HEAT TRANSFER AND PRESSURE DROP OF DEVELOPING FLOW IN SMOOTH TUBES IN THE TRANSITIONAL FLOW REGIME

advertisement

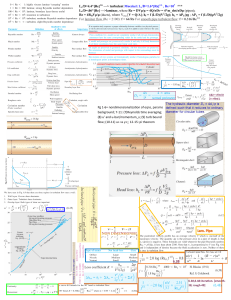

HEAT TRANSFER AND PRESSURE DROP OF DEVELOPING FLOW IN SMOOTH TUBES IN THE TRANSITIONAL FLOW REGIME Marilize Everts Study leader: Prof Josua P. Meyer Department of Mechanical and Aeronautical Engineering, University of Pretoria, South Africa 1 Background HIGH heat transfer coefficients and LOW pressure drops Laminar Low heat transfer coefficients Low pressure drops Turbulent High heat transfer coefficients High pressure drops Heat transfer enhancements Decreased mass flow rates Changes in operating conditions Corrosion and scaling Additional equipment Design constraints Transitional Higher heat transfer coefficients Lower pressure drop 2 Background • Flow regimes have been investigated from as early as 1883, especially focussing on laminar and turbulent flow • Research has been done on the transitional flow regime since the 1990s • Prof Afshin Ghajar (Oklahoma State University) Focussed on fully developed flow Tam et al. (2012) investigated pressure drop in both developing and fully developed flow Different mixtures of ethylene glycol (high Prandtl numbers) • Prof Josua Meyer (University of Pretoria) Average measurements across a tube length, therefore developing flow (laminar and transitional) and fully developed flow (turbulent) Focussed on effects of inlet geometries and enhanced tubes 3 Importance of Developing Flow • Thermal entrance length is a function of tube diameter, Reynolds number and Prandtl number • Chillers Typical tube diameter: 15 mm Thermal entrance length at a Reynolds number of 2 000: 9 m for water (average Prandtl number of 6) 30 m for glycol mixture (average Prandtl number of 20) Length of most industrial chillers is 4 m Flow will be developing rather than fully developed • Solar power plants operating with parabolic troughs Typical tube diameter: 66 mm Thermal oil (average Prandtl number of 5) Thermal entrance length at a Reynolds number of 2 000: 33 m Length of 40 m (consists of approximately 10 receiver tubes of 4 m) More than 80% (33 m) of the tube will have developing flow and only the last 7 m will have fully developed flow. 4 Problem Statement and Aim Problem Statement Previous work focused primarily on fully developed flow or the average measurements of developing flow across a tube length Heat transfer and pressure drop characteristics of developing flow in the transitional flow regime have not yet received the required attention Aim To investigate the heat transfer and pressure drop characteristics of developing flow in the transitional flow regime in a smooth horizontal tube 5 Objectives • To obtain the local and average heat transfer coefficients as a function of Nusselt number and Colburn j-factor for different Reynolds numbers under both forced and mixed convection conditions • To obtain the average friction factor data as a function of Reynolds number at different heat fluxes • To investigate the thermal entrance length • To investigate the effects of secondary flow • To determine the boundaries of the transitional flow regime for different values of x/D • To investigate the