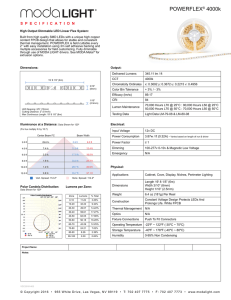

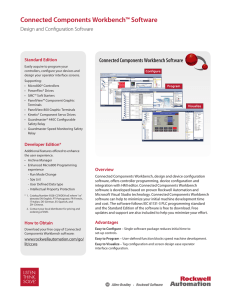

OEM Application Brochures Innovative Solutions to Improve Performance for Machine Builders End users want equipment delivered quickly and at a reasonable price. They rely on their Original Equipment Manufacturers (OEMs) to deliver high-performing, flexible machines that can easily integrate into a facility while offering the business the agility to react to ever changing market demands. To respond, OEMs must evaluate strategic ways to reduce costs and time to market while innovating to stay ahead of the competition. Rockwell Automation offers standardized, scalable control and information solutions to allow OEMs to quickly scale their equipment designs to meet changing requirements. These innovative automation systems are packaged with design tools, deep knowledge of industry safety standards, and security expertise to help OEMs navigate their most difficult design challenges. Content Title Publication Number Page Number Vertical Form Fill and Seal Application Solution Brochure OEM-BR044B-EN-P 4 Horizontal Form Fill and Seal Application Solution Brochure OEM-BR047B-EN-P 9 Ampoule and Vial Filling Machine Brochure OEM-BR046B-EN-P 14 Automation Control for Cartoner Machines Brochure OEM-BR062A-EN-P 19 Automation Control for Blister Packaging Machines Brochure OEM-BR020A-EN-P 24 Pasteurizer Solutions Brochure OEM-BR045A-EN-P 30 Skid Solutions for Mixing and Batching Brochure OEM-BR048A-EN-P 35 Water Filtration Skid Solutions Brochure OEM-BR051B-EN-P 40 Converting, Print and Web Handling Automation Control for Extruder Machines Brochure OEM-BR052A-EN-P 46 Manufacturing & Assembly Stamping Press Application Brochure OEM-BR060C-EN-P 52 Packaging Process Packaging Vertical Form Fill and Seal Application Solution Brochure Horizontal Form Fill and Seal Application Solution Brochure Ampoule and Vial Filling Machine Brochure Automation Control for Cartoner Machines Brochure Automation Control for Blister Packaging Machines Brochure VFFS Application Solution Vertical Form Fill And Seal Machine Solutions for Advanced, Customized And Stand-Alone Machines Machine/OEM Challenges • Material splice and film roll placement. • Film tension and gripping control. • Unique mechanical designs for different products. • Adjustable sealing pressure for different films and product sizes. • Grip control / slippage. • Proper force applied to the seal without energy waste. Development Tools • Design productivity tools –Standard and reusable software modules, AOIs, Motion Analyzer, Safety Automation Builder. • Modular code and HMI screens compliant with industry accepted standards. • Integrated Architecture® offers a scalable, multi-discipline Logix platform in a single programming environment. • Standard, off-the-shelf components. • Engineering expertise and support to help decrease time-tomarket. Product enters the system through the forming tube. Sensor Detects End of Roll Detecting Registration Mark to Synchroniuze Sealing and Cuting Operations Edge Detection (centering of film) The forming collar shapes the flat film into a round film tube. Low friction rollers guide the film to the forming area. Vertical sealing bars seal the edges of the film tube together. Detecting Overtravel of Tension Arm Film transport belts pull the film through the forming area. Cross sealing jaws create top and bottom seals in the pouches, and cut the filled pouch from the empty pouch. Detecting Jam at Outlet Missing Lug Check Advanced Machine Typical Architecture • Modern Human Machine Interface – ability to access PDFs and videos. • Servo for faster changeover. • Variable Frequency Drive on integrated architecture with cost effectiveness. • Reduction of panel space – I/O outside panel. Studio 5000 Logix Designer® Power programming which allows program designs to be modular for easier programming and higher equipment safety. It saves significant engineering time, enables faster startup, and commissioning. PanelView™ Plus 7 Human Machine Interface Stratix™ Switch EtherNet/IP CompactLogix™ L2 Controller Optimized electronic CAM profiles motion control systems may ensure smoother machine operation and enhance machine mechanical life. PowerFlex® Drive Kinetix®5500 Servo Drives Studio 5000 Logix Designer® Unwinder Film Feed Sealing Jaw Packaging Speed > 80 Packs Per Minute Network EtherNet/IP™ Controller CompactLogix™ L2 Variable Frequency Drive PowerFlex® 525 Servo Drive Kinetix® 5500 Synchronous Motion Up to Four axes Filler Jaw Unit Up/Down Optimal machine speeds by using motion sizing tools - Motion Analyzer. Diagnostic information regarding Servos available on Human Machine Interface. Programmable for constant seal-time for any machine speed. Dynamic change of machine speed and corresponding sections synchronize with Controller Master reference. Application program based on Pack ML State Model. Higher machine speeds by optimization of cycle. Customised Machine – Typical Architecture • Food grade servos and wash-down I/O for better sanitation. • Single network based control architecture. • Motion Analyzer – Advance Motion Design tools that improve performance. • Faster development cycle reduces time to market. Scalable control with a single programming environment with integrated motion instructions. PanelView Plus 7 Human Machine Interface Higher capability and scalability with up to 30 I/O modules and 16 motion axes. Compact logix L3 Controller Stratix Switch EtherNet/IP Integrated recipe management recipe controls allow companies to sidestep the repetitive process of tuning machines during a line change by saving and managing multiple settings. Kinetix 5500 Servo Drives Common Human Interface platform and networking services. Studio 5000 Logix Designer PowerFlex Drive Film Feed Unwinder Packaging Speed > 100 Packs Per Minute Network EtherNet/IP Controller CompactLogix L3 Variable Frequency Drive PowerFlex 525 Servo Drive Kinetix 5500 Synchronous Motion More than 16 axes Sealing Jaw Jaw Unit Up/Down Rotary Disc Filler Filler Nozzler Built-in security capabilities support security standards, particularly ISA SP99. Collaborate with IT security specialist company such as Cisco to leverage on their expertise. Safety enabled throughout. Stand-Alone Machine Typical Architecture Connected Components - proven optimal configuration. Cost effective solutions. Reduced panel engineering enables a shorter time for wiring and thus improves machine assembly time. Availability of plug-in modules at the controller allow for expanded machine features and functions. Filling of Materials 1 Material Feeding Vertical Sealing 2 Web Pulling 3 Sealing and Cutting Common programming software Connected Components Workbench™ software for Micro800®, PowerFlex (AC Drives), PanelView™ 800. PanelView™ 800 Human Machine Interface Film Registration Sensor Micro850® Controller Advanced Motion Control Supports up to 3 motion axes using Pulse Train Output. EtherNet/IP 0 1 2 6 7 8 9 Film Feed Encoder IN POWER RUN FAULT USB FORCE COMM 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 OUT Micro850 PTO Auger Feed Film Pull High flexibility Plug-in and expansion modules allow you to optimize your machine cost by choosing performance and functionality specific to your machine needs. Publication OEM-BR044B-EN-P – September 2015 5 20 21 22 23 24 25 26 27 Versatility of interfaces Up to 6 high speed counter inputs and up to 3 Pulse Train Outputs over embedded digital I/O. Up to 5 plug-ins and up to 4 expansion I/O modules. Touch probe function Able to capture accurate registration position at high speeds with built-in hardware. 