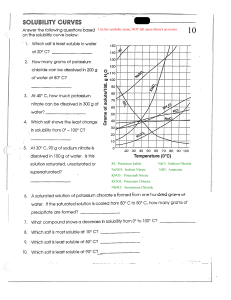

PROCESS 2 PRODUCTION OF POTASSIUM NITRATE FROM NITRIC ACID AND POTASSIUM CHLORIDE INTRODUCTION Potassium Nitrate is a transparent, white or colorless, crystalline (sand-like) powder or solid with a sharp, salty taste. It is used to make explosives, matches, fertilizer, fireworks, glass and rocket fuel. It mixes well with other materials simplifying processing of granular and nongranular fertilizer and it tends to reduce the hygroscopicity of mixtures, and thus favors maintenance of good mechanical condition. It has a low salt index and therefore reduces danger of seeding injury and plant burn. There are three primary plant nutrients, nitrogen (N), phosphate (P2O5) and potash (K2O). Plants need all three of these to grow properly. Numerous other elements are also needed in lesser amounts for satisfactory plant growth. However, the primary nutrients are depleted from almost all soils by continuous cropping. Then for satisfactory crop growth these nutrients must be replaced with naturally occurring or chemically produced fertilizer materials. Approximately 93% of the K2O applied as fertilizer in this country is applied as potassium chloride (KCl). With the exception of specialized crops, one potash fertilizer is as effective as any other as a source of potash for the plant. Tobacco is one example of a crop sensitive to chlorides; quantities of K20 in excess of 30 to 40 lb/acre as chloride are harmful to the tobacco burning quality. An alternate source of potassium is needed for tobacco and other chloride sensitive crops. Two forms of K2O are immediately brought to mind, potassium sulfate (K2SO4) and potassium nitrate (KNO3). Potassium sulfate is used to a limited extent while KNO3 has hardly been used at all. The purpose of this investigation was to develop a KNO3 process. Early in the work it was decided that KCl and nitric acid (HNO3) would be the reactants and that the most desirable co-product would be elemental chlorine (CI2). Initially the KCl was reacted directly with HNO3 on a batch basis. However, the solid product contained too much KCl. Published solubility curves for KCl and KNO3 in water indicated that a fractional crystallization process for KNO3 might be possible and a study of the mutual solubility of KNO3 and KCl in aqueous HNO3 solutions tended to confirm this possibility. Following the solubility study a continuous fractional crystallization process for KNO3 was investigated using glass equipment. REACTION MECHANISM Reaction between Potassium Chloride and Nitric Acid 3KCl + 4HNO3 = 3KNO3 + Cl2 + NOCl + 2H2O RAW MATERIALS Potassium Chloride Potassium chloride, also known as KCl or potassium salt, is a metal halide salt composed of potassium and chlorine. It is odourless and has a white or colourless vitreous crystal appearance. The majority of the potassium chloride produced is used for making fertilizer, called potash, since the growth of many plants is limited by potassium availability. The two main types of potash are: Muriate of Potash (MOP, Potassium Chloride) and Sulphate of Potash (SOP, Potassium Sulphate). Nitric Acid Nitric acid is a highly corrosive mineral acid. It is widely used for the production of fertilizers, such as ammonium nitrate, and some polymers. It is a powerful oxidizing agent, and reacts violently with many non-metallic compounds. By far the principal use of nitric acid (80%) is in the manufacture of fertilizers. Of this 96% is used to make ammonium nitrate and calcium ammonium nitrate. A relatively small amount of ammonium nitrate is used to make explosives. PROCESS FLOW DIAGRAM FOR THE PRODUCTION OF POTASSIUM NITRATE FROM POTASSIUM CHLORIDE AND NITRIC ACID PROCESS DESCRIPTION The process uses KCl and 60% HNO3 as the starting materials and the intended coproduct is Cl2 and NOCl. From information in the literature it was decided to react the KCl directly with HNO3 in a continuous stirred-tank reactor. The reactor operates at an absolute pressure of 349 mmHg and at a temperature of 90°C. The steam flow rate to the reactor jacket should be controlled in order to maintain the temperature and thereby the concentration constant. The liquid draw from the reactor should be controlled in order to maintain the liquid level. The gas flow rate to the gas treatment plant should be controlled in such a manner as to maintain the reactor pressure constant. The gas evolved from the reactor was Cl2 and NOCl. Solid residue was found to contain some excess chloride ions. And the liquid product is a mixture of KCl and KNO3 in HNO3 solutions. The gas withdraw from the reactor will now enter in a packed column, 2 1/2 in. o.d. by 18 in. long and packed 1 with 1/2 in., between the reactor