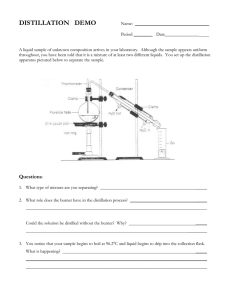

Ind. Eng. Chem. Res. 2010, 49, 1333–1350 1333 Externally Heat-Integrated Double Distillation Column (EHIDDiC): Basic Concept and General Characteristics Kejin Huang,* Wei Liu, Jiangpeng Ma, and Shaofeng Wang College of Information Science and Technology, Beijing UniVersity of Chemical Technology, Beijing 100029, People’s Republic of China In terms of the thermodynamic characteristics of simple distillation columns, a novel schematic of an externally heat-integrated double distillation column (EHIDDiC) is proposed and studied in this work. It consists of high-pressure and low-pressure distillation columns, with external heat integration between the whole rectifying section of the former and the whole stripping section of the latter. In comparison with conventional distillation systems (i.e., direct and indirect separation sequences), the EHIDDiC was found to require relatively small capital investment and low operating costs. It can even outperform conventional distillation systems with the condenser/reboiler type of heat integration under some favorable operating conditions. In terms of the separation of a ternary ideal mixture containing hypothetical components A, B, and C, the EHIDDiC was evaluated through intensive comparisons with its conventional counterparts. Sensitivity analysis was also conducted with respect to some relevant physical properties and design parameters, including the relative volatilities, feed composition, external heat-transfer area per stage, product specifications, and utility costs. It was confirmed that the EHIDDiC can be advantageous over conventional distillation systems with and without condenser/ reboiler-type heat integration, and the results obtained reflect the salient characteristics of the EHIDDiC. 1. Introduction Internal heat integration between the rectifying section and the stripping section of a simple distillation column (i.e., with one feed and two products) leads to the creation of an ideal heat-integrated distillation column (ideal HIDiC).1-3 A detailed schematic of an ideal HIDiC is illustrated in Figure 1. Although both theoretical analyses and experimental evaluations have demonstrated that the HIDiC can be much more thermodynamically efficient than its conventional counterparts, a large amount of capital must be invested, among which the necessity for a compressor constitutes one of the most expensive factors.4-8 Such intensive expenditures also constitute one of the primary reasons that have prevented the ideal HIDiC from finding wide application in the chemical and petrochemical process industries so far. To avoid the use of an expensive compressor, one might consider external heat integration between the rectifying section and the stripping section of two individual distillation columns (i.e., the rectifying section/stripping section type of heat integration), because the necessary temperature driving forces can be achieved instead through adjustments of the pressures of each distillation column through the condensers. (Recall that the heat duty of the top condenser is generally employed to control the system pressure.) This modification leads to the creation of a novel schematic of externally heat-integrated double distillation columns (EHIDDiCs). For the separation of close-boiling binary/multicomponent mixtures, a great reduction in process irreversibility is still likely to be obtained in both distillation columns, hence giving rise to a considerable improvement in the efficiency of energy utilization. Regarding the external heat integration between two individual distillation columns, the most frequently employed schematic is the condenser/reboiler-type configuration, where heat is transferred from the condenser of the high-pressure (HP) distillation column to the reboiler of the low-pressure (LP) distillation column. There are generally two types of schematics * To whom correspondence should be addressed. Tel.: +86 10 64434801. Fax: +86 10 64437805. E-mail: huangkj@mail.buct.edu.cn. for this type of external heat integration. One involves two individual distillation columns that might or might not have a direct mass connection. The other accommodates a number of distillation columns that separate a common mixture (i.e., a multieffect distillation system), where the feed splitting ratios are key design variables to maximize the effect of external heat integration between the distillation columns.9,10 Luyben and coworkers studied this type of external heat integration for a number of chemical processes and claimed that the reduction in utility consumption and capital investment could be achieved, simultaneously.11-13 Annakou and Mizsey claimed that this type of external heat integration could facilitate a conventional distillation system to be more thermodynamically efficient than the Petlyuk distillation system in the separation of ternary mixtures.14 Emtir et al. found that the composition of the mixtures separated dominated actually the structure of the condenser/reboiler type of heat integration for the separation of ternary mixtures.15 Engelien and Skogestad studied a four pressure-staged distillation system and indicated that the condenser/reboiler type of heat integration was advantageous in that no retrofit had to be made in process design.16 In addition, a great number of publications have addressed the trade-off Figure 1. Schematic of an ideal HIDiC. 10.1021/ie901307j 2010 American Chemical Society Published on Web 12/08/2009 1334 Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 between the design and operation of conventional distillation systems with the condenser/reboiler type of heat integration.17-19 The outcomes demonstrated that it was extremely important to consider process dynamics and operation at the early stages of process synthesis and design. As for the rectifying section/stripping section type of heat integration, only a few studies have been conducted so far. Recently, we studied external heat integration in a pressureswing distillation (PSD) system separating a binary azeotropic mixture of acetonitrile and water.20 We found that this type of external heat integration might help to improve process design in terms of not only operating cost but also capital investment. In pursuit of further improvement in system performance, simultaneous consideration of the condenser/reboiler type of heat integration with the rectifying section/stripping section type of heat integration between the LP