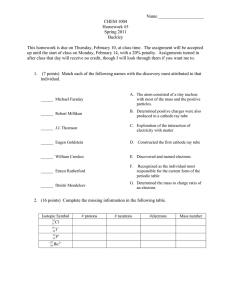

Journal of Materials Chemistry A View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. PAPER Cite this: J. Mater. Chem. A, 2020, 8, 12055 View Journal | View Issue Multidimensional Na4VMn0.9Cu0.1(PO4)3/C cottoncandy cathode materials for high energy Na-ion batteries† Vaiyapuri Soundharrajan,a Muhammad H. Alfaruqi, ab Seulgi Lee,a Balaji Sambandam,a Sungjin Kim,a Seokhun Kim,a Vinod Mathew,a Duong Tung Pham,c Jang-Yeon Hwang,a Yang-Kook Sun d and Jaekook Kim *a Sodium-ion batteries (SIBs) have attracted great attention for day-to-day applications as a replacement for lithium-ion batteries (LIBs) that deliver high voltage and high energy because of the low battery-preparation cost and vast availability of sodium resources. The recent exploration of Na+ superionic conductor or NASICON-type Na4VMn(PO4)3 (NVMP) cathodes for SIBs is a pioneering approach because of the high working voltage, high theoretical capacity, and stable three-dimensional framework of the NVMP cathodes. However, the inherently low electronic conductivity results in mediocre rate outputs and poor exploitation of the active material. Herein, we report, for the first time, the preparation of a cotton candy-like carbon-coated Cu-doped NVMP or Na4VMn0.9Cu0.1(PO4)3 (NVMCP/C/CC) cathode by a facile and ultrafast pyro-synthetic method. The robust structure of the NVMCP/C/CC and the highly reversible two-phase reaction upon Na-ion insertion/extraction were systematically revealed by the in situ synchrotron XRD and GITT studies, while the DFT calculations established the crucial reasons behind the enhanced electronic conduction of the NVMCP/C/CC. The superior electrochemical properties of the Received 6th April 2020 Accepted 24th May 2020 NVMCP/C/CC cathode at low (79 mA h g1 after 450 cycles at 1.5C) and high current rates (68 mA h g1 after 3000 cycles at 30C) demonstrate that the combination of a three-dimensional nanoarchitecture, DOI: 10.1039/d0ta03767b uniform carbon-coating, and Cu-doping is favorable for improving the electrochemical properties of the rsc.li/materials-a NVMP cathodes. 1. Introduction Among the many available energy storage devices, SIBs are a favorable option in the electronics eld in the post-LIB era. At present, LIBs appear to be inadequate in satisfying the massive requirement of grid-scale energy storage devices for the fastgrowing electronic market; thus, SIBs have gained attention because of their low cost and vast availability.1 Due to their intercalation chemistry, acceptable redox potential (EðNaþ =NaÞ ¼ 2:71 versus standard hydrogen electrode, similar to a Department of Materials Science and Engineering, Chonnam National University, 300Yongbong-dong, Bukgu, Gwangju 500-757, South Korea. E-mail: jaekook@ chonnam.ac.kr; Fax: +82-62-530-1699; Tel: +82-62-530-1703 b Departemen Teknik Metalurgi, Universitas Teknologi Sumbawa, Jl. Raya Olat Maras, Sumbawa, Nusa Tenggara Barat, 84371, Indonesia c Institute for Electrochemical Energy Storage, Helmholtz-Zentrum Berlin für Materialien und Energie, Hahn-Meitner-Platz 1, 14109 Berlin, German d Department of Energy Engineering, Hanyang University, Seoul 133-791, South Korea † Electronic supplementary information (ESI) available: SEM and PXRD pattern for MnS2 and NVMP samples, table with crystallographic information from Rietveld renement, TGA, Raman spectra, XPS, BET, and ICP data of NVMCP sample, CDC pattern at 30C rate, ex situ XRD and SEM, full-cell data. See DOI: 10.1039/d0ta03767b This journal is © The Royal Society of Chemistry 2020 that of lithium), and simple cell construction, the working principle of SIBs is not just inspired by the chemistry of LIBs, rather it is almost the same.2,3 For example, there are many lithium-based intercalation compounds that are almost as good as that in LIB cathodes and exhibit impressive electrochemical performances as their sodium equivalents (Na1.1Li2V2(PO4)3, Li2NaV2(PO4)3, Na2.4V2(PO4)3).4–6 Extensive investigations have revealed that the major bottleneck in realizing high electrochemical performance in SIB cathodes is the sluggish diffusion kinetics of the Na+ ions that results in poor rate performance because of the larger ionic radius of Na+ (1.02 Å) than that of Li+ (0.76 Å).7–10 To overcome this setback, SIBs have been systematically investigated in the current decade. Consequently, many cathodes with superior enhanced electrochemical properties have been introduced for SIBs including layered oxides, polyanionic compounds, and Prussian blue analogs.11–15 Among these, NASICON-structured polyanionic compounds, with the general formula NaxM2(PO4)3, are recognized as potential cathodes for SIBs because of their unique 3D crystal framework owing to the stable MO6 octahedral units (M ¼ transition metals) and XO4 tetrahedra (X ¼ P, S, Si, As), which ensure fast Na+ diffusion.16 More importantly, NASICON-based materials exhibit extreme J. Mater. Chem. A, 2020, 8, 12055–12068 | 12055 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Journal of Materials Chemistry A safety, good thermal stability, and structural rmness.17 Among the polyanionic groups, NVP-the most studied electrode material for SIBs-has a at working potential of 3.3–3.4 V operated by a V4+/V3+ redox couple that causes an adequate reversible capacity of 100 mA h g1 with a remarkable rate performance.18 Although, Na3V2(PO4)3 (NVP) is the most favored for SIB cathode applications, the use of the expensive and noxious vanadium component limits its large-scale applications.19 To address this concern, Goodenough's group introduced a new series of NASICON-structured NVMP cathodes for SIBs.20 The introduction of inexpensive and eco-friendly Mn into the NASICON framework has been advantageous in that the inexpensive Mn metal reduces the production cost of the cathode material;21 the introduction of Mn into NVP results in additional Na+ sites in the framework, thereby leading to improved capacity (110 mA h g1); also, the high-redox voltage of Mn2+/ Mn3+ (3.6 V) results in a higher working voltage for the NVMP cathode.22 However, like most polyanionic materials, NVMP exhibits poor electronic properties, which impedes the complete utilization of the NVMP capacity. This problem can be addressed by following the general strategies employed for typical polyanion cathodes such as the development of composites with carbon,23 swapping of transition-metal ions,24 particle downsizing,25,26 and controlling the morphology via different preparation techniques.24,27,28 Most of the previous documents have mainly focused on the NVMP/conducting carbon composite aspect to enhance the electrochemical reactivity.17,19,22 Herein, to exploit the complete utilization and progress of the potential of NMVP electrodes, an amalgamation approach comprising of a crystal arrangement variation, tailored morphology design with conned particle-sizes, and in situ carbon coating has been proposed to develop a Cu-doped Na4VMn0.9Cu0.1(PO4)3/C (NVMCP/C/CC) cathode with a unique cotton candy-like