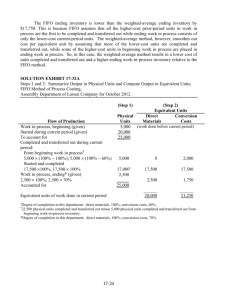

Chapter 14 Process Costing Process costing is a method of cost accumulation that accumulated production costs by department. This system is commonly used by companies that manufactures on a continuous basis only one product or standard products. Problems in process costing are often given in the CPA examination. To pass Practical Accounting 2, candidates must be thoroughly familiar with situations encountered in these problems, typical of which are the following: 1. Preparation of Cost of Production Report using: a. First-in, First – out (FIFO) costing method b. Average costing method 2. Accounting for spoilage (lost units) a. Normal spoilage b. Abnormal spoilage COST OF PRODUCTION REPORT At the end of each month the cost of production report is prepared for each department by the cost accountant of the department. A production report has two sections: 1. Quantity schedule, which shows the follow of units. 2. cost analysis which shows the flow of cost. Quantity Schedule This section shows the number of units that were in process in the department at the start of the month, the number of units begun during the month, the number of units transferred out of the department during the month, the number of units still in work in process at the end of the month. The principal problem in the quantity schedule is the computation of the equivalents production (measure of work done in terms of completed units) of units finished and units in process for materials and conversion costs (labor and overhead). The computation of the equivalent units of production (EUP) will depend on the inventory costing method used. a. First in, First out (FIFO) Costing. Under this method, the stage of completion of the units of Beginning Work in Process (BWIP) is determined separately from the units started and finished this month. This means that the equivalent units of production are calculated only for work actually performed during the month. b. Average Costing. Under this method, the unit in process at the beginning is combined with the units started and finished this month and presented in one batch of units. This means that the work performed on the units in progress beginning (last month) is treated as if it were performed this month. Cost Analysis This section summarized the costs incurred in the department, the cost per unit of the product, the total costs of products completed and transferred out of department, and the costs related to the ending inventory of work in process in each department. The principal problem in this section is the computation of unit cost and the allocation of the total costs to units finished and transferred out and to units in ending work in process. Unit cost: a. First in, first out (FIFO) Costing. Total costs incurred this month (current costs) divided by the equivalent units of production. b. Average Costing. Cost last month (cost incurred in BWIP) plus cost this month (current costs) divided by the equivalent units production. Allocation of total costs: a. First in, first out (FIFO) Costing: Finished and transferred out: BWIP: Cost last month Cost this month = EUP x UC Started in process = Actual units UC EWIP = EUP x UC b. Average Costing: Finished and transferred out = Actual units x total UC EWIP = EUP x UC ACCOUNTING FOR SPOILAGE (LOST UNITS) Spoilage units are units of product that have been damaged or improperly manufactured and cannot be completed as salable products. Spoilage may be classified as normal spoilage, because it is a common occurrence that is inherent in the manufacturing process and abnormal spoilage that results from unusual and nonrecurring factors, such as fire or water damage. Candidates should be familiar with the following procedures in presenting spoilage in the cost of production report. Quantity Schedule. Normal and abnormal spoilage are presented separately and the equivalent units of production computed bases on the work done. Cost Analysis. The costs of units lost through normal spoilage are absorbed by the remaining god units produced during the month. Costs of abnormal spoilage are presented separately and charged to a Loss Abnormal Spoilage account so that the completed units do not absorb the costs related abnormal lost units. Computation of the cost of normal spoilage: Spoiled units may be discovered at the start of the process, during the process or at the end of the process. The computation of the cost of lost units depends on the point of discovery as follows: a. if lost units are discovered at the start or during the process – In the first department = no cost In the subsequent department = lost units x unit cost from preceding department b. if lost units are discovered at the end of the process – In the first department = lost units x total unit costs in this department In the subsequent department = lost units x total unit cost from preceding and in this department c. if lost units are discovered at inspection point- In the first department = EUP of lost units x unit cost In the subsequent department = cost from preceding department plus cost in this department (EUP x UC) Allocation of cost of normal spoilage Cost of normal spoilage is to be absorbed by the good units because good units cannot be made without also making some units that are spoiled. Cost of normal spoilage should be alloxated pro-rate among the good units on the bases of actual units or EUP. The allocations procedures are: a. If lost units are discovered at the start or during the process – First In, First Out Costing – To all the goods units started finished this month and units in process at the end. Average costing – To all the good units, finished and in process. b. If lost units are discovered at the end of the process – First in, First out costing – To all the units finished and transferred out. Average costing – to all the good units finished and in process. c. if lost units are discovered at inspection point. To all the good units that passed the inspection point. PROBLEMS 1. Department of Hope Manufacturing Company presents the following production data for the month of May, 2013: Opening inventory 3/8 completed Started in process Transferred Closing inventory, 1/2 completed 3/4 completed 4,000 units 13,000 units 9,000 units 4,000 units 4,000 units What are the equivalent units of production for the month of May, 2013. FIFO a.12,500 units b.17,000 units C. 12,500 units d. 15,000 units AVERAGE 13,000 units 12,500 units 14,000 units 14,000 units 2. Rose Co, bad 3,000 units in work in process at April 1, 2013, which were 60% complete as to conversion cost, During April, 10,000 units was completed. At April 30, 4,000 units remained in work in process which were 40% complete as to conversion cost. Direct materials are added at the beginning of the process. How many units were started during April? a. 9,000 b. 9,800 c. 10,000 d. 11,000 3. The Ilang-llang Corporation, engaged in a manufacturing business and using process costing, gave the following production data for three different situations. Stages of completion of the inventories apply to all cost elements. (1) Started in process, 6,500 units; transferred, 5,500 units; in process, 400 units 50% completed and 600 units 25% completed. (2 ) Beginning inventory, 6,250 units 40% completed; started in process, 25,000 units; transferred, 26,250 units; in process at the end, 3,000 units 50% completed and 2,000 units 25% completed. (3) Beginning inventory, 6,000 units 30% completed; started in process. I3,000 units; lost in processing, 500 units from production started this period (loss was normal and occurred throughout the production process); transferred, 14,000 units; in process at the end, 3,000 