts like spinel structure, perovskite structures, hopcalite and monel etc [27]. The noble metal catalysts were challenging for their slower reproducibility, high cost and deactivate easily [28]. The catalysts were deactivated easily by moisture or humidity but removing moisture at various temperatures simply improved the catalytic activity [29,30]. Low temperature/ambient condition CO oxidation is gaining a significant amount of interest at current situations, because of its urgency for life preservation in many practical applications in various industrial and environmental fields [31,32]. These include specialized heating, ventilation and air conditioning (HVAC) filters for air purification in a cabin [33], rescue equipments [34], CO leak detection sensors [35], automotive emission control [36], ice arenas, indoor and underground parking garages, confined spaces [37], smoking [38], etc. It also has applications in regenerative CO2 lasers used in orbiting applications for recombining dissociated CO2 for weather conditions monitoring and various other applications [39]. Further, low temperature CO oxidation is vital in minimizing emissions during the cold start of an internal combustion engine [40]. The oxidation of CO in H2 stream at low temperature is also significant for the effective operation of fuel cells in production of electricity [41,42]. Special consideration has been given to the personal protective equipment (PPE) application. It has tremendous application assessment to the PPE in respiratory protection systems for military, mining and fire fighting. It is also very useful in confined space protection such as submarines, deep sea welding and refuge chambers. Overall CO oxidation is vital in protecting vegetation and environment [43,44]. To fulfill this space, an endeavor has been made in this particular research interest to wrap all types of catalysts active, effects, sources, legislation, controlling methodology and their application parts. 2. Sources of CO emissions CO is an impartial oxide which combusted in atmosphere to produce CO2, which is an excellent reducing agent. Plants can produce CO is an ubiquitous molecule as a trace component in the ordinary environment [45]. The global concentrations of CO range between 0.06 and 0.14 mg/m3. CO is a major product of volcanic activity but also produced by the partial oxidation of carbon containing compounds like fuels/biomass, photochemical and biogenic oxidation of organic matters [46]. Obviously, there are many sources of CO as shown in (Fig. 2) which can be broadly classified into natural and anthropogenic processes. Fig. 2. Sources of CO emission. garbage landfills. The sunlight-initiated oxidation of organic matter in waste-waters discharged in rivers/ocean is primarily responsible for producing CO [49]. Creation of CO in clouds is apprehensively recognized to the photochemical oxidation of organic matter or the trivial dissociation of CO2 provoked by electrical discharge or both [50]. Submarine divers, space traveler and fire-fighters face a bulk amount of CO. Other natural sources of CO are incomplete burning of biomass: Forest/bushfires, building fires and fire-cleaning, smoke contain many toxic gases including CO in substantial quantity [51]. Depending upon the cases, fire can also contain as high as 3600 ppm of CO [52]. Each year an estimated 80,000 wild-land fire fighters battle wildfires, often spend long periods at the fire front where they are exposed to high levels of toxic smoke [53]. The sources of atmospheric CO have changed from seasons to seasons. It is extremely difficult to measure accurately the variable sources of CO emissions from year to year. Humans can also produce very small amounts of CO endogenously [54–56]. In human metabolic processes the heme-catabolism produce (Fig. 3) only very lower amount of CO. In both males and females, time to time variations in CO formation. The pregnant women also showed higher amount of endogenous CO production related to increased breakdown of red blood cells [57,58]. Endogenously produced CO is known to function in several important physiological processes, including vasodilatation, apoptosis, inflammation and neurotransmission [59,60]. 2.2. Anthropogenic sources The major amount of CO contamination in the atmosphere is contributed by the human-caused or anthropogenic sources. Approximately 60% of the total CO emissions are thought to be contributed by human endeavors and remainder by the natural sources. Anthropogenic sources of CO emissions are categorized as mobile, industrial and residential activities [61]. Mobile sources account for the main CO emissions. It includes both on-road vehi- 2.1. Natural sources In the environment the major amount of CO is produced in natural origin, due to the photochemical oxidation of methane emitted from wetland [47]. The huge amounts of CO are also produced from the earth’s mantle, where it was dissolved in the molten rock, by volcanic eruption [48]. In addition, CO is produced from the oxidation of biogenic VOCs emitted by vegetation and 609 Fig. 3. Global carbon monoxide cycle. 610 S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 cles (e.g., cars, buses, trucks) and off-road vehicles (e.g., bulldozers, mobile excavators, farm machinery, trains, snowmobiles, domestic lawn mowers etc.) [62]. Industrial sources are stationary sources; include thermal power plants, steel plants, coke ovens, hydrogen production, coal gasification and chemical production, petroleum refining and other industries using various carbon-based fuels as a source of energy [63]. The exhaust component of Diesel engines and Gasoline engines are shown in Table 1. Residential sources include space heaters (salamanders), stoves, furnaces, heaters, generators, and others. Kitchen applications that burn oil, LPG or other fuels [64]. Production of CO rises (Table 2) when vehicle is moving slowly. A large concentration of CO is produced during the cold start of vehicle (Fig. 4), as catalytic converters take certain time to get the working temperature. The diesel engines are widely applied in heavy-duty vehicles for its improved fuel efficiency and power yield than a petrol engine vehicle [65]. Table 1 Exhaust component of Diesel engines and Gasoline engines. Exhaust Component Diesel Engines Gasoline Engines CO HCs NOX Particulate Matter 300–1200 ppm 50–330 ppm 350–1000 ppm 20–200 mg/m3 1500–4000 ppm 50–5000 ppm 100–4000 ppm 12–40 mg/m3 Table 2 Composition of CO in dry atmosphere, by volume. Concentration Source 0.1 ppmv 0.5–5 ppmv 5–15 ppmv Normal atmosphere level (MOPITT) Average level in homes Near-properly used to gas stoves in homes, modern automobile emissions Exhaust from a residence wood fire Undiluted warm car exhaust without a catalytic converter 5000 ppmv 7000 ppmv ppmv: parts per million by volume. MOPITT: measurement of pollution in the troposphere. In the assessment of diesel engine, the petrol engine emitted more CO into the atmosphere. The CO emission from CNG vehicles is two times less than the gasoline engine vehicles. The vehicle emissions are also depending upon the vehicle design, maintenance, operation conditions and fuel composition, etc [66]. The CO emissions are also contributed to environmental from the incineration of solid wastes in urban and other incinerators [67,68]. Carbon monoxide is also encountered in mining operations in which explosives are used in confined spaces. The exposure of CO in warehouses propane-powered floor polishers are operated [69,70]. The major hazardous levels of CO contamination generally take place in air of buildings or enclosed spaces [71]. The higher amounts of CO can produces in indoor air (Fig. 5) as a result of inappropriately installed or unvented and poorly maintained cooking/heating. Dangerous levels of CO can build up by using older moveable propane heaters in enclosed indoor settings [72]. Gasoline-powered tools like a power generator (Fig. 6), pressure washers inside homes and idle running of the car for long periods of time in the garage lead to dangerous and deadly levels of CO. Undetected releases of CO in indoor settings can present serious health risks to building occupants [73]. A huge amount of CO is released from firewood, charcoal, coal, biomass and other fuels burning in cook-stoves indoors in various rural areas. The domestic sources release openly into the spaces at the phase of human residence [74,75]. The CO emissions resulting from burning various fuels in stove, thus represent cleanliness of the fuels in the subsequent order: charcoal < wood < dung < crop residue < coal < kerosene < LPG < biogas. The CO concentrations are very low for LPG and biogas, pointing them as cleaner fuels. This indicates that the CO production from biomass cooking is high; depends upon the biomass fuel activity pattern [76]. The options for CO exposure reduction (Fig. 7), are the use of cook stoves having flues or chimneys, or building hoods or exhaust fans, and use of cleaner fuels such as LPG or biogas [77,78]. Cigarette smoking is one of the major source of CO in indoor air contaminant [79]. CO is produced in home from the tobacco burning during the certain mainstream smoke by the flaming closing stages of the cigarette [80]. Accordingly Moschandreas et al. [81] the one cigar- Fig. 4. Schematic diagram of catalytic convertor for solution of cold start problems. Fig. 5. Emission of pollutants from vehicles and control technologies. S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 611 Fig. 6. Emission of CO from various sources. ette can be produced 88.3 mg CO. The summary of major contributions of natural and anthropogenic sources of CO emissions is given in Table 3. CO readily react with hydroxyl radical creating a much stronger, a greenhouse gas—CO2, it increases the percentages of CH4, another strong greenhouse gas. So, that the production of CO2 leaves smaller amount OH for CH4 to react with, thus rising CH4 concentration [81–84]. CO results from certain microbial fermentations, but even under exceptionally favorable conditions, it generally does not exceed 3% of the gases formed by bacterial fermentation of organic wastes. CO can also be generated in surface waters by ultraviolet photolysis of humic substances. The chemical reactivity of CO and relative ease with which various bacteria reduce it to methane or oxidize in to CO2 probably account for its absence or very low concentrations in most environments. Aerobic COoxidizing bacteria are distributed widely, especially in organicrich sediments. Species of Carboxydomonas, Hydrogenomonas, Bacillus, and certain methane-oxidizing bacteria oxidize CO [85–90]. CO þ 1=2O2 ! CO2 DG0 0 ¼ 66kcal=mol ð1Þ Additionally, the several aerobic bacteria in mixed populations quantitatively convert CO into CH4 in the presence of hydrogen: CO þ 3H2 ! CH4 þ H2 O DG0 0 ¼ 46kcal=mol ð2Þ In the absence of H2, some anaerobic bacteria (Methanosarcina) produce CO2 and CH4: 4CO þ 2H2 O ! 