relationship between heat transfer and pressure drop 6 Experimental Set-up 7 Test Section Test Section Calming Section Calming Section Square-edge inlet Smooth horizontal tube D = 11.52 mm L = 2.03 m Reynolds number: 500 – 10 000 Heat fluxes: 6.5, 8.0 and 9.5 kW/m² Test fluid: Water Mixing Section 8 Uncertainties Re f Re: ≈1% f: 0.5% - 7% 10 5 0 Change of pressure transducers 5000 10000 15 % Uncertainty % Uncertainty 15 10 5 0 15000 Re (a) 10 Re: ≈1% f: 0.5% - 15% Nu: ≈4.8% j: ≈4.8% Re f Nu j 5 0 2000 4000 6000 8000 10000 Re (c) 15 % Uncertainty % Uncertainty 15 10 Re: ≈1% f: 0.5% - 8% Nu: ≈4.9% j: ≈4.9% Re f Nu j Temperature fluctuations 2000 4000 6000 8000 10000 Re (b) Re: ≈1% f: 0.5% - 17% Nu: ≈4.6% j: ≈4.6% Re f Nu j 5 0 2000 4000 6000 8000 10000 Re (d) 9 35 Decreasing uncertainties due to increasing temperature differences along tube length 30 Present Study Oliver (1962) Shah & London (1978) Palen & Taborek (1985) Ghajar & Tam (1991) Ghajar & Tam (1994) Gnielinski (2010) Nu = 4.36 Best results Average deviation: 15% Minimum deviation: 2% Maximum deviation: 27% 25 Nu 20 15 Higher temperature uncertainties 10 5 0 Nu ≈ 4.57 .ˑ. within 4.6% 0 20 40 60 80 100 x/D 120 140 160 180 10 50 Similar trend Average deviation: 17% 45 Best results Average deviation 8.2 ≤ x/D ≤ 70: 15% 70 ≤ x/D ≤ 175: < 7% 40 35 30 Nu Present Study Oliver (1962) Shah & London (1978) Palen & Taborek (1985) Ghajar & Tam (1991) Ghajar & Tam (1994) Gnielinski (2010) Overpredicted results by 25% Developed for Pr > 40 25 20 15 Better suited for laminar forced convection flow 10 5 0 0 20 40 60 80 100 x/D 120 140 160 180 11 35 Present Study Oliver (1962) Shah & London (1978) Palen & Taborek (1985) Ghajar & Tam (1991) Ghajar & Tam (1994) Gnielinski (2010) 30 25 Best results Average deviation: 17% Developed for Pr > 40 Nu 20 15 10 Higher than 4.36 1. Developing flow (thermal entrance length: 2.4 m – 7.6 m) 2. Secondary flow (mixed convection) 5 0 Better suited for laminar forced convection flow 700 1000 2000 Re 12 80 Present Study Gnielinski (1976) Ghajar & Tam (1994) Meyer et al. (2013) 75 70 65 Nu 60 55 Average deviation 4 000 ≤ Re ≤ 10 000: 7.4% 4 000 ≤ Re ≤ 6 000 : 2.4% Maximum deviation: 15% Average deviation: 7.4% Maximum deviation: 9.4% Best results Average deviation: 2% Minimum deviation 0.82% Maximum deviation: 3% Heat flux of 13 kW/m² 50 45 40 35 30 4000 5000 6000 8000 Re 10000 13 Validation: Isothermal Friction Factors 0.12 Measured Poiseuille Equation Tam et al. (2013) Blasius (1913) Fully developed laminar flow 0.1 0.08 Developing laminar flow Average deviation: 2.2% Maximum deviation: 5% Fully developed turbulent flow Average deviation: 1% Maximum deviation: 2% f 0.06 0.04 8.3% difference Friction factors of developing flow greater than for fully developed flow 500 1000 2000 3000 Re 5000 10000 15000 14 Flow Regime Map with Experimental Data 6.5 kW/m2 Forced Turbulent 4 10 Forced Transition Forced/Mixed Convection Boundary 9.5 kW/m2 Mixed Transition Region C Re 8.0 kW/m2 Transition Start: Re ≈ 2 300 Region B Mixed Laminar 3 10 Region A 0 1 2 3 4 5 6 Ra 7 8 9 10 11 6 x 10 15 Temperature Profile @ 6.5 kW/m² Re = 600 Re = 1 000 Re = 1 500 Re = 2 000 Re = 2 400 Re = 2 600 Re = 2 800 Re = 3 000 Re = 4 