morphology through a modied pyrosynthetic reaction. In general for vanadium-based electrodes via the pyro-synthetic process, we use vanadium acetylacetonate directly, which is expensive, as a source for vanadium; also, it resulted in an agglomerated nanoparticle morphology.4,18 However, in the proposed modied pyro-synthetic method, we adopted a facile pre-reduction (vanadium) and successive pyrosynthetic method for the preparation of an NVMCP/C/CC cathode by using a low-cost ammonium vanadate precursor that cuts-down the nal product cost and also controls the crystal growth to yield a specic morphology. In particular, the achieved NVMCP/C/CC cathode with a unique cotton candy-like nanoarchitecture exhibits superior electrochemical properties compared to those of the NVMCP/C nanoparticle electrode because of the enhanced electronic conductivity and facile Na+ ion diffusion in the unique cotton-candy skeleton, as revealed from the experimental studies and the rst-principles calculations. Thus, this study demonstrates that polyanionic cathodes can be prepared with a unique morphology with uniform carbon coating within a short reaction time in an open-air environment. We believe that the present modied pyrosynthetic approach will facilitate the development of potential 12056 | J. Mater. Chem. A, 2020, 8, 12055–12068 Paper energy storage materials with distinctive morphology on a mass-scale. 2. 2.1 Experimental section Synthesis of NVMP/C/NPs, NVMP/C/CC, and NVMCP/CC As a control experiment, the NVMP/C/NPs were initially prepared by the conventional pyro-synthetic process by dissolving (Na and Mn) metal acetate precursors (Sigma-Aldrich, 99%) and V (acetylacetonate) precursors (Sigma-Aldrich, 97%) in tetraethylene glycol (TTEG) solvent before adding phosphoric acid (Daejung, 85%) in a stoichiometric ratio, followed by the ignition of the ammable reaction solution by a torch to obtain the combustion deposits, which were collected and heated at 800 C for 12 h in an Ar atmosphere to achieve the agglomerated NVMP/C nanoparticles. On the other hand, Na4VMn0.9Cu0.1(PO4)3/C Cotton candy-like material were synthesized by a modied pyro-synthetic process. Firstly, (4 mmol) sodium nitrate (Sigma-Aldrich, 99%) and (1 mmol) manganese nitrate (Sigma-Aldrich, 97%) were dissolved in 100 mL of tetraethylene glycol (TTEG) solvent to obtain solution A. Secondly, (1 mmol) ammonium vanadate (JUNSEI, 99%) was added to 5 mL DI water and (2 mmol) oxalic acid (DAEJUNG, 99.5%) was added as the reducing agent and stirred well for 20 min to get solution B (blue color). Aerwards, solution B was added to solution A, followed by the addition of (3 mmol) phosphoric acid (Daejung, 85%), which was mixed well to get a homogeneous solution. The resultant homogenous solution was poured into an aluminium boat and kept on a hotplate maintained at 450 C. Then, the polyol stock solution was ignited using a torch to activate the ultrafast self-extinguishable combustion reaction. Later on, the combustion deposits were harvested and annealed at 800 C in the Ar atmosphere for 12 h to realize carbon-coated NVMP cotton-candy-like micro-structures. In addition, Cu-doped Na4VMn0.9Cu0.1(PO4)3/C, Na4VMn0.85Cu0.15(PO4)3/C, and Na4VMn0.8Cu0.2(PO4)3/C Cotton candy-like products were also synthesized under the same modied pyro-synthetic conditions, in which copper nitrate (Sigma-Aldrich, 99%) precursor is used as the copper source. In all the above cases, 20 mL paint thinner (KCC, commercial paint thinner) was added as an igniter to trigger the pyro-reaction before transferring into an aluminium boat. 2.2 Structure and morphology characterization A Shimadzu X-ray diffractometer was used to obtain the powder X-ray diffraction (PXRD, Cu Ka radiation, l ¼ 1.5406 Å) pattern of the electrode materials. Thermogravimetric analysis (TGA) was conducted using an SDT Q600 thermobalance in air with a temperature gradient of 5 C min1. A 3D high-resolution Xray diffractometer (Empyrean, PANalytical, the Netherlands) was used to achieve the high-resolution XRD patterns of the samples. The surface morphology of the cathode materials was characterized by eld-emission scanning electron microscopy (FE-SEM) using a Hitachi S-4700 equipped with an energydispersive X-ray spectroscopic (EDS) detector and the lattice fringes were calculated by eld-emission transmission electron This journal is © The Royal Society of Chemistry 2020 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Paper microscopy (FE-TEM) using a Philips Tecnai F20 (200 kV; at KBSI Chonnam National University) equipped with a selected area electron diffraction system (SAED). The Raman spectra were recorded using a JASCO Laser Raman Spectrometer NRS5100 series to conrm the presence of carbon in the samples. The elemental compositons of the samples were characterized via ICP-OES (inductively coupled plasma-optical emission spectroscopy) analysis using a PerkinElmer 4300 DV analyzer. The surface area of the samples was calculated using nitrogen adsorption and desorption isotherms using a Brunauer– Emmett–Teller surface analyzer (BET, Micromeritics ASAP 2010). 2.3 earlier by our group.29 The MnS2 anode (80%) was mixed with super P carbon (10%) in the presence of 5 wt% aqueous solution of sodium carboxymethyl cellulose (4%) and a 50 wt% aqueous solution of styrene-butadiene rubber (6 wt%). The corresponding XRD pattern of the MnS2 anode (slurry-coated) along with the SEM images are presented in the Supplementary information† (Fig. S1†). The calculated and normalized weight ratios of the two electrodes were 1 : 7 (anode:cathode). The electrolyte was 1.0 M NaPF6 in DGM. The cathode and anode materials were tested in half-cells in the same electrolyte and the results are presented in the ESI.† The sodium full-cells were tested in the potential window of 0–3.6 V at a current density of 40 mA g1. In situ synchrotron XRD characterization In situ synchrotron XRD measurements were performed at beamline 1D KIST-PAL, Pohang Accelerator Laboratory, using a MAR345 image plate sensor at 2.5 GeV with an assured storage current of 200 mA. The X-ray beam was focused with a toroidal mirror and monochromatized to 12.4016 keV (0.9997 Å) using a double bounce Si (111) monochromator. An Si (111) monochromator and an Si (111) crystal detector were employed to conrm high-resolution formation in the reciprocal space. The patterns were established using a wavelength of 0.9997 Å. In addition, the XRD peaks were plotted aer recalculating the 2q values using Cu Ka radiation (l ¼ 1.5414 Å). For the construction of the in situ cell, 70% active material was mixed with 20% carbon black (Lion Corporation, Japan) and 10% TAB binder (Hohsen Corporation, Japan); then, the slurry was cast onto an aluminium mesh and kept in a spectroelectrochemical cell. The cell was cycled to a fully charged/discharged state using a portable potentiostat at a xed current density of 20 mA g1. The Kapton tape was glued on the apertures of the outer cases of the test cell. 2.4 Journal of Materials