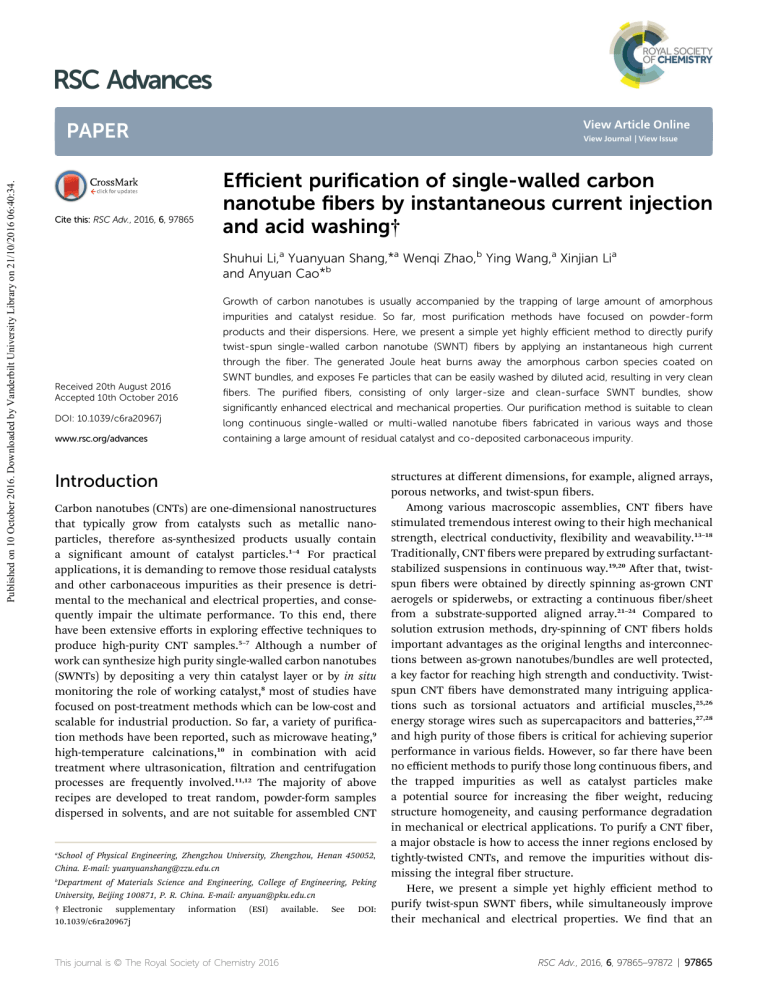

RSC Advances View Article Online Published on 10 October 2016. Downloaded by Vanderbilt University Library on 21/10/2016 06:40:34. PAPER View Journal | View Issue Cite this: RSC Adv., 2016, 6, 97865 Efficient purification of single-walled carbon nanotube fibers by instantaneous current injection and acid washing† Shuhui Li,a Yuanyuan Shang,*a Wenqi Zhao,b Ying Wang,a Xinjian Lia and Anyuan Cao*b Growth of carbon nanotubes is usually accompanied by the trapping of large amount of amorphous impurities and catalyst residue. So far, most purification methods have focused on powder-form products and their dispersions. Here, we present a simple yet highly efficient method to directly purify twist-spun single-walled carbon nanotube (SWNT) fibers by applying an instantaneous high current through the fiber. The generated Joule heat burns away the amorphous carbon species coated on SWNT bundles, and exposes Fe particles that can be easily washed by diluted acid, resulting in very clean Received 20th August 2016 Accepted 10th October 2016 fibers. The purified fibers, consisting of only larger-size and clean-surface SWNT bundles, show significantly enhanced electrical and mechanical properties. Our purification method is suitable to clean DOI: 10.1039/c6ra20967j long continuous single-walled or multi-walled nanotube fibers fabricated in various ways and those www.rsc.org/advances containing a large amount of residual catalyst and co-deposited carbonaceous impurity. Introduction Carbon nanotubes (CNTs) are one-dimensional nanostructures that typically grow from catalysts such as metallic nanoparticles, therefore as-synthesized products usually contain a signicant amount of catalyst particles.1–4 For practical applications, it is demanding to remove those residual catalysts and other carbonaceous impurities as their presence is detrimental to the mechanical and electrical properties, and consequently impair the ultimate performance. To this end, there have been extensive efforts in exploring effective techniques to produce high-purity CNT samples.5–7 Although a number of work can synthesize high purity single-walled carbon nanotubes (SWNTs) by depositing a very thin catalyst layer or by in situ monitoring the role of working catalyst,8 most of studies have focused on post-treatment methods which can be low-cost and scalable for industrial production. So far, a variety of purication methods have been reported, such as microwave heating,9 high-temperature calcinations,10 in combination with acid treatment where ultrasonication, ltration and centrifugation processes are frequently involved.11,12 The majority of above recipes are developed to treat random, powder-form samples dispersed in solvents, and are not suitable for assembled CNT a School of Physical Engineering, Zhengzhou University, Zhengzhou, Henan 450052, China. E-mail: yuanyuanshang@zzu.edu.cn b Department of Materials Science and Engineering, College of Engineering, Peking University, Beijing 100871, P. R. China. E-mail: anyuan@pku.edu.cn † Electronic supplementary 10.1039/c6ra20967j information (ESI) This journal is © The Royal Society of Chemistry 2016 available. See DOI: structures at different dimensions, for example, aligned arrays, porous networks, and twist-spun bers. Among various macroscopic assemblies, CNT bers have stimulated tremendous interest owing to their high mechanical strength, electrical conductivity, exibility and weavability.13–18 Traditionally, CNT bers were prepared by extruding surfactantstabilized suspensions in continuous way.19,20 Aer that, twistspun bers were obtained by directly spinning as-grown CNT aerogels or spiderwebs, or extracting a continuous ber/sheet from a substrate-supported aligned array.21–24 Compared to solution extrusion methods, dry-spinning of CNT bers holds important advantages as the original lengths and interconnections between as-grown nanotubes/bundles are well protected, a key factor for reaching high strength and conductivity. Twistspun CNT bers have demonstrated