Sustainable Food Factory: Nestlé Lighthouse Project Case Study

advertisement

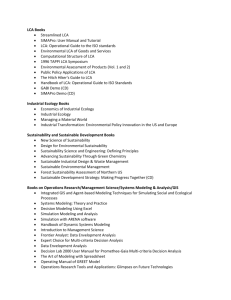

Available online at www.sciencedirect.com ScienceDirect Procedia CIRP 26 (2015) 229 – 234 Creating an environmentally sustainable food factory: A case study of the Lighthouse project at Nestlé J. H. Miah 1,2,, A. Griffiths 1, R. McNeill 3, I. Poonaji 3, R. Martin 3, S. Morse 2, A. Yang 4, J. Sadhukhan 2 1 2 Nestlé UK Ltd, Rowan Drive, Fawdon, Newcastle Upon Tyne, NE3 3TR, UK Centre for Environmental Strategy (CES), Faculty of Engineering & Physical Sciences, University of Surrey, Guildford, GU2 7XH, UK 3 4 Nestlé UK Ltd, Group Technical, Haxby Road, York, YO91 1XY, UK Department of Engineering Science, University of Oxford, Parks Road, Oxford, OX1 3PJ Abstract Many manufacturing companies recognise the need to produce products that are cleaner, greener, and environmentally sustainable, yet they are only at the early stages of this transition in addressing the symptoms of unsustainability at their direct operations by reducing waste and the use of energy, water and material. The implementation of reductions in these areas can be disparate and minimal given the life cycle of a product. Bridging the gap between the rhetoric of sustainable manufacturing and reality requires a holistic, systems thinking approach to ensure the implementation of sustainability is unified and strategic. This paper presents a novel environmentally sustainable manufacturing framework that encompasses energy, water, waste, biodiversity, and people & community. It adopts a systems thinking perspective to address the factories ‘environmental life cycle impact to deliver factory and supply chain benefits. The insights from the application at a Nestlé confectionery factory are reported. Keywords: Environmental Sustainability; Sustainable Manufacturing; Life Cycle Analysis; Systems Thinking; Food Factory; Confectionery 1 INTRODUCTION In recent years, there has been a growing interest in ‘sustainable manufacturing’ [1-5] as part of the endeavour to move towards a green and resource-efficient global economy [6, 7]. The UK’s largest manufacturing sector – the food industry – is under increasing pressure from regulators, consumers, and NGOs to ensure they are operating more sustainable [8-11]. Due to the diversity of food products and scale of operations (i.e. global to local), the implementation, pace and principles of sustainable manufacturing in industry is disparate, uncoordinated and limited in scope. At a system level, many manufacturing companies operate in complex business, environmental and social environments (Figure 1). This requires many actors to ‘act’ in alignment simultaneously to contribute to a system-level change and therefore overcome the ‘Prisoners’ Dilemma’ [12]. Although the goal of a system-level change is desirable and important, many manufacturing companies are at the early stages of the transition towards sustainable manufacturing. The general approach by companies toward sustainable manufacturing in practice [13-17] has been to focus resource (e.g. time, people, finance) at direct operations with a limited impact boundary i.e. factories with an external local/regional impact level. The common areas that are addressed in an incremental process to varying degree include; energy, water, waste, packaging, transport, buildings, employee, community and supplier engagement. Although innovation is key for future progress there are general frameworks available to focus on these areas through the implementation of the energy, water, and waste hierarchy, and the adoption of sustainability certification schemes for buildings (e.g. BREEAM). Also, in recent times, awareness of biodiversity and ecosystems has risen [18] to the extent some companies are seeking to demonstrate these considerations within their operations [17, 19]. However, industrial practices are largely shaped and subjected to economic models based on neoclassical economic theory. This hinders a fast transition towards sustainable manufacturing e.g. long paybacks. In comparison, conceptual sustainable manufacturing themed frameworks can also vary in scope and breadth from machine-level [3], facility-level [4] and supply chain-level [5] and can cover a range of environmental, social and economic considerations. This can be attributed to the floating signifier properties of the sustainability dimension and the complexity of modern manufacturing in its entirety. For example, the OECD has developed a sustainable manufacturing toolkit [4] that provides a step-by-step guide for ‘environmental excellence’ at a facility-level covering; materials, water, energy, infrastructure, travel and logistics, releases, and products. However, the toolkit is limited to the facility-level. In contrast, Duflou et al [20] focuses solely on energy efficiency but at multiple levels; device/unit, line/cell/multi-machine system, facility, multi-factory system, enterprise/global supply chain. In a similar manner, Jayal et al [5] advocates a sustainable manufacturing framework that takes a holistic