3CO2 þ CH4 Fig. 7. Diagrammatic representation showing common sources of CO in the indoor environment. ð3Þ 612 S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 Table 3 Sources of carbon monoxide in the environment. CO production (million tonnes per year) Anthropogenic Natural Range Directly from combustion Fossil fuels: Transportation, coal, oil, natural gas Biomass burning: Agricultural clearing, wood, refuse Forest fires: 500 650 – 400 200 30 1000 800 10–50 Oxidation of hydrocarbons Methane: Wetlands, rice cultivation, animal husbandry, landfills, coal mines Non-methane hydrocarbons: alkanes, alkenes, aromatics, isoprene, terpenes 300 90 300 600 400–1000 300–1400 Other sources Plants: Metabolic by-product Oceans: Oxidation of organic substances Total – – 1500 100 40 1100 50–200 20–80 2000–3000 3. An adverse effect of CO emissions Higher concentration of CO emissions adversely affects on human health, vegetation and the environment. However, endogenously produced CO is taking part in a key role in cytoprotection against damage of body tissues [91,92]. 3.1. Impact of CO on health Carbon Monoxide (CO) is lethal to every aerobic form of life. It was simply absorbed in the blood through the lungs [96]. CO affinity to hemoglobin is 240 times higher than that of oxygen so, this prevents oxygen binding to hemoglobin. Carboxy-hemoglobin reduces the oxygen-carrying ability of the blood and interferes with oxygen discharge (Fig. 8) at the tissue level. Continued supplying of oxygen can interfere with cellular respiration and result in tissue hypoxia [97,98]. Increased levels of Carboxy-hemoglobin (COHb) in the blood decrease the oxygen carried by hemoglobin around the body in red blood cells. The acute CO poisoning includes headedness, uncertainty and flu-like effects; higher exposures of CO can lead to higher toxicity of the main nervous system and heart, impaired vision and coordination and even death. Following acute poisoning, long-term squeal often occurs [103]. The chronic exposure to smaller levels of CO regularly (such as at home, or in the workplace) can also cause long-term health problems characterized by the effect on pulse rate, respiration, blood pressure and neurological reflexes which can lead to fatigue, headaches, dizziness, depression, confusion and memory loss. Significant exposure of CO may lead to a heart damage [104,105]. The signs and symptoms at various concentrations of CO in the atmosphere and duration of exposure are illustrated in Fig. 9. At concentrations more than 0.1% by volume in atmosphere can seriously affect human aerobic metabolism resultant in respiratory system failure and death. CO poisoning is the most common type of fatal air poisoning in many countries [106,109,110]. The effect of CO at various concentrations in normal air on human health is representing in Table 4. According to the national institute for occupational safety and health (NIOSH) has recommended that lowering the level of CO exposure is 35 ppm. Children of age under 14 years are more probable to sustain poisoning than adults at lower levels. On average, the exposures at 100 ppm or more is dangerous to human health [111,112]. 3.2. Impact of CO on vegetation CO is a lower molecular weight diatomic gas; it’s capable to influence the plant seed germination, bring on the adventitious Fig. 8. Effects of CO emission on human health. (Source: https://en.wikipedia.org/wiki/Carbon_monoxide_poisoning). S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 613 Fig. 9. Effect of exposure to various concentrations of CO. Table 4 The effects of carbon monoxide at various concentrations in air. CO Concentration (ppm) Physiological Effects on Humans 50 100 200 400 900 1500 Safe for continuous exposure No Perceptible effect Slight effect after six hours Headache after three hours Headache and nausea after an hour Death after one hour rooting development. Due to the CO poisoning, the plant leaf is curling, reduces the leaf size, premature ageing of the chlorophyll. It reduces the cellular respiration system of plants and also reduces the agriculture productivity [113]. The longtime CO exposure causes reduce the length of primary roots; plant leaf is discolorization (Fig. 10), droops its shape and reduces the distance from seed to tip of the leaf. The current indication suggests that the concentration of atmospheric CO is a major implication for plant physiology and growth [92–95]. The increasing of CO concentrations more than 120 ppm in most plant species explain higher rates of photo- synthesis decreased water use, better growth and lowered tissue concentration of N2 and protein [114,115]. In plants, the effects of CO has been considered to illuminate in Fig. 10. Accumulating the confirmation in plants has revealed that CO is used for a numeral intracellular biological functions. The rising of CO concentration is highly affected both agricultural production and food quality [100–102]. CO exerted a beneficial effect on improving seed germination in a dose-dependent way in various plants. [117]. Stomata function significantly control the plant water status and produce by many environment or hormonal factor [119,120]. 3.3. Impact of CO exposure on global warming and ozone-layer depletion Carbon monoxide is individual one of major reactive trace-gases in the earth’s atmosphere. The amount of CO is increasing in the atmosphere day by day by the increasing of fossil fuel consumptions. CO is a weak direct greenhouse gas and an important indirect effects on global warming (Fig. 11) [116–118,121]. The initiating reaction for CO destruction is given by Eq. (4). Fig. 10. Adverse effects of CO emission on plant. (Source: https://www.skepticalscience.com/co2-plant-food.htm). 614 S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 Fig. 11. Adverse effects of CO emission on Green house effects. (Source: https://myassignmenthelp.com/free-samples/ozone-layer-depletion-and-global-warming). CO þ OH ! CO2 þ H ð4Þ The troposphere photochemical oxidation of CO (Eq. (5)), in the presence of enough NOx (i.e., above 3–8ppbv at ground level and 20ppbv in the upper troposphere) also lead to the creation of significant amount of ground-level ozone (a secondary pollutant). Excess quantities of ozone can trigger serious respiratory problems, damage crops and natural ecosystem [107,108,124]. CO þ 2O2 þ hm ! CO2 þ O3 To address this problem, significant efforts have been made since 1970. The emissions from gasoline-fueled vehicles can be condensed through the changes in engine design, burning conditions and catalytic after treatment. The emissions of CO can be controlled by A/F ratio, turbulence in the combustion chamber and exhaust gas re-circulation [121–124]. 4.1. Regulations of CO emissions and recommended limits ð5Þ Since CO has not direct effect on global warming and is complicated to evaluate the global warming potential of the emission. CO is reported to have a Global-warming potential (GWP) about 3.2 on a 20 years’ time span [140]. It means that CO is 3.2 times more potent than CO2. CO þ O3 ! CO2 þ O2 ð6Þ Similarly, the incidence of CO, at concentrations ranging from 15 to 30ppmv, leads to major decreases in the rate of oxidation of atmospheric SO2 to form sulfate aerosols as a result of reducing the amount of OH present. In the troposphere, it act as cloudcondensation nuclei (Fig. 11) which reflect sunlight back to space, therefore neutralize the global warming effect of the greenhouse gases [125,126]. 4. Control of CO emissions The control of CO emissions from automobile vehicles has become a global challenge in achieving improved urban air quality. The emission standards are set by the certain limits to the concentration of CO and other pollutants that can be free in the air that people breathe. Many emission standards focus on the variable pollutants released by automobile vehicles and from industry, small equipment such as forklifts, lawn moters generators, etc. 4.1.1. Motor vehicle emission standards The increasing of number of automobile vehicles on roads, the CO concentrations have reached an alarming level in metropolitan areas. To regulatory actions have been adopted to restrain the danger of automobile pollution [166,167]. There had been a much perceptible concern in the early 1980s on the adverse environmental impact of increased automobile traffic in developing countries like India. India has started adopting European emission norms and fuel regulations for four-wheeled light-duty and heavy-duty vehicles [127]. All vehicles produced after the exploit of norms have to be compliant with the regulations. At present, Bharat Stage IV (BS IV) parallel to Euro IV regulations since April 1st, 2010 is applicable for various types of vehicles; this is given in Table 5 for CO emissions Table 5 Emission norms in India parallel to EU emission standards. Norms European Year CO (g/Km) HC + NOx (g/Km) 1991Norms 1996 Norms 1998Norms India Stage 2000 norms Bharat Stage-II Bharat Stage-III Bharat Stage-IV Bharat Stage-V Bharat Stage-VI – – – Euro Euro Euro Euro Euro Euro – – – 2000 2001 2005 2010 2017 2020 14.3–27.1 8.68–12.40 4.34–6.20 2.72 2.2 2.3 1.0 0.63 0.50 2.0(Only HC) 3.00–4.36 1.50–2.18 0.97 0.5 0.35 0.18 0.10 0.07 1 2 3 4 5 6 615 S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 (REL) for CO (mostly for the workplace). EPA and WHO has recommended exposure of ambient air quality guideline values for CO at 9 ppm and 25 ppm as an 8 h and 1 h time-weighted avg. concentration respectively. The exhaust pollutants regulations of CO emissions from various countries is represented in Table 7. In the United States (US), the OSHA limits long-term exposure levels of CO has been less than 50 ppm averaged over an 8-hour period. [128]. India has recognized limits on CO exposures (at idle) for motorcycles, cars and innovative emission standards for gasolinefueled cars took effective in 1991. The automobile emissions are affected by driving pattern; overcrowding, temperature, traffic speed, vehicle’s engine conditions and emissions control equipment and its maintenance [129,130]. 