many intriguing applications such as torsional actuators and articial muscles,25,26 energy storage wires such as supercapacitors and batteries,27,28 and high purity of those bers is critical for achieving superior performance in various elds. However, so far there have been no efficient methods to purify those long continuous bers, and the trapped impurities as well as catalyst particles make a potential source for increasing the ber weight, reducing structure homogeneity, and causing performance degradation in mechanical or electrical applications. To purify a CNT ber, a major obstacle is how to access the inner regions enclosed by tightly-twisted CNTs, and remove the impurities without dismissing the integral ber structure. Here, we present a simple yet highly efficient method to purify twist-spun SWNT bers, while simultaneously improve their mechanical and electrical properties. We nd that an RSC Adv., 2016, 6, 97865–97872 | 97865 View Article Online Published on 10 October 2016. Downloaded by Vanderbilt University Library on 21/10/2016 06:40:34. RSC Advances instantaneous large current can burn away the carbonaceous impurities and expose residual Fe catalyst particles that can be easily washed by diluted acid. Our method could obtain very pure SWNT bers (from surface to inside), and is especially suitable for cleaning very dirty bers containing a large amount of carbonaceous impurity and residual catalyst. Preliminary tests have revealed 3 to 4-fold improvement of electrical conductivity and enhanced strength as well as cyclic loading behavior of those highly puried bers. Experimental section Preparation of as-spun SWNT bers We synthesized thin lms consisting of interconnected singlewalled nanotubes by chemical vapor deposition as reported in our previous work. Precursors are ferrocene (catalyst) and xylene (carbon source). Reaction temperature was set as 1160 C; at this temperature single-walled nanotubes will form in the vapor phase and be blown out to low-temperature zone by the carrier gas (mixed Ar/H2). The freestanding CNT lms were picked up from the downstream side of the CVD reaction quartz tube, and then used for spinning. One end of the CNT lm was xed to the sha tip of an electric motor that was controlled by a power supply (voltage controller, set as 1.5 V for spinning). The other end of the lm was xed to the edge of a metal block that could move freely across a smooth glass surface. The entire lm was suspended between the motor and the block. The motor was operated at a speed of about 3000 revolutions per minute (rpm), and the CNT lm was spun into a straight yarn. Purication of as-spun SWNT ber by current injection and acid washing An as-spun SWNT ber was connected to electrical wires by conductive adhesive and silver paste applied at its two ends on glass slides, and the ber between two ends was suspended between glass slides to avoid touching other substrates and nonuniform heating. The resistance of sample was measured with a multimeter. Typically, we applied a voltage of 45 V on a SWNT ber with a resistance of 25 U (length ¼ 8 cm, diameter ¼ 138 mm). Such an appropriate voltage value depending on the ber resistance was loaded for a short period of about 1 second. In a word, the voltage was selected to ensure that the current density through the ber is in a suitable range to avoid inadequate or excessive oxidation. Aer loading the voltage, the ber was soaked in dilute hydrochloric acid (HCl, 0.1 mol L1) for 12 hours, and then washed in deionized water for several times. At last the ber was dried in a vacuum drying oven at 80 C for 4 hours. We also prepared puried bers without current-induced heating as a reference sample. In this case, as-spun bers were directly puried through hydrogen peroxide (H2O2, 1 mol L1, 12 hours) and dilute hydrochloric acid (HCl, 0.1 mol L1, 12 hours) treatment. At last the bers were dried in a vacuum drying oven at 80 C for 4 hours. Characterization and calculation The surface and internal morphology of SWNT bers before and aer purication were characterized