3 4 10 11 12 13 14 15 16 17 18 19 PTO Connected Components Workbench Software PTO Cross Jaw Discrete/ Analog Film Unwind Packaging Speed < 80 Packs Per Minute Network Modbus / Pulse Train Output Controller Micro800® Family Variable Frequency Drive PowerFlex® 523 Servo Drive Kinetix® 3 / Kinetix® 300 Motion Up to 3 axes PowerFlex 523 Drive Copyright ©2015 Rockwell Automation, Inc. All Rights Reserved. HFFS Application Solutions Horizontal Form Fill & Seal Machine Horizontal Flow Wrap Line Helping You To Design, Develop and Deliver Machine Basics & Challenges • Wrapper film feeding in-line to product length. • Product feeding into wrapper zone and matching the print mark to align with product length. • Rotary knife or cross sealer to synchronize with wrapper linear speed and cut length. • Adjust machine speed without stopping running machine On fly machine change. • Empty wrapper out leads to wastage. Pre-tested & Validated Instructions • Advance registration control with length compensation and position correction of laminate. • Advance CAM design with controlled jerk for rotary knife and film movement. • Advanced smart belt control algorithm for smooth product flow in to wrapper. • Sample code to support `No Product No Bag` feature. Benefits of Rockwell Solutions • Reduction of lamination wastage due to “No Product No Bag” feature. • Improved OEE of line due to auto-recovery of most common production errors or faults. • Improved productivity of machine parts as they operate with controlled jerks with reduced vibration. • Support of machine code & operator interface in-line to global standards (PackML, ISA 88 Etc). • Faster time to build HFFS Line. • Object oriented combined with common network based architecture to support modular design. • Modular program concepts to reuse of code. • Optimized mechanical components with increased line performance. HFFS - Intermittent or Continuous Machines Typical Architecture for Customized Machines • Advanced Human Machine interface with ability to set machine variabilities such as wrapper length, laminate slip factor, sealing time, adaptable speeds to match upstream and so forth. • Advance Motion control enables machine to improve with more flexibility. • Servo motors with food grade and wash down environment, exclusively required in Food and Life Science Industries. Studio 5000 Logix Designer™ power programming which allows program designs to be modular for easier programming and higher equipment safety. It saves significant engineering time, enables faster CompactLogix L3 startup, and commissioning. PanelView Plus Human Machine Interface Stratix Switch EtherNet/IP Controller Compact Logix L2 Controller Optimized electronic CAM profiles motion control systems may ensure smoother machine operation and enhance machine mechanical life. PowerFlex Drive Optimal machine speeds by using motion sizing tools - Motion Analyzer. Film Feed Diagnostic information regarding Servos available on Human Machine Interface. Kinetix 5500 Servo Drives Studio 5000 Logix Designer Programmable for constant seal-time for any machine speed. In Line Pusher 1 In Line Pusher 2 Packaging Speed Up to 250 Packs per Min. Network EtherNet/IP™ Controller CompactLogix™ L2 Variable Frequency Drive PowerFlex® 523 Servo Drive Kinetix®5500 Synchronous Motion Up to Four Axes Cross Pusher 1 Cross Pusher 2 Dynamic change of machine speed and corresponding sections synchronize with Controller Master reference. Application program based on Pack ML State Model. Typical Architectures Various Range of HFFS Machines Scalable Architectures with common control system environment to address low speed machines to high performance lines by connecting over Upstream Equipment to Downstream packaging lines. ControlLogix L6 All Servo System High Performance Lines CompactLogix L3 with Kinetix 350 or Kinetix 5500 & AC Drives Low Speed Solution CompactLogix L2 System with EtherNet/IP Scalable control with a single programming environment with integrated motion instructions. PanelView Plus Human Machine Interface Higher capability and scalability with up to 30 I/O modules and 16 motion axes. Compact logix L3 Controller Stratix Switch EtherNet/IP Integrated recipe management recipe controls allow companies to sidestep the repetitive process of tuning machines during a line change by saving and managing multiple settings. Kinetix 5500 Servo Drives Common Human Interface platform and networking services. Studio 5000 Logix Designer PowerFlex Drive Smart Belt Conveyor -1 Smart Belt Conveyor -2 Film Feed Packaging Speed Up to 600 Packs per Min. Network EtherNet/IP™ Controller CompactLogix™ L3 Variable Frequency Drive PowerFlex® 525 Servo Drive Kinetix® 5500 Synchronous Motion Up to Sixteen Axes Film Feed Drive In Feed Belt / Lug Chain Conveyor Rotary / Cross Sealer -1 Rotary / Cross Sealer -2 Built-in security capabilities support security standards, particularly ISA SP99. Collaborate with IT security specialist company such as CISCO to leverage on their expertise. Safety enabled throughout. Intermittent Machine - Typical Architecture for Entry Level Connected Components - proven optimal configuration. Cost effective solutions. Reduced panel engineering enables a shorter time for wiring and thus improves machine assembly time. Availability of plug-in modules at the controller allow for expanded machine features and functions. Common Programming Software Connected Components Workbench for Micro800®, PowerFlex® (AC Drives), PanelView™ Components. PanelView™ 800 Human Machine Interface Micro850® Controller Advanced Motion Control supports up to three motion axes using ‘Pulse Train Output’. COMO • I-00 • I-01 • I-02 • I-03 • I-04 • I-05 • I-06 • I-07 COM1 • I-08 • I-09 • I-02 • I-10 • I-11 • I-12 • I-13 2080-LC50-24QBB PWR MAC ID 00:00:BC:CE:3A:10 1 Stratix™ Switch Shafted Machine Master Encoder MS NS 2 3 Micro850™ 4 Versatility of Interfaces up to six high speed counter inputs and up to three ‘Pulse Train Output’ over embedded digital I/O. Up to five plug-ins and up to four expansion I/O modules. High Flexibility plug-in and expansion modules allow you to optimize your machine cost by choosing performance and functionality specific to your machine needs. Touch Probe Function able to capture accurate registration position at high speeds with built-in hardware. Publication OEM-BR047B-EN-P – July 2015 1783-US5T RUN-REM-PRG 5 +DC -DC • 24 24 COM • 0-00 CM1 • 0-01 CM2 • 0-02 • 0-03 • 0-04 • 0-05 CM3 • 0-06 • 0-07 • 0-08 • 0-09 Kinetix Component Class Servo Drive Film Registration Sensor PTO Film Pull Belt Kinetix Component Class Servo Drive Connected Components Workbench Software Cross Jaw PowerFlex Drive MODBUS RTU Packaging Speed <80 Packs Per Min. Network Controller Variable Frequency Drive Servo Drive Motion MODBUS RTU, Ethernet/IP Micro800 Family PowerFlex® 523 Kinetix ® 3 and 300 Up to Three Axes Film Unwind Infeed Conveyor PowerFlex Drive Copyright ©2015 Rockwell Automation, Inc. All Rights Reserved. Ampoule and Vial Filling Machine Safe, Secure and Sustainable Solution Challenges Globalization, pricing pressures, and increasingly stringent environmental regulations are constant challenges to pharmaceutical companies. The bottom line is to find a solution that provides better and faster results, delivers projects faster with better regulatory compliance and a longer sustained value. In addition, machine builders specifically expect ampoule filling machines to be: • Standard Modular Solution: Mix and match ampoule filling machine functions specific to products, customer applications, and local market demands, with pre-developed Add-on Instructions (AOI) for all potential end user requirements. • Scalable: Full range products with the ability to customize features to particular market and add functionality that are based on customers’ requirements. • Cost-effective solution that reduces machine integration, mechanical, electrical optimization and wiring costs while shortening software development time and maintenance. • Global support: Fast response and remote access to decrease end-user downtime. Recycled water flushing washing the bottle outside Bottle infeeding on mesh belt Compress air blowdrying the bottle Ultrasonic tank removes the particle inside the bottle Infeeding with screw, steady and smooth Water-alternatinggas ejection flushing Hoist wheels put bottle into fine washing section Outfeeding on mesh belt steadily Faster time to build Ampoule Filling Line • Flexible common network based architecture. • Modular program concepts for easy re-use of code. • Premier Integration capabilities to increase flexibility & performance. • Global support availability to ensure minimum downtime. Advanced Machine Typical Architecture • Modern Human Machine Interface – ability to access videos and PDF files. • Advanced servo system for one button changeover. • Variable Frequency Drive in the integrated architecture. • Customized filling time for filling process optimization. PanelView™ Plus Human Machine Interface Studio 5000 Logix Designer® Power programming which allows program designs to be modular for easier programming and higher equipment safety. It saves significant engineering time, enables faster startup and commissioning. PanelView Plus 1250 Optimized electronic CAM profiles on motion control systems may ensure smoother machine operation and enhance machine mechanical life. Stratix™ Switch Diagnostic information regarding Servos available on Human Machine Interface. ArmorPOINT® 0/1 Faceplate functionality diagnosis allows easy monitoring and troubleshooting Optimized variable frequency drive commissioning that improves efficiency, increases quality and reduces downtime Programmable filling curves reduce carbonization rate Kinetix® Servo Drives ArmorPower® Cost savings by using standard competitive solutions. Machine Speed > 40 Cycles Per Minute Network EtherNet/IP Controller CompactLogix™ L3 OR ControlLogix L7 Human Machine Interface PanelView Plus 6 Variable Frequency Drive PowerFlex® 525 Servo Drive Kinetix 5500 Synchronous Motion More than Sixteen Axes Advanced Machine Typical Architecture • Optimized machine efficiency: online filling volume adjustment. • No bottle no filling program: saves product and raw material and reduce wastage. • Open interface for online check weight