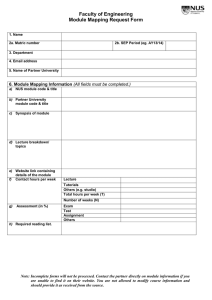

ASSIGNMENT FACULTY OF MANUFACTURING ENGINEERING UNIVERSITI TEKNIKAL MALAYSIA MELAKA INDUSTRIAL AUTOMATION BMFG 3213 / BMFG4223 SEMESTER 1 SESSION 2020/2021 FLEXIBLE MANUFACTURING SYSTEM (FMS) No 1. 2. Name Matric No OBJECTIVES By the end of this activity, student will be able to: i. Analyze a flexible manufacturing system problem. LEARNING OUTCOMES Course Learning Outcome (CLO) CLO2 – Analyze an automation system that consists either of fluid power equipment, robot work cell, PLC, vision system, or other types of automation tools Program Outcome (PO) PO2 - Able to identify, formulate, research literature and analyse complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences and engineering sciences. 1 Description A semi-automated flexible manufacturing cell (FMC) is used to produce three products. The products are made by two automated processing stations followed by an assembly station. There is also a load/unload station. Material handling between stations in the FMC is accomplished by automated guided vehicles (AGVs) that move tote bins containing the particular components to be processed and then assembled into a given product. The AGVs transfer tote bins between stations. In this way, the AGVs are kept busy while tote bins are queued in front of the workstations. Each tote bin remains with the product throughout processing and assembly. The details of the FMC can be summarized in Table 1. The product mix fractions and station processing times for the parts are presented in the Table 2. The same station sequence is followed by all products: 1 > 2 > 3 > 4 > 1. The operation frequency fijk = 1.0 for all operations. The average AGV transfer time between stations is 4.T minutes (see notes below to determine value of T). 2 Questions 1. Analyse the bottleneck station in the FMC, if the material handling system is not the bottleneck. [10 marks] 2. Identify the minimum number of carts in the material handling system required to keep up with the production workstations. [3 marks] 3. Compute the overall utilization of the FMC. [5 marks] 4. Recommend an improvement to increase the efficiency and/or reduce the cost of operating the FMC. [2 marks] 5. The FMS will be operated 8 hours per day, 250 days per year. If the required annual production is P pieces (see notes below to determine value of P), determine: a. the minimum number of servers at each station and the minimum number of carts in the transport system that are required to satisfy production demand. [11 marks] b. the utilization of each station for the answers in part 5(a). [5 marks] Notes T is the last digit of the first student’s matric no. Example: Matric no is b051910088, then T is 8. So the transfer time is 4.8 minutes. P is the last two digits of the second student’s matric no × 1000. Example: Matric no is b051910123, then P is 23 × 1000 = 23000. So the annual production is 23000 pieces. Example: Matric no is b051910100, then P is 00 × 1000 = 0. In this case, choose P as 10000. So the annual production is 10000 pieces. 3