by scanning electron 97866 | RSC Adv., 2016, 6, 97865–97872 Paper microscopy (SEM, JEOL JSM-6700F, Japan) and transmission electron microscopy (TEM JEOL JEM-2100). Chemical composition of the puried bers is detected by X-ray photoelectron spectroscopy (XPS). The resistance of ber were recorded by fourelectrode method with a digital source-meter (Keithley2636 and 2400). Raman spectrometer (Renishaw-in Via Reex) was used to authenticate the degree of purication while the excitation wavelength was 514 nm. The mass ratio of the original SWNTs ber and puried ber were evaluated by thermal gravimetric analysis (TGA LINSEIS STA PT1600) in air at 1000 C (10 C min1). Mechanical tests were carried out in a single-column testing instrument (Instron 5843) equipped with a load cell of 10 N. The two ends of a CNT ber were xed on a small piece of paper cutting centrally with a rectangular window by polyvinyl alcohol as adhesive paint. Both ends of the paper were clamped with the grips with the ber dangling vertically and aligned along the grip axis. The paper was cut from the side to free the CNT ber. For tension tests, the upper grip was moved away at a constant speed of 1.0 mm min1. For 1000 loading–unloading cycles, the strain rate was 125% per minute for all the cycles. The conductivity of the SWNT bers was calculated using follow formula: L RS k¼ (1) where k represents the electrical conductivity, L is the diameter of the bers measuring centimeter scale; R is the resistance of the bers; S is the sectional area of the bers and it was calculated by formula S¼ pd 2 ; 4 (2) where d is diameter of ber. Four-electrode method was used to measure the resistance. Neighboring distance of four electrodes which were marked with A, B, C and D in sequence were about LAB ¼ 2.6 cm, LBC ¼ 1.7 cm and LCD ¼ 2.3 cm as an example, while homologous sectional area were labeled as SAB, SBC, SCD. We loaded constant current 0.002 A between electrode A and D (IAD) and measured simultaneously the voltage between electrode A and B (VAB), B and C (VBC), C and D (VCD) by turn. Consequently, the resistances of three sections were RAB ¼ VAB ; IAD (3) RBC ¼ VBC ; IAD (4) RCD ¼ VCD : IAD (5) and Finally the conductivity is average value of these three conductivities 1 LAB LBC LCD : (6) k¼ þ 3 RAB SAB RBC SBC RCD SCD This journal is © The Royal Society of Chemistry 2016 View Article Online Paper RSC Advances Published on 10 October 2016. Downloaded by Vanderbilt University Library on 21/10/2016 06:40:34. Results and discussion Our purication method involves two sequential steps including (1) an instantaneous high current injection through the ber length and, (2) washing by diluted hydrochloride acid (illustrated in Fig. 1a). The rst step removes amorphous carbon and exposes Fe particles, whereas the second step cleans residual catalyst completely by mild acid dissolution. To do this, an as-spun SWNT ber suspended between two metal electrodes was subjected to a current injection by applying a high voltage instantaneously (40 to 110 V, depending on the ber length and diameter). Given a ber resistance of 25 U at a span of 80 mm (shown in Fig. 1b), the current ow through the ber is on the order of hundreds of mA. Upon the current injection, the ber exhibited very bright incandescent light with a slight yellow smoke coming out, indicating that carbonaceous species and some Fe particles are burnt away. We estimate that the instantaneous temperature of the ber might reach more than 1000 C to give such bright emission. Aer subsequent acid Fig. 1 washing, rinsing and drying, the ber maintained the original morphology without obvious change in the ber length and diameter as seen by eyes. In principle, this method is applicable to bers consisting of SWNTs or multi-walled nanotubes made from various methods, and bers of different diameters and lengths. We have carried out scanning electron microscopy (SEM) and transmission electron microscopy (TEM) characterization on the structural evolution of the SWNT bers through the above process. The as-spun ber shows