units 50% completed and 1,500 units 75% completed. What are the equivalent production of the three different situations under FIFO and average costing? FIFO 1 a.5,850 b. 5,850 c.8,550 d. 5,058 2 25,750 27,550 20,575 20,775 3 14,825 18,425 15,428 12,524 AVERAGE 1 5,850 5,580 5,508 5,850 2 28,250 22,850 28,025 28,250 3 16,625 15,662 16,265 16,625 4. Orchids Company has a process cost system using the FIFO cost flow method. All materials are introduced at the beginning of the process in Department One. The following information is available for the month of January 2012: Units Work in process, 1/1/08 (40% complete as to conversion 500 costs) Started in January 2,000 Transferred to Department Two during January 2,100 Work in process, 1/31/08 (25% complete as to 400 conversion costs) What are the equivalent units of production for the month of January 2013? Materials a.2,500 b.2,500 c.2,000 d.2,000 Conversion 2,200 1,900 2,200 2,000 5. Anahaw Company's production cycle starts in the Mixing Department. The following information is available for the month of April 2013? Units Work inprocess, April 1 (50% complete) 40,000 Started in April 240,000 work-in-process, April 30 (60% complete) 25,000 Materials are added in the beginning of the process in the Mixing Department. Using the weighted average method, what are the equivalent units of production for the month of April 2013? Materials a.240,000 b.255,000 c.270,000 d.280,000 Conversion 250,000 255,000 280,000 270,000 6. Materials are added at the start of the process in Jasmin company's cutting department, the first stage of the production cycle. The following information is available for the month of March 2013. units Work in process, March 1 (60% complete as to 60,000 conversion costs) Started in March 150,000 Transferred to the next department 110,000 Lost in production 30,000 Work in process, March 31 (50% complete as to 70,000 conversion costs Under Jasmin's cost accounting system, the costs incurred on the lost units are absorbed by the remaining good units. Using the First in, First out method, what are the equivalent units for the materials unit cost calculation? a. 120,000 b.145,000 c. 180,000 d. 210,000 7. Bayani Manufacturing Company, using the FIFO process cost system, has the following data for the month of April: Percent Complete Actual Units Materials Conversion cost Beginning Inventory 15,000 * I 00% 40% Transferred in 150,000 Transferred out 120,000 Ending Inventory 45,000 100% 30% What are the equivalent units of production for the month of April? Materials a.150,000 b.165,000 C. 135,000 d. 150,000 Conversion Costs 127,500 139,500 124,500 133,500 8. Eastern Products Inc., Input all materials at the start of operations in Process 1. The inventory is process at the beginning of January consisted of 4,000 units with a total cost of materials of P100,000 and labor and overhead of P20,000 . In January, 20,000 units were started in process with material cost of P500,000. Labor and overhead in January cost P280,000. As of end of January., the inventory was 100% complete in materials but only 60% in labor and overhead. The ending inventory consisted of 10,000 units. The equivalent units of labor and overheard for the month of January amounted to: a.20,000 b.10,000 C. 26,000 d. 30,000 9. Yakal Company computed the flow of physical units completed for Department M for the month, of March 2013 as follows: Units completed: From work-in process on March 1, 2008 15,000 From March production 45,000 No. 9 – Continued Materials are added at the beginning of the process. The 12,000 units of work in process at March 31, 2013, were 80% complete as to conversion costs. The work in process at March 1, 2043 was 80% complete as to conversion costs. Using the FIFO method, the equivalent units for March conversion costs were: a. 55,200 b. 57,000 C. 60,600 d. 63,600 10. Mataba Company sells food processors and manufactures them in a single continuous process. At the end of August there were 200 units valued at P30,095, which consists of P25,200 in materials cost and P4,895 in conversion cost. These were 100% complete as to materials and 25% complete as to conversion cost 1200 units were added to production during September, and these had materials costs of P168,000. Processors which have not been completed at the end of September total 200 units and were 100% complete as to materials and 50% complete as to conversion cost. Conversion cost during September were P158,125. There were no units lost in process. What are the equivalent units of production for September? Materials Conversion Cost a.1,400 b.1,200 c.1,200 d.1,200 1,350 1,100 1,150 1,250 11. The Wiring Department is the second stage of Acacia Company's production cycle. On May 1, the beginning work-in process contained 25,000 units which were 60% complete as to conversion costs. During May, 100,000 units were transferred-in from the first stage of Acacia's production cycle. On May 31, the ending work in Process contained 20,000 units which were 80% complete as to conversion costs. Material costs are added at the end of the process, using the weighted-average method, the equivalent units were: Materials a.125,000 b.105,000 c.105,000 d.125,000 Conversion costs 100,000 105,000 121,000 121,000 12. Dhalia Company adds materials at the beginning of the process in Department A Information concerning the materials used in April 2013 production is as follows: Work-in-process at April Started during April Completed and transferred to next department during April Normal spoilage incurred Abnormal spoilage incurred Work in process at April 30 Units 10,000 50,000 36,000 3,000 5,000 16,000 Under Dhalia's cost accounting system, costs of normal spoilage are treated as part of the costs of good units produced. However, the costs of abnormal spoilage are charged to factory overhead. Using the weighted-average method, what are the equivalent units for the materials unit cost calculation for the month of April? a.47,000 b.52,000 C. 55,000 d. 57,000 13. The following information pertains Lanao's First Department for the month of April: Beginning work-in-process Started in April Units completed Ending work-in-process Number of units 15,000 40,000 42,000 12,000 Cost of Materials P 5,000 18,000 All materials are added at the beginning of the process. Using the weighted average method, the cost per equivalent unit for materials is: a.P0.59 b.P0.55 C. P0.45 d. P0.43 14. Information concerning Dept. B of Simon Co. follovvs: Units Beg. work in process 5,000 P6,300 P2,90 Units transferred in 35,000 58,000 17,500 40,000 P64,300 P20,400 Units completed End. work in process P25,500 25,500 P 3,400 15,000 P18,400 37,000 3,000 Conversion costs were 20% complete as to the beginning work in process and 40% complete as to the ending work in process. All materials are added at the end of the process. Simon Co. uses the weighted average method. The unit cost for conversion costs and for transferred-in cost rounded to the nearest centavo are: a. P0.44 and P0.48 b. P0.46 and P0.51 c.P0.48 and P0.51 d. P0.50 and P0.53 15. Reyna Company manufactures product X in a two-stage production cycle in Departments A and B, Materials are added at the beginning of the process in Department B. Roy uses the weighted-average method. Conversion costs for department B were 50% complete as to the 6,000 units in the beginning work-in- process and 75% complete as to the 8,000 units in the ending work-in-process,12,000 units were completed and transferred out of Department B during February 2013. An analysis of the costs relating to work-in-process and production activity in Department B for February 2013 is as follows: Work-in-process, February 1: costs attached February activity: costs added Transferred In Cost Materials Conversion P12,000 P2,500 P1,000 29,000 5,500 5,000 The total cost per equivalent unit transferred out for February 2013 of product X, rounded to the nearest centavo, was: a. b. c. d. P2.75 P2.78 P2.82 P2.85 16. On April 1,2013, the Hari Company had 6,000 units of WIP in Department B, the second and last stage of their production cycle. The costs attached to these 6,000 units were P12,000 of costs transferred in from Department A, P2,500 of material cost added in department B and P2,000 of conversion cost added in Department B. Materials are added in the beginning of the process in Department B. Conversion was 50% complete on April 1,2013. During April, 14,000 units were transferred in from Department A at a cost of P27,000; and a materials costs of P3,500 and conversion costs of P3,000 were added in Department B. On April 30, 2011, Department B had 5,000 units were added in Department B. On April 30,2011 Department B had 5,000 units of WIP 60% complete as to conversion costs. The costs attached to these 5,000 units were P 1 0,500 of costs transferred in from Department A, P1,800 of material costs added in Department B and P800 of conversion costs added in Department B. Using the weighted-average method, what are the unit costs? Transferred Materials in a.P1.95 P.25 b.P1.95 P.30 c.P1.80 P.30 d. P1.70 P.25 Conversion cost P.27 P.28 P.27 P.28 I 7. Department CC has the following April production information: Beginning work in process Units started during the month Units transferred to next operation in April Ending work in process (40% complete) Beginning work in process cost April's production cost 24,000 units 780,000 units 744,000 units 60,000 units P 120,000 5,256,000 No 17 Continued The unit cost of production is: a.P 7.00 b. P20.22 c. P 6.89 d. P 6.69 I 8. For the month of March, Payaso Inc. registered the following information: Beginning work in process (70% complete) Started in March Ending work in process (80% complete) 40,000 units 300,000 units 60,000 units The cost of beginning work in process was FP 140,000 while the production costs for the month registered at P 1 ,172,000. Using the average method, what is the unit cost of production for March? a.P4.00 b.P3.86 C. P3.91 d. P4.69 I 9. The Masaya Corporation manufactures only one product, and the raw materials must pass through Processes A, B, and C, in that order, before completion. On October 1, the inventories of Process C and Finished Goods were: Process C Finished Goods --- 1,200 units, 2/3 completed, P4,200. 1,000 units, at P3.00 per unit. During October, 2,000 units valued at P5,000 were transferred in from Process B. Direct labor cost in Process C was P3,100 and the overhead cost applied to Process C was P3,200. The inventories on October 31 were: Process C -660 units, 1/2 completed. Finished Goods -1,300 units The conversion cost per equivalent unit for October is: No. 19 --- continued a.P1.50 b.P2.75 C. P3.00 d. P3.50 20. Materials are added at the start of the process in Arce Company's Blending Department, the first stage of the production cycle. The following information is available for the month of July, 2013. Work-in-process, July 1 (60% complete as to conversion 60,000 units costs) Started in July 150,000 units Transferred to the next department 110,000 units Lost in production 30,000 units 'Work-in-process, July 31 (50% complete as to 70,000 units conversion costs) Under Arce's cost accounting system, the costs incurred on the lost units are absorbed by the remaining good units. Using the weighted-average method, what are the equivalent units for the materials unit cost calculation? a. b. c. d. 120,000 145,000 180,000 210,000 21. Information for the month of May concerning Department A, the first stage of Pinay Corporation's production cycle is as follows: Work-in-process, beginning Current costs Total costs Equivalent units based on Weighted-average method Average unit costs Goods completed Work in process, end Materials P 4,000 20,000 P24,000 Conversion Costs P 3,000 16,000 P19,000 100,000 P 0.24 95,000 P 0.20 90,000 units 10 000 units No. 21 --- Continued Material costs are added at the beginning of the process. The ending work-in process is 50% complete as to conversion costs. How would the total costs accounted for be distributed, using the weighted-averaged method? Goods Completed a P39,600 b. P39,600 C. P43,000 dr. P44,000 Work-in Process, End P3,400 P4,400 P0 P3,400 22. Samahan, Inc. manufactures a highly sensitive smoke alarm and uses the first-in, first-out method for process costing and finished goods costing. In costing finished goods, the unit cost for units completed from the work in process at the beginning of the period is kept separate from the unit cost of those started and completed during the period. The total manufacturing costs for the month of June is P264,000 and 2,750 units are completed during the month. The inventories at the beginning of June area Smoke alarms in process (8O% complete) Smoke alarms on hand (complete) The inventories at the end of June are: Smoke alarms in process (50% complete) Smoke alms on hand (complete) 1,250 units P128,000 600 units 76,800 500 units 700 units How would the total costs accounted for be distributed? Work-in Process a. P33,000 b. P33,000 c. P32,000 d. P66,000 Finished Goods P92,000 P79,000 P92,000 P52 23. China, Inc. manufactures a product which goes through three consecutive Processes, Process I , Process 2 and Process 3. Data for the month of September, 2013 are as follows: Process 1 Process 2 Process 3 P8,000 P13,000 P2,000 Opening Work in Process 20,000 4,000 5,000 Materials added 10,000 10,000 16,000 Conversion Costs 6,000 9,000 4,000 What was the value of the output transferred from Process 3 to the finished goods warehouse for the month of September? a. b. c. d. P63,000 P65,000 P67,000 P69,000 24. Lucas Company adds materials in the beginning of the process in the 'Forming Department, which is the first of two stages of its production cycle. Information concerning the materials used in the Forming Department in October 2013 are as follows: Work in process at October 1, 2013 Units started during October Units completed and transferred to the next department during October Units 6,000 50,000 Material Costs P3,000 50,000 40,000 Using the weighted-average method, what was the materials cost of work in process at October 31, 2013? a. P3,060 b. P5,520 C. P6,000 d. P6,120 25. During March 2013 Binata Co.'s Department Y equivalent unit product costs, computed under the weighted-average method, were as follows: Materials Conversion Transferred-In P1 3 5 Materials are introduced at the end of the process in Department There were 4,000 units (40% complete as to conversion cost) in work-in-process at March 31, 2013, The total costs assigned to the March 31, 2013, work-in-process inventory should be a. b. c. d. P36,000 P28,800 P2 7,200 P24,800 26. The following data pertains to Finishing Department for the month of May, 2013: I. Opening Inventory 4,000 units Material Labor Overhead Percentage of completion 100% 50% 50% Value P1,992 1,074 826 Put in process 20,000 units Materials value - P 12,000 Labor --- P9,984 Overhead is 100% of labor cost. 2, Units completed and transferred to store a 21,000 units 3. In process at the end - 3,000 units Materials - all Labor and overhead - 60% No. 26 Continued What is the cost of the work-in process at the end for the month of May? Average Method a. P3,577 b. P3,477 c. P3,528 d. P3,500 FIFO Method P3.500 P3,228 13,477 P3,577 27. For the month of May, the Cutting Department of Damit Co had 80% complete as to the beginning work in process and 50% complete as to the ending work in process. Related data