500 Re = 6 200 Re = 600 Re = 1 000 Re = 1 500 Re = 2 000 Re = 2 400 Re = 2 600 Re = 2 800 Re = 3 000 Re = 4 500 Re = 6 200 Laminar Transition Low-Re-end Turbulent 16 Temperature Gradients @ 6.5 kW/m² 45 Re = Re = Re = Re = Re = Re = Re = 40 35 T/x [C/m] 30 Temperature gradients in the laminar flow regime: • Decreased with increasing x/D • Increased with increasing Re T/x [C/m] 20 15 10 Re = 5 700 Re = 800 0 Re = 1 000 Re = 1 400 -5 Re = 1 600 0 Re = 1 800 Re = 2 000 50 40 25 2 200 2 600 3 000 3 200 3 400 3 800 4 300 Zero gradient for fully developed flow 20 40 60 80 100 120 140 160 x/D Temperature gradients in the transitional flow regime: • Decreased with increasing x/D • Increased with increasing Re (Re < 2600) • Decreased with increasing Re (Re > 2600) 30 20 10 0 17 0 20 40 60 80 100 x/D 120 140 160 Local Heat Transfer Coefficients and Nusselt Numbers @ 6.5 kW/m² Turbulent Low-Re-end Transition Laminar 18 Secondary Flow @ 6.5 kW/m² ht/hb ht/hb Re = 4 400 Re = 4 800 Re = 5 300 Re = 5 800 Re = 6 200 Re = 7 600 Re = 9 500 ht/hb Re = 2 000 Re = 2 200 Re = 2 400 Re = 2 600 Re = 2 800 Re = 3 600 Re = 3 800 Re = 600 Re = 1 000 Re = 1 400 Re = 1 800 19 Local Nusselt Numbers and Colburn j-factors: 1.3 ≤ x/D ≤ 36 @ 6.5 kW/m² 110 100 90 x/D = x/D = x/D = x/D = x/D = 1.3 8.2 16.9 25.6 36 x/D = x/D = x/D = x/D = x/D = 0.02 1.3 8.2 16.9 25.6 36 80 0.01 Redl 60 j Nu 70 50 40 Relre 0.005 30 20 Recr Recr 10 3 4 10 10 Re (a) 0.0025 3 4 10 10 Re (b) 20 Five Flow Regimes 21 Local Nusselt Numbers and Colburn j-factors: 53.4 ≤ x/D ≤ 174.9 @ 6.5 kW/m² 80 70 x/D = x/D = x/D = x/D = x/D = 53.4 70.7 105.5 140.2 174.9 x/D = x/D = x/D = x/D = x/D = 0.01 53.4 70.7 105.5 140.2 174.9 60 j Nu 50 40 0.005 30 20 Relre Ret due to secondary flow secondary flow increase Relre due to Recr 10 Recr secondary flow decrease 103 4 10 Re (a) 0.0025 Prandtl number 3 4 10 10 Re (b) 22 Local Heat Transfer Coefficients: 6.5 kW/m² vs 9.5 kW/m² 0.01 0.01 x/D = 1.3 x/D = 8.2 x/D = 16.9 x/D = 25.6 x/D = 36 j 0.02 j 0.02 0.005 0.0025 0.005 3 0.0025 4 10 10 3 Re (a) 0.01 4 10 10 Re (b) secondary flow signficant 0.01 x/D = 53.4 x/D = 70.7 x/D = 105.5 Relrex/D = 140.2 x/D = 174.9 Ret j j Ret 0.005 0.005 Recr 0.0025 Relre 3 4 10 10 Re (c) 0.0025 Recr Transition delayed Relre 3 4 10 10 Re (d) 23 Transition Gradients and Transition Region Gradients -5 3 -6 x 10 1.5 2 6.5 kW/m2 8.0 kW/m2 8.0 kW/m2 9.5 kW/m2 9.5 kW/m2 6.5 kW/m 2.5 x 10 2 Transition Region Gradient Transition Gradient 1.5 1 0.5 0 Approximately constant 1 Both Recr and Relre delayed .ˑ. Relative distance remained approximately constant 0.5 -0.5 -1 -1.5 0 50 100 x/D (a) 150 0 0 50 100 x/D (b) 150 24 Boundaries of Transitional Flow Regime 4500 4000 ∆Re ≈ 2 100 6.5 kW/m2 Start Re 6.5 kW/m2 End 8.0 kW/m2 Start 3500 8.0 kW/m2 End 9.5 kW/m2 Start 3000 9.5 kW/m2 End 2500 2000 0 20 40 60 80 100 x/D 120 140 160 180 25 Average Nusselt Numbers 70 6.5 kW/m2 8 kW/m2 60 No difference between heat fluxes 2 9.5 kW/m Meyer et al. (2013) 50 Relre Nu 40 30 Ret Recr 20 ↑secondary flow 10 600 secondary flow developing flow 1000 Relre ↓secondary flow Recr 2000 3000 Re 5000 10000 26 Average Colburn j-factors 0.014 0.065 kW/m2 (Average) 0.012 0.065 kW/m2 (Fully developed) 0.01 6.5 kW/m2 