printing etc. • One single network. CompactLogix L3 Controller ControlLogix L7 Controller ISPE GAMP5 based methodology To help ensure quality of the pharmaceutical products. Capability and experience of the regulatory compliance with FDA, EU, and China SFDA GMP. PowerFlex Drive PowerFlex Drive Capability and experience to verify Equipment Control System, Batch Control System, Manufacturing Execution System, and relevant Interfaces. PowerFlex Drive The ampoule filling machine control system is a 21 CFR Part 11 compliance system to help verify electronic records and signatures are trustworthy, reliable, and equivalent to paper records. Kinetix Servo Drive Support of Flexible Mass Serialization. Industry Regulation is becoming stringent. With Adaptable and Modular solutions from RA combine Serial Data Engagement with High speed device management. Kinetix Servo Drive Master Infeed Screw Stack Screw Outfeed Screw Pump Valve 4-16 Filling Motors Stand-Alone Machine Typical Architecture Connected Components - proven optimal configuration. Cost effective solutions. Reduced panel engineering enables a shorter time for wiring and thus improves machine assembly time. Availability of plug-in modules at the controller allow for expanded machine features and functions. Common Programming Software Connected Components Workbench for Micro800®, PowerFlex (AC Drives), PanelView™ 800. PanelView 800 Human Machine Interface Micro800® Controller EtherNet/IP Kinetix 3/300 servo drives with embedded indexing simplifies motion control. 0 1 2 3 4 Embedded communications: USB for configuration and monitoring, Ethernet for HMI, Serial Port for simple device connectivity. Publication OEM-BR046B-EN-P - September 2015 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 IN POWER RUN USB FAULT FORCE COMM 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 OUT Micro850 Versatility of Interfaces up to six high speed counter inputs and up to three ‘Pulse Train Output’ over embedded digital I/O. Up to five plug-ins and up to four expansion I/O modules. High Flexibility plug-in and expansion modules allow you to optimize your machine cost by choosing performance and functionality specific to your machine needs. 5 Digital I/O Nozzle Up/Down Control (Index) Discrete/ Analog Connected Components Workbench Software Main Drive Discrete/ Analog In-feed Conveyor Machine Speed <40 Cycles Per Minute Network EtherNet/IP, USB Controller Micro800 Family Variable Frequency Drive PowerFlex 523 Servo Drive Kinetix 3 and 300 Motion 1 Indexed servo axes Discrete/ Analog Bottle Rotation for Heating Copyright ©2015 Rockwell Automation, Inc. All Rights Reserved. Automation Control for Cartoner Machines Solutions for Advanced, Customized and Stand-Alone Machines image courtesy of ADCO Manufacturing Machine Builder Efficiency • Flexible, modular machine and code design for maximum reuse potential. • Creating differentiation in a competitive / global market. • Partnership association with key suppliers. Machine Optimization • Smoother and faster machines that need to adopt quick changes. • Increased machine flexibility to overcome product variability. • Information enabled machine designs. • Functional machine safety to compete in global market. End User • Ease of use and maintenance, graphical diagnostics, and OEE capabilities. • Secured remote access for online information including parts ordering and maintenance schedules. • Seamless integration and support with rest of production line. • Optimal power consumption and reduce product wastage. Erecting Carton erected into flight chain Loading of line To endipment equ r e minoin d i s d a Non LoFlaps tucked inor de m in i s g d in Load ps tucke fla Carton Handling (outfeed) Product insertion section feed uct In veyor d o r P con Loading side flaps prepared to load Extended machine lifecycle and noise reduction • Flexible control architectures can effectively manage the various methods of product handling. • Reduced manufacturing time and cost. • Global availability of replacement parts and remote diagnostics capability. Advanced Machine Typical Architecture • Advanced Human Machine Interface with ability to set the machine variability which includes pick up delay, carton drop angle, product infeed slip factor, and adaptable speeds to match upstream. • Advanced motion control improves machine flexibility. • Servo motors with food grade and wash down environment, required in consumer packaged goods industries. • Leverage NPNC (No Product, No Carton) feature. • Secured Remote Access providing real-time data collection, alarming, analytics, and troubleshooting. Secured Remote Access PanelView™ Plus 7 Human Machine Interface Studio 5000 Logix Designer® power programming which allows program designs to be modular for easier programming, saving significant engineering time with faster startup and commissioning. Controller L3 Guardmaster® Safety Relay Stratix™ 5700 Optimized electronic CAM profiles motion control systems can help ensure smoother machine operation and improved machine mechanical life. Studio 5000 Logix Designer PowerFlex 525 Kinetix® 5500 Servo Drive 5700 5700 5700 5700 Optimal machine speeds by using motion sizing tools -Motion Analyzer. 5700 5700 527 527 Case Conveyor In-Feed Conveyor Smart Belt Conveyor 1 Product Transfer Smart Belt Conveyor 2 Blank Carton Transport Cartoner Speed Up to 300 Cartons Per Minute Network EtherNet/IP™ Variable AC Drive PowerFlex® 527 Servo Drives Kinetix 5500 Synchronized Motion Up to Sixteen Axes Loaded Carton Transport Carton Guide Adjustment Human Machine Interface includes servo diagnostic information. Dynamic change of machine speed and corresponding sections synchronize with Controller Master reference. Application program based on Pack ML State Model. Custom Machine Typical Architecture • Continuous operation, fully automatic with higher throughput, capable handling many carton variations. • Manage critical sections with advanced motion and sophisticated actuators. • Tightly integrated to upstream line with adaptable speeds. • Improved machine productivity and reduced maintenance. • Leverage NPNC (No Product, No Carton) feature. • Secured Remote Access providing real-time data collection, alarming, analytics, and troubleshooting. Secured Remote Access Scalable control with a single programming environment with integrated motion instructions. GuardLogix® Safety Controller EtherNet/IP™ Logix5573S™ Logix55L7SP™ EtherNet/IP™ Logix5573™ PanelView Plus 7 Human Machine Interface Stratix 5700 Higher capability and scalability with up to 30 I/O modules and 100 motion axes. PowerFlex 527 Drive 9 9 9 1734-AENTR Series-B MS 24VDC Safety Sink Input Network Activity IO Modules Machine and Safety Link 1 Activity Status Network Status Point Bus Status System Power Field Power IP ADDRESS Studio 5000 Logix Designer Integrated recipe management simplifies line changing process by managing multiple settings. NS LK Module Status P W R 1734-IB8S Common Human Interface platform and networking services. Link 2 Activity Status PowerFlex 525 Kinetix 5700 Servo Drive Mod Net Mod Net 5700 5700 Risk of electric shock. Power off and wait 5 min. 2 Risk of electric shock. Power off and wait 5 min. 1 1 1 4 5700 Mod Net 11 I/O 6 1 6 1 I/O-B 1 1 4 10 5 10 5 UFB-A 10 UFB-b 5700 Risk of electric shock. Power off and wait 5 min. 11 I/O 6 1 10 5 I/O-A 6 1 I/O-B 6 4 I/O UFB Mod Net 5700 22 11 1 1 Mod Net Risk of electric shock. Power off and wait 5 min. 22 6 I/O 5 Risk of electric shock. Power off and wait 5 min. 2 1 I/O-A 5700 Risk of electric shock. Power off and wait 5 min. 2 4 I/O Mod Net 5700 Risk of electric shock. Power off and wait 5 min. 22 11 1 1 Mod Net 5700 Risk of electric shock. Power off and wait 5 min. 22 2 Mod Net I/O 527 5 UFB 10 5 UFB-A 10 UFB-b Infeed/Outfeed Conveyor Smart In-feed Solution - Robotics Packaging Speed 400 -600 Cartons Per Minute Network EtherNet/IP Controllers ControlLogix® 5570 Servo Drives Kinetix 5700 Synchronized Motion As high as 90 Axes Blank Carton Transport Carton Loader Flap Closer Loader Carton Transport Built-in security capabilities support security standards, particularly ISA SP99. Collaborate with IT security specialist company such as CISCO to leverage on their expertise. Safety enabled throughout under unsafe condition of “Machine”, “Safe shut down” will be performed by integrating safety signals (safe torque off in drives and motion) to control system. - This enables faster recovery of machine thus improves productivity. Stand-Alone Machine Typical Architecture • Leverage Connected Components for optimized configuration using a common software. • Simplified motion using indexing drives. • Controller plug-in modules allow for cost effective expansion of machine features and functions. Common Programming Software Connected Components Workbench® software for Micro800®, PowerFlex (AC Drives), PanelView™ 800. PanelView™ 800 Human Machine Interface Registration Sensor Micro850® Controller EtherNet/IP Kinetix 3/300 servo drives with embedded indexing simplifies motion control. 