follow: Units Conversion Costs Work in process, 1 May 50,000 P88,000 Units started and costs incurred in May 270,000 572,000 Units completed and transferred to the next department in May 200,000 If the company were using FIFO method, the conversion cost of the work in process in the Cutting Department at the end of May would amount to a.P156,000 b.P254,000 C. P132,000 d. P176,000 28. Matalino, Inc. instituted a new process in October 2013. During October, 10,000 units were started in Department A. Of the units started, 1,000 were lost in the process, 7,000 were transferred to Department B and 2,000 remained work-in-process at October 31, 2013. The work-in-process at October 31, 2013 was 100% complete as to material costs and 50% complete as to conversion costs. Material costs of P27,000 and conversion costs of P40,000 were charged to Department A in October. What were the total costs transferred to Department B? a. P46,900 b.P5.3,600 c. P56,000 d. P57,120 29. The following data for September were taken from the cost records of the Mixing Department of Love Manufacturing Company, which uses average costing method: Work in process, August 31: (all materials, 50% converted) Put into process during the month of September Work in process, September 30: (all materials, 60% converted) Costs: Work in process, August 31: Materials Labor Factory overhead Put into process during September Materials Labor Factory overhead 1,000 units 10,000 units 1,400 units P 24,000 15,000 7,000 251,000 193,000 149,000 The total cost of the units completed and transferred was: a. b. c. d. P576,000 P605,400 P640,400 P693,800` 30. The Forming Department is the first of a two stage production process. Spoilage is identified when the units have completed the forming process. Cost of spoiled units are assigned to units completed and transferred to the second department in the period spoilage is identified. The following information concerns Forming 's conversion costs in May 2013. Beginning work-in-process (50% complete) Units started in May Spoilage-Normal Units completed and transferred Ending work in process (80% complete) Units 2,000 8,000 500 7,000 2,500 Conversion Cost P10,000 75,000 No. 30 Continued Using the weighted-average method, what was Forming's conversion cost transferred to the second production department? a. P59,850 b. P64,125 C. P67,500 d. P71,250 31. Manuel Company uses process cost system with average costing to account for the production of its only product The product is manufactured in two departments. Units are started in Assembling Department, and then transferred to the Finishing Department, where they are completed. Units are inspected at the end of the production process in the Assembling Department, and the cost of abnormal lost is charged to Factory Overhead Control account. Data related to June operations in the Assembling Department are: Quantity: Units in beginning inventory (60% materials, 35% labor, and 25% overhead) 1,000 Units started in process this period 59,000 Units transferred to the Finishing Department this 8,000 period Units in ending inventory (100% materials, 75% labor, Aand 50% overhead) 1,500 Cost data: Beginning Inventory Costs charged to the Department: Materials P 1 ,260 Direct labor 770 Factory overhead 1,400 Added This Period P36,240 10,780 21,725 What is the total cost transferred to the Finishing Department? a. P56, 752 b. P59,600 C. P59,452 d. P58,000 or less 32. Datu Chemical Industries, Inc. produces a product through a continuous process in different departments. Each department has an independent cost accountant who prepares cost of production report. You have been assigned as cost accountant for Department A. Production data of Department A for the month of July, 2013 were as follows: Work in process, July 1 (70% completed) Started in process Work in process, July 31 (60% completed) Lost units (normal) at end of process In this department, costs are applied as follows: Materials --- added at the start. Labor and overhead --- evenly applied Department costs incurred in July were: Materials Labor Overhead Work in process, July 1 14,000 units 70,000 units 12,000 units 2,000 units P56,000 17,000 13,000 8,000 What is the cost of? Units transferred a. P82,390 b. P81,890 c. P72,000 d. P82,3 90 Work in process-July 31 P 9,600 P 9,600 P12,840 P12,840 33. The Classmate Company manufactures a single product in a continuous process in two departments. Cost and production data for the finishing department, the last department for the month of April, 2013 are shown below: Costs: Cost from preceding department Work in process, April 1 Materials Labor Factory overhead P135,000 18,000 85,800 47,200 No. 33 Continued Quantity: Units in process, April 1 (All materials, 50% converted) Units received from preceding department Units in process, April 30 (All materials, 60% converted) Loss during the process 4,000 30,000 6,000 3,000 In the Finishing Department, what is the total cost transferred to finished goods? a. P250,000 b. P286,000 C. P238,000 d. P210,000 34. Adonis Manufacturing Company makes a single product in two departments. The production data for Department 2 for May 2013 follows: Quantities: In process, May I, (40% completed) 4,000 units Received from Department 1 30,000 units Completed and transferred 25,000 units In process, May 31, (60% completed) 6,000 units Production Costs: May 1 May 31 Received from Department 1 P16,300 P89,100 Materials 3,800 67,500 Conversion cost 1,940 81,000 Materials are added at the start of the process, and losses normally occur during the early stage of the operation. Using the Average Costing Method, what is the inventory cost of the ending work in process? a. P44,640 b. P45,460 c. P45,600 d. P46,000 Numbers 35 to 37 are based on the following information Air Force Inc. manufactures their product in two departments in a continuous process. Production data for the month of October 2013 are as follows: Beginning work in process, 40% completed 500 units Received from preceding department Normal spoilage Abnormal spoilage Units completed and transferred out Ending work in process, 1/3 completed Conversion costs in beginning inventory Current period conversion costs 2,000 units 200 units 300 units 1,700 units 300 units P610 P3,990 All spoilage occurs at the end of the process. 35. What is the conversion cost per equivalent unit? FIFO Method a. P1.90 b. P2.19 c. P2.00 d. P1.90 Average Method P1.73 P2.00 P1.90 P2.00 36. What is the conversion cost of normal spoilage? FIFO Method a. P438 b. P380 c. P400 d. P380 Average Method P400 P346 P380 P400 37. What is the conversion cost of abnormal spoilage? FIFO Method a. P570 b. P657 c. P570 d. P600 Average Method P519 P600 P600 P570 Use the following data in answering Numbers 38 to 41 The Cooking Department of Red Crab, Inc., uses process system Direct materials are added at the beginning of the cooking process. Conversion costs are added evenly during the cooking process. Consider the following data for the Cooking Department for January: Physical Units Direct Materials Conversion costs Work in process, January 1: 25% conversion costs Started in January 74,000 250,000 30,000 Good units completed and transferred out during January Spoiled units Work in process, January 31 Costs added during January Cost per equivalent unit of work done in January 61,000 8,000 15,000 P1,480,000 P942,000 P20 P12 Red Crab uses the FIFO method of process costing. Inspection occurs when production is 100% complete, normal spoilage is 11% of good units completed during the period. 