4.1.2. Recommended exposure limits (REL) for CO The natural concentration of CO in air is around 0.9 ppm, and that amount is not harmful to humans. The higher amount of CO can occur in various settings, include those at home or at work. Average levels of CO in homes without gas stoves vary from 1 to 5 ppm [133]. CO concentrations indoors automobile vehicles are usually around 9–25 ppm and irregularly over 35 ppm. The peak exposures of CO over 200 ppm in the vehicle exhaust. People in certain occupations (e.g., car, bus and taxi drivers etc.) can have long-term CO exposure (Table 6). Acute as well as chronic exposure of CO has concern for potential effects [134,135]. Studies indicates that the auto mobile vehicle interior has the maximum level of CO concentration (averaging 10–29 mg/m3 (9–25 ppm)) of all environments [136]. There are several government organizations and professional organizations that have posted recommended exposure limits 5. Formation of CO in internal combustion (IC) engine The internal combustion (I.C.) engine is operating by the combustion of fossil fuels like petrol or diesel, both contain a mixture of hydro carbon (HC). When an I.C. engine gets a stoichiometric mixture of air and fuels (A:F = 14.7:1), it produces the smallest amount of pollutants. The CO is produced as an intermediate reaction during the partial combustion of HC. When the air–fuel (A/F) ratio was too low and there was not enough oxygen to convert all CO present in a fuel into the CO2. The CO concentration was raises as the A/F ratio decreases and its maximum when the automobile was an idled conditions [137]. The ratio of A/F acts as a significant role in the combustion process. There are different situation in the combustion chamber which prevents perfect combustion and also causes of unnecessary chemical reactions. There- Table 6 Exhaust Pollutants Regulations in India (g/Km). Vehicle Type CO CO2 NOX SOX HC PM Two wheelers Four wheelers (Petrol engine) Four wheelers (Diesel engine) Six wheelers (Petrol engine) Six wheelers (Diesel engine) 1.5 2.25 1.0 3.20 3.20 1.5 5 5 12 12 0.25 0.40 0.85 0.60 1.20 0.02 0.04 0.04 0.10 0.10 0.12 0.28 0.28 0.40 0.40 – – 0.10 – 0.18 Table 7 Exhaust pollutants regulations of CO emissions from various countries. Vehicle Type India (gm/Km) U.S. (gm/Km) Canada(gm/Km) China (gm/Km) Europe (gm/Km) Japan (gm/Km) Two wheelers Four wheelers (Petrol engine) Four wheelers (Diesel engine) Six wheelers (Petrol engine) Six wheelers (Diesel engine) 0.5 1.25 1.00 2.20 2.20 0.40 1.0 0.5 2.60 2.40 1.42 2.11 1.50 2.20 2.00 0.75 2.1 1.50 2.0 2.0 0.80 1.22 0.70 2.20 1.0 1.36 2.0 1.60 2.20 2.00 Fig. 12. Formation of CO in internal combustion engine. 616 S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 The reactions done on the automobile exhaust catalysts are extremely complex as listed below in Eqs. (8)–(10): 2NOx þ CO þ HC ! CO2 þ H2 O þ N2 ð8Þ 2CO þ O2 ! 2CO2 ð9Þ CX H2Xþ2 þ ½ð3x þ 1Þ=2O2 ! XCO2 þ ðX þ 1ÞH2 O Fig. 13. Catalytic Converter. fore the harmful exhaust gasses are emitted into the environment [169,170]. The excess HC can also be influenced by the amount of A/F mixture as it enters into the incineration chamber as shown in Fig. 12. If the A/F combination does not have sufficient oxygen present during the ignition, therefore it will be not burned completely [138]. When burning takes place in an oxygen starved environment (Fig. 13), there was inadequate oxygen present to convert completely CO into CO2. When carbon atom bonded only with one oxygen atom, therefore, CO was formed [171,172]. A composition of main primary pollutants from the engine exhaust, complex reactions in I.C. Engines: FuelðHCÞ þ AirðN2 þ O2 Þ ! CO2 þ H2 O þ N2 þ O2 þ CO þ HCðUnburnedÞ þ NOx þ PM ð7Þ The engine design modification, clean fuels, proper maintenance and post-combustion control device reduces the CO emissions from vehicles. The diesel combustion is heterogeneous in nature, but petrol combustion is homogeneous in nature [139]. The hydrocarbon (HC) pollutant also enters into the atmosphere through the fuel evaporation. The fuel evaporation is done from the fuel tank, carburetor and tailpipe of the vehicle. When the engine is at warm idle, therefore very little CO was produced. The reason behind this the presence of sufficient oxygen during the combustion process to fully oxidize all the carbon atoms [140,141]. 6. Control of CO emission by application of catalytic converter A catalytic converter is an automobile emissions control device that converts more contaminated pollutants present in the exhaust gasses to the lower poisonous pollutants by a catalyzing redox reaction. The basic reactions of HC and CO in the exhaust are oxidation (Table 8) with the certain products being CO2 and H2O, while the NOx reaction is a reduction with preferred products of N2 [142]. The major three pollutants (CO, HC and NOx) are concurrently impassive from the exhaust by a sole converter. These converters often function at 90% efficiency, almost removing the diesel odor and decreases the particulates (soot). During this period, since the temperature of tailpipe-gases is relatively low the conventional three-way catalysts illustrate especially low catalytic efficiency to convert all the harmful pollutants. The catalyst employs in a ceramic honeycomb structure or monolith apprehended in a converter apply for an exhaust stream [143]. Table 8 Typical exhaust gas Composition. Component Concentration Component Concentration CO CO2 HC NOX PM (Soot) SOX 100–1000 ppm 2–12 vol% 50–500 ppm 30–1000 ppm 20–200 mg/m3 2–7 ppm Ammonia Aldehydes Benzene Cyanides PAH Toluene 2.0 mg/mile 0.0 mg/mile 6.0 mg/mile 1.0 mg/mile 0.3 mg/mile 2.0 mg/mile ð10Þ At the time when the automobile vehicle initially starts up both the engine and catalyst are in cold conditions. After startup, the high temperature combustion reaction is move from the engine to the exhaust piping initiate to warm up. At last, a temperature is reached inside the catalyst that start the catalytic reactions [144]. The reaction temperature and kinetic reaction rate depends much upon the chemistry of catalyst. Although the catalytic converters are most frequently apply to the mining equipment, electrical generators, trucks, buses, locomotives, motorcycles, forklifts and airplanes [145]. 7. Catalysts for CO oxidation The catalytic conversion of CO at lower temperature has significant attention due to its values in human safety in mining, deep sea diving, space investigation, masks for fire fighters, CO sensors and in reducing the CO build-up in CO2 lasers [130–132]. The CO oxidation also applications in industrial processes such as water–gas shift reaction and production of methanol. The capacity to convert CO at ambient temperatures is an important in many applications [50–52]. At lower temperature the CO conversion was difficult to sustain due to the strong adsorption and self-poisoning (which preferentially accumulates CO on the surface) versus surface oxidation kinetics which removes CO from the surface [146–148]. Commercially available CO oxidation catalysts fall into three categories. 1. Noble metal catalyst 2. Transition metal catalyst 3. Mixed metal oxide catalyst The activity, selectivity and stability of catalyst are a fundamental step for improving the combustion reaction process between the catalyst and reaction gasses. The base metals (Cu, Mn, Co, Cr, Ni, Fe etc.), noble metals (Pt, Pd, Rh, Au etc.) and metal oxide (Cu2O, CeO2, ZnO, ZrO2, TiO2 etc.) are broadly used as a catalyst in the catalytic converter [140–143]. The platinum group metal catalysts have a huge activity and thermal stability. The effectiveness of catalytic converter is also depending upon the temperature [145–147]. 7.1. Noble metal catalysts The noble metals are most commonly considered to be (Pt, Rh, Ru, Ag, Pd, Ir and Au) and utilize of this element in vehicle as a catalytic converter. In the noble metal catalyst, the Rh was used as a reduction catalyst, Pd was used as an oxidation catalyst and Pt is use for both the reduction and oxidation catalyst. Gold (Au) is shows good performances for low-temperature CO oxidation, if isolated on suitable metal oxides and composite oxides [145– 148]. Au supported on reducible oxides is known to catalyze the CO oxidations efficiently at very low temperatures (even below 0 °C). The Pt/SnO2 and Pd/SnO2 catalysts are widely used for ambient temperature oxidation of CO [149]. The catalytic performance of PtOx, PdOx, RhOx and RuOx is strongly influenced by the oxygen coordination around their surfaces. The oxidized noble-metal catalyst (Fig. 14) has been indeed more active than the completely reduced particles. The disadvantage of noble metal catalyst is a S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 Fig. 14. Noble metal catalysts. high-cost and lower availability. Silver (Ag) is an outstanding catalyst for different catalytic reactions for a long time. The activity of silver based catalysts strongly depends on the surface structure and active sites. The performances of AgO catalyst is often regarded as a result of the incidence of various Ag-O interactions [150–154]. Out of noble metal catalysts, the Pd is mostly used and changing the Rh and Pt metals. The noble metal catalysts are moisture tolerant but generally require a temperature above 100 °C for better operation. The Pt/Pd/SnO2 catalysts need a high priced metal loadings therefore it was extremely costly materials to be used in this application [151–152]. 