0 1 2 3 4 5 6 7 8 20 21 22 23 24 25 26 27 IN 2080-OF2 POWER 1 RUN FORCE 1 2 2080-OF2 3 4 A COM COM COM COM COMM 0 2 B VO-0 CO-0 VO-1 CO-1 FAULT USB Master Encoder on Upstream Conveyor 9 10 11 12 13 14 15 16 17 18 19 3 4 5 6 7 8 1 2 3 4 B VO-0 CO-0 VO-1 CO-1 A COM COM COM COM 9 10 11 12 13 14 15 16 17 18 19 OUT Micro850 Versatility of Interfaces up to six high speed counter inputs and up to three ‘Pulse Train Output’ over embedded digital I/O. Up to five plug-ins and up to four expansion I/O modules. High Flexibility plug-in and expansion modules allow you to optimize your machine cost by choosing performance and functionality specific to your machine needs. Digital I/O Carton Pick Up & Erection (Index) Digital I/O 2 Connected Components Workbench Software Feeder (Index) Discrete/Analog/Modbus Touch Probe Function in 2080-MOT-HSC plug-in captures accurate registration position. Serial Port in 2080-SERIALISOL plug-in adds isolation for Modbus RTU. Publication OEM-BR062A-EN-P – August 2015 In-feed Conveyor Discrete/Analog/Modbus Packaging Speed < 180 Cartons Per Minute Network EtherNet/IP, USB, Modbus RTU Controller Micro800 Family Variable Frequency Drive PowerFlex 523 Servo Drives Kinetix 3 / Kinetix 300 Motion 2 Indexed servo axes, master encoder feedback axis Upstream Conveyor Copyright ©2015 Rockwell Automation, Inc. All Rights Reserved. Automation Control for Blister Packaging Machines Solutions to Help You to Design, Develop, and Deliver Innovative Machines Blister Packing Machine Basics and Challenges • Formation of uniform blisters on aluminum or plastic sheet through thermal forming process. • On-the-fly feeding of product (capsule or tablet) into blisters. • Print mark registration control for accurate sealing of blisters, at desired length. • Adjust machine speed without interrupting running machine on-the-fly machine change. • Reduce wastage due to unfilled blisters or improper sealing. Machine Builder Efficiency • Flexible, modular machine, and code design for maximum reuse potential. • Creating differentiation in a competitive and global market. • Partnership association with key suppliers. Machine Optimization • Smoother and faster machines that need to adopt changes quickly. • Increased machine flexibility to overcome product variability. • Information enabled machine designs. • Functional machine safety to compete in global market. End User Challenges • Ease-of-use and maintenance, graphical diagnostics, and OEE capabilities. • Secured remote access for online information including parts ordering and maintenance schedules. • Seamless integration and support with rest of production line. • Optimal power consumption and reduce product wastage. Automatic feeding system (option) PanelView™ Plus HMI Aluminum foil feeding 5 4 era Cam Sealing station Perforation 10 Product 8 6 9 Trimming 7 Coding & embossing 1 2 Forming film reels Forming film preheating 3 Pocket forming Extended machine lifecycle and reduced noise • Flexible control architectures can effectively manage the various methods of product handling. • Reduced manufacturing time and cost. • Global availability of replacement parts and remote diagnostics capability. Advanced Machines Typical Architecture • Advanced human machine interface (HMI) with ability to set machine variabilities such as wrapper length, laminate slip factor, sealing time, and adaptable speeds to match upstream. • Advance motion control enables machine to improve with more flexibility. • Servo motors with food grade and wash down ratings designed to meet requirements in food and life sciences industries. • Secured remote access provides real-time data collection, alarming, analytics, and troubleshooting. PanelView Plus HMI Secured Remote Access CompactLogix™ L2 Controller Stratix 8000™ Ethernet Switch EtherNet/IP Network LK 9 9 9 1734-AENTR Series-B MS Network Activity Link 1 Activity Status NS 24VDC Safety Sink Input Module Status Network Status Point Bus Status System Power IP ADDRESS Field Power P W R 1734-IB8S I/O Modules Link 2 Activity Status Optimized electronic CompactLogix L3 CAM profiles can help Controller ensure smoother machine operation and improve machine mechanical life. Optimal machine speeds by using Motion Analyzer Software, a comprehensive motion-application sizing tool. PowerFlex® 525 AC Drive Studio 5000 Logix Designer® Software Studio 5000 Logix Designer® Power programming offers modular program designs for easier programming, saving significant engineering time, faster startup, and commissioning. Human Machine Interface includes servo diagnostic information. Kinetix® 5500 Servo Drives Film Unwinder Dynamic change of machine speed and corresponding sections synchronize with Controller Master reference. Application program based on Pack ML State Model. Sealing & Cutting Packaging Speed Up to 250 Packs per Min. Network EtherNet/IP™ Controller CompactLogix™ L2 Variable Frequency Drive PowerFlex® 525 Servo Drive Kinetix®5500 Synchronous Motion Up to Four Axes Product Feeding Thermo Forming Custom Machines Typical Architecture • Continuous operation, fully automatic with higher throughput, capable to handle many carton variations. • Manage critical sections with advanced motion and sophisticated actuators. • Tightly integrated to upstream line with adaptable speeds. • Improved machine productivity and reduced maintenance. • Secured remote access providing real-time data collection, alarming, analytics, and troubleshooting. PanelView Plus HMI Secured Remote Access 1oo2 Architecture PLe (ISO13849) Compact GuardLogix® Compact Guard Logix SAFETY CPU SFTY RUN SFTY TASK SFTY LOCK SFTY OK E4:90:69:A1:1A:EE Stratix Managed Ethernet Switch EtherNet/IP Network 9 9 9 1734-AENTR Series-B MS 24VDC Safety Sink Input Network Activity Network Status Point Bus Status System Power Field Power IP ADDRESS Kinetix 5500/5700 Servo Drives NS LK Module Status Link 1 Activity Status ISPE GAMP5 based methodology To help ensure quality of the pharmaceutical products. Capability and experience of regulatory compliance with FDA, EU, and China SFDA GMP. Capability and experience to verify Equipment Control System, Batch Control System, Manufacturing Execution System, and relevant Interfaces. P W R 1734-IB8S Link 2 Activity Status PowerFlex 525 AC Drives I/O Modules Standard & Safety 21 CFR Part 11 compliant control system to help verify electronic records and signatures are trustworthy, reliable, and equivalent to paper records. Built-in security capabilities support security standards, particularly ISA SP99. Collaborate with IT security specialist companies such as CISCO® to leverage on their expertise. Robotics Integration Conveyor Control Packaging Speed Up to 600 Packs per Min. Network EtherNet/IP Controller CompactLogix L3 Variable Frequency Drive PowerFlex 525 Servo Drive Kinetix 5500/5700 Synchronous Motion Up to Sixteen Axes Motion Control Various Section of Blister Packaging Machine Integrated safety assists with “safe shut down” of machine. Safety functions including Safe Torque-off and Safe Speed Monitor in the drives, enable faster machine recovery for improved productivity. Stand-Alone Machine Typical Architecture • Leverage Connected Component solutions for simple blister packaging solutions using one common configuration software with broad portfolio of safety components in the industry. • Simplified motion using PLC Open instructions. • Controller plug-in modules offer cost-effective expansion of machine features and functions. Common Programming Software Connected Components Workbench™ software for Micro800® controller, PowerFlex AC drives, PanelView 800 HMI, and Guardmaster® 440C-CR30 safety relay. PanelView 800 Human Machine Interface Micro850® Controller COMO • I-00 • I-01 • I-02 • I-03 • I-04 • I-05 • I-06 • I-07 COM1 • I-08 • I-09 • I-02 • I-10 • I-11 • I-12 • I-13 Shafted Machine Master Encoder 2080-LC50-24QBB MAC ID Advanced Motion PTO supports up to three motion axes using ‘Pulse Train Output’. 00:00:BC:CE:3A:10 A B Z O PWR MS NS 2080-MOT-HSC 1 B 0+ A+ B+ Z+ A 0- A- B- Z- Stratix Switch 2 Micro850™ 3 RUN-REM-PRG Versatility of Interfaces up to six high speed counter inputs and up to three ‘Pulse Train Output’ over embedded digital I/O. Up to five plug-ins and up to four expansion I/O modules. 