and multiple view of manufacturing that involves the entire supply chain centred on product innovation via Design for Environment (DfE). Therefore, taken together, the picture for sustainable manufacturing is broad and challenging to implement in practice, given the complex business, environmental and social environment of manufacturing (Figure 1). A recent trend in industry as an approach to setting the pace towards sustainable manufacturing is to establish sustainability pilot projects (Table 1) that will act as a beacon or a ‘Lighthouse’ for encouraging comparatively high sustainability performance across a company’s multiple manufacturing sites. The alternative approach – i.e. top-down The Global Conference on Sustainable Manufacturing 2212-8271 © 2015 Elsevier B.V. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/3.0/). Peer-review under responsibility of Assembly Technology and Factory Management/Technische Universität Berlin. doi:10.1016/j.procir.2014.07.030 230 J.H. Miah et al. / Procedia CIRP 26 (2015) 229 – 234 – is to decide how to strategically select sites for specific solutions; this often results in a series of feasibility studies and often ends in delayed action or no action – i.e. paralysis by analysis. The bottom-up approach is an alternative to the top-down approach as it provides flexibility and freedom for a site. It enables more accelerated development, as bottom-up practical and workable solutions then establish a site with high sustainability performance. The main benefit of the pilot approach is that it enables a company to test in the context of sustainable manufacturing; ideas, technologies, and technical & social processes outside of the organisational mainstream before scaling-up and rolling-out across the multiple-sites of a company’s operations. To this end, this paper provides a short overview of the role of pilot projects with a sustainability remit and is supported by a selected case study of the application of a novel environmentally sustainable manufacturing framework. This case study is called the ‘Lighthouse Model’ (Figure 2) by Nestlé UK Ltd and covers energy and Life Cycle Assessment. The aim of the framework is to further drive the transition towards sustainable manufacturing by demonstrating the practical implementation at a confectionery factory that will act as a blueprint for other manufacturing sites within the Nestlé factory network and wider industry. 2 THE ROLE SUSTAINABILITY OF PILOT INITIATIVES AND In the Multi-Level Perspective (MLP) discourse [21, 22] the role of pilot projects, technologies, grassroots movements are critical to the Niche (micro) level in bringing about higher changes at the Regime (Meso) and the Landscape (Macro) level; a three-level system for transformative change. The Niche level or ‘area’ is the protected space provided for radical innovation and experimentation e.g. electric cars, ecodesign, and renewable technologies. This level is less subject to market/organisational and regulation influences and can facilitate the interactions between actors that support wider adoption. The Regime (Meso) level refers to the dominant practices, rules and technologies that provide stability and reinforcement to the prevailing socio-technical systems. The Landscape (Macro) level refers to the overall socio-technical setting that encompasses both the intangible aspects of social values, political beliefs and world views and the tangible facets of the built environment including institutions and the functions of the marketplace such as prices, costs, trade patterns and incomes. [21, 22] In the context of MLP theory, the implementation of sustainability pilot projects by different companies (Table 1) seeks to bring about a new way of thinking – mainly internally to the company, but also the wider industry and society. This can come from learning-by-doing, expectation formation and collective impact. Table 1: Different sustainability-themed pilot initiatives by manufacturing companies. Company Project title / aim Frito-Lay [23] Near net-zero manufacturing facility Ecover [24] Ecological factory Arla Foods [25] Zero-carbon dairy plant MAS Intimiates Thurulie [26] Eco-factory Renault-Nissan [27] Zero-carbon car factory Nestlé UK Ltd [28] Lighthouse Model 3 ASPECTS OF THE STUDY 3.1 Energy efficiency The rise in industrial energy prices over the past decade [29] and interest in environmental sustainability has seen many food manufacturers – the largest manufacturing sector in the UK - focusing on energy reduction as a top priority [8]. The food industry, with 9,340 food factories in the UK, is a major energy user accounting for about 14% of energy consumption by UK businesses [11, 30]. While this represents a rather significant proportion of industrial energy use, improving the energy efficiency of food factories can be a complicated endeavour given the diversity of the food products manufactured and the technologies employed. There are various options open to food processing factories via the energy hierarchy; energy reduction, energy efficiency and renewable energy. As