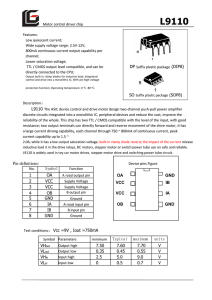

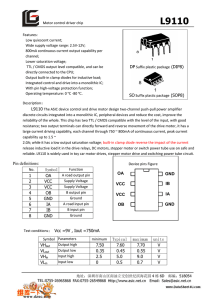

200ACDC training manual Shanghai WTL Welding Equipment Manufacture Co.,Ltd FEB 2012 FEB.2012 Catalogue • • • • • • 1、Introduction of working principle 2、Introduction of main circuit 3、Introduction of control circuit 4、Introduction of panel circuit 5 Introduction of other circuit 5、 6、Troubleshooting 1、Introduction of working principle i i l 1.1 Working principle 1.2 System chart 1.3 Explosion drawing 1.4 No Component Listing Code Title Quantity 1 8.253.020 HANDLE 1 2 8.301.099 COVER 1 3 8.062.543 4 7.202.123 5 7 202 029 7.202.029 6 5.496.931-D WSE(WSME)-200(PFC) EMC BOARD 1 7 5.496.526-D WSE-160/200 SWITCH POWER BOARD 1 8 5.496.875-J 315A OUTPUT RECTIFIER BOARD 1 9 5.496.415-I TP、WSME MCU CONTROL BOARD 1 10 5.496.470-C 11 6.185.515-A MAIN TRANSFORMER 1 12 6.271.515 INDUCTANCE 1 13 6.174.523 HIGH FREQUENCY COUPLING INDUCTANCE 1 14 7.321.102 HALL 1 15 8.055.523 BASE 1 16 8.050.099 MOUNTING PLATE(RIGHT) 2 BREADBOARD MOUNTING FUSE (LONG) FUSE BLOCKS HIGH FREQUENCY BOARD 1 1 1 1 17 5.496.416-E 18 8.068.099 19 8.306.523 FRONT PANEL COVER 1 20(1) 8.103.523 DISPLAY MASK 1 20(2) 7.458.053-B KNOB(285C) 1 21 8.065.570-C FRONT OUTPUT BOARD 1 22 7.152.312 SOCKET 2 23 7.132.116 8 PIN AIR SOCKET 1 24 8 462 010 CB 8.462.010-CB FRONT GAS JOINT 1 25 8.307.634 26 7.232.022 SWITCH 1 27 7.155.001 CABLE CLAMP 1 28 7.154.474 POWER PLUG 1 29 8.122.366 30 7.253.013 31 7.720.030 TP/TS/WSME DISPLAY BOARD REAR PANEL BACK BLANKING PLATE FAN MOUNTING PLATE TWO-POSITION SOLENOID VALVE FAN 1 2 1 1 1 1 PART 1 A--1 8.425.500 A--2 8.746.030 A--3 8.425.501 A--4 7.445.311 ALUMINUM RESISTOR 2 A--5 7.231.280 THERMAL SWITCH 2 A--6 7.425.631 DISCRETE IGBT 12 A--7 7.421.681 FRD 2 A--8 5.496.674-F WSE-160 AC INVERTER BOARD 1 A--9 8.306.301 DUSTPROOF PLATE Ⅰ 1 HEAT SINK Ⅰ HEAT SINK BOX HEAT SINK II 1 1 1 PART 2 B--1 8.425.503 B--2 8.425.502 HEAT SINK III 1 B--3 8.746.029 HEAT SINK BOX 1 B--4 7.411.010 RECTIFIER 2 B--5 5.496.527-D WSE-160/200 DC IGBT MOUNTING PLATE 1 B--6 7.460.800 MAIN CAPACITOR 6 B--7 8.052.500 WIND SHUTTER II 1 HEAT SINK IV 1 2、Introduction of main circuit PART1: RECTIFIER AND INVERTER PCB 8.066.527-D Schematic Diagram Soft start and Rectifier SD 1 2 DC+ OC ttestt D22 OC 2 1 J1 1 3 D21 AC220V1 R12 R19 R20 AC + AC - C6 C7 R24 2 ZBYQ1 R23 4 1 CY1 1 1 C8 Q2 AC + C9 C10 R26 2 R25 D19 3 AC220V2 OC 1 CU3 AC - DC- 4 CU4 Gdn R8 T3 DC+ R9 IN C1 1 R1 2 3 4 5 6 OC 7 D5 R10 T4 U3 1 2 R2 3 4 VCC VCC IN OUT NC OUT GND GND 8 7 T1 C2 U4 2 R3 3 4 VCC VCC IN OUT NC OUT GND GND ZD2 ZD3 R11 B2 ZBYQ 1 5 R4 D2 1 R7 R6 D1 6 8 7 R15 R13 R16 ZD5 T2 R17 T6 R5 R18 6 5 T5 D6 R14 ZD4 C3 D3 D4 Drive transformer C30 R21 PTC C32 D20 C5 Q1 DC- IGBT driver C31 View of main board Photo of main board Description 1)The main purpose of this PCB is rectifier、 filter andd inverter; i t 2)The function of Q1、Q2 is rectifier, The