5 +DC -DC • 24 24 COM • 0-00 CM1 • 0-01 CM2 • 0-02 • 0-03 • 0-04 • 0-05 CM3 • 0-06 • 0-07 • 0-08 • 0-09 Kinetix Component Class Servo Drive 1783-US5T 4 PTO High Flexibility plug-in and expansion modules allow you to optimize your machine cost by choosing performance and functionality specific to your machine needs. Touch Probe Function to capture accurate registration position at high speeds with built-in hardware. High Speed Counter module supports up to 4 feedback axes. Position feedback from encoders or servo drives. Publication OEM-BR020A-EN-P – March 2016 Film Registration Sensor Aluminium foil index Kinetix Component Class Servo Drive Connected Components Workbench Software PTO MODBUS RTU MODBUS RTU Thermo Forming PowerFlex Drive Unwinder Packaging Speed <80 Packs Per Min. Network Controller Variable Frequency Drive Servo Drive Motion MODBUS RTU, Ethernet/IP Micro800 Family PowerFlex 523 Kinetix 3 and 300 Up to Three PTO Axes Outfeed Conveyor PowerFlex Drive Copyright ©2016 Rockwell Automation, Inc. All Rights Reserved. Process Pasteurizer Solutions Brochure Skid Solutions for Mixing and Batching Brochure Water Filtration Skid Solutions Brochure Pasteurizer Solutions Automation Control Solutions for Pasteurization Rockwell Automation Solution Rockwell Automation Solution The Rockwell Automation emphasis of “COLLABORATING WITH YOU”, allows Machine and Equipment Builders to effectively compete in this global market place by differentiating itself. Machine and Equipment Builders need to define value beyond the cost of machines and maximize company’s performance. Whether measured from a business, commercial or technical perspective, Rockwell Automation can help improve Machine and Equipment Builders’ performance with services and solutions to lower the Total Cost of DESIGN, DEVELOP and DELIVERSM machines and meet customers’ requirements. Design Maximize design productivity, reducing design labor time and cost and also creating consistent, modularized designs help improve manufacturing efficiency to meet delivery needs. Scalable Control Solutions Process Objects Libraries Functional Safety Standards Compliance Develop “Faster Time to Market” to meet customer delivery commitments is important to be competitive in today’s economy. Engineering Workstation Modular Programming EtherNet/IP Network On Machine Solutions Hardware Integration Scalable Data Collection and Decision Support Tools Deliver Delivery lead time is often a considerable factor important for Machine and Equipment Builders to help communicate effectively to the extent to which machines can be delivered in a shorter time period. Information Enabled Solutions Remote Monitoring Network and Security Services Global Service and Support DESIGN Design Productivity Extensible Engineering Scalability Global Standards Risk Assessment Design for Sustainability DEVELOP Time to Market Supply Chain Efficiency Flexible Equipment Models Simplified Integration Design Optimization DELIVER Commissioning Global Service & Support Reliability & Quality Machine Performance Core Process Control Solution Typical Architecture for High Temperature Short Time (HTST) or Ultra High Temperature (UHT) Pasteurizer Skid Pasteurizers are being used increasingly in food & beverage production worldwide. The ability to offer ‘right sized’ efficient equipment is essential to remain competitive. Rockwell Automation solutions can give Machine and Equipment Builders a competitive advantage by optimizing energy usage, maximizing throughput and reducing waste. Our scalable solutions using standardized objects can deliver a competitive advantage and reduce time to market to food & beverage equipment builders. PanelView™ Plus Human Machine Interface CompactLogix™ L3 Controller Supervisory Connection Stratix™ Switch E/IP Raw Supply ArmorPOINT® I/O Hot Water Supply LC Chilled Water Supply ArmorPOINT® I/O LSH Hart TIC Hart TIC LSL PT PIC Supply Tank I TT PIC SC PT TT AB or E+H Temp Sensor SC Product to Form & Fill Heater FT FIQ Chiller Hot Water Return Booster Pump Supply Pump PowerFlex® Drive Chiller Water Return PowerFlex® Drive Pressure/Flow Meter Benefits of Integrated Architecture Scalable solution EtherNet/IP e.g. premier integration that allows savings On commissioning costs Real-time information Pre validated process library Seamless integration with analytical instruments Plate or Tube Heat Exchanger Network EtherNet/IP HART and Profibus where applicable for instrumentation Controller CompactLogix™ L1 / L2 / L3 Variable Frequency Drive PowerFlex® 525 Instrumentation I/O Allen-Bradley 4-20mA Temperature Sensors, E+H (Endress + Hauser) EtherNet/IP and flow instrumentation Point / Compact / ArmorPOINT® I/O. All options can be used Core Process Control Solution Typical Architecture for High Temperature Short Time (HTST) or Ultra High Temperature (UHT) Pasteurizer Skid Rockwell Automation Core Solution Offering Rockwell Automation delivers the tools and expertise to help OEMs build equipment control solutions that are more scalable, highly reusable, and plug-and-play enabled. System Architecture Integrated Architecture® provides scalable solutions to meet specific requirements through a wide range of controllers, I/O, HMI, and power control devices EtherNet/IP network offers scalable, high bandwidth, fast and ‘future ready’ control network architecture, compatible with the enterprise’s IT network – Incorporates enabling technologies including cloud, mobile and personal devices – Simplifies remote monitoring and support utilizing unmodified Ethernet Developed based on design-for-security philosophy to facilitate physical and logical access control, IP preservation and protection against external threats Provides integration to process control networks including seamless EtherNet/IP, HART, FOUNDATION Fieldbus, and Profibus-PA Power Integration Premier integration of power control devices, such as variable frequency drives and motor control centers, saves time and energy Provides real-time diagnostics for asset management Programming Software Engineering and Configuration Software Integrated design and configuration environment shorten debugging time and minimize human errors Faster software development cycle Reduced equipment cost Drives consistent specifications Helps preserve OEM’s Intellectual Property Modular programming Easier to expand the program with the copy function Smoother and more consistent data flow (Unit EM CM) Easy for recipe management Programming standardization Reusable code S88 Compliant Running States Management Compliance to standards for batch control and definition of the physical model Design running states flow to ensure equipment can work safely. Specially designed for pasteurizer/UHT/HTST Logix Batch & Sequence Manager delivers cost-effective recipe management for a single unit – ideal for “clean-inplace” and “steam-in-place” Information Management Easily integrates to MES and ERP systems for real-time information and better decision making Population of Historian and audit data, supporting cGMP and compliance in regulated industries Immediate diagnostic information enables quick troubleshooting and intervention Drives continuous improvement using trends, dashboards and reports Process Libraries PIDE Autotune function on Human Machine Interface Standard faceplates for common devices such as pump, valve, PID, instruments, switches Quickly assemble applications utilizing Add-On Instructions, Global Objects and Faceplates Reduce engineering time with pre-defined objects for common functions Rapidly develop information-rich operator displays Simply configure a device from I/O to operator interface Advanced Process Control Instructions Coordinated control function block can be utilized in processes where several control variables can be manipulated to control one process variable Internal Model Control (IMC) helps regulate temperature control to prevent overheating Reduce temperature variation Minimize energy usage Typical Architecture for Small Controller Solution PanelView™ Component Human Machine Interface High Performance Networks and Standardized Communication Protocols Use open communication standards and leverage on ethernet as it’s backbone to make real-time information available. Connected Components Workbench Software Modular Devices Availability of plug-in modules, expandable I/O, flexible safety functions. Modular AC drive designs and an array of Human Machine Interface panel sizes. Micro850® Controller RTD Sensor Instrumentation Pressure Sensor PowerFlex® Drive Defined objects and standardized connectivity providing for instrumentation management, instrumentation calibration, the ability to get information from the instrumentation to display the key KPIs. Touch Probe Function Able to capture accurate registration position at high speeds with built-in hardware. Cost Effective Solution Rockwell Automation offers scalable options for your discrete control applications. Machine specific sample code, pre-configured drive parameters, sample Human Machine Interface screens make development and commissioning easier with online software acquisition, multiple site installations and application IP protection. Rockwell Automation solution provides faster time to market and lower total cost of ownership. Publication OEM-BR045A-EN-P PID Process Loop Able to help control physical properties such as Temperature, Pressure, Liquid level & Flow rate. Recipe Management Up to 10 recipe sets each containing up to 128 variables per recipe to support manufacturing needs. Copyright © 2014 Rockwell Automation, Inc. All