7.2. Base metal catalysts The base metal catalysts are very active for catalytic reactions. The base metal oxides like (Co3O4, CuO and MnO2) have a large catalytic activity per unit surface area for CO oxidation. The low price and high performance of supported base metal oxide catalysts may have high perspective to find its appliance to the catalytic reaction [153]. The different supported base metal oxide catalysts used for CO oxidation is as follows Co3O4, Cu2O, Fe2O3, MnO, NiO, Cr2O3 and V2O5, etc and represented in Fig. 15. The cobalt-based catalysts have been found to be mostly active for CO conversion and highly susceptible to the presence of moisture. It has outstanding thermal resistance [155–158]. In comparison to Co3O4, the CuO/Cu2O have been found rarely use in CO conversion. This is necessary the distinctive structure of cobalt oxide, which contains both Co2+ and Co3+, whereas CuO or Cu2O have only either Cu2+ or Cu+ ions. The CuO is not very steady; the oxidation state of Cu may differ in path of the reaction, CO/O2 ratio and temperature [153]. The outstanding behavior of Cu2O in CO oxidation at ambient temperature has studied the kinetics of O2 chemisorptions over the same cuprous oxide. The MnOx (MnO2 or Mn2O3) nano-particles are willingly to synthesized by self-assembly in a one-pot reaction under ambient conditions for conversion of CO to CO2 at low temperatures [150–152]. The iron (Fe) based catalyst main advantage is that it has a long life-time, therefore, it could resist more poisoning from CO2. Presence of Fe2+ or Fe3+ ion has been identified as one of the key factors governing the structure and texture property of Fe based products. Iron was frequently used as the active metal in the catalyst for industrial scale due to their lower cost [154]. The high activities of nickel (Ni) were correlated to the existence of both intra and inter-particle porosity of the catalysts and this lead to high Ni dispersion on the catalyst surfaces. Nickel is a cheap, active and suitable catalyst to be produced economically. Nickel oxide has a bimodal pore structure, which entails high activity for CO oxidation [155]. Chromium (Cr) also belongs to the group of refractory metals, which includes all metals with a higher melting point than platinum (1772 °C). The reducibility of chromium (III) oxide, Cr2O3 is highly application in CO oxidation [156]. Fig. 15. Base metal oxide catalysts. 617 Fig. 16. Catalysts for CO oxidation. 7.3. Groups of catalysts for CO oxidation In the exhaust gases, CO proves the most perilous so that more attention has been paying on catalytic control of CO emissions (Fig. 16) from vehicles exhaust. A wide variety of catalysts used in a catalytic converter, which initiates the oxidation of CO such as pyrochlores, spinel, hopcalite and monel based catalyst, etc. The success of catalyst is highly depends upon the role played by each element and nature of active sites. 7.3.1. Hopcalite In 1920 Bray, Lamb and Frazer discovered that various oxides mixture of Cu and Mn, recognized as a group of catalysts known as a hopcalite (CuMnOx). Jones and Taylor confirm the catalytic activity of such a arrangement called hopcalite in the year 1923. It can well catalyze the oxidation of dry CO even at room temperature [15–18]. In recent times, the ambient temperature CO oxidation has seen a revival in its importance to the catalytic community. The addition of Co, Au, Ce and Ag improves the catalytic activity of hopcalite catalyst. A lot of interest has been given to the adaptation of CuMnOx catalyst to remove its faults of moisture deactivation and lower activity [156,157]. The preparation of catalysts by other methods including anti-solvent precipitation method, sol–gel method is reported to give better CO conversion than commercial hopcalite [158]. The morphological, structural and catalytic activity of hopcalite catalyst is also depending upon the synthesis methods. The recent work shows that the addition of gold into the hopcalite catalyst not only improved its activity but also prevents the deactivation of catalyst [159,160]. 7.3.2. Perovskites Many perovskite catalysts are shows good catalytic active for CO oxidation at ambient temperature. The general formula of perovskites is ABO3; typically the A elements are rare earth alkaline (Ce, La, Pr etc.), alkaline earth metals (Ca, Cs, Sr, Ba etc.) and the B sites are usually occupied by transition metals (Fe, Co, Cu, Mn, Ni and Cr). The main benefit of perovskites lies in the fact that they can possess the higher activity and stability compared to pure oxides [161]. There are many problems related to perovskite-based catalyst such as thermal stability, catalytic activity and deactivation of catalyst by the potential poisons of sulfur and lead in the fuel. Very few numbers of perovskite was until reported, which was active for CO oxidations at the ambient conditions [162]. 7.3.3. Spinel The spinels are natural resources minerals and formulation 2 A2+B3+ 2 O4 which crystallize in the cubic (isometric) crystal system. The A and B can be divalent, trivalent cations, including Mn, Zn or Fe, Mg, Al, Cr, Ti and Si. Spinels are transition metal oxide catalysts. The aluminum and ferric based spinels are homogeneous due to their great size difference. The NiFe2O4 spinel catalyst obtained by combustion reaction method and preferential for CO oxidation. The spinel catalysts are highly active for CO oxidation at high temperature [163,164]. 618 S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 7.3.4. Monel Monel is a nickel-copper mixture catalyst and used for controlling the emissions of CO, HC and NOx from vehicle exhaust. The composition of monel catalyst which usually contains 31.5% by weight of copper, 66.5% by weight of nickel and 2% by weight of impurities. It has a low cost, short life and less durable catalyst [165]. These compounds prepared from mixed oxides after calcination treatment and unique properties like high surface area, porosity and good thermal stability. 7.4. Preparation of catalysts The structure of catalyst is highly affected by the synthesis methods. The various methods have been applied for the synthesis of catalyst. The property of heterogeneous catalyst was also depending upon the synthesis conditions. There are three fundamental stages of catalyst preparation may be illustrious: I. Synthesis of primary solid (or first precursor solid) associate all the valuable components (e.g., impregnation or coprecipitation or amorphous, crystallization). II. Processing of that primary solid to get the catalyst precursor, for Ex. by heat treatment. III. Activation of the precursor to provide the active catalyst and activation may take place instinctively at the beginning of the catalytic reaction (selective oxidation catalyst). The effect of preparation conditions including metal ions concentration, ageing time, pH, drying temperature and calcination temperature is highly effective on the catalytic activity of the catalyst. The various parameters which highly effected on the activity of resulting catalyst, it includes calcination temperature, reduction temperature and reduction time, etc [167,168]. The calcination temperature has a strong influence on the chemical composition and physicochemical properties of the resulting catalyst. The using of different supports in the catalyst for improved their performance in CO oxidation reactions [172–174]. The promoters are the substances that increase the activity of catalyst; they are creating the ideal conditions of the catalyst and even enhance the life of catalyst by saving them from poison [172]. There are several methods used for the preparation of catalysts and each methods effect on the activity of resulting catalyst for CO oxidation was as follows: 7.4.1. Co-precipitation method The co-precipitation is one of the simplest and most commonly used methods for the synthesis of catalyst. The synthesis of catalyst by co-precipitation of soluble salts of the constitute metals in a right solvent then co-precipitated by the addition of an acid/base or another reagent to cause the precipitation [10,11]. The precipitation of catalyst has three main stages: Super saturation, nucleation and growth. After ageing, filtration, washing thoroughly with deionizer water rather than the precipitate solution was obtained in an amorphous phase or crystalline phase. Then after further steps followed it: drying, calcination and activation [2,28]. These precursors can be voluntarily improved into the catalyst by thermal treatment. The different characterization techniques confirm that the coprecipitation method created minor crystalline and more surface area than the other methods. In the co-precipitation method the phase association contains two main elements, if one of them contained an anion and following one contained cation, the precipitate would have a fixed or smallest amount very nonflexible composition [29,30]. There are many procedures use for the coprecipitation processes; one of the easy processes is that adding drop-wise to the solution containing the active component to the precipitate solutions. This is the easiest method to synthesized the catalysts based on more than one component. The bulk catalysts as well as support catalysts are prepared by this method [32,38]. 7.4.2. Sol-gel method The sol–gel method is a method for creating the solid materials from small molecules. The catalyst also prepare by a sol–gel method is as follows: the reagents (acetate and nitrate salts of preferred oxides) initially dissolve in deionizer water in stochiometric amount [35]. A known amount of completing agents dissolve in deionizer water was added over the solution as a ligand. The solution was maintained pH to (7.5–8.0) with acid, stirring and heating to a temperature of 60–80 °C for 4 h, then after the syrup was obtained heated to 100 °C for 24 h in air, followed by calcination at 400 °C for 2 h or 500 °C for 2 h [179]. 7.4.3. Impregnation method The impregnation was associated to an ion exchange or adsorption processes, and applied in contact of solid with fluid components to be deposited on the catalyst surfaces. Throughout impregnation, several different processes have done at different rates. The individual adsorption species by coulomb force; ion exchange between the electrolyte and charged surface; incomplete suspension on the surface of solid [180]. The type of product is depending on the nature of reactants (solid and liquid surfaces) and reaction conditions. The major parameters affecting the liquids are pH and concentrations of dissolved substances. It is one of the simplest methods of preparing supported catalysts [181]. 7.4.4. Reactive grinding method The reactive grinding is an important preliminary procedure and sometime used for the production of particular catalysts. In fine particles, this is a assortment of particles of very small size (typically 0.5 mm–l mm), the particles may have diverse shapes influences the catalytic operation strongly. The grinding operations producing particles of smaller size than after forming the operation pores of desired sizes. It is use with the materials of natural origin or with the products of action category [97]. This is a unique and valuable process to make a catalyst. The fused mass is crush into unequal lumps and sieved to the appropriate size. The powder obtained after reactive grinding, it has a broad particle size distribution [182]. 