part of improving energy efficiency, heat recovery by heat integration known as Pinch analysis [31, 32] is another key measure that can be implemented by a combination of direct and indirect approaches. A common approach in the practice of Pinch analysis is based on the use of graphical techniques for carrying out Pinch analysis and design, which are often applied for targeted areas in a factory that focuses on either direct or indirect heat exchange by first building the data bottom-up at a process-level; several heat integration studies have demonstrated energy savings of 1045% from process retrofitting [32-34]. Despite these achievements, the food processing industry has not been forthcoming to use such an approach, either at a targeted area or factory level primarily due to the low financial returns that can be gained from capturing low grade heat (typically 50-140°C), diverse thermodynamic profiles, material quality, non-continuous operation, small number of streams, integration complexity and seasonal operation [34]. While acknowledging these challenges, there are nonetheless significant opportunities for the food processing industry to improve energy efficiency, reduce costs and emissions and optimise heat recovery systems by applying heat integration as a retrofit for mature factories. The key results of the application of a novel heat integration framework developed by Miah et al [35] are reported in this paper as part of the ‘Lighthouse Model’ (Figure 2). 3.2 Life Cycle Assessment (LCA) Life Cycle Assessment (LCA) is a system analysis tool to describe the ‘cradle-to-grave’ environmental impacts of products and processes [36]. It is an advanced sustainability tool that powerfully captures the environmental impacts at different levels e.g. short, mid and long-term. The key benefits to industry include; environmental hot-spot analysis, product design & product improvement, strategic planning, supply chain management, marketing & communications, industrial ecology and industrial symbiosis. Recent developments in the LCA landscape for example the Product Environmental Footprinting (PEF) guidelines [37], World Food LCA Database [38], and ISO 14000 series updates [39] has positioned LCA after nearly 40 years since conception as a key sustainability tool for industry. However, the general methodology of LCA seems straightforward in principle but can be challenging and complex in reality where the company product portfolio is many and diverse e.g. thousands of product types across different product categories. This situation is characteristic in the food industry, due to changing consumer demand, competition and brand differentiation, thus a portfolio of products via creative- J.H. Miah et al. / Procedia CIRP 26 (2015) 229 – 234 destructive process is in constant flux (Figure 1). This poses a major practical challenge for factories and the overall company aspiring towards environmental sustainability. One approach to rationalise this complexity and understand key environmental hot spots across the value chain is to develop specific methodologies and rules for product categories e.g. coffee, dairy, confectionery [40]. The challenges associated with the application of LCA for environmental hot spotting of confectionery value chains are reported in this paper as part of the ‘Lighthouse Model’ (Figure 2). Figure 1: The life cycle of a food product at a system level. 4 METHODOLOGY The Lighthouse Model (Figure 2) is a six-pillar approach to sustainable manufacturing encompassing technical, environmental, economic and social aspects at a regional level. The difference between the Lighthouse Model and other pilot projects (Table 1) is the breadth of focus areas that includes biodiversity and Life Cycle Assessment. The scale of implementation is principally at a factory level but also extends to a regional and supply chain level on specific areas like biodiversity, people & community and value chain. The different implementation levels are due to the practical level and reach that a factory can influence externally. For example, the role of LCA is principally to identify environmental hot spots across the value chain which can inform both the factory and company to develop strategic environmental partnerships with major actors across the value chain. To address the different pillars a basic implementation methodology is first employed followed by further detailed investigation and research for each pillar. This involves: 1. Create a factory-level sustainability team. 2. Create an internal Lighthouse steering committee to accelerate decision making and review at a company level meeting every quarter. 3. Identify internal & external stakeholders on different pillars. 4. Engage with internal & external stakeholders by seeking advice and exploring different solutions for the different pillars. 5. Develop solutions into project proposals. 6. Present projects to Lighthouse steering committee to prioritise and approve. 7. Implement project. 8. Report full/partial results to Lighthouse steering committee every quarter. 