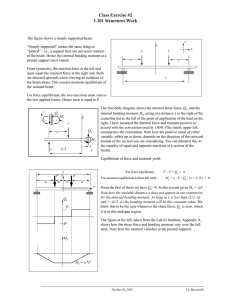

Abstract The bending is normally a process by which the material such as metal, alloy and etc can be deformed by deforming the material and changing its shape from the original shape. The material is applied to the type specimen to calculate how much the specimen can deflect. The material is stressed beyond the yield strength but below the ultimate tensile strength. The surface area of the material does not change much when the load is applied. Bending usually refers to deformation about one axis. Bending Bending is a flexible flexible process by which many different different shapes can be produced. The experiments done to learn about theory and use or apply in real life by visualize the experiment. Objective • To determine the elastic modulus (E) of beam specimen by method of deflection of mild steel, aluminum and brass. • To compare the data between experimental and theoretical values. • To understand how much the specimen can be deflect by list of type the specimen is use in the experiment. Introduction Bending is a flexible process by which many have different shapes can be produced. tandard die sets are used to produce a wide variety of shapes. The material is placed on the die, and positioned in place with stops and gages. !t is held in place with hold"downs. The upper part of the press, the ram with the appropriately shaped punch descends and usually forms the v"shaped bend. #hen the real life or the experiment the bending characterizes the behaviour of a slender structural element sub$ected to an external load applied perpendicularly to a longitudinal axis of the element. !n this experiment, the deflection of the beam when load is applied to the specimen at is to measured point along the specimen and from that the elastic modulus can be calculate by given data. Bending is done using %ress Bra&es and %rogrammable bac& gages, and multiple die sets available currently can ma&e for a very economical process. The figure shows that the standard bending moment in experiment. The calculation to calculate bending moment that usually done is using the Euler"Bernoulli bending. 'fter a solution for the displacement of the beam has been obtained, the bending moment and shear force in the beam can be calculated using the relations. sually the specimen is sub$ect to pure bending. This means that the shear force is zero, and that no torsional or axial loads are present. The material is isotropic and homogeneous. The material obeys oo&e*s law that it is linearly elastic and will not deform plastically .The beam is initially straight with a cross section that is constant throughout the beam length. !n the Euler"Bernoulli theory of slender beams, a ma$or assumption is that *plane sections remain plane*. !n other words, any deformation due to shear across the section is not accounted for no shear deformation. 'nd this linear distribution is only applicable if the maximum stress is less than the yield stress of the material. +or stresses that exceed yield refer to article plastic. 't yield, the maximum stress experienced in the section at the furthest points from the neutral axis of the beam is defined as the flexural strength. The Euler"Bernoulli euation for the bending of slender, isotropic, homogeneous beams of constant cross"section under an applied transverse load is #here E is the -oung*s modulus and I is the area moment of inertia of the cross"section, and #(x) is the deflection of the neutral axis of the beam. Theory Bending is a ma$or concept used in the design of many machine and structural components, such as beams and girders. !n 'pplied echanics, bending which is also &nown as flexure, characterizes the behavior of a slender structural element sub$ected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically /0/1 or less, of the other two. #hen the length is considerably longer than the width and the thic&ness, the element is called a beam. +or example, a closet rod sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. 2n the other hand, a shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thic&ness of the structure (&nown as the *wall*) is considerably smaller. ' large diameter, but thin"walled, short tube supported at its ends and loaded laterally is an example of a shell experiencing bending. !n the absence of a ualifier, the term bending is ambiguous because bending can occur locally in all ob$ects. To ma&e the usage of the term more precise, engineers refer to the bending of rods, the bending of beams, the bending of plates, the bending of shells, and so on. Bending of an !"beam #hen a beam experiences a bending moment it will change its shape and internal stresses will be developed. The figure below illustrates the shape change of elements of a beam in bending. 3ote that the material is in compression on the inside of the curve and tension on the outside of the curve, and that transverse planes in the material remain parallel to the radius during bending. hape change of elements of a beam. +our"%oint Bending The pure bending shown in the figure can be produced by applying four forces to the beam, two of opposite direction at each end. This configuration is &nown as 4four"point bending5 and produces a uniform bending moment over the center section of the beam as illustrated in (b) opposite. !n the Euler"Bernoulli theory of slender beams, a ma$or assumption is that *plane sections remain plane*. !n other words, any deformation due to shear across the section is not accounted for (no shear deformation). 'lso, this linear distribution is only applicable if the maximum stress is less than the yield stress of the material. +or stresses that exceed yield, refer to article plastic. 't yield, the maximum stress experienced in the section (at the furthest points from the neutral axis of the beam) is defined as the flexural strength The Euler"Bernoulli euation for the uasi static bending of slender, isotropic, homogeneous beams of constant cross"section under an applied transverse load, q(x) is6 4 d w( x ) EI dx 4 7 q(x) where E is the -oung*s modulus, I is the area moment of inertia of the cross"section, and w(x) is the deflection of the neutral axis of the beam. 'fter a solution for the displacement of the beam has been obtained, the bending moment, M and shear force, Q in the beam can be calculated using the relations imple beam bending is often analyzed with the Euler"Bernoulli beam euation. The conditions for using simple bending theory are8 / The beam is sub$ect to pure bending. This means that the shear force is zero, and that no torsional or axial loads are present. 9 The material is isotropic and homogeneous. : The material obeys oo&e*s law (it is linearly elastic and will not deform plastically). ; The beam is initially straight with a cross section that is constant throughout the beam length. W = 2,4,6,8,10,12,14,16 (N) a = 0.15m b = 0.020m d =0.004m l = 0.4m Tis is a sim!l" su!!orted beam sub#e$ted to uni%orm bending moment. &t $an be so'n tat te $entral de%le$tion relati(e to te su!!orts in te arrangement o% te diagram Ma)imum de%le$tion bet'een te su!!orts*+ 2 Wa l ∆= 8 EI 'ere I= bd 3 12 Te teoreti$al (alue %or elasti$ modulus o% steel, aluminum and brass is 210-!a, 70-!a and 100-a. Sample calculation I= bd 3 12 3 ¿ (0.02 m)( 0.004 m ) 12 & %0#' 2 Wa l ∆= 8 EI x −10 10 (2 N ) (0.15 m )( 0.4 m ) ¿ − 8 ( 210 Gpa ) ( 1.067 x 10 ) 2 10 ¿ 0000!#m ( 0!#mm The theoretical magnitude of load and the beam maximum deflection eam maximum deflection (mm) x !"!# Load, W (N) Mild %teel $luminum rass 0 2 0 0.26 0 0.24 0 0.13 4 0.54 0.55 0.25 6 0.80 0.89 0.38 8 1.07 1.12 0.50 10 1.33 1.43 0.63 12 1.55 1.67 0.75 14 1.77 1.81 0.88 16 1.98 2.15 1.00