Chemistry A Electrochemical characterization For electrochemical characterization, the cathodes were established from the active material (70%), Denta black conductive carbon (15%), and polyacrylic acid binder (15%) in N-methyl-2pyrrolidone to create a homogeneous slurry. The slurry was coated uniformly on the Al-foil current collector using the doctor blade technique, dried at 80 C in a vacuum oven, pressed between stainless steel twin rollers (maintained at 120 C), and tapped into circular discs. Sodium metal was employed as the counter electrode. NaPF6 (1 M) in ethylene carbonate/ propylene carbonate (EC/PC) electrolyte with 2% uoroethylene carbonate (FEC) additive was assembled in an argonlled glovebox and aged overnight before carrying out electrochemical charge/discharge characterizations using a BTS2004H (NAGANO KEIKI Co., LTD., Ohta-ku Tokyo, Japan) battery tester at different current densities between 2.4 to 3.8 V vs. Na+/Na. Cyclic voltammetry (CV) and galvanostatic intermittent titration technique (GITT) measurements were conducted using BIOLogic Science Instruments. For the assembly of sodium fullcell batteries, MnS2 was used as the anode and NVMCP/C/CC as the cathode in a CR2032-type coin-cell conguration. The MnS2 anode material was prepared using a strategy reported This journal is © The Royal Society of Chemistry 2020 2.5 Specic power and specic energy calculation Specic energy was calculated as E (W h kg1) ¼ specic capacity potential (average working potential). Specific power was calculated as P (W kg1) ¼ I V/2m, where I is the applied current (A), V is the average working potential (V), and m is the active mass at the cathode side.30 2.6 First-principles calculations First-principles calculations based on density functional theory (DFT) were performed using Quantum-Espresso package with projector augmented wave (PAW) pseudopotential and Perdew– Burke–Ernzerhof (PBE) exchange-correlation functional.31,32 A plane-wave basis set with a cutoff energy of 30 Ry (408 eV) was used. The positions of the atoms in the primitive NVMP and NVMCP structures were relaxed using Broyden–Fletcher–Goldfarb–Shanno (BFGS) and the Brillouin zones were sampled using a k-point mesh of 2 2 2 and 2 2 1, respectively. For the density of states (DOS) studies, the DFT + U method was applied with an on-site potential U of 3.9 and 3.25 eV for manganese and vanadium, respectively.33 3. Results and discussion The realization of cathode materials using a fast and scalable pyro-synthetic process with a short reaction time was demonstrated earlier by our group,34 followed by the fabrication of polyanion-type cathodes with nanoparticle morphology for SIBs in a short reaction time using a pyro-synthesis method.4,18,35 In particular, the utilization of such methods to arrive at cathodes with uniquely dened morphologies is of great necessity as it will help to achieve mass-scale production in a short period. With this concern in mind, we have demonstrated the synthesis of carbon-coated NVMP with a cotton candy-like morphology within a short reaction time. Scheme 1 compares the NVMP/C preparation process using conventional pyro-synthesis and modied pyro-synthetic methods. Conventional pyro-synthesis involves the dissolution of acetate (Na, Mn) metal precursors and V (acetylacetonate) precursors in tetraethylene glycol (TTEG) solvent before the addition of phosphoric acid. TTEG solvent with three glycol groups has higher boiling point and J. Mater. Chem. A, 2020, 8, 12055–12068 | 12057 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Journal of Materials Chemistry A Scheme 1 Paper Comparison of the conventional and modified pyro-synthetic processes. viscosity compared to mono (di)-ethylene glycol solvents. These advantages facilitate TTEG to strongly inuence the formation of chelating complexes with transition metals. Further, the higher boiling point of TTEG ensures sustained polyol combustion for apparently longer durations that can facilitate the formation of hierarchical or secondary particles. More importantly, TTEG solvent with a long chain network serves as a carbon-rich backbone for the active NVMP particles. This is followed by the ignition of the ammable reaction mixture using a torch to obtain the combustion deposits; these were collected and heated at 800 C in an Ar atmosphere to produce agglomerated NVMP/C nanoparticles (NVMP/NPs). On the other hand, the modied pyro-synthetic process involves the dissolution of nitrate (Na, Mn) metal precursors in the TTEG solvent. For the vanadium source, we initially dissolved ammonium vanadate in deionized (DI) water, utilizing oxalic acid as the reducing agent to induce the reduction of V(5+) to V(3+) and added it to the metal stock solution. This was followed by the addition of phosphoric acid. Later on, the homogenous solution was ignited using a torch to induce a self-extinguishable combustion reaction to get cotton candy-like combustion deposits, followed by thermal-treatment, similar to that of the conventional pyro-synthetic method. The obtained cotton candy-like NVMP/C with uniform carbon coatings was labelled as NVMP/C/CC. By the inclusion of the Cu(NO3)2 precursor as the copper source in the same modied pyro-synthetic reaction conditions, the Cu-doped NVMCP/C cotton candy-like (NVMCP/ C/CC) cathode was also prepared. The doped NVMCP/C/CC cathode with unique morphology demonstrates superior 12058 | J. Mater. Chem. A, 2020, 8, 12055–12068 electrochemical properties compared to those of the two counterpart cathodes based on nanoparticles (NVMP/NP) and undoped cotton candy-like structure (NVMP/C/CC); this will be discussed in the following section. Moreover, to appreciate the origin of the cotton candy-like morphology, the NVMCP/C/CC combustion deposits were subjected to scanning electron microscopy (SEM), demonstrating that even the as-prepared sample itself consists of a cotton candy-like morphology (Fig.S2a†). The morphology retained its structure even aer annealing; this will be further discussed in the following section. On the other hand, the powder X-ray diffraction (PXRD) pattern of the combustion deposit unveiled amorphous features and their corresponding peaks were indexed to trigonal NVMP (this will be discussed in detail in the following section) (Fig. S2b†). However, several peaks were not completely grown in the as-obtained sample, demonstrating that the combustion deposits need heat treatment to yield the preferred product with high crystallinity. The comparative PXRD patterns of the prepared NVMP/C/ NP, NVMP/C/CC, and NVMCP/C/CC cathode samples revealed a similarity and all the Bragg diffraction peaks could be wellindexed to the monoclinic NVMP sample achieved from X'Pert Highscore Plus program (Fig. S3†).22 Moreover, to gain a complete understanding of the crystal arrangements of the NVMP/C/CC and NVMCP/C/CC materials, Rietveld renement was conducted with the help of X'Pert Highscore Plus utility on the obtained high-resolution XRD patterns of the NVMP/C/CC and NVMCP/C/CC