9. Repeat steps 3 – 8. Within each pillar, a specific line of research can be explored to identify further opportunities and solutions. The general research methodology involves: 1. 2. 3. 4. Literature review. Identify gaps in literature and opportunity. Develop novel methodology and solution. Present solution to Lighthouse steering committee to prioritise and approve. 5. Implement project. 6. Report full/partial results to Lighthouse steering committee every quarter. 7. Repeat steps 1 – 6. Figure 2: Six-pillar Lighthouse Model and aims. Since sustainability is an ambiguous term, the search for sustainable manufacturing is open-ended. As such, the Lighthouse Model process can continue until the Lighthouse steering committee are satisfied with the overall achievement. 231 232 J.H. Miah et al. / Procedia CIRP 26 (2015) 229 – 234 5 CASE STUDY The case studies is a selection of research projects that looks at maximising energy efficiency by heat integration and the role of LCA in environmental hot spotting of confectionery products. Due to the content and scope limitations of this paper, it is not possible to present full methodologies and results, and the reader is referred to supporting literature where available. 5.1 Confectionery factory description The site used for this case study is a confectionery factory in the UK that manufactures 13 different brand products that are sugar, chocolate and biscuit based, and utilises a diverse range of processing technologies. The 13 brand products are split across 130 Stock Keeping Units (SKUs) which are a variation of a brand product format e.g. single bar pack and multiple bars pack. The factory is over 50 years old and occupies a large footprint in an urban area with multiple dedicated production plants (zones) all housed in one building. The factory is physically constrained by the presence of housing, transport infrastructure and other industrial sites. In addition to the range of production zones there are a number of utility systems that support these production zones. The factory employs 650 people working in a number of shifts where the primary activity can vary from running production (ramp-up and continuous) to cleaning and maintenance. This is different for different zones and contributes to the discontinuous nature at a factory level. 5.2 Energy efficiency key results and discussion The key results and findings of the application of a novel decision-making framework for heat integration in complex and diverse food factories are presented [35]. The aim of the framework is to provide the user with a step-by-step guide to evaluate all heat recovery opportunities through a combination of direct and indirect heat integration. The key features that distinguish this approach from previous authors [32-34] are the practical holistic assessment of heat integration from a combination of direct and indirect heat exchange at both a zonal-level and a factory-level. The whole procedure comprises four stages; process zoning and data extraction, preliminary analysis, intra-zonal integration, and inter-zonal integration. By adopting an integrated approach, the framework seeks to maximise heat recovery for the total factory, as opposed to solely for targeted areas which focus either on direct or indirect heat integration as found in previous examples [32, 33]. Also, the inclusion of key decision events that cover potential energy reduction, material quality, and investment requirement ensure the assessment is rigorous and justified. The application of the framework at a confectionery factory in the UK has resulted in the development of five heat integration opportunities that collectively can deliver between 3.77–5.72% energy reduction at a factory level with a total investment of £321,328 and an annual cost saving between £48,884 – £104,661 resulting in a payback of the cost of the changes between 3.07 – 6.57 years. The expected energy savings is on the lower end as it was initially found that the potential factory energy reduction could be between 13.37– 16.61%. It was found that this factory had a larger heat sink that could not be matched by the smaller heat source available. Also, the entire heat source available was not integrated and the final assessment resulted in a number of unmatched streams that left the factory with a surplus heat and a number of unmatched cold sinks that could not be integrated due to lack of suitable streams, unfavourable geographical proximity, and potential compromise of material quality. This surplus heat was found to represent between 9.60-10.89% of the factory energy with a larger cold sink unmatched representing between 32 – 33.05% of the factory energy. This amount was unexpected and may be experienced at other food factories. At this stage, a factory energy reduction between 3.77 – 5.72% is the highest amount of what is achievable for this case site with heat integration. Therefore, other energy reduction measures must be explored at the unit operation level, such as energy efficient technologies, behaviour change that encourage efficient operation of machines, and redesign of production lines that can contribute to a factory energy reduction. 