function of C5…C10 is filter, the function of T3 T6 is T3…T6 i inverter; i t T3…T6 C5…C10 Q1、Q2 Test of FRD 1)The function of U5、U6 is to drive discrete IGBT; 2)D1、D2 is Fast Recovery Diode (FRD); 3)Please switch off the main power source, Only connect AC220V to 8.066.526 8.066.526-G. G. when testing IGBT driving waveform, and make sure that the welding mode is MMA. 220V INPUT IGBT Testing test discrete di IGBT as follows f ll (Wi h (Without Main M i Power) P ) 1)Select the continuity function on the meter (marked with a diode symbol). symbol) 2) Test the Collector and Emitter of IGBT with positive and negative pin. The IGBT is OK as it is showed below: From left F l f to right, i h the h three h pins i off IGBT are GATE COLLECTOR and EMITTER. The drive waveform is as it showed below; Otherwise please don’t connect the 220V input ppower and check the control board . PART2: AC/DC SELECTION PCB 9.066.674-F 2.2.1 Photo of AC Board IGBT AC Drive D i Part P U5、 U6 IGBT F t Recovery Fast R Diode Testt discrete T di t IGBT as follows f ll (With t Main (Without M i Power) P ) 1)Please switch off the main power source, Only connect AC220V to 8.066.526-G.when testing IGBT driving waveform, and d make k sure that h the h welding ld mode d is MMA/AC. / C 2)Test the Collector and Emitter of IGBT with positive and negative pin. The IGBT is OK as it showed below: From left to right, the three pins of IGBT are EMITTER、COLLECTOR and GATE。The positive pin connects to COLLECTOR and the negative pin connects to EMITTER. The drive waveform is as it showed below; Otherwise please don’t connect the 220V input ppower and check the control board . To test Fast Recovery Diode D1、D2 D1 D2 as follows (Without Main Power): ) the continuityy function on the meter ((marked with a diode 1)Select symbol). 2)When finished test ,switch the positive pin (RED) and negative pin (BLACK) andd test again. i The Th FRD is i OK as it i showed h d below: b l 3、Introduction of control circuit This page includes 2 parts: 1. The OT part works when the machine becomes too hot; 2. The Q QF/HF p part p provides control signal g for g gas valve and high frequency board. 24V OT R325 +15V U306 1 2 3 C312 R324 VSS OT C311 C100 R323 C101 VSS 24V GND2 D204 Ai Ct l AirCtrl U303 R314 QF/HF C106 24V T205 R316 C26 R315 GND2 C31 C306 VSS U301 HF R309 C302 VSS C307 C107 1 2 3 4 This page includes 3 parts: gun、remote、pedal. The Connector GUN connect to the 8pin control socket on the front p panel , to control g gun、remote and pedal respectly. VCC ZD201 R248 24V U304 gun D203 FC6 R250 FC8 FC5 R249 EMI滤波器 1 R70 VSS 2 C158 3 R158 U15 4 R152 R153 VCCU14 C153 VSS 9 R154 IN1 OUT1 IN2 OUT2 IN3 OUT3 IN4 OUT4 5 6 7 8 GUN GUN2 5 GUN1 4 3 2 1 GND 1 2 15V2 15V2 R150 VSS R151 VSS C150 24V 1 U20 R31 pedal_I U3C 8 8 10 9 ZD7 C2 +15V R63 C3 R45 7 6 5 8 7 6 3 5 4 3 C152 3 R67 C32 R66 VSS C9 R65 C5 2 2 Vout U12 VSS 1 1 Vin 15V2 2 VSS