samples. The detailed patterns and renement data are shown in Fig. 1, Tables S1 and S2,† respectively. This journal is © The Royal Society of Chemistry 2020 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Paper Journal of Materials Chemistry A Fig. 1 XRD Rietveld refinement pattern for (a) Na4VMn(PO4)3 (inset: goodness-of-fit values), (b) Na4VMn0.9Cu0.1(PO4)3 (inset: goodness-of-fit values) (c) structural model of NVMP/NVMCP, and (d) Facile Na-ion diffusion viewed from the expanded c-axis. Both of the samples are well-indexed to the characteristic c trigonal crystal system. The lattice paramefeatures of the R3 ters of the NVMP structure were calculated to be a ¼ b ¼ 8.9649 Å and c ¼ 21.47864 Å; noticeably, the “goodness-of-t” value for both the samples (inset in Fig. 1a and b) further conrms the renement process. The structural model of these samples was constructed using the VESTA package36 and is depicted in Fig. 1c. The NVMP/NVMCP structure is built from a cornershared M–O6 (M ¼ V, Mn, Cu) octahedron and PO4 tetrahedral units forming the [M2(PO4)3]4 anion framework. While the M elements are located in a similar Wyckoff site, i.e., 12c site, Na elements are situated at two different sites, i.e., 6b and 18e. Aer Cu-doping (NVMCP), the slightly different crystallographic parameters could be observed, i.e., a ¼ b ¼ 8.96072 Å and c ¼ 21.48843 Å (Table S2†). The expansion of the c-axis is also expected to provide facile Na-ion diffusion, as shown in Fig. 1d. Field emission-scanning electron microscopy (FE-SEM) was conducted to observe the size and morphology of all the prepared samples. The NVMP cathode prepared by the conventional pyro-synthetic process showed a nanoparticle morphology with an average particle size in the range of 50– 100 nm (Fig. S4a†), as witnessed in our previous reports.34,37 In contrast, the NVMP/C/CC cathode achieved by the modied pyro-synthetic process exhibited a unique cotton candy-like This journal is © The Royal Society of Chemistry 2020 morphology composed of several nanoarrays with an average particle size in the range of 1–2 mm (Fig. S4b†). Furthermore, the Cu-doped NVMP or NVMCP/C/CC cathode maintained the distinctive cotton candy-like morphology (composed of multiple nanoarrays) and the same particle size (Fig. 2a). As the NVMCP/C/CC cathode delivered remarkable electrochemical performance (described later in this section), further investigations except for the galvanostatic measurements were pursued only for this electrode sample. The transmission electron microscopy (TEM) studies to investigate the comprehensive crystallographic features conrmed that the NVMCP/C/CC cathode consists of a cotton candy-like microstructure assembled from nanoarrays (Fig. 2b). The high-resolution transmission electron microscopy (HRTEM) targeted at the edge of NVMCP/C/CC revealed a rich crystal lattice with an interlayer spacing of 0.28 nm, attributable to the (116) plane of trigonal NVMP (Fig. 2c). More importantly, it is clearly visible that the NVMCP cotton candy-like cathode is wrapped with a smooth amorphous carbon layer of 5–7 nm thickness. Further, the energy dispersive X-ray (EDX) elemental mapping examination was conducted to endorse the dissemination of all the elements in the composite product. The resultant elemental mapping images (Fig. 2d) illustrate the homogeneous distribution of Na, V, Mn, P, O, and Cu elements in the NVMCP sample. The additional TEM images (in Fig. S5a and b†) further endorse the J. Mater. Chem. A, 2020, 8, 12055–12068 | 12059 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Journal of Materials Chemistry A Paper (a) SEM image of NVMCP/C/CC. HRTEM images of NVMCP/C/CC at (b) low and (c) high magnifications, (d) elemental mapping in a bright field image with corresponding elements (Na, Mn, V, P, O, Cu), XPS profile for NVMCP/C/CC (e), V 2p lines, and (f) Mn 2p lines after deconvolution of the peaks. Fig. 2 cotton candy-like architecture. The nite lattice fringes of Na4VMn0.9Cu0.10(PO4)3 material can be clearly visible from the high magnication image with a calculated stripe space value of 0.61 nm, representing the (012) plane of the trigonal NVMP structure (Fig. S5c†). To determine the exact carbon quantity, thermogravimetric analysis was conducted and the precise carbon content existing in the NVMCP/C/CC cathode was found to be 3.5% (Fig. S6a†). Also, Raman spectroscopy was performed to understand the nature of carbon in the NVMCP/C/CC material; the results are illustrated in Fig. S6b.† The resultant prole presented two characteristic Raman footprints at 1346.3 cm1 (D-band) and 1587.4 cm1 (G-band). The ID/IG ratio (i.e., the ratio of sp3 to sp2) was calculated to be 0.85, demonstrating the amorphous nature of carbon.38 The specic surface area and pore structure of all the three electrodes were furnished by nitrogen adsorption–desorption investigation. The specic surface area of the NVMCP/C/CC material was measured to be 141 m2 g1, which is higher than 38.2 m2 g1 for NVMCP/C/NPs and near to 119.3 m2 g1 for NVMP/C/CC (Fig. S7†). It is to be 12060 | J. Mater. Chem. A, 2020, 8, 12055–12068 noted that a higher BET surface area could provide increased electrolyte–electrode contact for boosted sodium storage performance. To determine the inherent structural properties, X-ray photoelectron spectroscopy (XPS) was carried out for the NVMCP/C/CC material. Fig. 2e illustrates the V 2p spectrum, which exhibits two predominant peaks at 517.1 eV and 522.2 eV, corresponding to the 2p3/2 and 2p1/2 spin–orbit energy states, respectively, and dening the trivalent nature of V in the material.39 The Mn 2p prole in Fig. 2f shows two major peaks with binding energies of 641.2 eV and 653.5 eV, which individually represent the 2p3/2 and 2p1/2 spin–orbit energy states with an energy separation of 12.3 eV, respectively, indicating that the energy state of Mn is bivalent.22,40 Furthermore, the shake-up satellites existing at 645.3 eV and 658.1 eV were attributed to the paramagnetic metal state.40,41 The highresolution XPS prole of C (1s) in Fig. S8a† demonstrates the different forms of carbon at 282.3, 284.5, and 286.5 eV representing the (C–C), (C–O–C), and (COO) bonds, respectively, on the surface.42 Similarly, the high-resolution XPS spectrum of O This journal is © The Royal Society of Chemistry 2020 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Paper (1s) exhibits different peaks at 529.7, 530.6, and 533.2 originating from (M–O), (C–O–C), and (COO) bonds, respectively (Fig. S8b†).42 Furthermore, the XPS peaks at 1070 and 132 eV conrm the Na (1s) and P (2p) elements in the sample (Fig. S8c and d†). More importantly, at 935 eV, a small peak can be seen for Cu 2p, conrming that Cu2+ has been doped into the crystal network of the NVMP/C product (Fig. S8e†). Overall, the XPS survey results (Fig. S8f†) conrm the existence of multiple elemental features of the NVMCP/C/CC material. To acquire the exact elemental contribution information of the Na4VMn0.9Cu0.10(PO4)3 electrode material, inductively coupled plasmaoptical emission spectroscopy (ICP-OES) and elemental analysis were performed and the results are presented in Table S3 in the ESI.