Rights Reserved. Skid Solutions for Mixing and Batching Our goal is to use a mixing and blending process template to demonstrate the solution for simple to medium complexity batch application. The technology leverages off the Logix Batch and Sequence Manager (LBSM) along with Rockwell Automation Process Library. This offers the added benefit of ISA88 standardization that not only reduces both engineering and commissioning cost but also improves time to market. Rockwell Automation Solution Rockwell Automation Solution The Rockwell Automation emphasis of “COLLABORATING WITH YOU”, allows Machine and Equipment Builders to effectively compete in this global market place by differentiating itself. Machine and Equipment Builders need to define value beyond the cost of machines and maximize company’s performance. Whether measured from a business, commercial or technical perspective, Rockwell Automation can help improve Machine and Equipment Builders’ performance with services and solutions to lower the Total Cost of DESIGN, DEVELOP and DELIVERSM machines and meet customers’ requirements. Design Maximize design productivity, reducing design labor time and cost and also creating consistent, modularized designs help improve manufacturing efficiency to meet delivery needs. Scalable Control Solutions Mechatronics Functional Safety Standards Compliance Develop “Faster Time to Market” to meet customer delivery commitments is important to be competitive in today’s economy. Modular Programming EtherNet/IP Network On Machine Solutions Hardware Integration Supply Chain Integration Deliver Delivery lead time is often a considerable factor important for Machine and Equipment Builders to help communicate effectively to the extent to which machines can be delivered in a shorter time period. Information Enabled Solutions Remote Monitoring Network and Security Services Global Service and Support DESIGN Design Productivity Extensible Engineering Scalability Global Standards Risk Assessment Design for Sustainability DEVELOP Time to Market Supply Chain Efficiency Flexible Equipment Models Simplified Integration Design Optimization DELIVER Commissioning Global Service & Support Reliability & Quality Machine Performance Typical Architecture for Standard Equipment OEM, SI and End User Challenges The need for configurable equipment definitions without changing controller code High development, commissioning and validation cost due to non standardized programming Industry calls for ISA88 compliant code structure Market trend for integration to plantwide system Panel View™ Plus Stratix™ Switch CompactLogix™ L1 Controller I/O PowerFlex® Drive Control System Architecture High scalability due to an already ISA88 compliant code structure and Logix platform ISA88 compliant code structure with equipment module, control module allocation and phase configuration reduce engineering time and makes the system easily expandable Process library used on control module layer to drive standardization and replication HOT PRODUCT WATER FT100 FT Liquid Ingredient 1 Liquid Ingredient 2 FT Phases: • Add Milk • Add Water • Stir • Heat • Add Liquid Sugar • Add Cocoa • Discharge • CIP cleaning V100 FT101 V101 V102 MANUAL M100 ADDITIONS M XS100 XS Steam VS100 V104 DOSING ALARM (R) YS MAN. DOSING (Y) YS AUTO DOSING (G) YS MT100 WT TT100 TT LSL100 V103 TO PASTEURISER LS FT M101 P I Typical Architecture with Enhanced Features Network EtherNet/IP Controller CompactLogix™ L1 OR L3 Human Machine Interface PanelView™ Plus 6 Variable Frequency Drive PowerFlex® 525 Panel View™ Plus Stratix™ Switch CompactLogix™ L3 Controller Batch Application Features Controller based online equipment/recipe configuration Value-added, zero charge, un-licensed LBSM as batch manager to manage recipe without code change increase efficiency and reduce programming time when a change of recipe is required Intuitive operator runtime for recipe, equipment module and control module visualization Faster time to market Reduce engineering cost Reduce maintenance and modification effort Standardized ISA88 compliant code structure On line recipe management Integration with plant wide control including information availability Easy scale up Remote control and diagnostic capability I/O PowerFlex® Drive Typical Architecture for Simple Equipment Common programming software Connected Components Workbench™ software for Micro800®, PowerFlex® (AC Drives), PanelView™ Network EtherNet/IP Modbus Controller Micro800® series Component. Human Machine Interface PanelView™ Component Flexibility Variable Frequency Drive PowerFlex® 523 PanelView™ Component Human Machine Interface High uses of open communication standards as it backbone to make real-time information available. Touch Probe Function Able to capture a more accurate registration position at high speeds with built-in hardware. Connected Components Workbench Software PID Process Loop Able to help control physical properties such as Temperature, Pressure, Liquid level & Flow rate. Micro850® Controller RTD Sensor Recipe Management Up to 10 recipe sets each containing up to 128 variables per recipe to support manufacturing needs. Pressure Sensor PowerFlex® Drive Publication OEM-BR048A-EN-P Copyright © 2014 Rockwell Automation, Inc. All Rights Reserved. Water Filtration Skid Solutions Helping You To Design, Develop and Deliver • Modular Program Design • Process library blocks • Reusable code • Standardized programming • Program templates • Scalable architecture • Flexible network design • EtherNet/IP integration • Reduce build time & engineering effort • Information enabled system • Remote monitoring & diagnostics • Faster time to market Rockwell Software® Platform • Easier to expand the program with the copy function • Smoother and more consistent data flow • Standardized programming • Reuseable code PowerFlex 525 Armor POINT I/O ArmorPower Library: Process Automation System is Normally HMI Rich Application. • Add-On Instructions for Logix • Graphic Symbols and Faceplate • Displays for FTView (SE or ME) - For a variety of valves, motors, pumps, drives, inputs, outputs, and other devices - Supporting instructions for modes, alarms, permissives, interlocks, statistics • Reference Manuals • Supported by Tech Support Connectivity for all non EtherNet/IP™ Instruments & sensors Raw Water Pump (p ) Air PowerFlex 525 Back Wash Pump PowerFlex 525 Stratix 2000 Level Capturing Operator Knowledge Through Automated Sequencer • New sequencer object • Easily configurable to capture critical sequences • Handles exceptions • Rich visualization provided to the operator Pre-Filter Flow Turbidity H P P FAULT Running States Management • For safe running, the running states flow is designed to manage equipment running states • The states include: Startup, Standby, Filtration, Draindown, Backwash, Pressure Test, CIP, Maintenance Wash and Fault STOP START UP CIP DRAIN Recirculation Pump FILL IN FILTRATION BACKWASH PRESSURE TEST UF Module IntraNet to Plant Network, VPN or Email Pop Server Wired or Cell Connection Use the Rockwell Automation Cloud infrastructure to monitor all machines Managed Switch RA Cloud Agent PVP 1000 Equipment #1 Firewall A Cloud Agent enabled hardware is deployed at the remote site Rockwell Automation Cloud Permeate Tank RA Cloud Agent Firewall BIG DATA Equipment #2 L18ERM 0 DC INPUT 1 0 24VDC SINK DC OUTPUT 24VDC SOURCE 9 2 10 3 11 4 12 5 13 6 14 7 1 2 3 4 5 6 7 9 10 11 12 13 14 15 RA Cloud Agent Equipment #3 00:00:BC:66:0E:29 EtherNet/IP Email Notifications 15 0 0 Firewall WARNING EXPLOSION HAZARDDo Not Disconnect While Cirecuit Is Live Unless Area Is Known To Be Non-Hazardous DC INPUT DC OUTPUT 0 8 0 8 1 9 1 9 2 10 VDC + VDC CG FP+ FP- 3 11 4 12 5 13 6 14 2 10 3 11 4 12 5 13 6 14 7 15 7 15 V V C C V V C C 24VDC SINK 24VDC SOURCE Dashboards & Reports Reusable for each equipment 1 (Front) 2 (Rear) 1769-L1 Controller Temperature SCADA Computer Remote Access and Data Publish Skid 1 Skid 3 Skid 2 Add-On System for Central Monitoring, Data Archiving and Reporting • Central Control • Data Collection • Alarm Log-in • Trending • Reports Aggregate Equipment Data Benefits • Performance Dashboards • Alarm Diagnostics • Alarm Notification • Current Equipment Status • Historical Trends Data Accessibility Benefits • Secure Internet Access • Mobile Devices Remote Services/Support Benefits • Application Support • Remote Monitoring Services Typical Architecture for Entry Level Equipment Connected Components Workbench™ software - proven optimal configuration. Cost effective solutions. Reduced engineering and reduced wiring time & materials reduce commissioning time. Availability of plug in modules at the Controller allows for expanded features and functions. Connected Components Workbench Software Common Programming Software Connected Component Workbench Software for Micro800®, PowerFlex® (AC Drives), PanelView™ Components. High Performance Networks and Standardized Communication Protocols Use of open