and HP distillation columns (i.e., the EHIDDiC) is strongly recommended for the PSD process. Kataoka et al. reported a simulation study of external heat integration in a system producing fuel ethanol from the fermented mash (termed the compressor-free HIDiC) and found that more than a 50% reduction of utility consumption could be obtained.21 These encouraging outcomes gave us further impetus to perform systematic studies of the energy-saving potentials of the EHIDDiC. The main purpose of this work is to explore systematically the performance and characteristics of the EHIDDiC. After its principle and configuration are briefly introduced, the EHIDDiC is evaluated in terms of an example system separating a ternary ideal mixture of hypothetical components A, B, and C into three relatively pure substances. Intensive comparisons are made to conventional distillation systems with and without the condenser/ reboiler type of heat integration. Sensitivity analysis is also performed with respect to some relevant physical properties and design parameters, including the relative volatilities of the mixture components, feed composition, product specifications, external heat-transfer area per stage, and utility cost. The salient characteristics of the EHIDDiC are highlighted, and some concluding remarks are summarized in the last section of the article. 2. Principle and Configuration of the EHIDDiC For a conventional distillation column, the rectifying section (or the equivalent section in the case of a multiple-feed distillation column) releases heat during operation and is thus reasonably considered as a potential heat source. In contrast, the stripping section (or the equivalent section in the case of a multiple-feed distillation column) absorbs heat during operation and is thus reasonably considered as a potential heat sink. Hence, heat integration can be arranged between the rectifying section and the stripping section of two individual distillation columns. With regard to the necessary temperature driving forces, heat integration can be achieved with the sole adjustment of the pressure of each distillation column, thus circumventing the use of an expensive compressor and throttle valve. These factors represent the primary advantages of the EHIDDiC over the ideal HIDiC. Figure 2 shows a schematic of the EHIDDiC. As can be seen, the whole rectifying section of the HP distillation column is stage-by-stage heat-integrated with the whole stripping section of the LP distillation column. Because of the external heat integration, either the reboiler of the LP distillation column or the condenser of the HP distillation column can be omitted (although not simultaneously because of the mismatch between their heat duties), which is closely dependent on the relative Figure 2. Schematic of the EHIDDiC. Table 1. Physical Properties and Design Specification of the Example System parameter value(s) pressure of the LP distillation column (bar) heat-transfer area (m2 · stage-1) heat-transfer coefficient (kW · K-1 · m-2) feed flow rate (kmol · h-1) feed concentration (zA/zB/zC, mol %) feed thermal condition relative volatility (RA/RB/RC) molecular weight of the mixture (kg · kmol-1) latent heat of vaporization (kcal · kmol-1) product specification (A, B, and C, mol %) intermediate product specification (A or C, mol %) vapor-pressure constants A (Avp/Bvp) B (Avp/Bvp) C (Avp/Bvp) 3.0 1, 3, 5 0.6 100 1 1 1 /3: /3: /3 1.0 4:2:1 50 6944 99 0.25 13.0394/4634.4 12.3463/4634.4 11.6531/4634.4 magnitudes of their heat duties. This offers a possibility of simultaneously reducing capital investment and operating costs. 3. Illustrative Example: Separation of a Ternary Ideal Mixture with Hypothetical Components A ternary close-boiling mixture with hypothetical components A, B, and C is purified into relative pure substances with composition specifications of 99.0 mol % each. Because two simple distillation columns are needed in the separation operation, the specifications of the intermediate products are fixed arbitrarily at 0.25 mol % for component A in the direct separation sequence (DSS) and 0.25 mol % for component C in the indirect separation sequence (ISS), although they should be subjected to a detailed optimization study. Ideal vapor-liquid equilibrium behavior is assumed, with component A being the lightest and component C the heaviest. The relative volatilities between these hypothetical components are independent of the changes in mixture composition and system pressure. Equal latent heats are assumed for the three components, and sensible heat can be ignored as compared with latent heat. Table 1 summarizes the physical properties and design specifications for the separation problem. The ideal vapor-liquid equilibrium is expressed as P)xAPAS+xBPSB+xCPSC (1) where P signifies the system pressure and PiS represents the saturation pressure, which is given by the Antoine equation ln PSi ) Avp,i - Bvp,i /T i ) A, B, and C (2) Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 Table 2. Economical Basis for Process Synthesis and Design parameter condensers heat-transfer coefficient (kW · K-1 · m-2) temperature difference (K) reboilers heat-transfer coefficient (kW · K-1 · m-2) temperature difference (K) cooling water (US $ · ton-1) LP steam (US $ · ton-1) HP steam (US $ · ton-1) payback period (years) value 0.852 13.9 0.568 34.8 0.06 25 25 (0.985 + 0.015PHP) 3 where Avp and Bvp represent the vapor-pressure constants. With the stripping away of the nonlinearity by nonideal vapor-liquid equilibrium and temperature/composition dependence of heat of vaporization, the merits and demerits of the EHIDDiC can be analyzed in a more straightforward manner. In terms of the principles of mass and energy conservation in conjunction with the given vapor-liquid equilibrium relationship, steady-state models of a conventional distillation system with and without condenser/reboiler-type heat integration and of the EHIDDiC have been developed. The external heat integration between the HP and LP distillation columns is estimated with a lumped heat-transfer model (cf. eq 3). A modified Newton-Raphson method is employed as the nonlinear equation solver, and the satisfaction of both the component mass balance equations and the product specifications is taken as the convergence criterion. Given the flow rate and composition of the ternary mixture to be separated, the topological structures of the system flowsheets adopted, and the desired product specifications, the heat