† It is evident that the elemental ratio of the NVMCP powder is in the order of (Na ¼ 0.556; V ¼ 0.16; Mn ¼ 0.14; Cu ¼ 0.015), which is equivalent to the stoichiometric composition of Na3.97V1.1Mn0.994Cu0.106(PO4)3. Galvanostatic cycling inspections were conducted to investigate the electrochemical behavior of the three electrodes, prepared by the conventional and modied pyro-synthesis methods. The comparative galvanostatic charge/discharge pattern in the working voltage of 3.8–2.4 V at 0.25C is illustrated in Fig. 3a. All the electrodes exhibit two pairs of voltage plateaus near 3.45/3.35 V and 3.63/3.51 V originating from the V3+/V4+ and Mn2+/Mn3+ redox couples and signifying the reversible Na+ (de)insertion from/into the NVMP NASICON structure.20 The NVMCP/C/CC composite electrode delivered a superior discharge capacity (117 mA h g1) in the initial cycle compared to the NVMP/C/CC (112 mA h g1) and NVMP/C/NPs (108 mA h g1) composite electrodes due to the combined effects of copper doping and unique cotton candy-like morphology. Moreover, amongst the three electrodes, NVMCP/C/NPs exhibits the least electrochemical polarization, signifying an enriched electronic conductivity due to the Cu doping. To further clarify the morphological and doping effects in the rate performance, we subjected all the cathodes to rate testing at different current surges starting from 0.25C to 40C; the resultant rate performances are illustrated comparatively in Fig. 3b. Among the three cathodes, it is clear that the NVMP/C/ CC cathode has better rate capability than NVMP/C/CC and NVMP/C/NP cathodes. When driven at low C-rates of 0.25C and 0.5C, the differences between the electrodes are less. However, with the acceleration of C-rates, the reversible capacity and cyclability of NVMCP/C/CC are improved more than those of NVMP/C/CC and NVMP/C/NPs. For example, the reversible capacity (68 mA h g1) realized for the NVMCP/C/CC cathode at a very high rate (40C) is considerably higher than those for the NVMP/C/CC and NVMP/C/NP (45 and 20 mA h g1, respectively) at the same rate (40C). It is important to note that the appreciable rate performances in the present study are comparable to the recent results in the literature.17,20,22,43 These outcomes validate that the NVMP/C cathodes with a cotton candy-like structure exhibit superior electrochemical performance compared to that of NVMP/C/NPs due to the 3D electronic passage system. On the other hand, the improved electrochemical stability realized in the Cu-doped NVMCP/C/CC with cotton candy-like nano-architecture could originate from the This journal is © The Royal Society of Chemistry 2020 Journal of Materials Chemistry A combined electronic conductivity improvement due to the presence of Cu in the crystal structure and 3D electronic passage arrangements that arise from the unique 3D morphology.24,44 In addition to the unique cotton-candy architecture, Cu doping was also found to enhance the electrochemical activity of the NVMP cathode. Hence, to understand the effect of Cu content on the sodium storage properties, we studied two NVMP samples, i.e., Na4VMn0.85Cu0.15(PO4)3 and Na4VMn0.8Cu0.2(PO4)3 with 0.15 and 0.2 mol Cu content, respectively, prepared by the same modied pyrosynthetic technique. The obtained XRD patterns for the samples were clearly indexed to the standard triagaonal NVMP phase estimated by the Xpert highscore plus program (Fig. S9a†). On subjecting it to rate performance evaluation (Fig. S9b and c†), the NVMP samples with high Cu concentration of 0.15 and 0.2 mol demonstrated low-rate capacities of 40 and 35 mA h g1 at 40C, respectively, compared to that of the NVMP sample with low or 0.1 mol Cu concentration (68 mA h g1 at 40C). This clearly manifests that the NVMCP cathode with optimized Cu content (i.e., Na4VMn0.9Cu0.10(PO4)3), in addition, to the unique morphology is essential to realize distinguished sodium storage properties. As NVMCP/C/CC exhibits the best rate performance, we further observed the electrochemical properties of the NVMCP/ C/CC cathode by cycling at a 1.5C rate; the corresponding cyclability results are illustrated in Fig. 3c. The NVMCP/C/CC cathode delivers an initial discharge capacity of 87 mA h g1 and the cathode material undergoes a slight drop in capacity (81.26 mA h g1, 25th cycle) in the initial cycles. Aerwards, the cathode material underwent a slow activation process up to the 103rd cycle, which yielded an activation capacity of 84 mA h g1 due to the improved Na+ diffusion effects resulting from the increased availability of the reversible sites along the periphery of the electrode during the repeated cycling process.37,45 With the increase in the number of cycles, the capacity is slowly reduced; for example, aer the 200th cycle, the delivered specic capacity was 82.87 mAhg1, aer which it was apparent that the electrode exhibits adequate cycling stability; a stable reversible capacity of 79 mA h g1 aer 450 cycles and capacity retention of 90% were also observed. The superior cycling stability at a low-current rate decides the stability of the electrode. Thus, excellent cycling stability at a low current rate validates the long-term cycle life of the NVMCP/C/CC cathode. The corresponding selected charge–discharge patterns for the 50th, 100th, 200th, and 300th cycle, respectively, are presented in Fig. 3d. The shape of the charge–discharge pattern and position of the redox pairs for both V3+/V4+ and Mn2+/Mn3+ are retained over the entire cycling process period again, indicating that the cathode maintains a stable Na+ extraction/insertion mechanism due to the robust NASICON framework structure; this is further enhanced by the unique cotton candy-like morphology and electronic conductivity support from the Cu-doping.24,44 Also, fast Na+ intercalation and de-intercalation properties of NVMCP/C/CC were also assessed at a high current rate (30C) and the resultant long-term cycling stability curve is given in Fig. 3e. The cathode exhibits extraordinary cycle stability and stable reversible capacity of 68 mA h g1 even aer 3000 J. Mater. Chem. A, 2020, 8, 12055–12068 | 12061 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Journal of Materials Chemistry A Paper Fig. 3 (a) Comparison of the charge/discharge profiles for NVMP/C/NPs, NVMP/C/CC, and NVMCP/C/CC cathodes; (b) rate performance comparison for NVMP/C/NPs, NVMP/C/CC, and NVMCP/C/CC cathodes; (c) cyclability pattern for the NVMCP/C/CC cathode obtained at 1.5C rate, (d) charge/discharge profiles for the NVMCP/C/CC cathode at 1.5C rate, (e) the cyclability curve for the NVMCP/C/CC cathode at 30C rate, (f) Ragone-plot of the NVMCP/C/CC cathode along with that of different layered electrodes available in the literature. repeated cycles. During cyclability analysis, the coulombic efficiency is nearly entirely preserved. On the whole, aer delivering a high initial discharge capacity (79 mA h g1), the cathode showed a small drop in the capacity (70 mA h g1) up to the 40th cycle. Aer that, the electrode achieved its stabilization process and underwent a stable cycling passage. Thus, almost constant cycling performance and delivery of steady discharge capacity of 68 mA h g1 aer 3000 cycles were demonstrated, realizing an 86% capacity retention. This indicates the fast sodium ion reversibility of the present NVMCP/C/CC cathode. The corresponding selected discharge patterns for the 100th, 1000th, 1500th, 2000th, and 3000th cycles at the applied current rate are seen in Fig. S10a.