7.4.5. Hydrothermal method The hydrothermal method is considering the modification of precipitates and gels produce by the temperature under ageing in the presence of water. The hydrothermal transformations usually occur within the liquid phases. The variable of operations for a specified solid are pH, temperature, time, pressure and concentration [183]. In other instance, the hydrothermal transformations done by the unit operations such as precipitation, washing, drying and extrusion [8–12]. 7.4.6. Pyrolysis method Pyrolysis is a thermo chemical disintegration of organic materials at high temperature in the lack of oxygen. It concerned with the instantaneous modify of chemical composition and physical phase are irreversible. Pyrolysis is a type of thermolysis and usually observed in organic materials expose to higher temperatures [99]. The flame spray pyrolysis use to create a broad range of pure nano powders ranging from unique metal oxides to extra complex mixed oxides. It is a one-step process in which a liquid feed – a metal precursor dissolved in a solvent – is spray with an oxidizing gas into a flare zone [183,184]. S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 619 Fig. 17. Metal promoted catalyst. 7.5. Metals promoted on catalysts The addition of noble metals or base metals by a Coprecipitation method into the catalyst has been considered for low temperature CO oxidation. The addition of promoters into the catalyst, it will raise the amount of active sites presence on the catalyst surface; therefore, the performance of catalyst for CO oxidation has been increases [47]. The metal oxides and supported noble metal oxides are active for several deep oxidation reactions. The mechanism for CO oxidation over noble metal promoted catalysts (Fig. 17) may be different from the other metal oxide catalysts [48]. The noble metal oxide catalysts may follow either a LangmuirHinshelwood type of mechanism or an Eley-Rideal mechanism. On silver (Ag), the oxygen chemisorptions are relatively very strong, with a transmit of electrons to the oxygen taking place and on Pd, however, oxygen adsorption was comparatively weak [50– 53]. On Pt show that the oxidation done more rapidly in the air than in pure oxygen due to the development of moderately stable species in extremely oxidizing environments [68]. The precious metals are also able of reducing under atmospheric conditions to some extent. The addition (doping) of Co, Ce, Fe, Zn, Ni and other substituted metals into the catalyst has enhanced their activity for CO oxidation. The synergy effects are arises, the contact of promoters with catalyst being the binary catalyst, which was more active than each component [20]. 7.6. Mechanism and kinetics study of catalyst The performance of catalyst for CO oxidation was measured by the activation energy of the process. These data are desirable for modeling and design of catalytic converter. It is significant to improves the kinetic expressions for catalytic conversion of CO also because they can be applied into computational fluid dynamics (CFD) models useful for optimization and reactor design [143– 148]. The catalyst initially oxidized CO before it’s oxidized by air, and this is an investigation of a Mars van Krevelen-type mechanism, which has consequently found support [175–178]. The conversion of CO by the Marsvan Krevelen mechanism would shows the relationship between the catalyst activity and reducibility. In the first step of reaction, the CO and O2 adsorb into the catalyst surface. Then after, the adsorbed O2 molecules separate into the individual O atoms. The CO molecules and O atoms are initiate to disperse on the metal surface, when a CO molecule and O atom combine each other, they recombine and form CO2. In the last step, CO2 desorbs into the gas phase. Under reaction conditions, the rate was proportional to the O2 pressure and independent of CO pressure [150–154]. The dissociation of oxygen molecules followed by the reaction between adsorbed O2 atom and CO to form CO2 is individual one of the usual mechanisms for CO oxidation. In this condition, the reaction rate was restricted by the dissociation of O2. The molecular adsorption of CO occurs at the upper temperatures, which shows that the presence of reactive oxygen forms. The O ions are more reactive and reactivity of superoxide is also high, though much lower as compared to O. In oxygen species, the CO molecules from gas phase can be directly oxidized. The rate of reaction (Eqs. (11)–(13)) will be proportional to the surface coverage of Oads and COads [172–175]. O2 þ 2 ! 2Oads ð11Þ CO þ ! COads ð12Þ COads þ Oads ! CO2 þ 2 ð13Þ Fig. 18. Mechanism of CO chemisorptions over catalysts. 620 S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 Fig. 19. Adsorption of CO and dissociation of O2 over Pd catalysts. In the oxidation state, CO was oxidized by surface lattice oxygen in the metal oxide. An oxygen vacancy was created, reducing the metal ions to a poorer oxidation state. In the next step, the surface metal atoms are oxidized by gas-phase oxygen. The process of CO oxidation does not take place as long as the adsorbed molecules of O2 transform to the reactive form of oxygen. The rate of CO oxidation (Fig. 18) was measured by following either the rate of production of CO2 or, when the CO was captured and rate of removing of CO. The reaction rate was compacted when CO was added into the gas phase during the oxidation. The amount of CO2 molecules adsorbed corresponded exactly to the amount of oxygen atoms (Fig. 19) pre-adsorbed on the catalyst surfaces. The equivalent concentration of oxygen atoms in the gas phase over the surface, therefore, the heterogeneous reaction was taking places [160–165]. The inconsistent oxygen stoichiometry of transitional metal structure was responsible for the unusual performance of these palladium catalysts. For non-reducible supports, such as SiO2, TiO2 and Al2O3, the catalytic performance is much more dependent on the metal diffusion; in fact, the oxygen adsorption occurs only on the metal sites [150–154]. The Langmuir-Hinshelwood model has been applied to illustrate the CO oxidation mechanism taking place on the metal catalysts. In the Langmuir-Hinshelwood model, the CO oxidation done on the surface in the following steps are involved: COðgÞ ! COads ð14Þ O2 ðgÞ ! 2Oads ð15Þ COads þ Oads ! CO2 ðgÞ ð16Þ The CO oxidation over an unsupported catalysts proceeds according to a Langmuir–Hinshelwood mechanism, in which the certain steps take place in the adsorbed phase. Both reactants are adsorbed. The interface of metal oxide and support is certain interest since metal can act as a good promoter to transition metal oxides for CO oxidation reaction [157–160]. The kinetic data are taken by the steady-state reaction conditions at a low conversion of CO. Monometallic catalysts fast surface oxidation in ambient air, so that the CO chemisorptions experiments was done after in situ reduction, with oxygen being excluded [162–165]. 7.7. Use of catalysts at cold start emission conditions Catalysts operating efficiently at the ambient conditions are a different class of materials, in application as different as the cold start of engines to inside air quality. The 60%–80% of CO and HCs emissions from automobile occurs during this ‘‘cold-start” period. In the cold start period, the catalytic converter is entirely inactive, because the catalytic converter has not warmed up. The cold start phase is also depending upon the characteristics of vehicles [31]. The entire amount of fuel required for a cold start of the engine is a function of ambient air, engine design and coolant temperatures. The catalytic converter is uses in an automobile vehicle are capable to reach the reductions of CO, HCs and NOx up to 95% when they are completely warmed up [40]. The cold start emissions can be subdivided into two parts: the first was much more emissions due to the initiation of engine and second was over emissions during the warm-up procedure of the engine and catalyst. The amount of catalyst was required to entrap the toxic pollutants throughout the cold-start period is usually much less than that needed in catalytic converters so that added volume of catalyst in a adsorbed devices is comparatively low [173]. 8. Conclusions Carbon monoxide is one of the most poisoning gas present in the atmosphere. The main contribution of CO in the air is transportation section therefore catalytic converter has been invented. Catalytic oxidation has been widely studied for two main reasons first CO is a toxic gas which should be removed from the exhaust gases exist in mobile and stationary sources second CO oxidation is a simple reaction mostly used for evaluating the catalytic activity of new materials. The improvement of catalytic converters with noble metals led to an extremely high number of publications on metal catalysts. The activity of catalyst is strongly dependent on the reaction conditions (CO/O2 ratio, presence of steam or other impurities in the gas). The oxide catalysts show much more adaptable than metal catalysts for CO oxidation reaction. This review over CO oxidation at ambient conditions will be useful to researchers who are interested in a more comprehensive overview. There is an ever present need to develop new, effective CO oxidation catalyst composition working at ambient conditions with improved processes. Declaration of Competing Interest None. References [1] Air quality criteria for carbon monoxide. Washington, DC. US Environmental Protection Agency, Final Report, 2000. [2] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, Effect of preparation conditions on the catalytic activity of CuMnOx catalysts for CO Oxidation, Bull. Chem. React. Eng. Catal. 