and the reflux condenser. This column was added to the equipment to reduce the acid loss to the condensate from the final condenser. The solubility of KCl, is 27.5% or 0.275 gm/gm of solution at 30° C. This is greater than any of the values which would be experienced upon cooling to 30° C. Therefore, no KCl would be crystallized from any of these solutions when they were cooled to 30° C. Also a study of the solubility of KNO3 in solutions of 0.304 gm HNO3 per gm H2O with controlled amounts of KC1 was carried out at 30° C. These studies showed that the KNO3 solubility in such solutions changed markedly with temperature while the KCl solubility did not change very much over the range of temperature studied. The gas withdraw from the packed scrub column entered into a condenser and cooled it at a temperature of 0° C. The water is withdrawn from the condenser and enter into a condenser tank. The condenser will contain two products: the one with impurities and water without impurities. The purified water will sent back to the packed-column to maintain the temperature in the column. The gas withdrawn by the packed scrub column will contain NOCl and Cl2 gas that will undergo to a gas treatment plant. The liquid withdraw from the reactor was pumped into a crystallizer operating at 30° C. The crystallizer product is a mixture of KCl and KNO3 in HNO3 solutions. And will pumped into a centrifuge machine and was added by a wash water. Two products were withdrawn from the centrifuge: the mother liquor (the wet KCl) and the wet KNO3. The wet KNO3 will be subjected to drying to evaporate all the water in KNO3. And the mother liquor will be returned to the reactor. To demonstrate the final process, equipment was set up to continuously react KCl and HNO3, withdraw liquid from the reactor, and pumped into a crystallizer, then subject to centrifugation to separate KCl and KNO3 and continuously remove the gaseous products. This procedure produced solid KNO3 which contained no solid KCl. The mother liquor is returned to the reactor. The reaction was found to proceed more rapidly as the temperature or the concentration of the reactants was increased. I. SUSTAINABILITY Availability of Raw Materials Potassium Chloride Growth of the potassium chloride market is gaining traction by the surge in demand for potash fertilizers owing to its properties which supports the improvement in flavors, color, and texture to crops used as food. Additionally, the fertilizers industry is witnessing positive growth owing to higher demand from the developed and developing countries which are focusing on the improvement in agricultural sectors. The countries such as India and China are fuelling adoption of fertilizers and which is likely to boost the growth of the global potassium chloride market. The worldwide market for Potassium Chloride is expected to grow at a CAGR of roughly 0.8% over the next five years, will reach 13200 million US$ in 2024, from 12600 million US$ in 2019, according to a new Research Report. In Philippines, the supply of potassium nitrate is increasing as shown in the table. Nitric Acid Nitric acid market is majorly driven by fertilizer industry. The global nitric acid market is expected to reach USD 23.31 billion by 2025, owing to its high consumption in fertilizer production. The nitric acid market is expected to increase at a 2.0% CAGR during the forecast period. In Asia, the top main supplier of this chemical is China and India. Out of the total demand for nitric acid in Asia-Pacific, China held more than 60% of the total revenue share in 2017. Abundant availability of precursors and high presence of downstream industries are driving the product demand in the country. Moreover, the Indian nitric acid industry is also expected to witness a rapid boost attributed to the increasing growth of fertilizers and chemical manufacturing industries in the country. And in the Philippines, there are many companies that supply this type of chemical; 1. Labsmoni SSD Solution, 2. Nextlube, 3. Jadis Enterprise 4. TNC Chemicals Philippines 5. Emerald Chemicals Incorporated 6. Neco Philippines Incorporated. When in comes to the supply of nitric acid in the Philippines, there’s no need to import this chemical from other countries because the supply is still increasing every year. Cost of Raw Materials The following table shows the estimated prices of each raw material that will be used for the production of potassium nitrate from nitric acid and potassium chloride. Costs are based on the available quotations of standard weights (ton) of the raw materials. Table 2.1 Cost of Raw Materials (source: alibaba.com) Raw Material Price per ton (Php) Potassium Chloride 30,591.00 Nitric Acid 