communication standards and leveraging of Ethernet/IP as the backbone gives real time information availability. High Flexibility Plug-in and expansion modules allow you to optimize your machine cost by choosing performance and functionality specific to your machine needs. Micro850 Controller PanelView Plus 1250 PowerFlex Drive PanelView Component Human Machine Interface Instrumentation Defined objects and standardized connectivity providing for instrumentation management and calibration, and the ability to take information from the instruments to display process KPIs. Publication OEM-BR051B-EN-P – March 2016 RTD Sensor Network EtherNet/Serial Controller Variable Frequency Drive HMI Micro800 Family PowerFlex® 523 PowerFlex Drive Pressure Sensor PanelView™ Series Copyright ©2015 Rockwell Automation, Inc. All Rights Reserved. Converting, Print, Web Handling Automation Control for Extruder Machines Solutions for Advanced, Customized and Stand-Alone Machines Challenges for Plastic Extruders • Maximize profit margins and reduce the amount of raw resin material usage • Energy consumption management • Increase machine throughput rates without sacrificing product quality; repeatability even with variations in material characteristics • Increase market share in niche applications including wood plastic composites, encapsulation of active ingredients in pharmaceuticals, and fuel cell manufacturing. Benefits of Rockwell Automation Solutions • Global supplier of industrial automation solutions, providing local service and support • Integrated Architecture® solution offers system configuration ease and flexibility • Controller-based architecture with integrated drive and temperature control to help improve overall machine performance • Modular programming techniques based on proven code • Domain expertise support for extruder machine development Com IN2 Ref IN1 Feeder Output Shaft Gearbox Barrel Heating Screw Die Motor Input Shaft Flow Faster time to build Extrusion Machine or Line • Object oriented common network based architecture • Modular program concepts to re-use of code • Premier Integration capabilities to increase flexibility & performance Cooling Advanced Machine Typical Architecture The CompactLogix™ PAC offers a smaller form factor and cost-effective package which provides you a wider variety of options from which to choose. It also provides a best-fit alternative for extruder application requirements. Stratix Switch Studio 5000 Logix Designer™ Power programming modular program design, based on PackML state model, eases programming and helps improve equipment safety. Saves significant engineering time, L3 reduces CompactLogix start-up, and commissioning Controller time. L18ERM DC INPUT 24VDC SINK DC OUTPUT 24VDC SOURCE 0 1 2 3 4 5 6 7 0 9 10 11 12 13 14 15 0 1 2 3 4 5 6 7 0 9 10 11 12 13 14 15 00:00:BC:66:0E:29 WARNING EXPLOSION HAZARDDo Not Disconnect While Cirecuit Is Live Unless Area Is Known To Be Non-Hazardous DC INPUT VDC + VDC CG FP+ FP- DC OUTPUT 0 8 0 8 1 9 1 9 2 10 2 10 3 11 3 11 4 12 4 12 5 13 5 13 6 14 6 14 7 15 7 15 V V C C V V C C 24VDC SINK 24VDC SOURCE 1 (Front) 2 (Rear) CompactLogix L1 Controller 9 9 9 PanelView Plus 7 Human Machine Interface Diagnostic information of drives and motors available on HMI. 1734-AENTR Series-B Module Status Network Activity Link 1 Activity Status Network Status Point Bus Status System Power IP ADDRESS Field Power Integrated temperature control eliminates speciality modules and simplifies control. Link 2 Activity Status PowerFlex 520 AC Drive 1734 POINT I/O™ EtherNet/IP Feeder Motor Studio 5000 Logix Designer Main Motor Asynchronous Motor No Encoder Network Controller Main Screw Drive Temperature Control Temperature Zone EtherNet/IP CompactLogix™ L1 PAC PowerFlex® 750 AC Drive By PAC Up to twenty four Extrusion Motor (High Performance Asynchronous Motor) PowerFlex 750 AC Drive PowerFlex Series AC drives combine powerful performance, ease of use, and ultimate flexibility. Connect the drive to a synchronous motor to save more energy and panel space. The AppView and CustomView tools support faster and customized configurations. Custom Machine Typical Architecture Reduce development time and improve time to market with a Logix-based platform on EtherNet/IP™. Integrate a modern HMI to access PDFs and videos for operator training and machine maintenance. Reduce panel space with distributed I/O and optimize power ratings for extruder machine main motor using the Motion Analyzer tool. Stratix Switch Scalable control and single programming environment with integrated motion instructions. Higher capability and scalability with up to 30 I/O modules and 16 motion axes. CompactLogix L3Y Controller PanelView Plus 7 Human Machine Interface Main motor selection flexibility PowerFlex755 drive provides additional flexibility to connect asynchronous or synchronous type motor. PowerFlex 520 AC Drive EtherNet/IP Temperature control over distributed I/O Feeder Motor PowerFlex 520 AC Drive Traction Motor Studio 5000 Logix Designer Main Motor Asynchronous Motor No Encoder Network Controller Main Screw Drive Temperature Control Temperature Zone EtherNet/IP CompactLogix™ L3 PAC PowerFlex® 750 AC Drive By PAC Up to eighty Main Extrusion Motor (High Performance Asynchronous Motor) PowerFlex 750 AC Drive Integrated recipe management Save and manage multiple recipe control settings to eliminate the repetitive process of running machines during a line change. Common HMI platform and networking services. Built-in security capabilities support security standards, particularly ISA SP99. Collaborate with an IT security specialist company such as Cisco and leverage on their expertise. Integrated safety Stand-Alone Machine Typical Architecture Connected Components are cost-effective solutions with proven optimized configurations. You can reduce panel engineering and decrease wiring and machine assembly time. Plug-in modules are available for the controller to expand machine features and functions. Common Programming Software Connected Components Workbench™ software for Micro800 controller, PowerFlex (AC Drives), and PanelView™ 800 HMI. PanelView 800 Human Machine Interface High Flexibility plug-in and expansion modules allow you to optimize your machine cost. Up to five plug-ins and up to four expansion I/O modules are also allowed. Choose the performance and functionality specific to your machine needs. COMO • I-00 • I-01 • I-02 • I-03 • I-04 • I-05 • I-06 • I-07 COM1 • I-08 • I-09 • I-02 • I-10 • I-11 • I-12 • I-13 2080-LC50-24QBB MAC ID 00:00:BC:CE:3A:10 Micro850 Controller with Series Port plug-ins MS NS Micro850™ RUN-REM-PRG +DC -DC • 24 24 COM • 0-00 CM1 • 0-01 CM2 • 0-02 • 0-03 • 0-04 • 0-05 CM3 • 0-06 • 0-07 • 0-08 • 0-09 Bulletin 900 Temperature Controllers MODBUS RTU MODBUS RTU Maximum of six serial ports for communications to temperature controllers, bar code readers and other devices. PowerFlex 523 Drive Main Heater Connected Components Workbench Software Feed Heater Publication OEM-BR052A-EN-P – July 2015 Main Motor Asynchronous Motor No Encoder Network Controller Drives Main Screw Temperature Control Temperature Zone Modbus RTU, EtherNet/IP Micro850, Serial Port Plug-ins PowerFlex 523 AC Drive Asynchronous Motor, No Encoder Bulletin 900-TC Up to sixteen Cooler Feeder Motor Main Extruder Motor Copyright ©2015 Rockwell Automation, Inc. All Rights Reserved. Manufacturing & Assembly Stamping Press Application Press solutions for multiple sizes and types of metal forming equipment Photo courtesy of Simpac Machine Builder Challenges • Deliver safe, efficient, and reliable press automation solutions. • Build equipment to accepted industry standards that easily integrate with other equipment. • Reduce setup and changeover times with standardized solutions. • Drive sustainable production to reduce downtime, line inefficiencies, and energy consumption. • Balance machine performance, safety requirements, and machine costs. End User Challenges • Reduce setup and changeover times. • Develop solutions that reduce downtime and improve diagnostics to reduce repair times. • Enhance repeatability and reduce material variations to minimize scrap. • Provide connectivity for real-time data collection and analytics to drive continuous improvement. • Provide secure remote access for remote troubleshooting. • Implement off-the-shelf solutions with standardized products that can be supported globally. Helping You Differentiate Your Machines • Broad range of control, safety, and information disciplines with one single, fully-integrated platform that provides actionable, real-time data - Integrated Architecture offers single-source buying to ease design, development, and maintenance - Connected Component solutions for simple press solutions - Meet your customer demands for secure and information-enabled machines - Safety expertise and off-the-shelf integrated safety solutions - Low risk deployments with standard off-the-shelf solutions • Global