5.3 Life Cycle Assessment (LCA) key challenges and discussion The research for the LCA as part of the Lighthouse Model is not yet complete and an overview of the goal, scope and implementation challenges to date are provided. 5.3.1 Goal and Scope: The scope of the LCA research is from cradle-to-cradle i.e. full confectionery value chain. The goal is as follows: 1. 2. 3. Evaluate the practical challenges of implementing LCA from a factory-level perspective. Identify environmental hot spots across the confectionery value chain from a factory-level perspective. Develop a general LCA methodology for confectionery products 5.3.2 Functional Unit: The functional unit is 1000 kg of packaged product. 5.3.3 LCA challenges: A general attitude in industry [5, 41] is that conducting an LCA is time-consuming and not practical. Hence, the reluctance for wide application. However, this is dependent on the sector and product type e.g. conducting an LCA on a jet engine that has 10,000 components compared to a food product that has less than 20 ingredients. The most significant challenge with LCA lies in data comprehension, availability and reliability. In the context of the food industry, the diversity of food products across different product categories e.g. hundreds of thousands of products sold to consumers compounds the LCA implementation challenge for a company. From a factory-level perspective, food factories can manufacture a range of products in different product formats known as Stock Keeping Units (SKUs). A SKU is created for new products and brand extensions and can be in the form of new packaging material and/or different product size. As a result of the dynamic food retail environment, the portfolio of SKUs changes as companies try to appease a changing consumer palate. The approach to rationalise SKU diversity and develop a product subject that is representative is to group similar SKU products e.g. sugar, chocolate and biscuit that share similar processing technology and where the core product is similar. This is followed by a packaged volume comparison of the different product types within a group for a 1 year period. The highest product type is then selected for the LCA. From this, each product group contains a number of SKUs which are sold to a range of customers in different countries. For the selected product group, there will be a range of ingredients and packaging materials that are sourced from various locations and in different quantities with multiple suppliers e.g. UK, Brazil, and China. The challenge here lies in rationalising the multiple suppliers to one for each J.H. Miah et al. / Procedia CIRP 26 (2015) 229 – 234 ingredient and packaging material for environmental hot spotting. The approach taken was to determine the quantity of ingredients and packaging materials as a weight % of final product. This was done by extracting data from the product specification and recipe. Based on the weight % list, it will become apparent what the significant materials are and can be based on the Pareto principle. The approach taken to justify the selection of one supplier is to compare the volume of material purchased from each supplier and then select the highest. Once the LCA model is developed, it would be possible to change the supplier location parameter to determine the environmental impact sensitivity. For the selected product group, there will be a range of SKUs which have various destinations e.g. domestic or export markets. Within these markets there can be various customers e.g. retailers and wholesalers. The challenge here lies in rationalising the customer destination for environmental hot spotting. This can be resolved by comparing the SKU volume and select the significant SKUs based on the Pareto principle. From this, the significant SKUs are then grouped based on similar formats e.g. tube packaged product or bagged packaged product. The highest volume group is then selected for further analysis. This involves determining the logistical routes from the factory to the customer destination based on delivery order data. From the factory, a product will typically be stored in distribution centres before they are delivered to a customer. For a national company, there may be several distribution centres to be able to have a national reach. From the delivery order data, the delivery volume is compared for each customer and the significant customers are identified via the Pareto principle. At this stage, it is up to the company to decide which customer to select for the LCA as this can lead to environmental partnerships. Also, once the LCA model is developed, it would be possible to change the customer location parameter to determine the environmental impact sensitivity. Another challenge which constrains LCA is available Life Cycle Inventory (LCI) datasets. The largest and widely utilised database is EcoInvent [42]. However, even this database is limited and will not contain environmental profiles for all ingredients in a company product portfolio. Similarly, another