a uffy surface containing twisted SWNTs, among which a lot of small particles and short curved nanotubes are observed (Fig. 2a). We have adopted a high ferrocene concentration and precursor injection rate to grow bers with a considerable amount of impurities. The micro-morphology has changed noticeably aer current injection. There are numerous polyhedral nanocrystals appearing at the gaps between SWNT bundles, indicating the formation of iron oxide crystals due to the current-induced Joule heating in air (Fig. 2b). These crystals distribute Mechanism of purification of SWNT fiber by instantaneous current injection and acid washing. This journal is © The Royal Society of Chemistry 2016 RSC Adv., 2016, 6, 97865–97872 | 97867 View Article Online Published on 10 October 2016. Downloaded by Vanderbilt University Library on 21/10/2016 06:40:34. RSC Advances Fig. 2 Paper Structural evolution of as-spun (a), current injected (b), and current injected/acid washed (c) SWNT fibers during purification process. uniformly at both the surface part and inside of the ber, a consequence of the in situ current injection through the crosssection. Aer acid washing and drying, the ber diameter has decreased from originally 100 mm to now 64 mm, due to the removal of trapped oxide crystals (Fig. 2c). SEM images on both the ber surface and inside do not reveal any trace of catalyst particles (Fig. 2c, and ESI, Fig. S1†), suggesting that our purication method is highly efficient for tightly twisted bers. We also notice that initially the lateral sizes of SWNT bundles are relatively small (20–50 nm or less), but the bundle sizes in the puried ber have increased to 50–100 nm or more (Fig. 2i). This is a clear evidence that the interaction between SWNTs has been enhanced owing to the removal of amorphous carbon coating and residual catalyst, and adjacent small bundles tend to aggregate under van der Waals force between SWNT shells. TEM images reveal more useful information. In the as-spun ber, a thick amorphous carbon layer is coated on virtually all as-grown SWNT bundles (Fig. 3a). Co-deposition of such amorphous coating is a common phenomenon that has been observed in many SWNT products synthesized from different methods.29–31 Furthermore, it also covers on the residual Fe particles, forming carbon-encapsulated metal particles that are tough to remove. The main function of our current-injection step is to remove all the carbonaceous species, from both the SWNTs and Fe particles. As a result, we observe SWNT bundles with very clean surface and those exposed Fe oxide crystals where the carbon coating has disappeared (Fig. 3b). This has paved the way for subsequent acid dissolution of Fe particles. Aer HCl washing and drying, the ber became very dense and 97868 | RSC Adv., 2016, 6, 97865–97872 we have to split it in order to characterize its inner portion by TEM. Along the split ber edge there are close-packed SWNT bundles with few catalyst residue (Fig. 3c), consistent with SEM image. Although most of bundles are aligned along the ber axis, the circular cross-sections of SWNTs arranged in triangular lattice are frequently observed in those bending or kinked bundles. TEM results reveal that the catalyst residue trapped inside the ber has been removed completely. To further conrm that Fe atoms have been removed, the as-spun, current injected and puried bers were characterized by X-ray photoelectron spectroscopy measurements (XPS). As shown in Fig. 3d, the wide XPS spectrum of as-spun SWNT ber indicates the presence of C, O, and Fe elements in the sample. Aer purication by instantaneous current injection and hydrochloric acid, signals of C and O1s remain there but Fe2p peak has disappeared, indicating that the iron oxide particles have been removed completely. We also used Raman spectroscopy to check the structural evolution during our purication process and the presence of impurities or defects, structural integrity and distribution of different diameters of SWNTs. The as-spun ber, ber aer current injection, and puried ber (aer washing