38. What is the total cost of the units completed and transferred-out? a. b. c. d. P1,632,000 P1,972,000 P2,186,720 P2,228,000 39. What is the total cost of the units in ending work in process? a. P444,000 b. P685,280 C. P658,720 d. P300,000 40. What is the cost of abnormal spoilage? a. P256,000 b. P214,720 c. P 41,280 d. 41,000 Questions 41 and 42 are based on the following information: A sporting goods manufacturer buys wood as a direct material for baseball bats. The Fanning Department processes the baseball bats, and the bats are then transferred to the Finishing Department where a sealant is applied. The Forming Department began manufacturing 10,000 "Casey sluggers" during the month of May. There was no beginning inventory. Costs for the Forming Department for the month of May were as follows: Direct materials Conversion costs Total P33,000 17,000 P50,000 A total of 8,000 bats were completed and transferred to the Finishing Department; the remaining 2,000 bats were still in the forming process at the end of the month. All of the Forming Department's direct materials were placed in process, but, on average, only 25% of the conversion cost was applied to the ending work-in- process inventory. 41. The cost of the units transferred to the Finishing Department is: a. P50,000 b. P40,000 C. P53,000 d. P42,400 42. The cost of the work-in-process inventory in the Forming Department at the end of May is: a. P10,000 b. P 2,500 c. P20,000 d. P 7,600 Question 43 and 44 are based on the following information: A manufacturer began operations on October 1. It buys wood as a direct material for the production of floor lamps. The company’s Forming Department processes the lamp frames, and the frames are then transferred to the Finishing Department where a sealant is applied. The Forming Department began manufacturing 10,000 lamps during the month of October. Costs for the Forming Department for the month of October were as follows: Direct materials Conversion cost P66,000 34,000 43. The cost of the units transferred to the Finishing Department (after rounding each calculation to the nearest cent) is: a. b. c. d. P68,760 P60,000 P39,600 P29,160 44. The cost (after rounding each calculation to the nearest cent) of the work-in-process inventory in the Forming Department of October is: a. P11,460 b. P26,400 c. P31,260 d. P45,840 Question 45 and 44 are based on the following information: A company employs a process costing system for its two-department manufacturing operation using the first-in, first-out (FIFO) inventory method. When units are completed in Department 1, they are transferred to Department 2 for completion. Inspection takes place in Department 2 immediately before the direct materials are added, when the process is 70% complete with respect to conversion. The specific identification method is used to account for lost units. The number of defective units (that is, those failing inspection) is usually below the normal tolerance limit of 4% of units inspected. Defective units have minimal value, and the company sells them without any further processing for whatever it can. Generally, the amount collected equals, or slightly exceeds, the transportation cost. A summary of the manufacturing activity for Department 2, in units for the current month, is presented below: Beginning inventory (60% complete with respect to conversion) Units transferred from Department 1 Total units to account for Units completed in Department 2 during the month Units found to be defective at inspection Ending inventory (80% complete with respect to conversion) Total units accounted for Physical Flow(output units) 20,000 180,000 200,000 170,000 5,000 25,000 200,000 45. The equivalent units for direct materials for the current month would be: a. 175,000 units b. 181,500 units c. 193,000 units d. P200,000 units 46. The units that failed inspection during the current month would be classified as: a. b. c. d. abnormal spoilage normal scrap normal rework units normal waste 47 to 50 are based on the following data: DXR Compamy employs process cost system. A unit of product passes through two department. Assembly and Finishing before it is complete. Information regarding Assembly Department follow: BWIP, Aug. 1 Spoiled units Suited in Production Transffered out 4,000 units 3,000 26,000 24,000 Raw materials are added at the beginning of processing in the Assembly Department without changing the number of units being processed. Work-in-process on August 1 was 90% complete as to conversion while 80% converted on August 31. In the Assembly Department, inspection takes place when the units are 75% converted. The company usually experienced a 5% loss based on the completed units, Cost data for the month of August follow: BWIP Current cost Materials P32,400 111,600 Labor P26,400 88,200 Overhead P28,500 114,750 Using Weighted Average Costing: Assuming that the allocation of cost of normal lost units is based on EUP. 47. What the cost of units transferred-out? a. b. c. d. P331,200 P331,400 P343,684 P343,860 48. What is the cost of units of ending work-in-process? a. P37,376 b. P37,500 c.P36,200 d. P37,400 Using FIFO Costing: Assuming that the allocation of the cost of normal lost units is based on actual units. 49. What is the cost of units transferred out? a. P349,136 b. c. d. P258,067 P339,267 P368,069 50. What is the cost of units of ending work-in-process? a. b. c. d. P33,850 P32,310 P31,580 P33,580 ANSWERS 1.C 2.d 3.a 4.d 5.d 6.a 7.a 8.a 9.c 10.d 11.c 12.d 13.d 14.c 15.b 16.b 17.a 18.a 19.c 20.c 21.a 22.a 23.d 24.d 25.d 26.b 27.a 28.c 29.a 30.c 31.b 32.d 33.c 34.a 35.d 36.d 37.c 38.c 39.a 40.C 41.d 42.d 43.a 44.C 4S. C 46.b 47.a 48.a 49.a 5O. a SOLUTIONS AND EXPLANATIONS 1. Under FIFO method the work done this month on the opening inventory should be determined. The equivalent production is computed as follows: Transferred: Opening inventory (3/8 x 4,000) Started (9,000- 4,000) Closing Inventory: 1/2 x 4,000 3/4 x 4,000 Equivalent production 2,000 5,000 2,000 3,000 5,000 12,000 Under the average cost method, to compute the equivalent production, the work done on the opening inventory is not determined. Transferred Closing Inventory: 9,000 1/2 x 4,000 2,000 3/4 x4, 3,000 5,000 Equivalent production 14,000 2. This is computed by using the equation, units in process beginning and units started is equal to units completed and units in process at the end, therefore the with units started is 11,000 units as computed below: Units completed Units in process-end Units as accepted for Less: Units in process, beg. Units started 3. FIFO: Units completed and transferred Add: Units in process, ending: 1. (400 x 50%) + (600 x 25%) 2. (3,000 x 50%) + (2,000 x 25%) 3. (3,000 x 50%) + (1,500 x 75%) Equivalent production figures, Average Costing Less: Units in process, beginning: 2. (6,250 x 40%) 3. (6,000 x 30%) Equivalent production figures, FIFO Costing Units completed and transferred Add: Units in process, ending: 1. (400 x 50%) + (600 x 25%) 2. (3,000 x 50%) + (2,000 x 25%) 3. (3,000 x 50%) + (1,500 x 75%) Equivalent production figures, Average Costing (see also FIFO) 10,000 4,000 14,000 3,000 11,000 Case 1 5,500 Case 2 26,250 Case 3 14,000 350 2,000 ____ ____ 2,625 5,850 28,250 16,625 ____ 5,850 2,500 _____ 25,750 1,800 14,825 Case .1 5,500 350 Case 2 26,250 Case 3 14,000 2,000 _____ ____ 2,625 5,850 28,250 16,625 4. The computation is: Work to complete WIP-Beg. Units started and transferred Work to date on WIP-end EUP Materials 0 1,600 400 2,000 Conversion 300 1,600 100 2,000 Since materials are introduced at the beginning of the process, WIP Beg. is already complete as to materials. All materials were added this month for any units started this month, whether those units were transferred or remain in W1P End, since WIP Beg. is 40% complete on 1/1/08 as to conversion costs, 60% of the work (60% x 500, or 300) must have been done in January. WIP End is 25% complete at 1/31/08, which means 25% of the conversion work (25% x 400, or 100) was done in January. Remember, under the FIFO assumption, equivalent production measures only the work done in the current period. 