12 (3) (2017) 1–15. S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 [3] S. Singh, R. Prasad, Physico-chemical analysis and study of different parameters of hopcalite catalyst for CO oxidation at ambient temperature, Int. J. Sci. Eng. Res. 7 (4) (2016) 846–855. [4] Université de Bourgogne, France. Proceedings Satellite Meeting IUTOX VIIIth International Congress of Toxicology. Carbon monoxide: the unnoticed poison of the 21st Century, 1998. [5] G.M. Kumar, S. Sampath, V.S. Jeena, R. Anjali, Carbon monoxide pollution levels at environmentally different sites, J. Indian Geophys. Union 12 (1) (2008) 31–40. [6] Air Quality Criterion for Carbon Monoxide, U.S. Dept. of Health Education and 1360 Welfare, Washington D.C. 6-22, 1970. [7] O. Badr, S.D. Probert, Carbon monoxide concentration in the earth’s atmosphere, Appl. Energy 49 (1994) 99–143. [8] X. Guo, J. Li, R. Zhou, Catalytic performance of manganese doped CuO-CeO2 catalysts for selective oxidation of CO in hydrogen-rich gas, J. Fuel 20 (2016) 56–64. [9] W. Rudolf, Concentration of air pollutants inside cars driving on highways and in downtown areas, Sci. Total Environ. 146 (147) (1994) 433–444. [10] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, Low-temperature complete oxidation of CO over various manganese oxide catalysts, Atmos. Pollut. Res. 9 (2018) 755–763. [11] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, The choice of precursors in the synthesizing of CuMnOx catalysts for maximizing CO oxidation, Int. J. Ind. Chem. 9 (2018) 199–214. [12] J.A. Hoskins, Carbon monoxide: the unnoticed poison of the 21st century, Indoor Build. Environ. 8 (1999) 154–155. [13] T.J. Clarke, T.E. Davies, S.A. Kondrat, S.H. Taylor, Mechanochemical synthesis of copper manganese oxide for the ambient temperature oxidation of carbon monoxide, Appl. Catal. B 165 (2015) 222–231. [14] J.J. Rose, L. Wang, Q. Xu, C.F. McTiernan, S. Shiva, J. Tejero, M.T. Gladwin, Carbon monoxide poisoning: pathogenesis, management, and future directions of therapy, Concise Clin. Rev. 195 (5) (2017) 596–606. [15] L.S. Puckhaber, H. Cheung, D.L. Cocke, A. Clearfield, Reactivity of copper manganese oxides, Solid State Ionics 32 (1989) 206–213. [16] J.A. Raub, M. Mathieu-Nolf, N.B. Hampson, S.R. Thom, Carbon monoxide poisoning – a public health perspective, J. Toxicol. 145 (2000) 1–14. [17] G.C. Dhal, S. Dey, R. Prasad, D. Mohan, Simultaneous abatement of diesel soot and NOX emissions by effective catalysts at low temperature: an overview, Cat. Rev. – Sci. Eng. 60 (3) (2018) 437–496. [18] J. Sharaf, Exhaust emissions and its control technology for an internal combustion engine, Int. J. Eng. Res. Appl. 3 (2013) 947–960. [19] M. Votsmeier, T. Kreuzer, G. Lepperhoff, Automobile Exhaust Control, WileyVCH Verlag GmbH & Co KGaA, Weinheim, 2005. [20] J.B. Heywood, Internal combustion engine fundamentals. McGraw-Hill Series in Mechanical Engineering ISBN 007028637X, 1988. [21] India Bharat Stage VI emission standards, Policy Update, International Council of Clean Transportation, 2016. [22] EPA, Air Act, US. Summary of the Clean Air Act. www.epa.gov. Retrieved 2015-12-22. [23] The California Low-emission vehicles regulations (With Amendments Effective), 2010. [24] A. Faiz, S.C. Weaver, M.P. Walsh, Air Pollution from Motor Vehicles (Standards and Technologies for Controlling Emissions), The World Bank, Washington, D. C., 1996. [25] Martino, Wakim, Welstand. Comparison of HC and CO emissions estimates using FTP, IM240, and remote sensing. in: Paper presented at the 4th CRC OnRoad Vehicle Emissions Workshop, March 16–18 1994, San Diego, California, 1994. [26] H.M. Richards, D.T. MacDougal, The influence of carbon monoxide and other gases upon plants, Bull. Torrey Bot. Club 31 (1904) 57–66. [27] L. Cai, Y. Guo, A. Lu, P. Branton, W. Li, The choice of precipitant and precursor in the co-precipitation synthesis of copper manganese oxide for maximizing carbon monoxide oxidation, J. Mol. Catal. A: Chem. 360 (2012) 35–41. [28] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, R.N. Gupta, Cobalt doped CuMnOx catalysts for the preferential oxidation of carbon monoxide, Appl. Surf. Sci. 441 (2018) 303–316. [29] S. Dey, G.C. Dhal, R. Prasad, D. Mohan, Effects of doping on the performance of CuMnOx catalyst for CO oxidation, Bull. Chem. React. Eng. Catal. 12 (3) (2017) 1–14. [30] G.R. Chhatwal, M.C. Mehra, M. Sataka, T. Katyal, M. Katyal, T. Nagahiro, In Environmental air Pollution and its Control, Anmol Publications, New Delhi, 1975. [31] J. Gao, C. Jia, L. Zhang, H. Wang, Y. Yang, S. Hung, Y. Hsu, B. Liu, Tuning chemical bonding of MnO2 through transition-metal doping for enhanced CO oxidation, J. Catal. 341 (2016) 82–90. [32] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, Study of Hopcalite (CuMnOx) catalysts prepared through a novel route for the oxidation of carbon monoxide at low temperature, Bull. Chem. React. Eng. Catal. 12 (3) (2017) 393–407. [33] G.Y. Wang, W.X. Zhang, H.L. Lian, D.Z. Jiang, T.H. Wu, Effect of calcination temperatures and precipitant on the catalytic performance of Au/ZnO catalysts for CO oxidation at ambient temperature and in humid circumstances, Appl. Catal. A 239 (2003) 1–10. [34] K. George, S. Sugunan, Catalytic oxidation of cyclohexane over Cu-Zn-Cr ternery spinel system, React. Kinet. Catal. Lett. 94 (2) (2008) 252–260. 621 [35] C. Jones, K.J. Cole, S.H. Taylor, M.J. Crudace, G.J. Hutchings, Copper manganese oxide catalysts for ambient temperature carbon monoxide oxidation: effect of calcination on activity, J. Mol. Catal. A: Chem. 305 (2009) 121–124. [36] C. Jones, S.H. Taylor, A. Burrows, M.J. Crudace, C.J. Kielyb, G.J. Hutchings, Cobalt promoted copper manganese oxide catalysts for ambient temperature carbon monoxide oxidation, Chem. Commun. 1707 (2008) 1–7. [37] M.C. Raphulu, Catalytic Oxidation of Carbon Monoxide and Methane with gold Based Catalysts Ph.D. Thesis, the faculty of Science, University of the Witwatersrand, Johannesburg, 2004. [38] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, Synthesis and characterization of AgCoO2 catalyst for oxidation of CO at a low temperature, Polyhedron 155 (2018) 102–113. [39] D. Portehault, S. Cassaignon, N. Nassif, E. Baudrin, J. Jolivet, A core–corona hierarchical manganese oxide and its formation by an aqueous soft chemistry mechanism, Angew. Chem. 47 (2008) 6441–6444. [40] P. Singh, R. Prasad, Catalytic abatement of cold-start vehicular CO emissions, Catal. Ind. 6 (2) (2014) 122–127. [41] E.C. Njagi, H.C. Genuino, C.K. Kingondu, C. Chen, D. Horvath, S.L. Suib, Preferential oxidation of CO in H2 rich feeds over mesoporous copper manganese oxide synthesized by a redox method, Int. J. Hydrogen Energy 36 (2011) 6768–6779. [42] P. Brijesh, S. Sreedhara, Exhaust emissions and its control methods in compression ignition engines: a review, Int. J. Automot. Technol. 14 (2) (2013) 195–206. [43] M.R. Feaviour, E.M. Schofield, Scientific bases for the preparation of heterogeneous catalysts, Platin. Met. Rev. 51 (2007) 42–44. [44] M. Jin, J. Park, J.K. Shon, J.H. Kim, Z. Li, Y. Park, J.M. Kim, Low temperature CO oxidation over Pd catalysts supported on highly ordered mesoporous metal oxides, Catal. Today 185 (2012) 183–190. [45] S.D. Gardner, G.B. Hoflund, Catalytic behavior of noble metal/reducible oxide comparison of catalyst performance materials for low-temperature CO oxidation, Comparison of catalyst performance, ACS Langmuir 91 (1991) 2135–2140. [46] R. Rani, R. Prasad, Studies of carbon monoxide oxidation at ambient conditions, Recent Res. Sci. Technol. 6 (2014) 89–92. [47] B. Weinstock, H. Niki, Carbon monoxide balance in nature, Science 176 (4032) (1972) 290–292. [48] M. Rivera, J.C. Rodriguez, The dual role of Heme as cofactor and substrate in the biosynthesis of carbon monoxide, Metal Ions Life Sci. 6 (2009) 241–283. [49] A. Sigel, R.K.O. Sigel, Metal-carbon bonds in enzymes and cofactors, RSC Metal Ions Life Sci. 11 (2009) 243–252. [50] K. Mopper, X. Zhou, R.J. Kieber, D.J. Kieber, R.J. Sikorski, R.D. Jones, Photochemical degradation of dissolved organic carbon and its impact on the oceanic carbon cycle, Nature 353 (1991) 60–62. [51] R.D. Jones, J.A. Amador, Methane and carbon monoxide production, oxidation, and turnover times in the Caribbean sea as influenced by the Orinoco river, J. Geophys. Res. 98 (1993) 2353–2359. [52] J.W. Swinnerton, R.A. Lamontagne, V.J. Linnenbom, Carbon monoxide in rain water, Science 172 (1971) 943–945. [53] I. Iablokov, Manganese and cobalt oxides as highly active catalysts for CO oxidation, Ph.D. Thesis, Universite Libre de Bruxelles Faculte Des Sciences, Chimie Physique des Matériaux (Catalyse – Tribologie) (2011). [54] J.J. Spivey, Complete catalytic oxidation of volatile organics, Ind. Eng. Chem. Res. 26 (1987) 2165–2180. [55] I.M. Madany, Carboxyhemoglobin levels in blood donors in Bahrain, Sci. Total Environ. 116 (1992) 53–58. [56] P.D. Berk, T.F. Blaschke, B.F. Scharschmidt, J.G. Waggoner, N.I. Berlin, A new approach to quantitation of the various sources of bilirubin in man, J. Lab. Clin. Med. 87 (1976) 767–780. [57] S.A. Landaw, E.W. Callahan Jr, R. Schmid, Catabolism of heme in vivo: comparison of the simultaneous production of bilirubin and carbon monoxide, J. Clin. Invest. 49 (1970) 914–925. [58] D.L. Solanki, P.R. McCurdy, F.F. Cuttitta, G.P. Schechter, Hemolysis in sickle cell disease as measured by endogenous carbon monoxide production: a preliminary report, Am. Soc. Clin. Pathol. 89 (1988) 221–225. [59] S.R. Lynch, A.L. Moede, Variation in the rate of endogenous carbon monoxide production in normal human beings, J. Lab. Clin. Med. 79 (1972) 85–95. [60] G. Kolata, Carbon monoxide gas is used by brain cells as a neurotransmitter. New York Times Article. (Accessed July 12, 2012). [61] R.N. Colvile, E.J. Hutchinson, J.S. Mindell, R.F. Warren, The transport sector as a source of air pollution, Atmos. Environ. 35 (9) (2001) 1537–1565. [62] Y.C. Yao, J.H. Tsai, H.F. Ye, Comparison of exhaust emissions resulting from cold and hot-start motorcycle driving modes, J. Air Waste Manage. Assoc. 59 (2009) 1339–1346. [63] Air quality criteria for carbon monoxide, Book, United states, Environment Protection Agency, Office of research and development agency, Washington, 2000. [64] G.S. Cholakov, Catalytic converters and other emissions control devices, Pollut. Control Technol. III (1999). [65] P. Katara, Review paper on catalytic converter for automobile exhaust emission, Int. J. Sci. Res. (IJSR) 5 (2015) 30–33. [66] S. Alfuso, M. Aurlemma, G. Police, M.V. Prati, The effect of methyl-ester of rapeseed oil on combustion and emissions of Di-diesel engines. in: SAE Paper 932801. SAE International, Warrendale, Pennsylvania, 1993. [67] Clean Air Act Overview. Clean Air Act Text (https://www.epa.gov/clean-airact-overview/clean-air-act-text), 1990. 