duties of reboilers and condensers can be readily estimated in a robust and yet effective manner. These steady-state models can be employed to aid process synthesis and design. QHI ) US(THP - TLP) (3) 4. Conceptual Synthesis and Design of Conventional Distillation Systems with and without Condenser/ Reboiler-Type Heat Integration The minimization of total annual cost (TAC) is taken as the objective function for process synthesis and design. The TAC is the sum of the operating cost (OC) and the annual capital investment. The annual capital investment is assumed to be the capital investment (CI) divided by a payback period of 3 years (cf. eq 4). The cost of equipment is estimated with the formulas shown in Appendix I, and a recursive procedure is outlined in Appendix II for the conceptual synthesis and design of conventional distillation systems (CDSs) with and without condenser/reboiler-type heat integration [termed HICDS (i.e., heat-integrated CDS) and CDS, respectively]. Table 2 lists the relevant utility costs adopted in the current work. Note that the cost of HP steam is expressed as 25(0.985 + 0.015PHP), reflecting its dependence on pressure and temperature. (4) TAC ) OC + CI/β Figure 3I (where I indicates column I) presents three schematics of the CDS and HICDS for the DDS. For the sake of a general illustration, a trim-condenser and a trim-reboiler are drawn at the heat-integrated ends of the HP and LP distillation columns, respectively, in the two schematics of the HICDS (cf. Figure 3Ib,Ic). Once the detailed operating conditions are known, either the trim-condenser or the trim-reboiler should be removed, depending closely on the relative magnitudes of the heat duties of the condenser and reboiler that are 1335 heat-integrated. The two HICDS configurations differ mainly in the arrangement of external heat integration between the HP and LP distillation columns, leading to different pressure elevations, capital investment, and operating costs. Each one can be an economical option for the separation of the given ternary mixture, and this is closely dependent on the composition of the feed to be separated. If the feed composition of intermediate component B is not too small (i.e., greater than 1 /3), the schematic shown in Figure 3Ib is generally superior to that shown in Figure 3Ic because of the relatively strong degree of external heat integration allowed and the small pressure elevation necessitated between the LP and HP distillation columns. Therefore, the schematics shown in Figure 3Ia,Ib are designed and studied here. Figure 4I shows the relationships between the CI, OC, and TAC and the number of stages, Nc1 and Nc2, for the CDS (DSS). The optimum process design indicates a distillation system with 39 stages in each the first and second distillation columns. Table 3 details the comparison between the CDS (DSS) and HICDS (DSS). For the synthesis and design of the HICDS (DSS), the minimization of TAC is still taken as the objective function, and the operating pressure of the HP distillation column is determined by keeping a temperature driving force of 34.8 K in the reboiler of the LP distillation column (cf. eq 5). It is noticed that the condenser/ reboiler type of heat integration leads to simultaneous reductions of capital investment and utility consumption by 19.21% and 42.97%, respectively. PHP ) xAPAS(TNc1 + 34.8) + xBPSB(TNc1 + 34.8) + xCPSC(TNc1 + 34.8) (5) Figure 3II (where II represents column II) presents three schematics of the CDS and HICDS for the ISS. Similarly to the case of the DSS, if the feed composition of intermediate component B is not too small (i.e., greater than 1/3), then the schematic shown in Figure 3IIb is also generally superior to that shown in Figure 3IIc, and only those shown in Figure 3IIa,IIb are designed and studied here. Figure 4II shows the relationships between the CI, OC, and TAC and the number of stages, Nc1 and Nc2, for the CDS (ISS). It is readily seen that the optimum process design is a distillation system with 39 stages in each the first and second distillation columns. Table 4 details the comparison between the CDS (ISS) and HICDS (ISS). The condenser/reboiler type of heat integration again results in simultaneous reductions of capital investment and utility consumption by 16.64% and 35.28%, respectively. In Figure 5, the steady-state profiles of temperature, vapor and liquid flow rates, and liquid composition are depicted for the DSS (column I) and ISS (column II) of the CDS. It is stipulated here that the solid lines represent the static behaviors of the first distillation column, and the dashed lines represent the static behaviors of the second distillation column. For the HICDS (DSS) and HICDS (ISS), the steady-state profiles are similar and are not shown here. 5. Conceptual Synthesis and Design of the EHIDDiC An iterative procedure is outlined in Appendix III for the conceptual synthesis and design of the EHIDDiC. Figure 6I presents two schematics of the EHIDDiC for the DSS, and again, for the purpose of a general representation, a trimcondenser and a trim-reboiler are drawn at the heat-integrated ends of the HP and LP distillation columns, respectively. Similarly to the situations of HICDS (DSS), these two schematics differ mainly in the arrangement of the external 1336 Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 Figure 3. Schematics of the CDS and HICDS: (I) DSS, (II) ISS. heat integration between the HP and LP distillation columns, exhibiting different pressure elevations, capital investment, and operating costs. Closely dependent on the composition of the feed to be separated, each one can be an economical solution for the separation of the given ternary mixture. If the feed composition of intermediate component B is not too small (i.e., greater than 1/3), the schematic shown in Figure 6Ia is also generally superior to that shown in Figure 6Ib because of the relatively strong degree of external heat integration allowed and the small pressure elevation necessitated between the LP and HP distillation columns. Therefore, the process schematic shown in Figure 6Ia is designed and studied in this work. Figure 7I depicts the relationships between the CI, OC, and TAC and the number of externally heat-integrated stages, NHI, for the EHIDDiC (DSS). As can be seen, when NHI is around 23, the TAC approaches its minimum value. The optimum process design corresponds to the EHIDDiC with 40 stages in each the LP and HP distillation columns, and the optimum