away catalyst) all show typical G-band (1590 cm1), D-band (1340 cm1), and radial breathing modes (RBM) related to SWNTs (Fig. 3e). Specically, the D-band has diminished aer current injection, due to the burning of amorphous carbon which is highly defective. Correspondingly, the intensity ratio of G/D increases from 16 in as-spun ber to 42 aer purication. In addition, some RBM peaks (e.g. peaks at 168 cm1, under a laser This journal is © The Royal Society of Chemistry 2016 View Article Online Published on 10 October 2016. Downloaded by Vanderbilt University Library on 21/10/2016 06:40:34. Paper RSC Advances Fig. 3 TEM images of as-spun (a), current injected (b), and purified by current injected/acid washed (c) SWNT fibers. XPS (d), Raman (e) and TGA (f) curves of as-spun, current injected and purified by current injected/acid washed SWNT fibers. excitation wavelength of 514 nm) seen from as-spun bers have disappeared in puried bers. These SWNTs are categorized as metallic species.32 As metallic SWNTs carry out most of the current ow, they tend to be burned early (than semiconducting tubes) during large current injection, as described in a previous report on SWNT micro-bundles.33 It might be possible to fabricate semiconductor-dominating SWNT bers by controlling the current injection and selectively removing metallic species. Nonetheless, TEM and Raman study conrms that the integrity of bundle structure has been maintained and the defect degree has been reduced substantially. To determine the remaining impurities in the SWNT bers in a quantitative way, we performed thermogravimetry analysis (TGA) on as-spun, current injected and puried samples (Fig. 3f). Raising the temperature from ambient to 1000 C in air, the SWNTs are burned away (at around 600 C) leaving catalyst residue behind (in the form of iron oxide). The as-spun bers show a remaining mass of nearly 40%, due to the trapping of signicant amount of Fe particles introduced during chemical vapor deposition (CVD). In contrast, the mass retention of puried bers has decreased to less than 6% aer combustion, indicating a high purity of 94%. Our method is thus amenable to directly purify twist-spun CNT bers. Compared with the TGA result tested in air, CNTs in puried bers are very stable in N2 environment, with a mass loss of less than 5% aer rising temperature to 1000 C (Fig. S2†). In contrast, CNTs are burnt in air at a combustion temperature of 500–600 C, resulting in a sharp mass decrease. Efficient purication of SWNT bers lead to considerable improvement in both electrical and mechanical properties. The resulting puried ber shows a wrinkled surface morphology due to the volume shrinkage aer removal of internal impurities (Fig. 4a and S3†), which is distinct from other twist-spun bers without purication. These surface wrinkles indicate a strong condensation of SWNTs inward, and also might be useful as fatigue resistant bers if the wrinkles can be stretched This journal is © The Royal Society of Chemistry 2016 reversibly. As a result, the measured 4-probe electrical conductivity has increased from below 1600 S cm1 in as-spun bers to about 4000 S cm1 aer purication, mostly owing to the formation of bigger bundles and shrinkage of cross-sectional area (Fig. 4b). We also tested a control sample by the same purication process but without the current injection step. It shows that many impurities are still trapped within the bundle since the amorphous carbon-encapsulated Fe particles could resist acid attacking (Fig. S4†). The electrical conductivity increases to about 2000 S cm1, which is not prominent. As a result of high purity and enhanced conductivity, the puried SWNT bers can be illuminated more stably in air. Asspun bers usually break very quickly (within several seconds) aer applying a moderate voltage because of air oxidation at elevated temperature. However, when we applied a constant voltage of 7.5 V on a puried ber (2 cm segment), it produced a rather stable emission in the middle part, which lasted for nearly 2 minutes before breaking (Fig. 