R62 U13 7815 GND D remote R64 15V2 15V2 R68 4 VSS VSS High-Linearity Analog Optocouplers R69 C1 VCC 14 U2A 1 SPD 2 7 D12 U2B 3 R32 D2 4 D11 D4 PPG_AC R36 ACPOUT U2C 5 6 C34 1 2 3 R33 C46 R37 U2D 9 8 VCC 5 R30 D9 B 2 Y 4 11 U2E 10 D8 3 D6 A 3 R22 U9 5 1 C28 C43 The ACPOUT p part outputs p AC/DC drive signal g according g to the selection of AC/DC on the panel. AC20 +15V WA D3 -15V R47 R38 IF IF_adj0 R46 R59 D13 ZD1 C44 R39 2 -15V R34 U3A 1 3 D14 6 5 7 3 1 A R405 R404 C313 -15V ZD2 4 -15V Current_RT U3B 2 D5 R58 C45 11 1 2 3 4 +15V AD_adj0 R60 +15V The Connector WA connect to the HALL , It’ss the feedback of output current. It current Current_FT C413 C29 3 AC R51 V FB V_FB V+ C50 V- AC 1 2 R48 D7 R43 C56 R52 C54 R50 4 WV 2 1 R40 VSS2 V+ + V- R42 IN+ OUT IN IN- 3 R44 4 C52 C51 VSS2 C53 2 +15V2 +15V2 3 4 3 4 CPU 2 1 1 8 2 7 6 5 7 1 +15V 3 6 5 R306 U8 8 R53 C55 IN+ OUT INV+ V V- R41 R49 VSS2U7 1 5 U6 5 V_FB Voltage_RT 2 VSS2 4 R54 R304 ZD204 1 2 Wvf C301 3 R305 Voltage_FT C404 +15V VSS2 The Connector WV connect to the output , It’s the p voltage, g Through g the High-Linearity Analog feedback of output Optocouplers feedback to CPU. View of control board Photo of control board QF/HF GUN SOURCE WV OT MB SS WA POWER +15V ACPOUT DRIVE • DRIVE--Connected with main board to provide drive signal for discrete IGBT. Pin 1---- +15V;Pin 2~5---- Drive signal;Pin 6---- OC signal; Pin 7---- GND • SOURCE--Connected with switch power PCB5 066 526 G provide 24V power source . PCB5.066.526-G • MB--Connected with panel board to communicate. • QF/HF QF/HF--Connected Connected with main board to provide power source for the gas valve and high frequency signal for the HF arc making board. • GUN--Connected with the torch to provide signal of gun. • ACPOUT--Connected ACPOUT Connected with the IGBT driver PCB to provide AC/DC driver signal. • OT -- Connected with the temperature relay to provide over over-temperature temperature signal for MCU. MCU • SS -- Connected with 8.066.527-D to control start up the relay . • WV -- Connected with the output to sample voltage signal. • WA -- Connected with HALL sensor to sample current signal. Pin 1--- +15V;Pin 2--- -15V;Pin 3---0~4V; Pin 4--- GND • POWER -- Connected with switch power PCB5.066.526-G to provide control board with power source Pin 1--- +24V;Pin 2--- 0V;Pin 3--- -24V; • +15V -- This +15V voltage supplies power to part AC board to make sure the AC drive p works normally. 1)Please don’t switch off the machine when the alarm pilot lamp is on. Trouble: The alarm light is on. Handles: dl Check Ch k MS2003 S2003 module d l in i the h power board. b d If No.10 ppin is 15V,, OT alarm happens. pp ――― Decrease duty y cycle, y , interval work. or check fan. If No.9 pin is 15V, LV alarm happens. ―――Check the input voltage or use the stable power supply. If No.7 pin is 15V, OC alarm happens. ―――Check and repair the discrete IGBT ,FRD FRD or main transformer. transformer 2) If the th control t l board b d was broken, b k the th reasons will ill be b as following: f ll i The alarm pilot lamp is on without over-voltage, over-current, lower-voltage and over-temperature—MS2003 module may be broken. There is no +15 V supply voltage on the power board.