622 S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 [68] W.W. Pulkrabek, Engineering Fundamentals of the Internal Combustion Engine, Pearson Prentice Hall, New Jersey, 2004. [69] J. Stewart, Z.A. Ren, subzonal indoor airflow, temperature and contaminant dispersion model, Build. Environ. 41 (2006) 1631–1648. [70] J. Aguila, N. Chan, J. Courtis, Proposed Regulations for California Phase 2 Reformulated Gasoline Technical Support Document, California Air Resources Board, Sacramento, California, 1991. [71] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, Copper based mixed oxide catalysts (CuMnCe, CuMnCo and CuCeZr) for the oxidation of CO at low temperature, Mater. Discov. 10 (2017) 1–14. [72] J. Zhang, K.R. Smith, R. Uma, Y. Ma, V.V.N. Kishore, K. Lata, M.A.K. Khalil, R.A. Rasmussen, S.T. Thorneloe, Carbon monoxide from cookstoves in developing countries: 2. Exposure potentials, Chemosphere: Global Change Sci. 1 (1999) 367–375. [73] K.R. Smith, Fuel combustion, air pollution exposure and health: the situation in developing countries, Annu. Rev. Energy Environ. 18 (1999) 529–566. [74] I. Billick, Review of health effects literature for sub-acute carbon monoxide exposure and health effects. Environmental Health & Engineering, Natural Gas Codes and Standards Research Consortium, 2008. [75] S.T. Omaye, Metabolic modulation of carbon monoxide toxicity, Toxicology 180 (2) (2002) 139–150. [76] S. Saksena, R. Prasad, R.C. Pal, V. Joshi, Patterns of daily exposure to TSP and CO in the Garhwal Himalaya, Atmos. Environ. 26A (1992) 2125–2134. [77] H.F. Reid, K.R. Smith, B. Sherchand, Indoor smoke exposures from traditional and improved cookstoves: comparisons among rural Nepali Women, Mountain Resour. Dev. 6 (1986) 293–304. [78] J.B. Kandpal, R.C. Maheshwari, T.C. Kandpal, Comparison of CO, NO2 and HCHO emissions from biomass combustion in traditional and improved cookstoves, Energy 19 (2004) 1151–1155. [79] S.S. Rangaraj, D. Sarojini, Catalysts for the Oxidation of Carbon Monoxide in Cigarette Smoke, Philip Morris International, 2007, EP1765098. [80] Q. Zhang, L. Li, M. Smith, Y. Guo, G. Whitlock, Z. Bian, O. Kurmi, R. Collins, J. Chen, S. Lv, Z. Pang, C. Chen, N. Chen, Y. Xiong, R. Peto, Z. Chen, Exhaled carbon monoxide and its associations with smoking, indoor household air pollution and chronic respiratory diseases among 512 000 Chinese adults, Int. J. Epidemiol. 42 (5) (2013) 1464–1475. [81] D.J. Moschandreas, S.M. Relwani, H.J. O’Neill, J.T. Cole, R.H. Elkins, R.A. Macriss, Characterization of Emission Rates from Indoor Combustion Sources, Gas Research Institute, Chicago, Illinois, 1985, Report No. GRI 85/0075, available from NTIS, Springfield, Virginia, USA. [82] M.S. Pearce, L. Hayes, Self-reported smoking status and exhaled carbon monoxide: results from two population-based epidemiologic studies in the North of England, Chest 128 (2005) 1233–1238. [83] A. McGowan, S. Hamilton, D. Barnett, M. Nsofor, J. Proudfoot, D.M. Tappin, Breathe: the stop smoking service for pregnant women in Glasgow, Midwifery 26 (2010) 1–13. [84] B. Chen, C. Hong, H. Kan, Exposures and health outcomes from outdoor air pollutants in China, Toxicology 198 (2004) 291–300. [85] D. Vellore, Chapter 7-Air Pollutant Hazards. in: Fundamentals of Air Pollution, fifth ed., 2014, pp. 197–214. [86] P.G. Flachsbart, Long-term trends in United States highway emissions, ambient concentrations, and in-vehicle exposure to carbon monoxide in traffic, J. Expo. Anal. Environ. Epidemiol. 5 (1995) 473–495. [87] Air quality criteria for carbon monoxide. Washington, DC. US Environmental Protection Agency, Office of Research and Development, 1991 (publication no. EPA-600/B-90/045F). [88] C.M. Amin, P.P. Rathod, J.J. Goswami, Copper based catalytic converter, Int. J. Eng. Res. Technol. 1 (2012) 1–6. [89] Automobile and carbon monoxide, U.S. Environmental protection agency office mobile sources. EPA400-F-92-005. [90] W.B. Xue, J.N. Wang, H. Niu, J.T. Yang, B.P. Han, Y. Lei, H.L. Chen, C.L. Jiang, Assessment of air quality improvement effect under the national total emission control program during the twelfth national five-year plan in China, Atmos. Environ. 68 (2013) 74–81. [91] I. Esau, I. Repina, Wind climate in Kongsfjorden, Svalbard, and attribution of leading wind driving mechanisms through turbulence-resolving simulations, Adv. Meteorol. 22 (2012) 1–16. [92] I.N. Esau, T. Wolf, E.A. Miller, I.A. Repina, The analysis of results of remote sensing monitoring of the temperature profile in lower atmosphere in Bergen (Norway), Russia Meteorol. Hydrol. 38 (10) (2013) 715–722. [93] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, Characterization and activity of CuMnOx/c-Al2O3 catalyst for oxidation of carbon monoxide, Mater. Discover 8 (2017) 26–34. [94] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, Effect of various metal oxides phases present in CuMnOx catalyst for selective CO oxidation, Mater. Discover 12 (2018) 3–71. [95] C.R. Henry, D. Satran, B. Lindgren, C. Adkinson, C.I. Nicholson, T.D. Henry, Myocardial injury and long-term mortality following moderate to severe carbon monoxide poisoning, J. Am. Med. Assoc. 295 (4) (2006) 398–402. [96] U.S. Environmental Protection Agency, EPA 600/P-99/001F, Office of Research 1475 and Development, Washington, D.C., 2000. [97] Q. Liu, C. Liu, X. Nie, L. Bai, S. Wen, Facile synthesis of mesoporous Co3O4 via a soft reactive grinding route and their application in the CO oxidation, Mater. Lett. 72 (2012) 101–103. [98] K.J. Cole, A.F. Carley, M.J. Crudace, M. Clarke, S.H. Taylor, G.J. Hutchings, Copper manganese oxide catalysts modified by gold deposition: the influence [99] [100] [101] [102] [103] [104] [105] [106] [107] [108] [109] [110] [111] [112] [113] [114] [115] [116] [117] [118] [119] [120] [121] [122] [123] [124] [125] [126] [127] [128] on activity for ambient temperature carbon monoxide oxidation, Catal. Lett. 138 (2010) 143–147. G. Fortunato, H.R. Oswald, A. Reller, Spinel-type oxide catalysts for low temperature CO oxidation generated by use of an ultrasonic aerosol pyrolysis process, J. Mater. Chem. 11 (2000) 905–911. S.S. Yoon, S.C. Macdonald, R.G. Parrish, Deaths from unintentional carbon monoxide poisoning and potential for prevention with carbon monoxide detectors, JAMA 279 (1998) 685–687. E.P. Radford, T.A. Drizd, Blood carbon monoxide levels in persons 3-74 years of age: United States, 1976-80. Hyattsville, MD: U.S. department of health and human services, Public Health Service, National Center for Health Statistics; publication no. (PHS) 82-1250, 1982. N.B. Hampson, Trends in the incidence of carbon monoxide poisoning in the United States, Am. J. Emerg. Med. 23 (2005) 838–841. B.W. Jasper, R.O. Hopkins, H.V. Duker, L.K. Weaver, Affective outcome following carbon monoxide poisoning: a prospective, longitudinal study, Cognit. Behav. Neurol. 18 (2005) 127–134. M.T. Salam, J. Millstein, Y.F. Li, F.W. Lurmann, H.G. Margolis, F.D. Gilliland, Birth outcomes and prenatal exposure to ozone, carbon monoxide, and particulate matter: results from the Children’s Health Study, Environ. Health Prospect. 113 (2005) 1638–1644. M. Wilhelm, B. Ritz, Local variations in CO and particulate air pollution and adverse birth outcomes in Los Angeles County, California, USA, Environ. Health. Prospect. 113 (2005) 1212–1221. Use of carbon monoxide alarms to prevent poisonings during a power outage—North Carolina, December 2002. MMWR Morb Mortal Wkly Rep 53 (09), 189–192, 2005. J.M. Graber, A.E. Smith, Results from a state-based surveillance system for carbon monoxide poisoning, Public Health Rep. 122 (2) (2007) 145–154. B. Croxford, G.S. Leonardi, I. Kreis, Self-reported neurological symptoms in relation to CO emissions due to problem gas appliance installations in London: a cross-sectional survey, Environ. Health: Global Access Sci. Source 7 (34) (2008) 129–136. G. Volans, B. Armstrong, B. Croxford, Neuropsychological effects of chronic exposure to carbon monoxide in the indoor air. Final Report, Department of Health, 2006. P. Walsh, Domestic carbon monoxide alarms. Long-term reliability and use scoping study. Health & Safety Executive Research Report RR847, Health and Safety Laboratory for the Health and Safety Executive, 2011. M. Basarab, G.S. Leonardi, R. Ruggles, Carbon monoxide: elements of environmental public health surveillance, Health Protect. Agency Chem. Hazard Rep. 13 (2008). R. Close, M. Studden, G. Leonardi, J. Meara, Carbon monoxide poisoning in private dwellings (outcome tracking), Health Prot. Agency Environ. Public Health Tracking Newslett. 1 (2010). D. Boehning, C. Moon, S. Sharma, K.J. Hurt, L.D. Hester, G.V. Ronnett, Carbon monoxide neurotransmission activated by CK2 phosphorylation of heme oxygenase-2, Neuron 40 (2003) 129–137. Z.Y. Cao, W. Xuan, Z.Y. Liu, X.N. Li, N. Zhao, P. Xu, Carbon monoxide promotes lateral root formation in rapeseed, J. Integr. Plant Biol. 49 (2007) 1070–1079. J. Dulak, A. Józkowicz, Carbon monoxide: a ‘‘new” gaseous modulator of gene expression, Acta Biochim. Pollut. 50 (2003) 31–48. P. Fagone, K. Mangano, S. Mammana, E. Cavalli, R.D. Marco, M.L. Barcellona, Carbon monoxide-releasing molecule-A1 (CORM-A1) improves clinical signs of experimental autoimmune uveoretinitis (EAU) in rats, Clin. Immunol. 157 (2015) 198–204. K. Guo, W.W. Kong, Z.M. Yang, Carbon monoxide promotes root hair development in tomato, Plant Cell Environ. 32 (2009) 1033–1045. K. Guo, K. Xia, Z.M. Yang, Regulation of tomato lateral root development by carbon monoxide and involvement in auxin and nitric oxide, J. Exp. Bot. 59 (2008) 3443–3452. Y. Han, W. Xuan, T. Yu, W.B. Fang, T.L. Lou, Y. Gao, Exogenous hematin alleviates mercury-induced oxidative damage in the roots of Medicago sativa, J. Integr. Plant Biol. 49 (2007) 1703–1713. B.K. Huang, S. Xu, W. Xuan, M. Li, Z.Y. Cao, K.L. Liu, Carbon monoxide alleviates salt-induced oxidative damage in wheat seedling leaves, J. Integr. Plant Biol. 48 (2006) 249–254. Z. Hu, Y. Utiskul, J.G. Quintiere, A. Trouve, Towards large eddy simulations of flame extinction and carbon monoxide emission in compartment fires, Proc. Combust. Inst. 31 (2007) 2537–2545. J. Lubchenko, Entering the century of the environment: a new social contract for science, Science 279 (1998) 491–497. K. Taylor, Rapid climate change, Am. Sci. 87 (1999) 320–327. T. Sivasakthivel, S.K. Reddy, Ozone layer depletion and its effects: a review, Int. J. Environ. Sci. Dev. 2 (1) (2011) 30–38. J.K. Angell, The variations in global total ozone and north temperate layer mean ozone, J. Appl. Meteorol. 