4c). During this stage, the electric current passing through the ber maintains a stable value (90 mA) without uctuation. Based on a ber diameter of 250 mm, the current density sustained by the ber is estimated to be 1.8 105 mA cm2. The removal of impurities especially amorphous carbon enhances the ber resistance to air oxidation at high temperature, leading to improved structural stability in air environment. Our high-purity SWNT bers might have applications as stable lament-like light-emission sources. Mechanical properties have been evaluated by uniaxial tension tests and stress–strain (s–3) curves. As-spun SWNT bers with a length of 10 mm exhibit tensile stresses of about 200 MPa with failure strains in the range of 15% to 20% (Fig. 4d). Puried bers show higher tensile stresses (300 to 400 MPa) but reduced strains (<10%). To study the structural homogeneity along the ber axis, we adopt a larger gauge length (40 mm) to test our puried SWNT bers, and nd that both the tensile strength (300 MPa) and strain (8%) decrease compared with the results from RSC Adv., 2016, 6, 97865–97872 | 97869 View Article Online Published on 10 October 2016. Downloaded by Vanderbilt University Library on 21/10/2016 06:40:34. RSC Advances Paper Fig. 4 Electrical and mechanical properties of purified SWNT fibers. (a) SEM image of the purified fiber with a wrinkled surface morphology. (b) Statistical data of electrical conductivities of as-spun, purified and purified without current injection fibers. (c) Recorded current flow through an illuminated purified fiber. Insets show the photos of the fiber at point A and B. (d) Tensile stress–strain curves. (e) Cyclic stress–strain curves of a purified fiber. shorter bers (10 mm) (Fig. S5†). The enhancement of ber strength is mainly due to the decrease of cross-sectional diameter (thus densication of SWNT bundles as shown in Fig. 3c) aer purication. SEM images of the fractured section indicate that the failure mechanism of the SWNT ber in tension is dominated by the sliding between aligned SWNT bundles (Fig. S6†). On the other hand, burning of metallic SWNTs upon current injection might have negative effect on the mechanical strength. Puried bers are also less porous than as-spun sample, resulting in lower tensile strains upon breaking. We also performed cyclic tests on the puried bers with a wrinkled morphology. The ber can be repeated stretched to a modest strain (3 ¼ 2%, producing a stress of 20 MPa) and recover to its initial state, as the unloading curve returns to origin enclosing a hysteresis loop (Fig. 4e). Over 1000 loading– unloading cycles, the slope of loading curve remains constant although the maximum stress at 3 ¼ 2% drops slightly. A small permanent deformation (less than 0.5% residual strain) has been developed aer 1000 cycles. These results suggest potential applications of puried SWNT bers under various external conditions such as cyclic stresses. 97870 | RSC Adv., 2016, 6, 97865–97872 Conclusion We demonstrated a simple and efficient method to directly purify long carbon nanotube bers by introducing an instantaneous high current injection. This step burns away amorphous carbon coated on SWNT bundles and residual catalyst, and the exposed catalyst particles can be washed thoroughly by mild acid dissolution. Our high-purity SWNT bers show enhanced electrical and mechanical properties, and have many potential applications in developing high performance articial muscles as well as exible ber-shaped energy conversion and storage devices. Our method described here is suitable for purifying various carbon nanotube bers, for example, those made from multi-walled or single-walled nanotubes, and those fabricated by dry or wet-spinning techniques. Acknowledgements The authors greatly acknowledge nancial support from the National Natural Science Foundation under grants of NSFC 51325202, 51502267, and the Outstanding Young Talent Research This journal is © The Royal Society of Chemistry 2016 View Article Online Paper Fund of Zhengzhou University (1521317003), Startup Research Fund of Zhengzhou University (1512317001), Henan Province Science and Technology Research Project (162102410069). Certificate of Postdoctoral Research Sponsorship Henan Province (2015009). RSC Advances 12 Published on 10 October 2016. Downloaded by Vanderbilt University Library on 21/10/2016 06:40:34. 