† An analogous discharge shape was realized throughout the long run of the cycle, indicating the extremely stable framework of the NVMCP/C/CC cathode. Also, the trigonal Na4VMn0.9Cu0.1(PO4)3/C structure was retained even aer the deep cycling process (ex situ XRD in Fig. S10b†), yet again indicating that the lattice structure is effortlessly 12062 | J. Mater. Chem. A, 2020, 8, 12055–12068 preserved. More importantly, we investigated the morphological changes in the NVMCP cathode aer 3000 cycles at 30C using ex situ SEM analysis and the corresponding SEM image is presented in Fig. S10c.† It is evident that the NVMCP/CC/C cathode retained most of its cotton-candy architecture even aer harsh cycling conditions. This clearly conrms that the NVMCP/C/CC cathode with a unique cotton candy microstructure supports the overall electrochemical properties in addition to the Cu doping into the structure. Thus, employing dual strategies, i.e., engineering Cu-doped NVMP cathode with a distinctive architecture is highly benecial for achieving superior electrochemical properties, as revealed by the NVMCP/ C/CC composite cathode. Hence, the ex situ XRD and SEM studies signify the synergetic importance of the 3D cotton candy-like morphology for facile Na+ ion diffusion property and the Cu dopant that assists the enriched electronic conductivity. More remarkable features of our NVMCP/C/CC composite cathode were appreciated by comparing the Ragone plot of our This journal is © The Royal Society of Chemistry 2020 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Paper Journal of Materials Chemistry A recommended cathode with several other recently recorded polyanion-type cathodes (Fig. 3f). The specic energy and power values were calculated based on the entire active mass of the cathode attained from the charge/discharge plots at different current surges starting from 0.25C to 40C. The plot indicates that the NVMCP/C/CC cathode retains high a specic energy of 398 W h kg1 at a specic power of 90 W h kg1 and shows a distinct position amongst polyanion-based cathodes, formerly documented for SIBs. Thus, the NVMCP/C/CC composite cathode outperforms other cathodes such as NMVP/C/rGO,17 NMVP/C/GA,22 NMVP/C/CNTs,19 Na3MnTi(PO4)3/C,46 Na2FeP2O7/C/rGO,47 NaVTi(PO4)3/C,48 Na3.32Fe2.34(P2O7)2/C,49 Na7V4(P2O7)4(PO4)/C/graphene,50 and NaVPO4/C51 documented so far. It is notable to compare the electrochemical outputs of the present NVMCP/C/CC cathode with available registered reports on Na4MnV(PO4)3. A statistical correlation between different Na4MnV(PO4)3 materials is provided in Table S4† to underline the sodium storage properties of the present NVMCP/C/CC cathode synthesized through the ultrafast pyro-synthetic technique. To the best of the author's knowledge, the documented sodium-storage properties of the NVMCP/C/CC cathode realized via the super-fast pyro-synthestic process is comparable to the NVMP cathodes prepared by the time-consuming sol–gel and spray-drying methods. Cyclic voltammetry (CV) was performed at 0.1 mV s1 for the NVMCP/C/CC cathode in the potential window from 3.9 to 2.4 V vs. Na+/Na, as shown in Fig. 4a. The CV pattern comprises of two pairs of predominate redox peaks at 3.48/3.28 and 3.66/3.45 V resulting from the reversible transformation of V3+/V4+ and Mn2+/Mn3+, respectively, during Na+ (de)insertion from/into the NVMCP/C/CC framework. To determine the capacitive impact effects in the NVMCP/C/CC cathode, CV analyses at varying scan speeds (0.1–1 mV s1, Fig. 4b) were performed. At a denite potential, the current was revealed to be comprised of two inuences, surface (k1v) and diffusion (k2v) limited processes, which can be noted by the following equation:52 i ¼ k1v + k2v1/2 where i and v are the peak current and scan rate of the CV results, respectively, and k1v and k2v1/2 are the surface- and diffusion-controlled redox reactions, respectively.45 From this equation, the proportion of these two contributions at each sweep rate can be determined. The diagnostic outcome at 0.2 mV s1 (Fig. 4c) discloses a 17.12% ratio of the surfaceoriented contribution. Furthermore, the histogram in Fig. 4d illustrates the two different contributions at multiple scan rates. The proportion of the surface-driven reaction is increased with increasing scan rates. In particular, the contribution of the surface-oriented reaction to the specic capacity increased from 17.12% (0.2 mV s1) to 72% (1 mV s1), thereby representing the overriding role of the surface reaction at high sweep rates. The reaction mechanism behind the NVMCP/C/CC cathode material is analyzed using an in situ synchrotron XRD technique. Fig. 5 elucidates the in situ XRD patterns recorded under different charge/discharge states in the rst cycle, in which the constructed cell is initially charged to 3.8 V and then discharged This journal is © The Royal Society of Chemistry 2020 to 2.4 V at a current density of 20 mA g1. The resultant charge/ discharge prole along with the selected in situ scan numbers are provided in Fig. 5a and the selected XRD 2q regions are presented in the remaining panels from b to d. Aer the initiation of Na+ extraction, a clear shi is perceived for the (211), (116), (030), (223), (226), (140), and (146) reections. During the charging process, all the planes exhibited changes in the peak position towards a higher 2q angle (aer the 220th scan number) and returned progressively to their original spot aer the discharge process (scan no. 450, indicating the completion of the cycle), thus lightening the lattice breathing in the course of Na+ (de)insertion in the controlled electrochemical working agenda. On the other hand, the (104) and (113) reections split into two peaks from scan no. 120–220 (i.e., from 3.5 to 3.8 V) during the charge response. This clearly suggests that the initial Na+ extraction was a coupled V4+/V3+ redox induced singlephase reaction and the remaining Na+ extraction allied with the bi-phasic reaction originated from the Mn3+/Mn2+ redox couple.22 More importantly, aer the end of the discharge process, two peaks were fused into a single peak, as perceived in the open-circuit voltage (OCV), at scan no. 450 (end of discharge, 2.4 V). This conrms that the original structure is recovered at the end of the discharge process. The NVMCP/C/CC cathode experienced sequential two-phase transitions during the reversible Na+ (de)intercalation process that preserved the