27 (1) (2007) 91–97. D.H. Stedman, Atomic chlorine and the chlorine monoxide radical in the stratosphere: three in situ observations, Science 198 (1981) 21–34. M. Dastoorpoor, E. Idani, N. Khanjani, G. Goudarzi, A. Bahrampour, Relationship between air pollution, weather, traffic, and traffic-related mortality, Trauma Monthly 21 (4) (2016) 1–7. F. Palmgren, R. Berkowicz, A. Ziv, O. Hertel, Actual car fleet emissions estimated from urban air quality measurements and street pollution models, Sci. Total Environ. 235 (1–3) (1999) 101–109. S. Dey, G.C. Dhal / Materials Science for Energy Technologies 2 (2019) 607–623 [129] K.S. Nesamani, Estimation of automobile emissions and control strategies in India, Sci. Total Environ. 408 (8) (2010) 1800–1811. [130] C. Johansson, M. Norman, L. Burman, Road traffic emission factors for heavy metals, Atmos. Environ. 43 (31) (2009) 4681–4688. [131] R. Smit, L. Ntziachristos, P. Boulter, Validation of road vehicle and traffic emission models—a review and meta-analysis, Atmos. Environ. 44 (25) (2010) 2943–2953. [132] R. Dallmann, T.W. Kirchstetter, S.J. DeMartini, R.A. Harley, Quantifying onroad emissions from gasoline-powered motor vehicles: accounting for the presence of medium- and heavy-duty diesel trucks, Environ. Sci. Technol. 47 (23) (2013) 13873–13881. [133] B.G. Wang, Y.H. Zhang, C.J. Zhu, K.H. Yu, L.Y. Chen, Z.Y. Chen, A study on city motor vehicle emission factors by tunnel test, Environ. Sci. 22 (2) (2001) 55–59. [134] K.F. Ho, S.C. Lee, W.K. Ho, Vehicular emission of volatile organic compounds (VOCs) from a tunnel study in Hong Kong, Atmos. Chem. Phys. 9 (19) (2009) 7491–7504. [135] Low emission vehicle programmed. California Air Resource Board, 2017. [136] A.F.A. Shuhaili, S.I. Ihsan, W. Faris, Air pollution study of vehicles emission in high volume traffic: Selangor, Malaysia as a case study, WSEAS Trans. Syst. 2 (12) (2013) 67–83. [137] P.K. Gupta, L.M. Das, R. Gulati, Performance evaluation of a hydrogen-fuelled spark ignition engine using electronically controlled solenoid actuated injection system, Int. J. Hydrogen Energy 25 (2000) 569–579. [138] L.D. Prockop, R.I. Chichkova, Carbon monoxide intoxication: an updated review, J. Neurol. Sci. 262 (1–2) (2007) 122–130. [139] A. Russell, W.S. Epling, Diesel oxidation catalysts, Catal. Rev. Sci. Eng. 53 (2011) 337–423. [140] M.V. Twigg, Catalytic control of emissions from cars, Catal. Today 163 (1) (2011) 33–41. [141] M.V. Twigg, P.R. Phillips, Cleaning the air we breathe – controlling diesel particulate emissions from passenger cars, Platin. Met. Rev. 53 (1) (2009) 27–34. [142] R. Heck, R. Farrauto, Automobile exhaust catalysts, Appl. Catal. A 221 (2001) 443–457. [143] A. Bera, M.S. Hegde, Recent advances in auto exhaust catalysis, J. Indian Inst. Sci. 90 (2) (2010) 299–325. [144] M.N. Rao, H.V.N. Rao, Air Pollution Chapter 2, Tata McGraw-Hill Publishing Company Limited, New Delhi, 1989, pp. 4–12. [145] R. Burch, J.P. Breen, F.C. Meunier, A review of the selective reduction of NOx with hydrocarbons under lean-burn conditions with non-zeolitic oxide and platinum group metal catalysts, Appl. Catal. B 39 (2002) 283–303. [146] W.M. Hoskins, W.C. Bray, The catalytic oxidation of carbon monoxide. II. The adsorption of carbon dioxide, carbon monoxide and oxygen by the catalysts, manganese dioxide, cupric oxide and mixtures of these oxides, J. Am. Chem. Soc. 48 (1926) 1454–1474. [147] J.A. Almquist, W.C. Bray, The catalytic oxidation of carbon monoxide, J. Am. Chem. Soc. 45 (1923) 2305–2322. [148] H.D. Draper, The catalytic oxidation of carbon monoxide. IV. The pore volume of the catalysts manganese dioxide, copper oxide, copper oxide and mixtures of these oxides, J. Am. Chem. Soc. 50 (1928) 2637–2653. [149] S. Chauhan, Noble metal catalysts for monolithic converters, J. Chem. Pharm. Res. 4 (2010) 602–611. [150] M.D. Argyle, C.H. Bartholomew, Heterogeneous catalyst deactivation and regeneration: a review, Catalysts 5 (2015) 145–269. [151] G. Dong, J. Wang, Y. Gao, S. Chen, A novel catalyst for CO oxidation at low temperature, Catal. Lett. 58 (1999) 37–41. [152] M. Date, M. Okumura, S. Tsubota, M. Haruta, Vital Role of moisture in the catalytic activity of supported gold nanoparticles, Angew. Chem. Int. Ed. 43 (2004) 2129–2134. [153] D.P. Dissanayake, Applications of metal oxides for volatile organic compound combustion Chapter 17 Metal Oxides Chem. Appl. (2006) 543–568. [154] Y. Wang, B.H. Davis, Fischer-Tropsch Synthesis: conversion of alcohols over iron oxide and iron carbide catalysts, Appl. Catal. A 180 (1) (1999) 277–285. [155] A. Marinoiu, E. Carcadea, M. Raceanu, C. Cobzaru, M. Varlam, Carbon dioxide conversion to methane over nickel base catalyst, Adv. Environ. Agric. Sci. 127–134 (2015). [156] S. Royer, D. Duprez, Catalytic oxidation of carbon monoxide over transition metal oxides, ChemCatChem 3 (2011) 24–65. [157] E.C. Njagi, C. Chen, H. Genuino, H. Galindo, H. Huang, S.L. Suib, Total oxidation of CO at ambient temperature using copper manganese oxide catalysts prepared by a redox method, Appl. Catal. A 99 (2010) 103–110. [158] C.D. Jones, The Ambient Temperature Oxidation of Carbon Monoxide by Copper-Manganese Oxide Based Catalysts Ph.D. Thesis, Cardiff Catalysis Institute, Cardiff University, UK, 2006. [159] S. Dey, G.C. Dhal, R. Prasad, D. Mohan, The effect of doping on the catalytic activity of CuMnOx catalyst for CO Oxidation, IOSR J. Environ. Sci. Toxicol. Food Technol. 10 (11) (2016) 86–94. 623 [160] A. Elmhamdi, L. Pascual, K. Nahdi, A. Martínez-Arias, Structure/redox/activity relationships in CeO2/CuMn2O4 CO-PROX catalysts, Appl. Catal. B 217 (2017) 1–11. [161] H. Einaga, Y. Nasu, M. Oda, H. Saito, Catalytic performances of perovskite oxides for CO oxidation under microwave irradiation, Chem. Eng. J. 283 (2016) 97–104. [162] F. Patel, S. Patel, La1-XSrXCoO3 (x = 0, 0.2) perovskites type catalyst for carbon monoxide emission control from auto-exhaust, Procedia Eng. 51 (2013) 324– 329. [163] L. Shi, Z. Hu, G. Deng, W. Li, Carbon monoxide oxidation on copper manganese oxides prepared by selective etching with ammonia, Chin. J. Catal. 36 (2015) 1920–1927. [164] L. Pan, L. Li, X. Bao, Y. Chen, Highly photocatalytic activity for p-nitrophenol degradation with spinel-structured CuCr2O4, Micro Nano Lett. 7 (5) (2012) 415–418. [165] J. Arana, P.R. Piscina, J. Llorca, J. Sales, N. Homs, Bimetallic silica-supported catalysts based on Ni-Sn, Pd-Sn and Pt-Sn as materials in the CO oxidation reaction, Chem. Mater. 10 (1998) 1333–1342. [166] S.J. Korf, H.J.A. Koopmans, B.C. Lippens, A.J. Burggraaf, P.J. Gellings, Electrical and catalytic properties of some oxides with the fluorite or pyrochlore structure. CO oxidation on some compounds derived from Gd2Zr2O7, Journal of Chemical Society, Faraday Trans. 83 (1987) 1485–1491. [167] P. Li, F. Yu, N. Altaf, M. Zhu, J. Li, B. Dai, Q. Wang, Two-dimensional layered double hydroxides for reactions of methanation and methane reforming in C1 chemistry, Materials 11 (221) (2018) 1–27. [168] G. Martínez-Lozano, M. Hesiquio-Garduño, B. Zeifert, J. Salmone, Structural and microstructural characterization of Co-hydrotalcite-like compounds by X-ray diffraction, J. Alloy. Compd. 434–435 (2007) 816–819. [169] M. Gabrovska, R. Edreva-Kardjieva, K. Tenchev, P. Tzvetkov, A. Spojakina, L. Petrov, Effect of Co-content on the structure and activity of Co–Al hydrotalcite-like materials as catalyst precursors for CO oxidation, Appl. Catal. A 399 (2011) 242–251. [170] J. Wang, M. Feng, H. Zhang, X. Xu, Catalytic decomposition of N2O over Mg-Fe mixed oxides, J. Fuel Chem. Technol. 42 (12) (2014) 1464–1469. [171] B.F.F. Benjamin, P. Alphonse, Co-Mn-oxide spinel catalysts for CO and propane oxidation at mild temperature, Appl. Catal. B 180 (2016) 715–724. [172] J. Lee, H. Kim, H. Lee, S. Jang, J.H. Chang, Highly efficient elimination of carbon monoxide with binary copper-manganese oxide contained ordered nanoporous silicas, Nanoscale Res. Lett. 11 (2016) 2–6. [173] J. Favez, M. Weilenmann, J. Stilli, Cold start extra emissions as a function of engine stop time: evolution over the last 10 years, Atmos. Environ. 43 (2009) 996–1007. [174] Y.H. Yap, M.S.W. Lim, Z.Y. Lee, K.C. Lai, M.A. Jamaal, F.H. Wong, H.K. Ng, S.S. Lim, T.J. Tiong, Effects of sonication on co-precipitation synthesis and activity of copper manganese oxide catalyst to remove methane and sulphur dioxide gases, Ultrason. Sonochem. 40 (2018) 57–67. [175] J. Papavasiliou, G. Avgouropoulos, T. Ioannides, Steam reforming of methanol over copper–manganese spinel oxide catalysts, Catal. Commun. 6 (2005) 497–501. [176] S.H. Libardi, L.H. Skibsted, D.R. Cardoso, Oxidation of carbon monoxide by perferrylmyoglobin, J. Agric. Food. Chem. 62 (8) (2014) 1950–1955. [177] S. Dey, G.C. Dhal, D. Mohan, R. Prasad, Kinetics of catalytic oxidation of carbon monoxide over CuMnAgOx Catalyst, Mater. Discover 8 (2017) 18–25. [178] L.A. Petrovy, Y. Alhameda, A. Al-Zahranim, M. Daous, Role of chemical kinetics in the heterogeneous catalysis studies, Chin. J. Catal. 32 (6–8) (2011) 1085–1112. [179] M. Kramer, T. Schmidt, K. Stowe, W.F. Maier, Structural and catalytic aspects of sol–gel derived copper manganese oxides as low-temperature CO oxidation catalyst, Appl. Catal. A 302 (2006) 257–263. [180] F. Severino, J.L. Brito, J. Laine, J.L.G. Fierro, A.L. Agudo, Nature of copper active sites in the carbon monoxide oxidation on CuAl2O4 and CuCr2O4 spinel type catalysts, J. Catal. 177 (1998) 82–95. [181] B. Solsona, G.J. Hutchings, T. Garcia, S.H. Taylor, Improvement of the catalytic performance of CuMnOx catalysts for CO oxidation by the addition of Au, New J. Chem. 28 (2004) 708–711. [182] S. Dey, G.C. Dhal, R. Prasad, D. Mohan, Ambient temperature complete oxidation of carbon monoxide using hopcalite catalysts for fire escape mask applications, Adv. Compos. Hybrid Mater. (2019), https://doi.org/10.1007/ s42114-019-00108-5, 1-19. [183] Z. Fuzhen, G. Miao, Z. Guangying, L. Jinlin, Effect of the loading content of CuO on the activity and structure of CuO/Ce-Mn-O catalysts for CO oxidation, J. Rare Earths 330 (2015) 604–610. [184] J. Nisar, M. Ali, I.A. Awan, Catalytic thermal decomposition of polyethylene by pyrolysis gas chromatography, J. Chil. Chem. Soc. 56 (2011) 653–654.