values of CI, OC, TAC, and other relevant design and operation variables are also reported in Table 3. Similarly to the HICDS (DSS), the EHIDDiC results in simultaneous reductions of capital investment and utility consumption by 0.62% and 42.51%, respectively, in comparison with the CDS (DSS). The steady- Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 1337 Figure 4. Relationships between (a) CI, (b) OC, and (c) TAC and the number of stages, Nc1 and Nc2, for the CDS: (I) DSS, (II) ISS. state profiles of temperature, vapor and liquid flow rates, and liquid composition are shown in Figure 8I. Gradual changes of the vapor and liquid flow rates take place in the heatintegrated sections of the HP and LP distillation columns. Analogously, there are two schematics for the ISS, as shown in Figure 6II. If the feed composition of intermediate component B is not too small (i.e., greater than 1/3), the schematic shown in Figure 6IIa is also superior to that shown in Figure 6IIb, and only the former is designed and studied here. Figure 7II depicts the relationships between the CI, OC, and TAC and the number of externally heat-integrated stages, NHI, for the EHIDDiC (ISS). When NHI is around 22, the TAC approaches its minimum value, and the optimum process design consists of an EHIDDiC with 39 stages in each the HP and LP distillation columns. The optimum values of CI, OC, TAC, and other relevant design and operating variables are also included in Table 4. The EHIDDiC results in simultaneous reductions of capital investment and utility consumption by 3.29% and 52.33%, respectively, in comparison with the CDS (ISS). The steady-state profiles of temperature, vapor and liquid flow rates, and liquid composition are shown in Figure 8II. Again, gradual changes of the vapor and liquid flow rates take place in the heat-integrated sections of the HP and LP distillation columns. 1338 Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 Table 3. CDS and HICDS versus EHIDDiC for the DSS parameter CDS HICDS EHIDDiC pressure of the first distillation column (bar) pressure of the second distillation column (bar) number of stages in the first distillation column number of stages in the second distillation column feed location of stages in the first distillation column feed location of stages in the second distillation column heat-transfer areas in condensers (m2) heat-transfer areas in reboilers (m2) side heat-transfer areas (m2) reflux flow rate in the first distillation column (kmol · s-1) reflux flow rate in the second distillation column (kmol · s-1) distillate flow rate in the first distillation column (kmol · s-1) distillate flow rate in the second distillation column (kmol · s-1) condenser heat duty in the first distillation column (MW) condenser heat duty in the second distillation column (MW) trim-condenser heat duty in the second distillation column (MW) reboiler heat duty in the first distillation column (MW) reboiler heat duty in the second distillation column (MW) trim-reboiler heat duty in the first distillation column (MW) bottom flow rate in the first distillation column (kmol · s-1) bottom flow rate in the second distillation column (kmol · s-1) diameter of the first distillation column (m) diameter of the second distillation column (m) height of the first distillation column (m) height of the second distillation column (m) annual capital investment (US$ × 106 · year-1) operating cost (US$ × 106 · year-1) TAC (US$ × 106 · year-1) 3.0 3.0 39 39 19 22 143.346 85.8841 0.0210 0.0190 0.0093 0.0092 0.8800 0.8176 0.8800 0.8176 0.0185 0.0093 0.8184 0.8006 28.5293 28.5293 0.2764 0.4957 0.7721 3.0 10.6641 39 39 19 22 74.3065 85.8841 0.0210 0.0190 0.0093 0.0092 0.8800 0.8176 0 0.8176 0.8176 0.0624 0.0185 0.0093 0.8183 0.6007 28.5293 28.5293 0.2233 0.2827 0.5060 3.0 4.2471 40 40 17 24 81.5021 62.3126 115 0.0239 0 0.0093 0.0092 0.9652 0 0.9372 0.2945 0.0185 0.0093 0.8571 0.6564 29.2608 29.2608 0.2747 0.2850 0.5596 parameter CDS HICDS EHIDDiC pressure of the first distillation column (bar) pressure of the second distillation column (bar) number of stages in the first distillation column number of stages in the second distillation column feed location of stages in the first distillation column feed location of stages in the second distillation column heat-transfer areas in condensers (m2) heat-transfer areas in reboilers (m2) side heat-transfer areas (m2) reflux flow rate in the first distillation column (kmol · s-1) reflux flow rate in the second distillation column (kmol · s-1) distillate flow rate in the first distillation column (kmol · s-1) distillate flow rate in the second distillation column (kmol · s-1) condenser heat duty in the first distillation column (MW) condenser heat duty in the second distillation column (MW) trim-condenser heat duty in the first distillation column (MW) reboiler heat duty in the first distillation column (MW) reboiler heat duty in the second distillation column (MW) trim-reboiler heat duty in the second distillation column (MW) bottom flow rate in the first distillation column (kmol · s-1) bottom flow rate in the second distillation column (kmol · s-1) diameter of the first distillation column (m) diameter of the second distillation column (m) height of the first distillation column (m) height of the second distillation column (m) annual capital investment (US$ × 106 · year-1) operating cost (US$ × 106 · year-1) TAC (US$ × 106 · year-1) 3.0 3.0 39 39 24 20 163.870 98.1808 0.0202 0.0188 0.0185 0.0093 1.1243 0.8164 1.1243 0.8164 0.0093 0.0092 0.9329 0.7882 28.5293 28.5293 0.2980 0.5658 0.8638 11.2101 3.0 39 39 24 20 94.9358 98.1808 0.0202 0.0188 0.0185 0.0093 0.8164 0.8164 0.3079 1.1243 0.8164 0 0.0093 0.0092 0.6916 0.7882 28.5293 28.5293 0.2484 0.3662 0.6146 4.8637 3.0 39 39 23 17 121.729 72.9322 110 0 0.0218 0.0185 0.0093 0 0.9045 1.3485 0.0931 0.0093 0.0092 0.7847 0.8297 28.5293 28.5293 0.2882 0.2697 0.5579 Table 4. CDS and HICDS versus EHIDDiC for the ISS Notice that, for the conventional distillation systems, the DSS outperforms the ISS in terms of both capital investment and utility consumption. With the inclusion of the condenser/reboiler type of heat integration in the HICDS, no variations occur in this tendency because this type of heat integration presents hardly any influences on the separation operation itself. For the rectifying section/stripping section type of heat integration, the tendency has been altered because this type of heat integration can have a strong impact on the synthesis and design of the EHIDDiC. 