database is the World Food LCA Database [38] which is currently under development. Therefore, it is unlikely a food LCA will be able to obtain all LCI data for the different ingredients given the diversity of food products in the world. The approach taken to overcome this data gap for environmental hot spotting is to identify significant ingredients based on the Pareto principle and then search LCI databases for relevant environmental profiles. If the profiles are not available, then direct engagement with suppliers is pursued. This route opens up a collaborative approach where the company and supplier seek to work together to understand environmental impacts and can result in environmental partnerships. Another challenge which is woven throughout the implementation is the handling and reconfiguring of data from multiple sources e.g. metered, archived, different IT platforms, CAD, production data measured in tons but delivered data measured in cases, inconsistent information from people. There is no simple approach to overcome this as data are generated and stored in their current manner for a specific purpose and the link to LCA is an afterthought which will require further integration. The experience of the LCA practitioner is important and some of the rules mentioned will help. 6 SUMMARY This paper presents an overview of a novel environmentally sustainable manufacturing framework, supported by a selected case study from its application at a confectionery factory in the UK. The case study has involved exploring the role of Pinch analysis in food factories in maximising energy efficiency and the implementation challenges of LCA for environmental hot spotting. 7 ACKNOWLEDGEMENTS We wish to gratefully acknowledge and thank the EPSRC and Nestlé UK Ltd for their assistance and support in funding this research. 8 REFERENCES [1] Seliger, G. Kim, H-J. Kernbaum, S. Zettl, M. 2008. Approaches to sustainable manufacturing. International Journal of Sustainable Manufacturing. Vol 1. pp. 58-77G [2] Arena, M. Ciceri, N.C. Terzi, S. Bengo, I. Azzone, G. Garetti, M. 2009. A state-of-the-art of industrial sustainability: definitions, tools and metrics. International Journal of Product Lifecycle Management. Vol 4. pp. 207-250 [3] Jawahir, I.S. Badurdeen, F. Goldsby, T. Iyengar, D. 2009. Assessment of Product and Process Sustainability: Towards Developing Metrics for Sustainable Manufacturing. NIST Workshop on Sustainable Manufacturing. [4] OECD. 2011. Sustainable Manufacturing Toolkit. [Online] [Accessed: 05/01/2012] Available from World Wide Web: http://www.oecd.org/document/55/0,3746,en_21571361_ 47075996_47076535_1_1_1_1,00.html [5] Jayal, A.D. Badurdeen, F. Dillon, O.W. Jawahir, I.S. 2010. Sustainable manufacturing: Modeling and optimisation challenges at the product, process and system levels. CIRP Journal of Manufacturing Science and Technology. Vol 2. pp 144 – 152. [6] UNEP. 2011. Towards a green economy: pathways to sustainable development and poverty eradication. [Online] [Accessed: 01/08/2013] Available from World Wide Web: http://www.unep.org/greeneconomy/Portals/88/documen ts/ger/ger_final_dec_2011/Green% [7] EC. 2011. Roadmap to a resource efficient Europe. [Online] [Accessed: 01/08/2013] Available from World Wide Web: http://ec.europa.eu/environment/resource_efficiency/pdf/ com2011_571.pdf [8] FDF. 2013. Our core ambitions: five-fold environmental ambition – progress report 2012. [Online] [Accessed: 01/08/2013] available from World Wide Web: http://www.fdf.org.uk/environment_progress_report2012-ambitions.aspx [9] Greenpeace. 2013. Ecological farming and food campaign. [Online] [Accessed: 01/08/2013] Available from world Wide Web: http://www.greenpeace.org/international/en/campaigns/a griculture/ [10] Foresight. 2011. The Future of Food and Farming – Final Project Report. [Online] [Accessed: 25/01/2012] Available from World Wide Web: http://www.bis.gov.uk/assets/foresight/docs/food-andfarming/11-546-future-of-food-and-farming-report [11] DEFRA. 2006. Food Industry Sustainability Strategy (FISS). [Online] [Accessed: 01/08/2013] Available from World wide Web: https://www.gov.uk/government/uploads/system/uploads 233 234 [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] J.H. Miah et al. / Procedia CIRP 26 (2015) 229 – 234 /attachment_data/file/69283/pb11649-fiss2006060411.pdf Econlib. 2008. Prisioners’dillema. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.econlib.org/library/Enc/PrisonersDilemma.ht ml Pepsico. 2012. Pepsico performance with purpose – Sustainability report 2011/2012. [Online] [Accessed: 29/08/2013] Available from World Wide Web: http://www.pepsico.com/Download/PEP_CSR12_20112012_Sustainability_Report_v8.pdf Kraft. 2011. Our progress in 2011 – Creating a more delicious world. [Online] [Accessed: 29/08/2013] Available from World Wide Web: http://www.mondelezinternational.com/SiteCollectionDoc uments/pdf/kraftfoods_deliciousworld2011.pdf Cargill. 2012. 