13 References 1 J. Kong, H. T. Soh, A. M. Cassell, C. F. Quate and H. J. Dai, Synthesis of individual single-walled carbon nanotubes on patterned silicon wafers, Nature, 1998, 395, 878–881. 2 T. Yamada, T. Namai, K. Hata, D. N. Futaba, K. Mizuno, J. Fan, M. Yudasaka, M. Yumura and S. Iijima, Sizeselective growth of double-walled carbon nanotube forests from engineered iron catalysts, Nat. Nanotechnol., 2006, 1, 131–136. 3 W.-H. Chiang and R. M. Sankaran, Linking catalyst composition to chirality distributions of as-grown singlewalled carbon nanotubes by tuning NixFe1x nanoparticles, Nat. Mater., 2009, 8, 882–886. 4 G. D. Nessim, A. J. Hart, J. S. Kim, D. Acquaviva, J. Oh, C. D. Morgan, M. Seita, J. S. Leib and C. V. Thompson, Tuning of vertically-aligned carbon nanotube diameter and areal density through catalyst pre-treatment, Nano Lett., 2008, 8, 3587–3593. 5 X. Xie, S. H. Jin, M. A. Wahab, A. E. Islam, C. X. Zhang, F. Du, E. Seabron, T. Lu, S. N. Dunham, H. I. Cheong, Y. C. Tu, Z. L. Guo, H. U. Chung, Y. H. Li, Y. H. Liu, J. H. Lee, J. Z. Song, Y. G. Huang, M. A. Alam, W. L. Wilson, J. A. Rogers and J. A. Rogers, Microwave purication of large-area horizontally aligned arrays of single-walled carbon nanotubes, Nat. Commun., 2014, 5(5332), 1–11. 6 Y. Q. Xu, H. Q. Peng, R. H. Hauge and R. E. Smalley, Controlled multistep purication of single-walled carbon nanotubes, Nano Lett., 2005, 5, 163–168. 7 Y. Wang, Y. Q. Liu, D. C. Wei, L. C. Cao, L. Fu, X. L. Li, H. Kajiura, Y. Li and K. M. Noda, Controlled growth of single-walled carbon nanotubes at atmospheric pressure by catalytic decomposition of ethanol and an efficient purication method, J. Mater. Chem., 2007, 17, 357–363. 8 O. Pornsunthorntawee, S. Chuaybumrung, B. Kitiyanan and S. Chavadej, Purication of single-walled carbon nanotubes (SWNTs) by acid leaching, NaOH dissolution, and froth otation, Sep. Sci. Technol., 2011, 46, 2056–2065. 9 K. Hata, D. N. Futaba, K. Mizuno, T. Namai, M. Yumura and S. Iijima, Water-assisted highly efficient synthesis of impurity-free single-walled carbon nanotubes, Science, 2004, 306, 1362–1364. 10 X. Xie, M. A. Wahab, Y. Li, A. E. Islam, B. Tomic, J. Huang, B. Burns, E. Seabron, S. N. Dunham, F. Du, J. Lin, W. L. Wilson, J. Song, Y. Huang, M. A. Alam and J. A. Rogers, Direct current injection and thermocapillary ow for purication of aligned arrays of single-walled carbon nanotubes, J. Appl. Phys., 2015, 117, 134303. 11 P. A. Tsai, H. Y. Kuo, W. M. Chiu and J. H. Wu, Purication and functionalization of single-walled carbon nanotubes This journal is © The Royal Society of Chemistry 2016 14 15 16 17 18 19 20 21 22 23 24 through different treatment procedures, J. Nanomater., 2013, 937697, 1–9. L. A. Montoro and J. M. Rosolen, A multi-step treatment to effective purication of single-walled carbon nanotubes, Carbon, 2006, 44, 3293–3301. Q. Cao and S. J. Han, Single-walled carbon nanotubes for high-performance electronics, Nanoscale, 2013, 5, 8852– 8863. L. M. Ericson, H. Fan, H. Peng, V. A. Davis, W. Zhou, J. Sulpizio, Y. Wang, R. Booker, J. Vavro, C. Guthy, A. N. G. Parra-Vasquez, M. J. Kim, S. Ramesh, R. K. Saini, C. Kittrell, G. Lavin, H. Schmidt, W. W. Adams, W. E. Billups, M. Pasquali, W.