6. Comparison between the HICDS and EHIDDiC The advantages of the EHIDDiC over the HICDS are twofold. One is the reduction in process irreversibility. The relatively large reflux ratios of conventional distillation columns (e.g., in the separation of close-boiling mixtures) is the main source of process irreversibility, but the condenser/reboiler type of heat integration gives no correction at all in this respect. External heat integration between the rectifying section and the stripping section of the HP and LP distillation columns can serve to reduce the reflux ratios and lead to a relatively small utility consump- Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 1339 Figure 5. Steady-state profiles of (a) temperature, (b) vapor and liquid flow rates, and (c) liquid composition for the CDS: (I) DSS, (II) ISS. tion. The other advantage is the relatively low pressure elevation from the LP to the HP distillation column. For the HICDS, because heat transfer in the heat-integrated condenser/reboiler needs to not only overcome the inherent negative temperature difference but also maintain a relatively large temperature driving force, a high pressure elevation is necessitated between the LP and HP distillation columns. For the EHIDDiC, owing to the structure modification for the rectifying section/stripping section type of heat integration, it is no longer necessary to keep the pressure elevation from the LP to the HP distillation column as high as in the HICDS. If the relative volatility of the mixture components appears to be sensitive to pressure variations, then the EHIDDiC could be more thermodynamically efficient than the HICDS. With reference to Tables 3 and 4, one can readily find that the two EHIDDiCs for the DSS and ISS allow a much smaller pressure elevation from the LP to the HP distillation column than the two HICDSs. In terms of operating cost, although the EHIDDiC appears to be comparable to the HICDS for the DSS, the former appears to be more advantageous than the latter for the ISS. These facts indicate that whether the EHIDDiC can be more thermodynamically efficient than the HICDS depends heavily on the process synthesis and design. 1340 Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 Figure 6. Schematic of the EHIDDiC: (I) DSS, (II) ISS. In terms of capital investment, the EHIDDiC always needs a higher CI than the HICDS, implying that the rectifying section/ stripping section type of heat integration must be accompanied by additional capital expenditures. To search for the operating conditions that favor the application of the EHIDDiC over the CDS and HICDS, sensitivity analysis should be conducted with respect to the relevant physical properties of the mixture components, the given design specifications, and the utility costs. 7. Influences of Feed Composition To simplify the analysis, the feed composition of component B is varied independently, and the ratio between the feed compositions of components A and C is kept unchanged in all situations. For the DSS, Figure 9I displays the influences of feed composition on the conceptual synthesis and design of the CDS, HICDS, and EHIDDiC. The CIs and OCs of the three process designs increase monotonically with increasing feed composition of component B, and the HICDS and EHIDDiC appear to be much more thermodynamically efficient than the CDS despite the great changes in operating conditions. Regarding the HICDS and EHIDDiC, the former is advantageous in terms of operating cost when the feed composition of component B is less than 40 mol %. When the feed composition of component B is greater than 40 mol %, the reverse becomes true. This phenomenon is, in fact, caused by the reduction in process irreversibility with the rectifying section/stripping section type of heat integration, indicating that the EHIDDiC can be a competitive alternative to the HICDS, although its being so closely dependent on the composition of the feed to be separated. For the ISS, Figure 9II displays the influences of feed composition on the conceptual synthesis and design of the CDS, HICDS, and EHIDDiC. In terms of capital investment, the HICDS needs the smallest CI, with the EHIDDiC and CDS ranked second and third, respectively. With reference to operating costs, the EHIDDiC is most thermodynamically efficient, with the HICDS and CDS ranked second and third, respectively. 8. Influences of External Heat-Transfer Area Because the external heat-transfer area between the HP and LP distillation columns is a key design variable for the EHIDDiC, it is therefore imperative to examine the influences of this area on process synthesis and design. Figure 10I shows the effect of the external heat-transfer area per stage on the Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 1341 Figure 7. Relationships between (a) CI, (b) OC, and (c) TAC and the number of externally heat-integrated stages, NHI, for the EHIDDiC: (I) DSS, (II) ISS. conceptual synthesis and design of the EHIDDiC (DSS). It is interesting to note that the CI and OC increase with increasing external heat-transfer area, indicating that the intensification of external heat integration is not always beneficial to the performance of the separation operation. This phenomenon is due to the complicated interplay between the integrated part and the nonintegrated part of the HP and LP distillation columns. In process synthesis and design, the assignment of external heattransfer area per stage should therefore be cautiously determined. Likewise, Figure 10II shows the effect of the external heattransfer area per stage on the conceptual synthesis and design of the EHIDDiC (ISS). As can be readily seen, a more complicated relationship than in the case of DSS is found between the CI and OC and the external heat-transfer area per stage. With an increase in the external heat-transfer area, the CI and OC show first a decrease in magnitude, implying that the extent of external heat integration is appropriate in these situations and has a positive influence on the system performance. Beyond their minimum points, the CI and OC exhibit an increase in magnitude, implying that the degree of external heat integration is stronger than necessary and has an adverse influence on the system performance. The outcomes again 1342 Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 Figure 8. Steady-state profiles of (a) temperature, (b) vapor and liquid flow rates, and (c) liquid composition for the EHIDDiC: (I) DSS, (II) ISS. indicate the great importance of determining the distribution of external heat-transfer area cautiously in process synthesis and design. 