2012 Corporate Sustainability Report – Our responsibility in a changing world. [Online] [Accessed: 01/08/2013] Available from World Wide Web: http://www.cargill.co.uk/wcm/groups/public/@ccom/docu ments/document/na3066211.pdf Associated British Food plc. 2010. Measuring our responsibility – Corporate Responsibility Report 2010. [Online] [Accessed: 01/08/2013] Available from World Wide Web: http://www.abf.co.uk/documents/pdfs/2010/2010_corpor ate_responsibility_report.pdf Nestlé SA. 2013. Nestlé in society. Creating Shared Value and meeting our commitments 2013 Full report. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.nestle.com/assetlibrary/documents/library/documents/corporate_social_re sponsibility/nestle-csv-full-report-2013-en.pdf UK National Ecosystem Assessment. 2011. The UK National Ecosystem Assessment: Synthesis of the Key Findings. UNEP-WCMC, Cambridge. The Dow Chemical Company. 2011. Valuing Ecosystems 2011 Global Conservation Report. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.dow.com/sustainability/pdf/2011Conservation-Report-COMBINED.pdf Duflou, J.R. Sutherland, J.W. Dornfield, D. Hermann, C. Jeswiet, j. Kara, S. Hauschild, M. Kellens, K. 2012. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Annals – Manufacturing Technology. Vol 61. pp 587 – 609. Geels, F.W. 2002. Technological transitions as evolutionary reconfiguration processes: a multi-level perspective and a case study. Research Policy. Vol 31. pp 1257 – 1274. Geels, F.W. 2005. Processes and patterns in transitions and system innovations: Refining the co-evolutionary multi-level perspective. Technological Forecasting & Social Change. Vol 72. pp 681 – 696. Frito-Lay. 2011. Frito-Lay Unveils ‘near net zero’ manufacturing facility. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.fritolay.com/about-us/press-release20111005.html ECOVER. 2013. Facts about our Factory. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.the-splash.co.uk/articles/factory-facts Foodprocessing-technology.com. 2014. Arla Foods Zero Carbon Dairy, United Kingdom. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.foodprocessing-technology.com/projects/arlafoods-zero-carbon-dairy/ Theguardian. 2011. Building a greener future. [Online] [Accessed: 16/04/2014] Available from World Wide Web: [27] [28] [29] [30] [31] [32] [33] [34] [35] [36] [37] [38] [39] [40] [41] [42] http://www.theguardian.com/honda-dreamfactory/vidhura-ralapanawe-cultural-engineer-winner Middle East online. 2012. Renault to inaugurate giant Tangier plant. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.middle-eastonline.com/english/?id=50527 Nestlé UK Ltd. 2013. Nestlé UK & Ireland Creating Shared Value Plan Update. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.nestle.co.uk/assetlibrary/documents/creatingsharedvalue/csv2013brochure_linked.pdf DECC. 2012. Energy Price Statistics. [Online] [Accessed: 01/08/2013] Available from World Wide Web: http://www.decc.gov.uk/en/content/cms/statistics/energy _stats/prices/prices.aspx DEFRA. 2013. Food Statistics Pocketbook 2013. [Online] [Accessed: 01/08/2013] Available from World Wide Web: https://www.gov.uk/government/uploads/system/uploads /attachment_data/file/243770/foodpocketbook2013report-19sep13.pdf Linnhoff, B. Townsend, D.W. Boland, D. Hewitt, G.F. Thomas, B.E.A. Guy, A.R. Marshland, R.H. 1982. A user guide on process integration for the efficient use of energy. Rugby, UK. Kemp, I.C. 2007. Pinch analysis and process integration. A user guide on process integration for efficient use of energy. Amsterdam: Elsevier Sadre-Kazemi, N. Polley, G.T. 1996. Design of energy storage systems for batch process plants. Trans IChemE. Vol. 74. Part A. Klemes, J. Friedler, F. Bulatove, I. Varbanov, P. 2011. Sustainability in the process industry – Integration and Optimisation. McGraw –Hill. USA Miah, J.H. Griffiths, A. McNeill, R. Poonaji, I. Martin, R. Yang, A. Morse, S. 2014. Heat integration in processes with diverse production lines: A comprehensive framework and an application in food industry. Applied Energy. Vol 132. pp 452 – 464. ISO (International Organization for Standardization). ISO 14041 environmental management – life cycle assessment – goal and scope definition and inventory analysis; 1998. EC. 2012. Product Environmental Footprint (PEF) Guide. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://ec.europa.eu/environment/eussd/pdf/footprint/PEF %20methodology%20final%20draft.pdf Quantis. 2014. World Food LCA Database. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.quantis-intl.com/wfldb/ ISO. 2012. ISO 14001 revision is underway. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.iso.org/iso/home/news_lindex/news_archive/ news.htm?refid=Ref1547 The International EPD System. 2014. What are Product Category Rules? [Online] [Accessed: 23/04/2014] Available from World Wide Web: http://www.environdec.com/en/PCR/What-are-productcategory-rules/ Feifel, S. Walk, W. Wursthorn, S. 2010. LCA, how are you doing? A snapshot from the 5th German LCA workshop. International Journal of Life Cycle Assessment. Vol 15. pp 139-142. Swiss Centre for Life Cycle Inventories. 2014. The ecoinvent database. [Online] [Accessed: 16/04/2014] Available from World Wide Web: http://www.ecoinvent.org/database/