-F. Hwang, R. H. Hauge, J. E. Fischer and R. E. Smalley, Macroscopic, neat, singlewalled carbon nanotube bers, Science, 2004, 305, 1447– 1450. K. Koziol, J. Vilatela, A. Moisala, M. Motta, P. Cunniff, M. Sennett and A. Windle, High-performance carbon nanotube ber, Science, 2007, 18, 1892–1895. X. F. Zhang, Q. W. Li, T. G. Holesinger, P. N. Arendt, J. Huang, P. D. Kirven, T. G. Clapp, R. F. Paula, X. Liao, Y. Zhao, L. Zheng, D. E. Peterson and Y. Zhu, Ultrastrong, stiff, and lightweight carbon-nanotube bers, Adv. Mater., 2007, 19, 4198–4220. N. C. Behabtu, C. C. Young, D. E. Tsentalovich, O. Kleinerman, X. Wang, A. W. K. Ma, E. A. Bengio, R. F. Waarbeek, J. J. de Jong, R. E. Hoogerwerf, S. B. Fairchild, J. B. Ferguson, B. Maruyama, J. Kono, Y. Talmon, Y. Cohen, M. J. Otto and M. Pasquali, Strong, light, multifunctional bers of carbon nanotubes with ultrahigh conductivity, Science, 2013, 339, 182–186. M. Zhang, K. R. Atkinson and R. H. Baughman, Multifunctional carbon nanotube yarns by downsizing an ancient technology, Science, 2004, 306, 1358–1361. B. Vigolo, A. Penicaud, C. Coulon, C. Sauder, R. Pailler, C. Journet, P. Bernier and P. Poulin, Macroscopic bers and ribbons of oriented carbon nanotubes, Science, 2000, 290, 1331–1334. A. B. Dalton, S. Collins, E. Munoz, J. M. Razal, V. H. Ebron, J. P. Ferraris, J. N. Coleman, B. G. Kim and R. H. Baughman, Super-tough carbon-nanotube bresthese extraordinary composite bres can be woven into electronic textiles, Nature, 2003, 423, 703. Y. L. Li, I. A. Kinloch and A. H. Windle, Direct spinning of carbon nanotube bers from chemical vapor deposition synthesis, Science, 2004, 304, 276–280. W. J. Ma, L. Q. Liu, R. Yang, T. H. Zhang, Z. Zhang, L. Song, Y. Ren, J. Shen, Z. Q. Niu, W. Y. Zhou and S. S. Xie, Monitoring a micromechanical process in macroscale carbon nanotube lms and bers, Adv. Mater., 2009, 21, 603–608. X. B. Zhang, K. L. Jiang, C. Teng, P. Liu, L. Zhang, J. Kong, T. Zhang, Q. Li and S. Fan, Spinning and processing continuous yarns from 4-inch wafer scale super-aligned carbon nanotube arrays, Adv. Mater., 2006, 18, 1505–1510. K. L. Jiang, Q. Q. Li and S. S. Fan, Spinning continuous carbon nanotube yarns–carbon nanotubes weave their way RSC Adv., 2016, 6, 97865–97872 | 97871 View Article Online RSC Advances Published on 10 October 2016. Downloaded by Vanderbilt University Library on 21/10/2016 06:40:34. 25 26 27 28 into a range of imaginative macroscopic applications, Nature, 2002, 419, 801. J. Foroughi, G. M. Spinks, G. G. Wallace, J. Oh, E. Kozlov Mikhail, S. Fang, T. Mirfakhrai, J. D. W. Madden, M. K. Shin, S. J. Kim and R. H. Baughman, Torsional carbon nanotube articial muscles, Science, 2011, 334, 494–497. M. D. Lima, N. Li, M. J. Andrade, S. L. Fang, J. Y. Oh, G. M. Spinks, M. E. Kozlov, C. S. Haines, D. S. Suh, J. Foroughi, S. J. Kim, Y. S. Chen, T. Ware, M. K. Shin, L. D. Machado, A. F. Fonseca, J. D. W. Madden, W. E. Voit, D. S. Galvão and R. H. Baughman, Electrically, chemically, and photonically powered torsional and tensile actuation of hybrid carbon nanotube yarn muscles, Science, 2012, 338, 928–932. J. Ren, L. Li, C. Chen, X. L. Chen, Z. B. Cai, L. B. Qiu, Y. G. Wang, X. R. Zhu and H. S. Peng, Twisting carbon nanotube bers for both wire-shaped micro-supercapacitor and micro-battery, Adv. Mater., 2013, 25, 1155–1159. H. J. Lin, W. Weng, J. Ren, L. B. Qiu, Z. T. Zhang, P. N. Chen, X. L. Chen, J. Deng, Y. G. Wang and H. S. Peng, Twisting 97872 | RSC Adv., 2016, 6, 97865–97872 Paper 29 30 31 32 33 aligned carbon nanotube/silicon composite bers for highperformance wire-shaped lithium ion battery, Adv. Mater., 2013, 26, 1217–1222. A. C. Dillon, T. Gennett, K. M. Jones, J. L. Alleman, P. A. Parilla and M. J. A. Heben, Simple and complete purication of single-walled carbon nanotube materials, Adv. Mater., 1999, 11, 1354–1358. L. Thiên-Nga, K. Hernadi, E. Ljubović, S. Garaj and L. Forró, Mechanical purication of single-walled carbon nanotube bundles from catalytic particles, Nano Lett., 2002, 2, 21349– 21352. J. B. Zhou, Y. Lan, K. L. Zhang, G. L. Xia, J. Du, Y. C. Zhu and Y. T. Qian, In situ growth of carbon nanotube wrapped Si composites as anodes for high performance lithium ion batteries, Nanoscale, 2016, 8, 4903–4907. M. S. Dresselhaus, G. Dresselhaus, A. Jorio, A. G. Souza Filho and R. Saito, Raman spectroscopy on isolated single wall carbon nanotubes, Carbon, 2002, 40, 2043–2061. P. G. Collins, M. S. Arnold and P. Avouris, Engineering carbon nanotubes and nanotube circuits using electrical breakdown, Science, 2001, 292, 706–709. This journal is © The Royal Society of Chemistry 2016