5. Equivalent units, under the weighted-average method, is equal to units completed plus equivalent units in ending work-in-process. Beginning work-in-process Units started Units to be accounted for Less ending work-in-process Units completed 40,000 240,000 80,000 25,000 255,000 Computation of equivalent units of production is then computed as follows: Units completed Equivalent units Equivalent units Materials 255,000 25,000 280,000 Conversion 255,000 15,000 270,000 Materials added at beginning of process; 100% complete (25,000) (60% complete) 6. Since the materials are added at the beginning of the process, all units are 100% complete with respect to materials. Actual Work Done Materials Actual Work Done Materials Finished and transferred: Work in process, March 1 60,000 Started in March (110,00050,000 100% 50,000 60,000) Work in process, March 31 70,000 100% 70,000 Equivalent units of 120,000 production As stated in the problem, the cost of the 30,000 spoiled units will be spread over the 180,000 equivalent units. Hence, the spoiled units are not considered in the equivalent unit computation. 7. The computation is shown below: Transferred out: Beginning inventory Transferred in (120,000-15,000) Ending inventory Equivalent production Materials Conversion Cost 105,000 45,000 150,000 9,000 105,000 13,000 127,000 8. Units finished [(R4,000 20,000 — 10,000) x 100% =] Units in process-end (10,000 x 60%) Equivalent units of labor and overhead 14,000 6,000 20,000 Note: The average method was used because the percentage of completion as to conversion cost on the units in process beginning is not given. 9. Equivalent units for conversion costs can be computed under the FIFO method as follows: Units completed: Work in process, March 1 (15,000 x 40%)* From March production Work in process, March 31 (12,000 x 80%) Equivalent units 6,000 45,000 9,600 60,600 * Work done this month. Another computation is: Units completed Work in process, March 31 Total Less: Work in process, March 1 (15,000 x 60%)* Equivalent units * Work done this month. 60,000 9,600 69,600 9,000 60,600 10. Using the FIFO, the computation is: Actual Units completed: In process, beginning 200 Started & completed 1,000 Units in process, end 200 Equivalent units Materials Conversion Cost 1,000 200 1,200 150 1,000 100 1,250 11. Under the weighted-average method, the computation is as follows: Actual Material Units in process, beg. 25,000 Units transferred in 100,000 Total units to account for 125 000 Units completed (Squeeze) 105,000 105,000 Units in process, end 20,000 ______ Units as accounted for 125,000 105,000 Conversion Cost 105,000 16,000 121,000 No. 11 - Continued Under the average method the equivalent production &the total units transferred-in would be the total units in process, beginning and the unit transferred-in of 100,000. 12. No equivalent production is to be computed on normal spoilage since the cost is to be allocated to all the good units. However abnormal spoilage is to be given a 100% e equivalent production since its costs are charged to factory overhead. Therefore, the equivalent production under the average method is 57,000 units, Computed as follows: Completed and transferred (100%) Work in process, end (100%) Abnormal spoilage (100%) Equivalent production of materials 36,000 16,000 5,000 57,000 13. Under the weighted average method, equivalent units of production and cost per unit are based on all work (this period's and last period's) done on units completed plus all work done to date on the units in ending work in process. Since materials are added at the beginning of the production process, both the units completed in the ending work-in-process are 100 percent complete with respect to materials. The cost per equivalent unit can be computed as follows: Units completed Ending work in process Total equivalent units Cost of materials: Beginning work in process Units started Total costs incurred Divided by Equivalent Production Cost pa equivalent unit 14. Unit cost for conversion cost Units completed Units in process, end (3,000 x 40%) Equivalent production for conversion cost Unit cost, rounded to the nearest centavo is: P18,400 + 38,200 42,500 12,500 55 000 P 5,500 18,000 P23,00 ÷55,000 P.43 37,000 1,200 38,200 P0.48 Unit cost for transferred-in cost is P0.51, completed by dividing transferred in cost (P20,400) by the total units of in Process beginning and units transferred-in (40,000 units). 15. Since Reyna Company is using the weighted-average method, the solutions approach is to combine the transferred-in cost, material costs and conversion costs in the beginning inventory with their counterparts for costs added in February The next step is to compute the equivalent units for the transferred-in, materials and conversion elements. Finally, dividing the total costs of the beginning inventory and costs added in the period for each element by the equivalent units for the corresponding element gives the unit cost for each of the elements. Department B Beginning work-in Completed and process (conv. 50%) 6,000 12,000 transferred Transferred in Ending work-in(not needed) ? 8,000 process (conv. 75%) Department B Product X Equivalent Units: Transferred in Units completed and transferred 12,000 Ending work-in process (conv. 75%) 8,000 Equivalent units production 20,000 Cost per Equivalent Unit: Beginning work-in process P12,000 Costs added in February 29,000 P41,000 Cost per EUP P 2.05 12,000 8,000 20,000 12,000 6,000 18,000 P 2,000 5,000 P 8,000 P 0.40 P 1,000 5,000 P 6,000 P- 033 Total P 2.78 16. First compute equivalent units of production as shown below: Physical Stage of TransferredFlow Completion in M CC Beginning work-inprocess, 4/1/08 6000 100% 50% Transferred in 14,000 Available 20,000 Units completed 15,000 15000 Ending work-inprocess, 4/30/08 5,000 100% 60% 5,000 Weighted average equivalent units 20,000 Materials Conversion 15,000 15,000 5,000 5,000 20,000 18,000 No. 16 -- continued Under the weighted average method, unit costs (rounded) as follows: Transferred in (P12,000 + P27,000) + 20,000 =P1.95 Materials (P2,500 + P3,500) + 20,000 = P0.30 Conversion cost (P2,000 • + P3,000) t 18,000 = P0.28 17. Total cost to account for (P120,000 + P5,256,000) Divided by the equivalent production: Units finished and transferred Work in process, end (60,000 x 40%) Unit cost of production P5,376,000 744,000 24 000 18. Total cost of units in process beginning and cost for the month (P140,000 + P1,172,000) Divided by the equivalent production: Units finished and transferred (340,000-60,000) 280,000 Work in process, end (60,000 x 80%) 48,000 Unit cost of production ÷768,000 P 7.00 P1,312,000 ÷ 328,000 P 4.00 19. Since no materials are added in process C, then only unit cost for conversion Cost is to be computed: Units in process, Oct. 1 (1,200 x 1/3) Units started and completed this October: Total units completed R1,200 + 2,000- 600] Less: In process, Oct. 1 Units in process, Oct. 31 (600 x 1/2) Equivalent units of production Unit cost of labor and overhead (116,300 ÷ 2,100) 400 2,600 1,200 1,400 300 2,100 p 3.00 Unit cost of labor and overhead (116,300 ÷ 2,100) 20. Since the materials are added at the beginning of the process, all units are 100% complete with respect to materials. Units % Complete Equivalent units completed units 110000 x 100% = 110000 Units in ending inventory 70,000 x 100% = 70,000 Total equivalent units 180,000 As stated in the problem, the cost of the 30,000 spoiled units will be spread over the 180,000 equivalent units. Hence, the spoiled units are not considered in the equivalent unit computation. 