services and support and locally available spare parts • Our end user relationships and dedicated OEM experts help extend your market reach Metal Forming and Stamping Line Layout Straightener Sizer Flattener Coil Handling Area Mechanical Press Servo Press Hydraulic Press Feeder Area Typical Architecture Un-coiler to Press Feeder to Stamping Press PanelView™ Plus 7 Human Machine Interface Studio 5000 Logix Designer® Compact Guard Logix® Compact Guard Logix SAFETY CPU SFTY RUN SFTY TASK SFTY LOCK SFTY OK E4:90:69:A1:1A:EE Press Angle Encoder Stratix™ 5700 EtherNet/IP 9 9 9 MS 1734-AENTR Series-B 24VDC Safety Sink Input Network Activity Network Status Point Bus Status System Power Field Power IP ADDRESS Mod Net Mod Net 5700 5700 Mod Net Mod Net 5700 5700 Mod Net Mod Net 5700 5700 Mod Net Mod Net 5700 5700 Two Hand Control NS LK Module Status Link 1 Activity Status P W R 1734-IB8S light curtain Link 2 Activity Status Risk of electric shock. Power off and wait 5 min. 2 Risk of electric shock. Power off and wait 5 min. 1 1 1 4 Risk of electric shock. Power off and wait 5 min. Risk of electric shock. Power off and wait 5 min. 22 11 1 1 Risk of electric shock. Power off and wait 5 min. 22 2 2 11 I/O 6 1 10 5 1 I/O-A 6 1 1 4 10 5 UFB-A 11 I/O 6 1 10 5 I/O-A 6 1 I/O-B 6 4 I/O UFB Risk of electric shock. Power off and wait 5 min. 22 11 1 6 I/O 5 Risk of electric shock. Power off and wait 5 min. 22 1 1 I/O-B 4 I/O Risk of electric shock. Power off and wait 5 min. 2 I/O 10 5 UFB UFB-b 10 5 UFB-A 10 Safety I/O UFB-b 9 9 9 MS 1734-AENTR Series-B Emergency Stop NS LK 24VDC Safety Sink Input Module Status Network Activity Network Status Link 1 Activity Status Point Bus Status System Power IP ADDRESS Field Power P W R 1734-IB8S Link 2 Activity Status Interlocking Switch Un Coiler AC Motor Straightener AC Motor Feeder Servo Motor Type: Mechanical Type: Servo Mod Net 2 1 Mod Net 5700 Risk of electric shock. Power off and wait 5 min. 5700 Risk of electric shock. Power off and wait 5 min. 22 11 1 1 1 4 Mod Net 5700 Risk of electric shock. Power off and wait 5 min. 22 2 1 Control Option for Main Motor Mod Net 5700 Risk of electric shock. Power off and wait 5 min. 11 I/O 6 1 10 5 I/O-A 6 1 I/O-B 6 4 I/O I/O 5 UFB 10 5 UFB-A 10 UFB-b Servo Drive - Kinetix® 5700 PowerFlex® AC Drive Scalable Press Solutions with Integrated Safety Architecture Compact Guard Logix SAFETY CPU SFTY RUN SFTY TASK SFTY LOCK SFTY OK PanelView™ Human Machine Interface Compact GuardLogix™ PAC E4:90:69:A1:1A:EE Left Front Upright Right Front Upright Slide Angle Single Turn Die Block, E-Stop, Run Bar Die Block, E-Stop, Run Bar Left Rear Upright Right Rear Upright PowerFlex® Drive Flywheel Motor Drive Die Block, E-Stop, Run Bar Die Block, E-Stop, Run Bar Final Output Basement Magnetics Enclosure CES Interface (optional) ROSS Valve Interface Clutch Valve Reset Reset OK Mod Switch, Inch P/B Clutch Control Reset Control Reset Clutch Valve Reset Faster Machine Start-up Power programming template in Studio 5000 Logix Designer™ offers modular program code to reduce engineering and commissioning time. Standard, reusable software modules and Add-on-Instructions (AOIs) also reduce development time. Modular Wiring Ethernet solutions for drives, servos and I/O reduce wiring and start up times with modular building blocks. Energy Management Motion Analyzer sizing tool helps identify the right drives products to optimize power usage. Motor Starter Outputs Aux Contact Inputs Slide Angle Single Turn Non Safety PB/SS/LT • BGIA certified instruction suite for § BGIA certified instruction suite for metal§ metal forming industry forming industry – EN692, ANSI B 11.1 & CSA Z142.02 § EN692, ANSI B 11.1 & CSA Z142.02 – Two hand Control station § Two hand Control station – Crank Shaft Position monitor § § Crank Shaft Position monitor – Main valve control § Main valve control – Position mode selector § Position mode selector Pre-engineered Solutions Proven, off-the-shelf solutions include PressGuard™ and Compact PressMaster™ pre-engineered press control systems. § § § § § EN692, ANSI B 11.1 & CSA Z142.02 Two hand Control station Crank Shaft Position monitor Main valve control Position mode selector Pre Configured Engineered solution for Press Control system – Press Guard § Pre Configured Engineered solution for Presson Control system – Press Guard system complexity Press and safety control a single platform to reduce Safety and Productivity Innovative safety solutions improve press machine functional operation and help to increase personnel safety, efficiency, and productivity. Real-time Information Information-enabled machines that use Rockwell Automation Integrated Architecture with EtherNet/IP easily integrate into production lines and provide actionable production information for improved decision making (e.g. OEE). BGIA certified instruction suite for metal forming industry Compact Guard Logix SAFETY CPU 0 1 2 3 4 5 6 7 8 9 SFTY RUN SFTY TASK SFTY LOCK SFTY OK 0 1 2 3 4 5 440C-CR30 2080-1040 1 B VO 2 3 2080-1040 4 CO CO1 V1 5 6 01 CO1 A COM COM COM COM V-5 C1-1 1 B VO 2 3 4 CO CO1 V1 5 6 01 CO1 A COM COM COM COM V-5 C1-1 E4:90:69:A1:1A:EE Compact Guard Logix Safety Relays Guardmaster® 440C-CR30 E-Stops and Signaling Laser Scanner Safety Contactors Gate Switches (For presses with physical guards) Safety Mats Light Curtains Safety Drives Stand-Alone Machine • Scaled solutions to match press functionality needs. • Leverage Connected Component solutions for simple press solutions using one common configuration software with broad portfolio of safety components in the industry. • Software configurable safety relay with SIL 3/PLE certification. • Controller plug-in modules offer cost-effective expansion of machine features and functions. Common Programming Software Connected Components Workbench™ software for Micro800® controller, PowerFlex AC drives, PanelView 800 HMI, and Guardmaster® 440C-CR30 safety relay. Typical Architecture for Micro-Solutions PanelView 800 Human Machine Interface Safety Functions and I/O provided by Guardmaster® 440C-CR30. Encoder Line Encoder Micro850 A 4 Position Mode Select Switch Micro850 B EtherNet/IP Heavy duty performance and high torque at low frequencies for fly wheel with PowerFlex 753 drive. Versatility of controller interfaces up to six high speed counter inputs and up to three ‘Pulse Train Output’ over embedded digital I/O. Up to five plug-ins and up to four expansion I/O modules also allowed. Controller expansion I/O and plugin for Die Protector, Tonnage Monitor and CAM output. Relays 2 Hand Control Stratix 2000 Reset Guardmaster® 440C-CR30 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 440C-CR30 2080-1040 1 B VO 2 3 2080-1040 4 CO CO1 V1 5 6 01 CO1 A COM COM COM COM V-5 C1-1 1 B VO 2 3 4 CO CO1 V1 5 6 01 CO1 A COM COM COM COM V-5 C1-1 Light Curtain Relays & SSRs PowerFlex Drive Flywheel Motor Drive E-stop Interlocking Switch Clutch Brake Valve Neutral Connected Components Workbench™ software Component Safety Solution Publication OEM-BR060C-EN-P – July 2016 Network EtherNet/IP, Modbus RTU Controller Dual Micro850 controllers Variable Frequency Drive PowerFlex 753 for fly wheel Safety Devices Guardmaster®440C-CR30 and Guardmaster® GuardShield Motion Dual encoder feedback from flywheeel Copyright ©2015 Rockwell Automation, Inc. All Rights Reserved. Supporting Your Business Every Step of the Way At every stage in the life cycle of your machines, Rockwell Automation is your collaboration partner. From design to build to operation and maintenance, you can count on the continuum of Rockwell Automation resources to deliver safe automation solutions for press applications. change, increasing profits and attracting new customers with high performance and innovative machines. Whether providing you with single components, entire systems or specialized consultation or trying to achieve sustainable production initiatives, our goal is to offer solutions on a personalized level. By taking advantage of our products and services, you can lower your Total Cost To Design, Develop and Deliver®, while improving your time to market. You will be better equipped to react quickly to For More Information: Call a Rockwell Automation sales office or an authorized distributor today or visit us online at www.rockwellautomation.com For more information about our OEM Solutions, please visit: http://www.rockwellautomation.com/go/lit/oem Allen-Bradley, Connected Components Workbench, CompactLogix, Integrated Architecture, Guardmaster, Kinetix, LISTEN. THINK. SOLVE., Micro800, Micro850, PanelView, PowerFlex, Rockwell Automation, Rockwell Software, Stratix, Studio5000 Logix Designer, and Total Cost to Design, Develop and Deliver are trademarks of Rockwell Automation, Inc. EtherNet/IP is a trademark of the ODVA. All other trademarks and registered trademarks are property of their respective companies. Publication OEM-CL002B-EN-P - August 2016 Copyright ©2016 Rockwell Automation, Inc. All Rights Reserved.