9. Influences of the Top- and Bottom-Product Qualities For the DSS, Figure 11I displays the influences of product qualities on the conceptual synthesis and design of the CDS, HICDS, and EHIDDiC. Here, to simplify the analysis, the compositions of the three products are assumed to be equal to each other, and the bottom composition of component A in the first distillation column is kept unchanged (i.e., 0.25 mol %) in any cases. Whereas the CI increases with an enhancement of the product qualities, the OC shows almost no variation, implying that the enhancement of product purities is mainly accomplished by the establishment of two increasingly tall and large distillation columns. For the ISS, Figure 11II displays the influences of product qualities on the conceptual synthesis and design of the CDS, HICDS, and EHIDDiC. Quite similar tendencies as in the case of the DSS can be observed. Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 1343 Figure 9. Feed composition versus conceptual process synthesis and design: (I) DSS, (II) ISS. 10. Influences of the Relative Volatilities of the Ternary Mixture Components R ) PAS /PSB ) To simplify the analysis, the relative volatilities between components A/B and B/C are assumed to be equal in this situation, that is, RAB ) RBC ) R. When the relative volatilities undergo changes, the vapor-pressure constants of components A and B have to be modified accordingly as follows Figure 12I displays the influences of the relative volatilities of the ternary mixture components on the conceptual synthesis and design of the CDS, HICDS, and EHIDDiC for the DSS. The advantages of the HICDS and EHIDDiC over the CDS in terms of operating costs diminish gradually with increasing PSB /PSC ) exp(Avp,A - Avp,B) ) exp(Avp,B - Avp,C) (6) 1344 Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 Figure 10. Effect of external heat-transfer area on the synthesis and design of the EHIDDiC: (I) DSS, (II) ISS. relative volatilities, implying that the HICDS and EHIDDiC are used favorably for the separation of close-boiling multicomponent mixtures. The HICDS outperforms the EHIDDiC in terms of operating costs when the relative volatilities of the ternary mixture components are below 2.3, and above that value, the reverse becomes true. This finding indicates that the latter could be more thermodynamically efficient than the former when the relative volatilities of the ternary mixture components are comparatively high. Analogously, Figure 12II displays the influences of the relative volatilities of the ternary mixture components on the conceptual synthesis and design of the CDS, HICDS, and EHIDDiC for the ISS. Quite similar conclusions as in the case of the DSS are obtained. Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 1345 Figure 11. Product qualities versus conceptual process synthesis and design: (I) DSS, (II) ISS. 11. Influences of Utility Cost Utility cost varies with the pressure and temperature requirements (cf. Table 2), and their relationship can confine the elevation of system pressures in the HICDS and EHIDDiC. Furthermore, the relative volatilities of the mixture components might decrease dramatically with increasing operating pressure, and this enhances the operating cost correspondingly. From a purely economic point of view, the phenomenon can be viewed as a net increase in utility cost if the relationship between the relative volatilities and the system pressure is not known. Therefore, it is worth examining here the impact of utility cost on the feasibility of external heat integration in conventional distillation columns. Figure 13I displays the influences of the utility cost on the conceptual synthesis and design of the CDS, HICDS, and EHIDDiC for the DSS. It is noted that, when the utility cost coefficient is less than 0.015 US $ · ton-1 · bar-1, the HICDS appears to be superior to the EHIDDiC in operating cost, and it loses the advantage beyond that value. When the 1346 Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 Figure 12. Relative volatility versus conceptual process synthesis and design: (I) DSS, (II) ISS. utility cost coefficient is greater than 0.18 US $ · ton-1 · bar-1, the HICDS cannot even compete with the CDS, demonstrating that the HICDS is most sensitive to the utility cost among the three processes studied. The EHIDDiC requires the least operating cost ever because the utility cost coefficient is beyond 0.015 US $ · ton-1 · bar-1, and the more expensive the utility is, the greater the advantage of the EHIDDiC becomes. However, it should be borne in mind that the distinct advantage of the EHIDDiC in operating cost is actually achieved at the expense of additional capital investment. Figure 13II displays the influences of the utility cost on the conceptual synthesis and design of the CDS, HICDS, and EHIDDiC for the ISS. Quite similar tendencies as in the case of the DSS can be observed. The above results indicate that the EHIDDiC can be more thermodynamically efficient than the HICDS when the utility cost is relatively sensitive to the elevation of system pressure. Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 1347 Figure 13. Utility cost versus conceptual process synthesis and design: (I) DSS, (II) ISS. 12. Discussion It is worth stressing here that the illustrative example studied in this work represents a general circumstance of a threecomponent mixture separation. Under some favorable operating conditions, such as a relatively high feed composition of intermediate component B and high utility costs, the EHIDDiC can be more thermodynamically efficient than the CDS and HICDS for both the DSS and ISS. This outcome lends definite support to the rationale of considering the EHIDDiC as a valuable alternative for the separation of multicomponent mixtures. Although the EHIDDiC considered in this work has the same number of stages in the heat-integrated sections of the HP and LP distillation columns (and is therefore called a symmetrical EHIDDiC), different numbers of stages can be involved according the physical properties of the mixture components, which would lead to an asymmetrical EHIDDiC. Because an asymmetrical EHIDDiC might display a higher energy efficiency with an even lower capital investment than a 1348 Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 external heat exchangers to approximate external heat integration between the HP and LP distillation columns.22,23 Through the careful arrangement and design of these external heat exchangers, a good approximation to the EHIDDiC can be achieved, offering an alternative means of practical implementation. 