complete framework,43 indicating the two well-established charge/discharge voltage plateaus. Besides, to completely understand the biphasic reaction mechanism and the diffusion rate of Na+ ions in the Cu-doped and un-doped NASICON framework, galvanostatic intermittent titration technique (GITT) analysis was performed on the NVMCP/C/CC and NVMP/C/CC cathodes at the rate of 20 mA g1 in the specied working voltage region (OCV – 3.8 V) for the rst cycle (Fig. 6a and b), with an equal interval of pulses (10 min); the rest time was xed as 1 h to reach a quasielectrochemical equilibrium voltage. This was preserved throughout the operating potential space. The resultant single titration output during the cycling process for the NVMCP/C/CC and NVMP/C/CC cathodes are illustrated in (Fig. 6c and d), respectively. Signicant variation in the equilibrium voltage shape for both the cathodes (Fig. 6a and b) indicated the presence of bi-phasic response during the Na+ de-intercalation between 3.5 and 3.8 V. The transient potential responses evidenced from the GITT results can be used to calculate the sodium ion diffusion coefficient according to Fick's second law:53 DNa ¼ 4/Ps(mBVM//MwA)2(DEs/DEs)2 where DNa (cm2 s1) indicates the diffusion coefficient, MB (g) is the total mass loading of the active material, VM (cm3 mol1) is the molar volume, MW (g mol1) is the molecular weight, A (cm2) is the sum of the surface area of the cathode, and s (s) is the current pulse time; DEs and DEs are the variations in the steady-state voltage and total variation in the cell voltage taking place during the constant pulse of a single-stage GITT analysis.54 The chemical diffusivity plots for the NVMCP/C/CC and J. Mater. Chem. A, 2020, 8, 12055–12068 | 12063 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Journal of Materials Chemistry A Paper Fig. 4 (a) CV profile for NVMCP/C/CC at 0.1 mV s1, (b) multi-scan CV profile at various scan rates, (c) the contribution ratio of the diffusionlimited capacities and capacitive capacities at 0.2 mV s1, (d) bar chart for capacity contribution ratios at different scan rates. NVMP/C/CC cathodes for charge and discharge reactions are provided in Fig. 6e, f and g, h, respectively. The GITT results clearly demonstrate that the NVMCP/C/CC cathode exhibited enhanced sodium diffusion attainment than the NVMCP/C/CC cathode. For example, the calculated diffusion coefficient values for the NVMCP/C/CC sample (2.46 108 to 8.6 109 cm2 s1) is higher than that of the NVMP/C/CC sample (6.83 109 to 9.14 1010 cm2 s1) for the Na+ de-insertion process, respectively, which are comparable to those of NASICON based cathodes materials,22,55,56 thereby depicting the superior mobility of Na+ ions in the NVMCP/C/CC NASICON framework. This clearly portrays that Cu doping signicantly encourages the mobility of Na+ ions, which helps in the rapid sodium storage properties of the NVMCP/C/CC cathodes. Thus, it is clear that the Cu-doped sample exhibits exceptional rate performances and remarkably fast current testing capabilities when compared to the un-doped sample due to the superior Na+ diffusion properties. First-principles calculations based on density functional theory were also performed to gain more insight into the evolution of the electronic structures of pure (NVMP/C/CC) and Cu-doped (NVMCP/C/CC) samples. The total density of states 12064 | J. Mater. Chem. A, 2020, 8, 12055–12068 (DOS) of the NVMP and NVMCP samples are displayed in Fig. 7a and b, respectively. It can be seen that the NVMP sample exhibited a semiconductor feature with a bandgap of 0.83 eV. Remarkably, aer the inclusion of Cu within the structure, the impurity levels appeared within the Fermi energy, indicating an increase in the conductivity of the NVMCP sample. In addition, the partial DOS of the NVMP sample showed that the conduction and valence bands were dominated by transition metal-3d electrons with some portions of P and O 2p electrons (Fig. 7c). Aer the addition of Cu, a similar trend can still be observed, however, with some impurity levels (Fig. 7d). Based on the DOS studies, it is worth noting that the Cu-doped sample essentially showed a metallic behavior, which indeed has a much higher conductivity compared to the pure sample, thus facilitating fast electron transport, which is also in agreement with the experimental results. To evaluate the diverse application of the NVMCP/C/CC cathode, the full cell is assembled with the MnS2 anode. Since the MnS2 anode exhibits stable electrochemical properties in the diglyme-based electrolyte (1 M NaPF6 in DGM) before the full cell examination, both the anode and cathode were optimized in the sodium half-cell setup using the diglyme-based This journal is © The Royal Society of Chemistry 2020 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Paper Journal of Materials Chemistry A (a) Electrochemical charge/discharge profile of the constructed NVMCP/C/CC spectro-electrochemical cell tested within 3.8–2.4 V at 20 mA g1. The resultant profile kickoff from scan no. 1 (OCV) to scan no. 450 (2.4 V, end of first discharge). In situ XRD profiles within the selected scanning angle (2) regions of (b) 18–26 , (c) 27–36 , and (d) 41–66 . Fig. 5 electrolyte and the comprehensive electrochemical outputs are illustrated in the ESI (Fig. S11a and d†). This gives an opportunity to test the endurance of the NVMCP/C/CC cathode in highly viscous diglyme-based electrolytes as well and the stable electrochemical properties validate the permanence of the cathode even in a high-viscosity electrolyte. More importantly, the mass ratio of 1 : 7 for MnS2 : NVMCP/C/CC was employed to gain the desired yield. The corresponding galvanostatic charge/ Fig. 6 Voltage profile during GITT at 20 mA g1 current density for (a) the NVMCP/C/CC and (b) NVMP/C/CC cathodes. The expansion of single titration curve during the charging process for (c) NVMCP/C/CC and (d) NVMP/C/CC cathodes. Sodium ion chemical diffusion coefficient calculated from GITT curves from the charge/discharge process during the electrochemical reaction of (e and f) NVMCP/C/CC and (g and h) NVMP/C/CC cathodes. This journal is © The Royal Society of Chemistry 2020 J. Mater. Chem. A, 2020, 8, 12055–12068 | 12065 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Journal of Materials Chemistry A Paper Fig. 7 The total DOS of the (a) NVMP and (b) NVMCP samples and the projected DOS of the (c) NVMP and (d) NVMCP samples. discharge prole along with the cyclability pattern of the MnS2 : NVMCP/C/CC full-cell is presented in Fig. S11e and f† and the cycling pattern clearly illustrates that the full-cell exhibits a stable cycle life aer 50 cycles with 73% capacity retention of its initial value. It is worth noting that the high cathode mass ratio and slow-diffusion kinetics of Na+ ion in highly viscous diglyme electrolyte denitely affected the nal productivities of the full cell. However, the reasonably good performance of the NVMCP/C/CC cathode along with the MnS2 anode in full-cell formations even in the