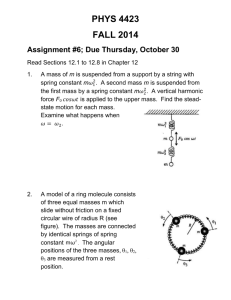

ME124 Mechanical Engineering Laboratory III Experiment 3: Rotational Pendulum: Parameter Identification and Dynamic Responses Text Adapted from ECP Systems Handbook. Purpose: To allow you to formulate experiments to determine the dynamic behavior of a second order one or two degrees of freedom systems. Experiments will be performed with the Model 205 apparatus, from ECP Systems (Figures 1-3). This open-ended laboratory allows you transfer what you learned in the linear system experiments to a rotational system You will need to formulate an experimental protocol using the new system to determine the system parameters and achieve a desired output. Masses can be fixed on two of four radii on disks. The spring connecting the disks is a small thin cylinder of metal. The software control is exactly the same as for the linear system. Unlike the other laboratories in this class, you need to present a Methods section describing the steps that you performed and why. Warning: The device can move suddenly, if it becomes unstable. This can occur at anytime. Be aware of the area near the drive pulley and disks, where hands and fingers could get pinched. Test for stability as requested to during the experiments. Also Important: The torsional spring shaft may be permanently damaged or broken by any excessive angular deflection (twisting). Take extra caution during all handling of the mechanism to never cause more than 0.3 radians (20 degrees, 900 encoder counts) rotation between any two adjacent disks. The angular positions of the disk may be read from the Encoder Position fields on the Background Screen. Figure 1: Configuration (Model 205a shown) Figure 2: Possible Experimental Configurations (Model 205a shown) Secure masses by tightening screw. Loosen and slide to relocate. Concentric rings @ r = 2.0 to 9.0 cm in 1 cm intervals to assist in mass c.g. measurement. (Measure to edge of 5.00 cm dia mass) All masses must be concentrically located (within ± 1 mm) prior to operation. Disk Mass 500 ± 1 gr (incl bolt & nut) Disk Plate Flat side of square nut must face upward Hub Split Line If only two masses are used, they must be located along the hub split line. Each disk may have four, two or zero masses only. One or three masses will imbalance disk. Figure 3: Guidelines For Changing Or Adjusting Disk Masses Experimental procedure: 1) Determine for the first two disks: the polar moment of inertia of the disks, the elastic modulus of the torsional bar material and any damping in the motor or bearings. 2) Determine for a one degree-of-freedom system, the damping coefficients that achieve critical, under- and overdamped responses with an input as a Step input shape of 250 mN-m amplitude, 2500 ms duration and 1 repetition. 3) Use a two degree-of-freedom system with the device in free-free or clamped-free conditions. Configure the location and number of masses. Come up with two experimental configurations, one each for free-free and clamped-free. For each configuration, locate the masses so that the natural frequency of one of the disks is twice that of the other disk. Use: Force + Spring + Damper driving function with k = 0.20 N/rad and c = 0.010 N/rad/s; and, logarithmic sine sweep from 0.8 to 10 Hz, 300 mN-m amplitude, and 120 second sweep time. Theoretical calculations: Support your experimental findings for each step with theoretical calculations. How did you come up with the mass positions in steps 2 and 3? Does theory match experiment? Possible sources of error? What material are the torsional bars made out of?