13. Conclusions Figure 14. Schematic of the EHIDDiC separating a single binary/ multicomponent mixture. In light of the principle of the rectifying section/stripping section type of heat integration, a novel schematic for the EHIDDiC has been proposed and studied in this work. In terms of the separation of an ideal ternary mixture of hypothetical components A, B, and C, the EHIDDiC was evaluated through intensive comparisons with the CDS and HICDS. It was found that the EHIDDiC is advantageous over the CDS in terms of operating costs and capital investment. Under appropriate operating conditions, the EHIDDiC can be made more thermodynamically efficient than the HICDS, demonstrating the fact that the former can be a valuable alternative for the separation of binary and multicomponent mixtures. Future work will be focused on the development of an effective and yet practical way to implement the EHIDDiC. There are two alternatives in this respect. One is to accommodate the EHIDDiC within one shell through the deliberate arrangement of the external heat exchangers, and the other is to use several external heat exchangers to approximate the external heat integration between the LP and HP distillation columns. Owing to the strong coupling between the LP and HP distillation columns, it is quite likely that complicated process dynamics and potential control difficulties would occur, just as in the case of the ideal HIDiC.24-26 Therefore, this represents another important issue to be studied in the near future. Acknowledgment Figure 15. Simplified schematic of the EHIDDiC with three external heat exchangers. symmetrical EHIDDiC, it is not difficult to understand that the conclusions obtained in the current work are all based on a relatively conservative stance. Similarly to the HICDS, the EHIDDiC can be used in two alternative ways. One is for the accomplishment of two separation tasks simultaneously, and the example studied in this work is of this type. The other is for the accomplishment of only one separation task, and Figure 14 presents a schematic for this situation. Notice that the latter case is quite similar to a double-effect distillation system, but with a high degree of external heat integration between the HP and LP distillation columns. The feed splitting ratio still represents a key variable for process synthesis, design, and operation. Finally, we have to consider seriously the implementation issues of the EHIDDiC. Although it is advantageous to implement the EHIDDiC in one shell, which could lead to a further reduction in capital investment, a number of challenging issues, including the internal structure design for heat transfer, the arrangement of sufficient heat-transfer area, and the possible influences on mass transfer, have to be resolved. To avoid these challenging issues, one can still adopt the two-column structure and use a number of external heat exchangers (notice that the number should be much smaller than the number of heatintegrated pairs of stages) to approximate the heat transfer between the HP and LP distillation columns. Recently, we devised a simplified scheme for the EHIDDiC as shown in Figure 15, which is characterized by the use of only three This project was financially supported by the National High Technology Research and Development Program of China (i.e., 863 Program under Grant 2007AA05Z210) and the Scientific Research Foundation for the Returned Overseas Chinese Scholars, State Education Ministry. Notation A ) component Avp ) vapor-pressure constant (Pa) b ) bottom-product flow rate (kmol · s-1) B ) component Bvp ) vapor-pressure constant (Pa · K) c ) utility cost (US$ · ton-1) C ) component CDS ) conventional distillation system CI ) capital investment (US$) d ) diameter (m) D ) distillate flow rate (kmol · s-1) DSS ) direct separation sequence EHIDDiC ) externally heat-integrated double distillation columns F ) feed flow rate (kmol · s-1) H ) height (m) HICDS ) heat-integrated conventional distillation system ∆HV ) heat of vaporization (kJ · kmol-1) HIDiC ) heat-integrated distillation column ISS ) indirect separation sequence L ) liquid flow rate (kmol · s-1) m ) number of stages MW ) molecular weight of a mixture (kg · kmol-1) n ) number of stages Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 NF ) feed stage OC ) operating cost (US$ · year-1) P ) pressure (Pa) Q ) heat duty (kW) S ) heat-transfer area (m2 · stage-1) T ) temperature (K) TAC ) total annual cost (US$ · year-1) U ) overall heat-transfer coefficient (kW · K-1 · m-2) V ) vapor flow rate (kmol · s-1) x ) liquid composition y ) vapor composition z ) feed composition Greek Letters R ) relative volatility β ) payback time period (years) ∆ ) perturbation Φ ) splitting ratio Subscripts A ) component B ) component C ) component c ) conventional distillation column CON ) condenser F ) feed HI ) heat integration HP ) high pressure LP ) low pressure REB ) reboiler vp ) vapor pressure (Pa) Superscript S ) saturation employed for the synthesis and design of conventional distillation systems with and without the condenser/reboiler type of heat integration. (i) Given the flow rate and composition of the feed to be separated, the topological structure of the distillation system adopted, and the desired product specifications, do the following: (ii) Determine the number of stages for each distillation column, Nc1 and Nc2. (iii) Determine the feed locations for each distillation column, NF1 and NF2. (iv) Conduct the steady-state calculation and determine the operating conditions. (v) Calculate the TAC using the formulas in Appendix I. (vi) Check whether the TAC is minimal with respect to the feed locations, NF1 and NF2. If yes, go to the next step; otherwise, go to step iii. (vii) Check whether the TAC is minimal with respect to the number of stages, Nc1 and Nc2. If yes, go to the next step; otherwise, go to step ii. (viii) Summarize the design results, and stop. Appendix III: Procedure for the Synthesis and Design of the EHIDDiC Appendix I: Sizing and Economic Basis of Distillation Columns Assuming an F factor of 1 in engineering units, the diameter of a distillation column is calculated with the equation d ) 173.5(MW × T/P)0.25VN0.5 1349 (A1) The height of a distillation