8.0 kW/m2 0.008 secondary flow developing flow j 0.006 9.5 kW/m2 Nu = 4.36 Ghajar & Tam (1994) 0.004 developing flow Relre Ret Recr 0.002 1000 2000 3000 Re 5000 7000 27 10000 Isothermal Friction Factors 0.12 Measured Poiseuille Equation Tam et al. (2013) Blasius (1913) Olivier and Meyer (2010) Tam et al. (2013) 0.1 0.08 f 0.06 Relre Ret Recr 0.04 500 1000 2000 3000 Re 5000 10000 15000 28 Isothermal Friction Factors: Transitional Flow Regime 0.045 TG developing flow 0.04 TG TG developing flow and fully developed flow f fully developed flow 0.035 Measured Poiseuille Equation Tam et al. (2013) Blasius (1913) Olivier and Meyer (2010) Tam et al. (2013) TG TG TG 0.03 1500 2000 3000 Re 4000 29 Diabatic Friction Factors 0 kW/m2 (Isothermal) 0.06 6.5 kW/m2 8.0 kW/m2 f 9.5 kW/m2 Poiseuille (1840) Tam et al. (2013) Blasius (1913) Allen & Eckert (1964) 0.04 Relre Ret 0.03 1000 Recr 2000 3000 Re 5000 10000 30 Simultaneous Heat Transfer and Pressure Drop 0.1 f Recr Relre Ret 0.05 0.02 6.5 kW/m2 8.0 kW/m2 9.5 kW/m2 j 0.01 0.005 0.002 1000 2000 3000 Re 5000 7000 10000 31 Relationship between Heat Transfer and Pressure Drop 12 Recr Relre Ret 6.5 kW/m2 8.0 kW/m2 11.5 9.5 kW/m2 11 f/j 10.5 10 9.5 9 secondary 8.5 flow linear 8 1000 2nd order 2000 3000 linear linear 5000 7000 Re 10000 32 Correlations Results 70 6.5 kW/m2 60 Nu cor 50 Max Laminar: 6% Transitional: 5.5% Low-Re-end: 1.5% Turbulent: 1.7% 8.0 kW/m2 9.5 kW/m2 +/- 10% +/- 3% Ave 1.44% 1.1% 0.67% 0.63% 40 30 20 10 10 20 30 40 Nuexp 50 60 70 33 Conclusion • Secondary flow effects Suppressed near inlet of the test section Became significant as the thermal boundary layer increased along the tube length Increased with increasing heat flux Decreased with increasing Reynolds number • Local heat transfer data Maximum at the inlet of the test section Five flow regimes (laminar, developing laminar, transitional, low-Reend and turbulent) identified between x/D = 1.3 and x/D = 36 Recr occurred earlier with increasing heat flux and x/D for x/D < 36 Recr delayed with increasing heat flux and x/D for x/D < 36 Relre delayed with increasing heat flux and x/D Width of transition (Recr < Re < Relre) decreased slightly with x/D 34 Conclusion • Average heat transfer data Increased laminar heat transfer coefficients due to secondary flow and developing flow Increased heat transfer coefficients in turbulent and low-Re-end regimes due to enhanced mixing inside tube Heating delayed Recr, but did not affect Relre • Average pressure drop data Secondary flow increased laminar friction factors Diabatic friction factors lower than isothermal friction factors in the transitional, low-Re-end and turbulent flow regimes Transition delayed for increasing heat flux • Relationship between heat transfer and pressure drop Boundaries of different flow regimes the same Correlations developed to predict the Nusselt number as a function of friction factor, Reynolds number and Prandtl number • Heat transfer characteristics of developing flow and fully developed significantly different 35 Acknowledgements The funding obtained from the NRF, TESP, Stellenbosch University/ University of Pretoria, SANERI/SANEDI, CSIR, EEDSM Hub and NAC is acknowledged and duly appreciated. 36