15,295.50 TOTAL 45,886.50 II. MANUFACTURABILTY Table 2.1 Equipment that will be utilized for the Production of Potassium Nitrate from Nitric Acid and Potassium Chloride 1 2 3 4 EQUIPMENT Continuous Stirred-Tank Reactor Packed Scrub Column Condenser Condensate Tank 5 6 7 Crystallizer Centrifuge Dryer Process Usage in the Industry The corrosive nature of aqua regia is well known. Very similar conditions will occur in a reactor built to react KCl with HNO3 and corrosion difficulties may develop throughout a plant built to produce KNO3. Many corrosion problems are inherent in Solvay Process Company's sodium nitrate process. A study of possible materials of construction is necessary. A corrosion study to find materials of construction suitable for the various pieces of equipment is recommended. A proper study is important especially the material of construction of the equipment because nitric acid and potassium chloride is highly reactive with each other. III. SAFETY Toxicological Rating Toxicity level of raw materials was analysed based on the corresponding health hazards that it may cause to humans. The basis for attaining the level of toxicity was in Table 2.2 which elaborates the health hazards of the raw materials. The basis is obtained from the Material Safety Data Sheet of each raw material used in the process. Health hazard rating from Table 2.33 was used to evaluate the level of toxicity of raw materials. Table 2.2 Basis for attaining Toxicity of Raw Materials Raw Materials Criteria The severity of Immediate Effects Sensitization Level Potassium Chloride Nitric Acid Skin and eye contact may cause mild irritation. No data available. Skin and eye contact may cause irritation. Carcinogenicity Level Not classified as carcinogen. Reproductive Toxicity Level No data available. The severity of Chronic Effects No data available No data available. No substance in this material has been considered carcinogen. No data available. Extremely corrosive and destructive to tissues. Table 2.3 Health Hazard Rating Level 0 1 2 3 4 Health Hazard Rating For minimal hazard or no significant risk for health For slight hazard or minor reversible injury possible For moderate hazard, a temporary or minor inquiry may occur For serious hazard, a major inquiry likely unless prompt action is taken and medical treatment is given For severe hazard, life-threatening, major or permanent damage may result from single or repeated exposures Table 2.4 Toxicity Rating of Raw Materials Criteria The severity of Immediate Effects Sensitization Level Carcinogenicity Level Reproduce Toxicity Level The severity of Chronic Effects Weighted Score Average TOTAL Raw Materials Levels of Importance Potassium Chloride Nitric Acid 3 1 1 3 0 0 5 0 0 4 0 0 5 0 2 3 13 0.15 0.65 0.8 IV. ENVIRONMENTAL ASPECT Environmental hazard level of raw materials was analysed based on the corresponding hazards that it may cause to the environment. The basis for attaining the level of environmental hazards was in Table 2.5 which is explained in details. The basis is obtained from the Material Safety Data Sheet of each raw material used in the process. Environmental hazard rating from Table 2.6 was used to evaluate the raw materials. Table 2.5 Basis for attaining Environmental hazard level of Raw Materials Criteria Aquatic Toxicity Raw Materials Potassium Chloride Nitric Acid Toxic to some aquatic May be harmful to aquatic organisms due to shift of pH. invertebrates. Toxicity on Plants and Animals Toxicity of Immediate Degradation Long-term Degradation Effects No data available. No data available. No data available. No data available. No data available. No data available. Table 2.6 Environmental Hazard Rating Level 0 1 2 3 4 Environmental Hazard Rating For minimal hazard or no significant risk to environment For slight hazard or minor reversible damage possible For moderate hazard, a temporary or minor damage may occur For serious hazard, a major damage to environment unless prompt action is taken For severe hazard, major or permanent damage may result Table 2.7 Environmental Rating of Raw Materials Criteria Aquatic Toxicity Toxicity on Plants and Animals Toxicity of Immediate Degradation Long-term Degradation Effects Subtotal Average TOTAL Level of Importance 3 3 4 5 15 Raw Materials Potassium Chloride Nitric Acid 1 1 0 0 0 0 0 0 3 3 0.2 0.2 0.4 REFERENCES Joshi, Chirag S.; Shukla, Krunel Patel; Joshi, Jigar S.; “Environmentally and Economically Feasibility Manufacturing Process of Potassium Nitrate for Small Scale Industries: A Review” (2014). Gabrielson, James Earl; “Potassium nitrate form nitric acid and potassium chloride” (1964). Retrospective Theses and Dissertations. 2664 https://lib.dr.iastate.edu/rtd/2664