21. The total cost of P43,000 (P24,000 for materials and P19,000 for Conversion cost) is distributed as follows: Goods completed (90,000 x P.44) P39,600 Work in process, end: Materials (10,000 x P0.24) P2,400 Conversion cost (5,000 x P0.20) 1,000 3,400 Total P43,000 22. Cost assigned to work in process inventory, end: Units completed: Units in process, June 1 (1,250 x 20%) 250 Units started and completed (2,750 —1,250) 1,500 Units in process, June 30 (500 x 50%) Equivalent production Unit cost, FIFO (P264,000 ÷ 2,000) Cost of work in process inventory (250 x P132) 1,750 250 2,000 P 132 p33,000 Cost assigned to the finished inventory at the end of June: 700 x P132 P92,400 Note: On a "first-in, first-out" basis, all units in the finished goods inventory at the end of June would have come from units that were started and completed during the month of June. 23. Total cost of opening work in process (8,000 +13,000 + 2,000) Add: Materials cost Conversion cost Total cost Less: Cost of closing work ,in process Cost of units transferred to finished goods P23,000 P29,000 36,000 65,000 88,000 19 000 P69,000 24. The major point to remember is that both the equivalent units and equivalent units cost computations combine the beginning inventory with the current Production. Beginning inventory Started Available Completed Ending inventory Weighted average equivalent units Equivalent Units Physical Flow Raw Material Stage of Completion 100% Physical Flow 6,000 50,000 56,000 44,000 12,000 100% 100% Equivalent units Raw Materials 44,000 12,000 56,000 Unit cost of material [(P3,000 P25,560) ÷ 56,000] = P.51 Material cost of work in process, Oct 31 (12,000 x .51) P6,120 25. Cost of work-in process at March 31, 2011. Materials Conversion cost (4,000 x 40%) x P3 Transferred in cost (4,000 x P5) Total 26. Equivalent productions: Average method: Units completed Material 21,000 0 P 4,800 20,000 P24, 8000 Conversion Cost 21,000 In process, end Equivalent production 3,000 24,000 1,800 22,800 FIFO Method: Unit in process Units started (21,000-4,000) In process, end Equivalent production 4,000 17,000 3,000 24,000 2,000 17,000 1,800 20,800 Unit Cost: Average method: Material (P1,992 + P12,000) + 24,000 = Conversion cost (P1,920 + P19,968) 4- 22,800 = Total units cost P0.583 0.96 P1.543 FIFO method: Materials (P12,000 ÷ 24,000) Conversion cost (P19,968 ÷ 20,800) Total unit cost P 0.50 0.96 P 1.46 Cost of work in process, end: Average: Materials (3,000 x P0,583) Conversion cost (3,000 x 60%) x P0.96) Total P1,749 1,728 P3,477 FIFO method: Materials (3,000 x P0.50) Conversion cost (3,000 x 60%) x P.96 Total P1,500 1,728 p3,228 27. Equivalent Production of Conversion cost: Work in process, May I (50,000 x 20%) Units started and completed (200,000 -- 50,000) Work inprocess, May 30 (320,000 200,000) X 50%) Total Unit cost (P572,000÷ 220,000) Conversion cost (60,000 x P2.60) 28. Equivalent production; 10,000 150,000 60,000 220,000 P 2.60 P156,000 Unit completed Units lost in process, end Equivalent production Materials 7,000 Conversion Cost 7,000 2,000 9,000 1,000 8,000 Unit cost: Material (P27,000 ÷ 9,000) Conversion cost (P40,000 ÷ 8,000) Total unit cost P3 5 P8 Total cost of units transferred to Dept. B: 7,000 units x P8 = P56,000 Note - This situation allocates all the material and conversion costs incurred to "units lost". Assuming a conceptually sound cost system, the following implications can be drawn: 1. the loss was "normal", and 2. the loss was reported before work-win-process reached the current stage Of completion. 29. The total unit cost is computed first as follows: Equivalent production units In process, Aug. 31 Put into process In process, Sept. 30 Completed In process, Sept. 30 (all M; 60% L&OH) Equiv. production units Materials (Labor & Overhead) 1,000 10,000 ( 1 400) 9,600 9,600 9,600 1,400 1,400 840 11,000 10,440 Average unit costs: Materials: Conversion cost (P24,000 + P251,000)/11,000 = P25 Direct Labor: (P15,000 + P193,800)/10,440 = 20 Overhead (P 7,600 + P149,000)/10,440 = 15 Total P60 Total cost of units completed and transferred: 9,600 x P60 P576,000 30. The computation is as follows: Actual Units 7,000 500 2,500 10,000 Units completed Spoilage --- normal Work in process, end (80%) Unit Cost (P85,500/9,500) Conversion Costs 7,000 500 2,000 9,500 P9 Conversion Costs transfered: Good units completed (7,000 x P9) Spoiled units (500 x P9) Conversion costs transferred 31. P63,000 4 500 P67,500 The computations are as follows: Actual Quantity 1000 Schedule: In process, 9000 beginning Started in 10000 process Accounted for as follows: Finished and 8,000 transferred In process, end 1,500 Work Done EP Mat. Work Done EP Lab. Work Done EP CC 100% 8,000 100% 8,000 100% 8,000 100% 1,500 75% 1,125 50% 750 Abnormal lost 500 100% 10,000 500 10,000 100% 500 9,625 100% 500 9250 Total cost transferred: Materials: (P1,260 + P36,240) ÷ 10,000 P 3.75 Direct Labor: (P770 + P10,780) ÷ 9,625 1.20 Overhead: (P1,400 + P21,725) ÷9,250 2.50 Cost per equivalent unit P 7.45 Multiplied by: No. of units transferred 8,000 Total cost transferred P59,600 32. Since the details of the costs of Work in Process, beginning is not given, FIFO method is to be used. Equivalent productions: WIP, beginning, F/T Started, F/T (squeeze) In process, ending Normal lost units Total Actual 14,000 56,000 12,000 2,000 84,000 Materials: 56,000 (100%) 12,000 (100%) 2000 (100%) 70,000 Unit costs: Materials (P56,000 / 70,000) P0.80 Conversion costs (P31,230/69,400) P0.45 Adjustment for lost units: Cost of lost units (2,000 x P1.25) P2,500 Divided by absorbing good units (F/T) 70,000 Conversion Costs 4,200 ( 30%) 56,000 (100%) 7200( 60%) 2000 (100%) 69,400 Adjusted unit cost P0.35714 No. 32 -- continued Cost of units finished and transferred: Beginning MP, F/T: Cost last month P8,000 Cost this month: Conversion costs (4,200 x 1,890 P0.45) Adjustment for lost units ( 500 14,000 x P0.35714) started, F/T [56,000 x (P1.25 + P0.35714)] Total Cost of units in process Materials (12,000 x P.80) P9,600 Conversion costs (7,200 x 3,240 P.45) 33. The computations are shown below: Quantity Schedule: In process, beginning Received from Preceding Dept. Accounted for as follows: In process, beg., F&T Started F&T (25,000 - 4,000) In process, ending Normal lost Cost per equivalent unit: From preceding dept.: (P135,000 /30,000) From this dept: Materials Conv. cost: (P85,800 + P47,200) 26,600 Adjustment for lost units: (3,000 x P4.5) + P10,390 72,000 P82,390 P12,840 Actual 4,000 30,000 34,000 Work Done EP CC 4,000 21,000 6,000 3,000 34,000 1/2 100% 60% 2 21 3 26,000 P4.50 5.00 50 P10,000 27,000* Total cost transferred: In process, beg., F&T Cost last month Cost this month: Materials Conv. Costs: (PS x 2,000) Started F&T: (P 1 0.00 x 21,000) Total cost transferred to FG *21,000+ 6,000, remaining good units. P18,000 0 10,000 28,000 210,000 P238,000 34. To compute the cost of the ending work in process, the following are the First: Compute the equivalent units of production as follows: Completed and transferred In process, end Lost units (34,000 -31,000) Total equivalent production Actual 25,000 6,000 3,000 Materials 25 6 31,000 Second: Compute the unit cost using the average method as follows: Total EUP Cost Cost from preceding department: May 1 P 16,300 4,000 May 31 89,100 30,000 Total P105,400 34,000 Cost added this department: Materials: May I P 3,800 May 31 67 500 Total P 71,300 31,000 Conversion Costs: May 1 P 1,940 May 31 81,000 Total P 82,830 28,600 Adjustment for lost units: Cost from preceding department: (3,000 x P3.10) P 9,300 31,000 Total adjusted unit cost Finally: Compute the