--LM2576 may be broken. The normal output waveform (amplitude to 5 V) of the 11th or 14th pin of SG3525 is as follows: The output waveform of the 11th or 14th pin of SG3525 If there is false waveform or no waveform, first ,test IGBT, then test SG3525. At the end, replace the broken electronic parts. Pin1 - Pin8 Pin9 – Pin16 Connect to Pin11 Connect to Pin14 Pin11 and Pin14 are output pins of chip SG3525. • SWITCH--To select test or normal status. • 1、2、3—To select current • 4—up normal status 4—down • 5 No use test status A: by adjusting it to make the display current accord with the actual current. Imax: By adjusting it to make the pre-setting maximum current accord with the actual current. Imin: By adjusting it to make the pre-setting minimum current accord with the actual current. R68: by adjusting it to make the remote maximum current is 200A. Wvf: by adjusting it to make the actual voltage accord with display voltage 4、Introduction of panel circuit Schematic of panel board Key driver d i chip hi U2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 DIG7-3R38 DIG6-3R37 DIG5-3R36 DIG4-3R35 DIG3-3R34 DIG2-3R33 DIG1-3R32 DIG0-3R31 DIG7-1 DIG6-1 DIG5-1 DIG4-1 DIG3-1 DIG2-1 DIG1-1 DIG0-1 DIG7 DIG6 DIG5 DIG4 DIG3 DIG2 DIG1 DIG0 GND GND NC NC. RST RST# H3L2 28 27 26 25 24 23 22 21 20 19 18 17 16 15 RSTI SCL SDA ADDR INT# VCC SEG7 SEG6 SEG5 SEG4 SEG3 SEG2 SEG1 SEG0 VCC SCL1 SDA1 ADDR0 KEY VCC VCC SEG7-1 SEG6-1 C1 SEG5-1 SEG4-1 SEG3-1 SEG2-1 SEG1-1 SEG0-1 R_TP L33 R19 TP/TS C2 R_TS C19 VCC SEGA SEGB SEGC SEGD SEGE SEGF SEGG SEGA SEGB SEGC SEGD SEGE SEGF SEGG SEGDP DIG3 DIG4 DIG5 11 7 4 2 1 10 5 6 3 12 9 8 VCC C9 U1 1 12 13 2 11 6 7 3 10 5 8 24 SDA1 LOAD SCL1 A B C D E F G NC DP DIG1 DIG2 DIG3 DIG0 DIG1 DIG2 DIG3 DIG4 DIG5 DIG6 DIG7 4 DIN VCC LOAD CLK ISET DIG0 SEG A DIG1 SEG B DIG2 SEG C DIG3 SEG D DIG4 SEG E DIG5 SEG F DIG6 SEG G DIG7 DOUTSEG DP GND 19 C5 18 14 16 20 23 21 15 17 R1 VCC SEGA SEGB SEGC SEGD SEGE SEGF SEGG 22 Key SEG7-1 A B C D E F G NC DP DIG1 DIG2 DIG3 Indicator driver chip U4 SEG6-1 SEGDP DIG0 DIG1 DIG2 11 7 4 2 1 10 5 6 3 12 9 8 U3 SEGDP 9 GND K1 DIG0-3 VCC C18 Indicator L4 L5 SEGF_1 L3 SEGE_1 L2 SEGD_1 L1 SEGC_1 SEGB_1 DIG1_1 SEGA_1 DIG0_1 DIG0_1 DIG1_1 DIG2_1 DIG3_1 DIG4_1 DIG5_1 DIG6_1 DIG7_1 L6 L7 L8 L9 L10 L11 L12 L13 L14 L15 L16 L17 L18 DIG2_1 DIG3_1 DIG4_1 L19 L20 L21 L22 L25 L26 L27 L28 1 12 13 2 11 6 7 3 10 5 8 24 L24 L23 4 U6 DIN VCC LOAD CLK ISET DIG0 SEG A DIG1 SEG B DIG2 SEG C DIG3 SEG D DIG4 SEG E DIG5 SEG F DIG6 SEG G DIG7 DOUTSEG DP GND 19 C6 18 14 16 20 23 21 15 17 R2 3 C1 C2 O1 O2 K9 2 1 4 3 1 DIG1-3 3 DIG2-3 