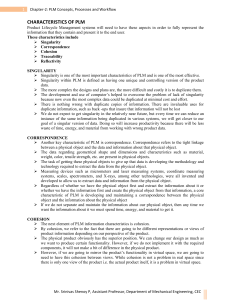

Position: STSI Mechanical Engineer (0-5 years) Essential Responsibilities and Duties: • • • • • • • • • • • • Responsible for mechanical design of components and assemblies for surface or downhole products, as part of Sustaining or New Product Development team Develop and review manufacturable drawings in accordance with standard modelling and detailing practices using 3D modelling software like Creo/Solidworks and use PLM platforms like Windchill to manage the Product Lifecyle process Carry out detailed engineering calculations Define testing procedures and coordinate with others to perform tests; document test results Conduct and/or participate in technical design reviews Plan, coordinate and manage professional engineering work; this may involve modifying proven approaches, devise new techniques with continuous improvement approach Make presentations effectively to technical and management audiences Contribute to design standards and support design re-use (best practices, lessons learnt, design books, standard work instructions, etc.) Author/co-author technical specification documents, reports, papers, articles, patents and presentations Share expertise and expand the informal network throughout the organization: field, research, engineering, manufacturing, other domains and clients Comply with applicable company policies, including Personnel, Quality System and Health, Safety & Environment standards and procedures Successfully complete required safety training (including but not limited to drugs and alcohol, electrical, emergency response, fire, first aid, health and hygiene, PPE, SIPP, risk reporting, IT security, hazardous materials, driving) Required Skills / Qualifications • • • • • Recognized Bachelor or Master’s degree in Mechanical / Production Engineering Previous knowledge of 3D CAD software and/or PLM/PDM software. Experience in Creo and Windchill would be advantageous Strong oral and written communication skills Demonstrated Problem Solving and Critical Thinking skills Strong engineering fundamentals in the areas of strength of materials, manufacturing techniques and engineering drawing The Following Would Also Be Very Highly Regarded • • • • • • • Background in performing FEA and reviewing FEA results Exposure to Manufacturing environment and prior knowledge of DFM and DFA principles Proficiency in using MathCAD / MATLAB / Microsoft Excel along with Visual Basic Coding Sound knowledge of Geometric Dimensioning and Tolerancing Conversant with ASME, ISO and API standards Demonstrated ability to think independently and make decisions using engineering judgment Demonstrated ability to work in cross-functional teams and deliver collaborative projects Schlumberger-Private