cost of ending work in process (6,0(0 units): Cost from preceding department(6,000 x P3.10 cost added this department EUP x unit cost) Conversion cost 25 3 28,000 Unit Cost P3,10 2.30 2.90 30 P8.60 P18,600 Materials (6,000 x P2.30) Conversion costs (3,600 x P2.90) Adjustment fat lost units (6,000 x .30) Total 35. Quantity schedule, In process, beginning Received from preceding department Accounted for as follows ask FIFO: in process, beg., F&T Received, F&T (1,7004- 500) In process, ending Normal lost Abnormal lost Accounted for as follows Average Finished and transferred. In process, ending Normal lost Abnormal lost Conversion cost per equivalent unit: In-process, beginning Added Conversion Costs Divided by Equivalent Units EUP P13,800 10,440 24,240 1,800 p44 640 Actual 500 2,000 2,500 Work Done EP CC 500 1,200 300 200 300 2,500 3/5 100% 1/3 100% 100% 500 1,200 300 200 300 2,100 1,700 300 200 300 2,500 100% 1/3 100% 100% FIFO 1,700 100 200 300 2,300 Average P 3,990 P3,990 2,100 P1.90 P 610 3,990 P4,600 2,300 P2.00 36.FIF 0: Conversion Costs component of normal lost: 200 x P1.90 = P380 Average; Conv, Costs component of normal lost: 200 x P2.00 = P400 37. FIFO: Conv. Costs component of abnormal lost: 300 x P1.90 = P570 Average: Conv. Costs component of abnormal lost: 300 x P2,00 = P600 38. To compute cost of good units completed and transferred out, the following steps are to be used Step I: Compute the total equivalent units of production for Materials and conversion Costs as follows: Cost added in January (Current cost) Divided by cost per equivalent unit of production for January Equivalent units of production in January Direct Materials P1,480,000 Conversion Costs P942,000 P 20 74,000 P 12 78,500 Step 2: Compute the equivalent units of production of units in process, ending by working backward in the quantity schedule as follows: Work in process, beginning Started during January To account for Completed and transferred (61,000) From beginning work in process Started and completed, 100% Normal spoilage (61,000 x 11%), 100% Abnormal spoilage (8,000— 6 710), 100% Work in process ending Total (a) , Total equivalent units ofproductton (step I) Less equivalent twits of production: Completed and transferred: From beginning WIP From started and completed Normal spoilage Abnormal spoilage Equivalent production of WIP Actual Units 10,000 74,000 84,000 10,000 51,000 6,710 1,290 15,000 84,000 Equivalent production Direct Conversion Materials Costs 51,000 6,710 1,290 15,000(a) 74,000 74, ,000 7 51,000 6,710 1,290 12,000(b) 78,000 78,500 (51,000) (6 1,290 15,000 ( 7,500) (51,000) (6,710) ( 1,290) 12,000 No 38 Continued step 3: The cost of the units completed and transferred out can now be computed as follows: Completed and transferred out (61,000) units From beginning WIP: Cost last month Cost this month: Conversion costs (7,500 x P12) Total From started (5 1 ,000 x P32) Normal spoilage (6,710 x P32) Total cost of units transferred out P 250k000 90,000 P 340,000 1,632,000 214,720 P2,186,720 39. The cost of units in ending work in process is computed as follows: Direct materials (15,000 x P20) P300,000 Conversion costs (12,000 x P 2) 144,000 Total cost of work in process, ending P444,000 40. The computation of abnormal spoilage is shown below: Abnormal spoilage (1,290 x P32) P41,280 41. The correct answer is (d). The total equivalent units for raw materials equal I 0,000 because all materials for the ending work-inn-process had already been added to production. Hence, the materials cost per unit was P330 (P33,000 4. 10,000). For conversion costs, the total equivalent units equals 8,500 [8,000 completed + (25%x 2,000 in EWIP)}. Thus, the conversion cost was P2.00 per unit (P17,000 /8,500). The total cost transferred was therefore P42,400 [8,000 units x. (133.30+P2.00)), 42. The correct answer is (d). As calculated in the preceding question, P42,400 ofcosts were transferred out. Consequently, the cost of ending work-in-process must have been P7,600 (P50,000 total costs incurred --- P42,400). 43. The correct answer 00. The total equivalent units for raw materials equal i10,000 units (the total units placed into production) because all direct materials were added to production. The materials cost per equivalent unit is therefore P6 60 (P66,000 total DM costs 10,000 equivalent units). The total equivalent units for conversion costs equal 7,000 units [6,000 finished units /(25% x 4,000 units in EWIP)] Hence conversion cost per equivalent unit is P4.86 (P34,000 total CC ÷ 7,000 equivalent units). Total product cost per equivalent unit is P,11.46 (P6.60 + P4.86), so total transferred-out cost is P68,760 (P11.46 x 6,000 units transferred). 44.The correct answer is (c). As determined in the preceding question, direct materials cost and conversion cost per equivalent unit are P6.60 and P4.86, respectively.Because the ending work in-process contains 4,0® equivalent units of direct materials costs (4,000 physical units x 100%) and 1,000 equivalent units of conversion costs (4,000 physical units x 25%). its recorded balance is P31,260 (4,000 x P6.60) + (1,000 x P4.86). 45. The correct answer is (c). The equivalent unit for direct materials equals 195,000 units (20,000 BWIP + 150,000 units started and completed + 25,000 EWIP). This calculation recognizes that direct materials had not been added to beginning inventory (60% complete) and spoiled units (70% complete), but that ending inventory (80% complete) includes direct materials. 46. The correct answer is (b). The units that failed inspection are classified as normal scrap because they have minimal value and can be sold without further reworking. The defective units are less than 4% tolerance limit for normal spoilage. Scrap can be sold, disposed of, or reused. 47.The answer is (c), computed as follows: First, compute the EIJP and the unit cost as follows: EUP Transferred-out Ending WIP Normal lost units Abnormal lost units Actual 24,000 3,000 1200 1,800 30,000 Materials 24,000 3,000 1,200 1,800 30,000 Conversion Cost 24,000 2,400 900 1,350 28,650 N0.47 continued Unit Cost. Materials (P1 44,000 ÷ 30,000) Conversion cost (P257,850 ÷ 28,650) Total units cost P4.80 9.00 P13.80 The cost of units transferred-out can now be computed as follows: Transferred out (24,000 x P331 ,200 P13.80) Add: Cost of normal lost units M (1,200 x 4.80) 5,760 CC (900 x 9.00) 8,100 Total 13,860 Allocation: M (24/27 x 5.760) 5,120 CC (24/26.4 x 8,100) 7,364 12,484 Total cost of units transferredout P343,684 48. The answer is (a). The computation is: Ending work-in-process: M (3,000 x 4.80) 14,400 CC (2,400 x 9.00) 21,60 Normal lost units: M (3127 x 5,760) 640 CC (2.4/26.4 x 8,100) 736 Total cost of ending work-inprocess 49. The answer is (a) as computed below: EUP Actual Transferred-out Beginning WIP 4,000 SIP 20,000 Ending WIP 3,000 Normal lost units 1 ,200 Abnormal lost units 1,800 30,000 P36,000 1,376 P37,376 Materials Conversion Cost 20,000 3,000 1,200 1,800 26,000 4,000 20,000 2,400 900 1,350 25,050 No. 49 -.Continued Schedule I - Allocation of normal lost units based on actual units: Transferred-out Beginning WIP(4/27 x P13,860) SIP (20/27 x P13,860) Ending W1P ( 3/27 x P13,860) Total Unit Cost (Rounded): Materials (11,600 +26,000) CC (202,950 25,050) Total unit cost Transferred-out: BWIP: Cost last month Cost this month Normal lost units (Sch. 1) SIP: Completed (20,000 x P12.39) Normal lost units (Sch. 1) Total cost of units transferred-out P 2,053 10,267 1,540 P13,1860 P 4.29 8.10 P12.39 P 87,300 1,716 2,053 P247,800 10,267 P 91,069 258,067 P349,136 50. The answer is (a) as computed below: EWIP: M (3,000 x P4.29) CC (2,400 x P8.10) Normal lost unit (Sch. 1) Total cost of EWIP P 12,870 19,440 1,540 P33,850