1 3 SEGDP_1 K3 C1 C2 O1 O2 2 4 9 GND pulse duty iso2 Connector Knob iso1 DIG4-3 3 R41 3 C1 C2 O1 O2 K6 C1 C2 O1 O2 2 4 2 4 U5A 6 C16 1 O1 C15 DIG5-3 VCC C17 K5 B C14 1 VCC C4 A C13 R40 LR1 C3 O2 C12 R39 1 2 3 4 5 6 7 8 9 10 C C11 R20 TP/TS SDA1 R21 SCL1 R22 ADDR0R23 KEY R24 LOAD R25 B0 R26 B1 R27 VCC C10 R18 2 1 32 41 J1 R28 R17 MP1 3 4 5 S D 3 C7 Q 1 B1 CLK C8 C1 C2 O1 O2 2 4 VCC SEGA_1 SEGB_1 SEGC_1 SEGD_1 SEGE_1 SEGF_1 SEGG_1 22 1 R Q 2 1 4 R29 R30 DIG7-3 3 B0 K8 C1 C2 O1 O2 2 4 K10 C1 C2 O1 O2 2 4 Vi View off panell board b d Photo of p panel board Key driver chip DIG7-3R38 DIG6-3R37 DIG5-3R36 DIG4 3R35 DIG4-3 DIG3-3R34 DIG2-3R33 DIG1-3R32 DIG0 3R31 DIG0-3 U2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 DIG7-1 DIG6-1 DIG5-1 DIG4 1 DIG4-1 DIG3-1 DIG2-1 DIG1-1 DIG0 1 DIG0-1 VCC CC DIG7 DIG6 DIG5 DIG4 DIG3 DIG2 DIG1 DIG0 GND GND NC NC. RST RST# H3L2 RSTI SCL SDA ADDR INT# VCC SEG7 SEG6 SEG5 SEG4 SEG3 SEG2 SEG1 SEG0 28 27 26 25 24 23 22 21 20 19 18 17 16 15 SCL1 SDA1 ADDR0 KEY VCC SEG7-1 SEG6 1 C1 SEG6-1 SEG5-1 SEG4-1 SEG3-1 SEG2 1 SEG2-1 SEG1-1 SEG0-1 C2 Indicator driver chip VCC C9 U1 SDA1 LOAD SCL1 DIG0 DIG1 DIG2 DIG3 DIG4 DIG5 DIG6 DIG7 1 12 13 2 11 6 7 3 10 5 8 24 4 DIN VCC LOAD CLK ISET DIG0 SEG A DIG1 SEG B DIG2 SEG C DIG3 SEG D DIG4 SEG E DIG5 SEG F DIG6 SEG G DIG7 DOUTSEG DP GND GND 19 C5 18 14 16 20 23 21 15 17 R1 22 100n 10uF/25V VCC 20K SEGA SEGB SEGC SEGD SEGE SEGF SEGG SEGDP 9 MAX7221 VCC C18 DIG0_1 DIG1_1 DIG2_1 DIG3_1 DIG4_1 DIG5 1 DIG5_1 DIG6_1 DIG7_1 1 12 13 2 11 6 7 3 10 5 8 24 4 U6 DIN VCC LOAD CLK ISET DIG0 SEG A DIG1 SEG B DIG2 SEG C DIG3 SEG D DIG4 SEG E DIG5 SEG F DIG6 SEG G DIG7 DOUTSEG DP GND MAX7221 GND 19 C6 18 14 16 20 23 21 15 17 R2 22 9 SEGA_1 SEGB_1 SEGC_1 SEGD_1 SEGE_1 SEGF 1 SEGF_1 SEGG_1 SEGDP_1 100n 10uF/25V 20K VCC 5 、Introduction of other circuit 5.1.1 Photo of HF Board 9.066.470-C 5.1.2 Schematic of HF Board T1 5 2 4 4 1 1 3 KG COIL R1 2 2 R3 D1 1 V1 3 3 D2 L1 1 2 3 R2 4 3 2 1 C3 R4 C4 D3 D4 110V 3 2 1 SOU +24 HF absorb circuit 2 4 1 2 C8 K1 1 C7 R7 1 B V3 C5 C6 E 1 2 R5 3 HF C 2 3 12 D5 34 R6 2 + - connect to the welder output terminal 1 2 5 C1 3 2 1 G 1 220V V2 521 5.2.1 Photo Ph t off Switch S it h Power P Board B d 8 066 526 G 8.066.526-G 1 2 5 2 1 Schematic 5.2.1 S h ti off Switch S it h Power P Board B d 1 R40 2 1 C40 2 L1 D10 D11 DCIN B1 3 2 1 12 D8 C41 C11 C12 TVS1 R41 D19 1 R27 D21 11 9 D9 18 7 6 2 5 4 2 R29 D20 3 C15 C16 C17 C18 1 2 12 C19 11 9 R31 +24V C20 D13 C21 POWER/FJ 1 2 3 4 5 8 7 6 D15 D14 C24 L3 5 4 3 C23 C22 -24V R32 L4 NTCS 3 D16 D17 C25 C26 C27 C28 R33 TAP A R34 D18 2 6 U2A 1 4 C29 L D 1 3 U1 1 R35 2 F X S ZD6 5 3 4 R36 C13 R37 DY3 +01 L2 D12 B C DY2 +24V1 24V1 R28 2 1 2 R30 DY1 C14 ZD7 1 2 6、Troubleshooting g Power Source Problems FAULT CAUSE REMEDY 1. Mains supply voltage is ON power iindicator ON, di t is illuminated however unit will not commence welding when the torch trigger