column is calculated assuming a tray spacing of 0.61 m and allowing 20% more height for the base-level volume H ) 0.73152N (A2) The heat-transfer areas of the reboiler and condenser are calculated using the steady-state vapor flow rates and the heat of vaporization With the application of the steady-state models introduced in section 3, the following grid-search philosophy can be employed for the synthesis and design of the EHIDDiC separating a given mixture. (i) Given the flow rate and composition of the feed to be separated, the topological structure of the EHIDDiC adopted, and the desired product specifications, do the following: (ii) Determine the number of stages for external heat integration, NHI. (iii) Determine the number of stages for the HP and LP distillation columns, NLP and NHP, respectively. (iv) Conduct the steady-state calculation and determine the corresponding operating conditions. (v) Calculate the TAC using the formulas in Appendix I. (vi) Check whether the TAC is minimal with respect to the number of stages, NLP and NHP. If yes, go to the next step; otherwise, go to step iii. (vii) Check whether the TAC is minimal with respect to the numbers of the externally heat-integrated stages, NHI. If yes, go to the next step; otherwise, go to step ii. (viii) Summarize the design results, and stop. SREB ) VN∆HV /(UREB∆TREB) (A3) Literature Cited SCON)V2∆HV /(UCON∆TCON) (A4) (1) Nakaiwa, M.; Huang, K.; Endo, T.; Ohmori, T.; Akiya, T.; Takamatsu, T. Internally Heat-Integrated Distillation Column: A Review. Chem. Eng. Res. Des. 2003, 81, 162. (2) Olujic, Z.; Fakhri, F.; Rijke, A.; Graauw, J.; Jansens, P. J. Internal Heat Integration: The Key to an Energy-Conserving Distillation Column. J. Chem. Technol. Biotechnol. 2003, 78, 241. (3) Huang, K.; Matsuda, K.; Iwakabe, K.; Takamatsu, T.; Nakaiwa, M. Graphical Synthesis of an Internally Heat-Integrated Distillation Column. J. Chem. Eng. Jpn. 2006, 39, 703. (4) Naito, K.; Nakaiwa, M.; Huang, K.; Endo, A.; Aso, K.; Nakanishi, T.; Nakamura, T.; Noda, H.; Takamatsu, T. Operation of a Bench-Scale Ideal Heat Integrated Distillation Column (HIDiC): An Experimental Study. Comput. Chem. Eng. 2000, S24, 495. (5) Huang, K.; Matsuda, K.; Iwakabe, K.; Takamatsu, T.; Nakaiwa, M. Interpreting Design of an Ideal Heat-Integrated Distillation Column through Exergy Analysis. J. Chem. Eng. Jpn. 2006, 39, 963. (6) Iwakabe, K.; Nakaiwa, M.; Huang, K.; Nakanishi, T.; Rosjorde, A.; Ohmori, T.; Endo, A.; Yamamoto, T. Energy Saving in Multi-Component Separation Using an Internally Heat-Integrated Distillation Column (HIDiC). Appl. Therm. Eng. 2006, 26, 1362. In terms of the above sizes, the capital and operating costs of a distillation column can be roughly estimated using the following equations column shell cost ) 17640d1.066H0.802 stage cost ) 229d 1.55 heat exchanger cost ) 7296SREB0.65 (A5) (A6) N + 7296SCON 0.65 utility cost ) 3600 × 24 × 300 × (cCONQCON /∆HV + cREBQREB /∆HV) (A7) (A8) Appendix II: Procedure for the Synthesis and Design of the CDS and HICDS With the application of the steady-state models introduced in section 3, the following grid-search philosophy can be 1350 Ind. Eng. Chem. Res., Vol. 49, No. 3, 2010 (7) Huang, K.; Shan, L.; Zhu, Q.; Qian, J. A Total Heat-Integrated Distillation Column (THIDiC)sThe Effect of Feed Pre-Heating by Distillate. Appl. Therm. Eng. 2008, 28, 856. (8) Huang, K.; Iwakabe, K.; Nakaiwa, M.; Matsuda, K.; Horiuchi, K.; Nakanishi, T. Considering Heat Integration to Improve Separation Performance. Hydrocarbon Process. 2008, 87, 101. (9) Wankat, P. C. Multi-Effect Distillation Processes. Ind. Eng. Chem. Res. 1993, 32, 894. (10) King, C. J. Separation Processes; McGraw-Hill: New York, 1980. (11) Chiang, T. P.; Luyben, W. L. Comparison of Energy Consumption in Five Heat-Integrated Distillation Configurations. Ind. Eng. Chem. Res. 1983, 22, 175. (12) Luyben, W. L. Distillation Design and Control Using Aspen Simulation; John Wiley & Sons: New York, 2006. (13) Luyben, W. L. Design and Control of a Fully Heat-Integrated Pressure-Swing Azeotropic Distillation System. Ind. Eng. Chem. Res. 2008, 47, 2681. (14) Annakou, O.; Mizsey, P. Rigorous Comparative Study of EnergyIntegrated Distillation Schemes. Ind. Eng. Chem. Res. 1996, 35, 1877. (15) Emtir, M.; Rev, E.; Fonyo, Z. Rigorous Simulation of Energy Integrated and Thermally Coupled Distillation Schemes for Ternary Mixture. Appl. Therm. Eng. 2001, 21, 1299. (16) Engelien, H. K.; Skogestad, S. Multi-Effect Distillation Applied to an Industrial Case Study. Chem. Eng Process. 2005, 44, 819. (17) Bildea, C. S.; Dimian, A. C. Interaction between Design and Control of a Heat-Integrated Distillation System with Pre-Fractionators. Chem. Eng. Res. Des. 1999, 77, 597. (18) Rix, A.; Gelbe, H. On the Impact of Mass and Heat Integration on Design and Control of Distillation Column Systems. Chem. Eng. Res. Des. 2000, 78, 542. (19) Tsai, W. H.; Huang, X. P.; Yu, C. C. Control Structure Design for Parallel Process. Application to Heat-Integrated Column. Chem. Eng. Res. Des. 2005, 83, 153. (20) Huang, K.; Shan, L.; Zhu, Q.; Qian, J. Adding Heat Integration to a Pressure-Swing Distillation (PSD) Process. Appl. Therm. Eng. 2008, 28, 923. (21) Kataoka, K.; Yamaji, H., Noda, H.; Mukaida, T.; Kaneda, M.; Nakaiwa, M. Compressor-Free Heat-Integrated Distillation Column System for Dehydration of Fermented Mash In Production of Fuel Bio-Ethanol. Presented at the AIChE 2008 Annual Meeting, Philadelphia, PA, Nov 16-21, 2008. (22) Huang, K.; Wang, Y.; Zhang, X.; Chen, H.; Wu, G.; Wang, S. Apparatus of Externally Heat-Integrated Double Distillation Columns (EHIDDiC) and its Control Technology. Chinese Patent 200910084908.4, 2009. (23) Wang, Y.; Huang, K.; Wang, S. A Simplified Scheme of Externally Heat-Integrated Double Distillation Columns with Three Heat Exchangers. Ind. Eng. Chem. Res., manuscript submitted. (24) Huang, K.; Nakaiwa, M.; Owa, M.; Akiya, T.; Nakane, T.; Sato, M.; Takamatsu, T. Identification and Internal Model Control of an Ideal Heat-Integrated Distillation Column (HIDiC). J. Chem. Eng. Jpn. 1998, 31, 218. (25) Zhu, Y.; Liu, X. Dynamics and Control of High Purity HeatIntegrated Distillation Columns. Ind. Eng. Chem. Res. 2005, 44, 8806. (26) Huang, K.; Wang, S.; Iwakabe, K.; Shan, L.; Zhu, Q. Temperature Control of an Ideal Heat-Integrated Distillation Column (HIDiC). Chem. Eng. Sci. 2007, 63, 6486. ReceiVed for reView August 20, 2009 ReVised manuscript receiVed November 4, 2009 Accepted November 23, 2009 IE901307J