switch is depressed. A. Power source is not in th correctt mode the d of f operation. A. Set the power source t th to the correctt mode d of operation with the process selection switch switch. B. Repair or replace torch trigger switch/lead. switch/lead B Faulty torch trigger. B. trigger 2. Mains supply voltage is A. Primary control fuse ON, indicator light is not is blown. lit and weldin welding arc cann cannott be established. B. Broken connection in primary circuit. A. Replace primary control fuse. B Have an Accredited B. CIGWELD Service Agent check primary circuit. circuit 3. Welding output continues when torch t i trigger released. l d A. Change to 2T (NORMAL) mode. B Repair B. R i or replace l Torch/trigger lead. A. Trigger mode selection is in 4T(LATCH) mode. d B. Torch trigger leads shorted. FAULT CAUSE REMEDY 4. Welding output current is present when the torch trigger switch is depressed but arc cannott be b established. t bli h d Poor or no work lead contact Clean work clamp area and ensure good electrical contact. 5. Welding output currentt is i nott presentt when torch trigger depressed. Faulty trigger switch /l d /lead. Repair or replace Torch /t i /trigger llead. d 6. TIG electrode melts when arc is struck. TIG torch is connected Connect the TIG torch to the (+) VE terminal. to the (-) VE terminal. 7.Arc 7 Arc flutters during TIG welding. Tungsten electrode is too Select the correct size large for the welding of tungsten electrode. current. 8.No HF output in HF mode. Spark gap points too far apart. Set spark gap points within 4mm. Other Problems FAULT 1. No AC output when chosen “AC” AC mode mode. 2. The depth of weld 2 pool is not enough 3. Arc flutters during TIG welding. ldi CAUSE REMEDY A. The power board AC d i control drive t l signal i l iis wrong A. Repair or replace th power board the b d B. AC drive board is damaged B. Repair or replace the drive board C. AC IGBT is damaged C. Replace the IGBT The range of welding current is too small Increase the preset value of welding current WAVE BALANCE is too large Adjust the Balance in AC MODE Tungsten electrode is t llarge f too for the th welding current. Select the right size t tungsten t electrode. l t d FAULT CAUSE REMEDY Welding current is too high//Reduce the current Over h O heatt protection Continuous use time is too much//Reduce the load continuous rate (use intermittently) The thermal relay is damaged//Replace the relay Over voltage O lt P Power grid id is i unstable//Connect t bl //C t into i t stable t bl grid id protection 4. The 4 red alarm is on Power grid is unstable or there is defect of Under voltage it//Connect into stable grid protection Power grid is stable//Check the power of main circuit Over current There is unusual current in main circuit//Check and protection repair the main circuit and drive board All of above MS2003 is damaged//Replace MS2003 or power oar board