high-viscosity electrolyte demonstrates their high suitability for real-world applications. It is to be noted that the explored research outputs for the NVMP cathode mainly uses hard carbon anode for full-cell construction. However, the present study demonstrates the versatility of the NVCMP/C/CC cathode in the sulde-based anode. The present NVMCP/C/CC cathode demonstrated superior sodium storage ability because of the following features. It is rational to propose that the high electrochemical performance can be attributed to the distinctive cotton candy-like morphology with the thin uniform carbon coating, which improves the interfacial redox reactions due to the decreased diffusion pathways for Na+ ions originating from the electrochemically active spots owing to the 3D cotton candy-like morphology and good conductive assistance owing to the uniform carbon coating. Furthermore, for the present composite cathode, Cu doping played an important role in providing conductive channels that enable electronic conductivity. Thus, we have demonstrated the successful synthesis of Cu-doped carbon-coated NASICON-type NVMCP/C cathode with 12066 | J. Mater. Chem. A, 2020, 8, 12055–12068 a unique cotton candy-like morphology in a short time by an open-air ultrafast modied pyro-synthetic method for highperformance SIBs. 4. Conclusions In this study, a Cu-doped NVMCP cotton candy-like cathode with uniform carbon coating was produced by a facile and ultrafast modied pyro-synthetic method. The distinctive structural assemblies, such as stable and open NASICON framework, nanoake-constructed cotton candy-like architecture, optimized Cu-doping, and uniform carbon coating provide the NVMCP/C/CC cathode with a superior rate capability (68 mA h g1 at 40C) and outstanding cycling stability both at low (79 mA h g1 aer 450 cycles at 1.5C rate with 90% capacity retention) and high current rates (68 mA h g1 aer 3000 cycles at 30C rate with 86% capacity retention). More importantly, a two-phase reversible electrochemical reaction mechanism in the NVMCP/C/CC cathode was revealed using real-time in situ XRD and GITT studies. First-principles calculations based on the DOS studies authenticated the enhanced conductivity originating from the Cu-doping compared to the pure sample that encourages fast electron transport, leading to enhanced rate capability. More importantly, the achieved cathode was subjected to full-cell fabrication using an MnS2 anode and demonstrated the possibilities of using this cathode diversely. Thus, we believe that this cotton candy-like architecture model and the modied pyro-synthetic protocol can be expanded to develop high-performance cathodes with unique nanoarchitecture and enhanced electrochemical consistency and can This journal is © The Royal Society of Chemistry 2020 View Article Online Paper accelerate the development of stable electrochemical energy storage devices. Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Author contribution Vaiyapuri Soundharrajan Conceptualization, Investigation, Methodology, Formal analysis, Writing-Original Dra, Muhammad H. Alfaruqi performed Rietveld renement and DFT computations. Seulgi Lee performed in situ XRD analysis. Balaji Sambandam and Sungjin Kim performed GITT and reviewed the manuscript; Seokhun Kim and Vinod Mathew Writing, Reviewing, and Editing. Duong Tung Pham directed the full-cell fabrication. Jang-Yeon Hwang, Yang-Kook Sun, and Jaekook Kim Conceptualization, Supervision, and Funding acquisition. Conflicts of interest There are no conicts to declare. Acknowledgements This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (2017R1A2A1A17069397). This work was also supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (2018R1A5A 1025224). Notes and references 1 M. H. Han, E. Gonzalo, G. Singh and T. Rojo, Energy Environ. Sci., 2015, 8, 81–102. 2 M. D. Slater, D. Kim, E. Lee and C. S. Johnson, Adv. Funct. Mater., 2013, 23, 947–958. 3 B. L. Ellis and L. F. Nazar, Curr. Opin. Solid State Mater. Sci., 2012, 16, 168–177. 4 J. P. Baboo, J. Song, S. Kim, J. Jo, S. Baek, V. Mathew, D. T. Pham, M. H. Alfaruqi, Z. Xiu, Y.-K. Sun and J. Kim, Chem. Mater., 2017, 29, 6642–6652. 5 Y. Tang, C. Wang, J. Zhou, Y. Bi, Y. Liu, D. Wang, S. Shi and G. Li, J. Power Sources, 2013, 227, 199–203. 6 Y. Lee, J.-K. Yoo, Y. Oh, H. Park, W. Go, S.-T. Myung and J. Kim, J. Mater. Chem. A, 2018, 6, 17571–17578. 7 H. Huang, S.-C. Yin, T. Kerr, N. Taylor and L. F. Nazar, Adv. Mater., 2002, 14, 1525–1528. 8 W. Song, X. Ji, Y. Yao, H. Zhu, Q. Chen, Q. Sun and C. E. Banks, Phys. Chem. Chem. Phys., 2014, 16, 3055–3061. 9 W. Song, X. Ji, Z. Wu, Y. Zhu, Y. Yao, K. Huangfu, Q. Chen and C. E. Banks, J. Mater. Chem. A, 2014, 2, 2571–2577. 10 H. Kim, I. Park, D.-H. Seo, S. Lee, S.-W. Kim, W. J. Kwon, Y.-U. Park, C. S. Kim, S. Jeon and K. Kang, J. Am. Chem. Soc., 2012, 134, 10369–10372. 11 W. L. Pang, J. Z. Guo, X. H. Zhang, C. Y. Fan, X. J. Nie, H. Y. Yu, W. H. Li, Q. Yang and X. L. Wu, J. Alloys Compd., 2019, 790, 1092–1100. 12 Y. Fang, X. Y. Yu and X. W. D. Lou, Angew. Chem. Int. Ed., 2017, 56, 5801–5805. This journal is © The Royal Society of Chemistry 2020 Journal of Materials Chemistry A 13 L. Gao, S. Chen, L. Zhang and X. Yang, ChemElectroChem, 2019, 6, 947–952. 14 Z. LIU, Acta Phys. Sin., 2019, 35, 804–805. 15 X. Pu, H. Wang, D. Zhao, H. Yang, X. Ai, S. Cao, Z. Chen and Y. Cao, Small, 2019, 15, 1805427. 16 J. Dong, G. Zhang, X. Wang, S. Zhang and C. Deng, J. Mater. Chem. A, 2017, 5, 18725–18736. 17 P. Ramesh Kumar, A. Kheireddine, U. Nisar, R. A. Shakoor, R. Essehli, R. Amin and I. Belharouak, J. Power Sources, 2019, 429, 149–155. 18 J. Song, S. Park, V. Mathew, J. Gim, S. Kim, J. Jo, S. Kim, M. H. Alfaruqi, J. P. Baboo, I.-H. Kim, S.-J. Song and J. Kim, ACS Appl. Mater. Interfaces, 2016, 8, 35235–35242. 19 W. Zhang, Z. Zhang, H. Li, D. Wang, T. Wang, X. Sun, J. Zheng and Y. Lai, ACS Appl. Mater. Interfaces, 2019, 11, 35746–35754. 20 W. Zhou, L. Xue, X. Lü, H. Gao, Y. Li, S. Xin, G. Fu, Z. Cui, Y. Zhu and J. B. Goodenough, Nano Lett., 2016, 16, 7836– 7841. 21 L. Gao, S. Chen, L. Zhang and X. Yang, J. Alloys Compd., 2019, 782, 81–88. 22 H. Li, T. Jin, X. Chen, Y. Lai, Z. Zhang, W. Bao and L. Jiao, Adv. Energy Mater., 2018, 8, 1801418. 23 L. L. Zhang, Z. Li, X. L. Yang, X. K. Ding, Y. X. Zhou, H. Bin Sun, H. C. Tao, L. Y. Xiong and Y. H. Huang, Nano Energy, 2017, 34, 111–119. 24 D. Zhang, P. Feng, B. Xu, Z. Li, J. Qiao, J. Zhou and C. Chang, J. Electrochem. Soc., 2017, 164, A3563–A3569. 25 X. Ge, S. Liu, M. Qiao, Y. Du, Y. Li, J. Bao and X. Zhou, Angew. Chem. Int. Ed., 2019, 58, 14578–14583. 26 J. Xu, E. Gu, Z. Zhang, Z. Xu, Y. Xu, Y. Du, X. Zhu and X. Zhou, J. Colloid Interface Sci., 2020, 567, 84–91. 27 K. Saravanan, C. W. Mason, A. Rudola, K. H. Wong and P. Balaya, Adv. Energy Mater., 2013, 3, 444–450. 28 W. Ren, Z. Zheng, C. Xu, C. Niu, Q. Wei, Q. An, K. Zhao, M. Yan, M. Qin and L. Mai, Nano Energy, 2016, 25, 145–153. 29 D. T. Pham, T. T. Vu, S. Kim, B. Sambandam, V. Mathew, J. Lim and J. Kim, Adv. Energy Mater., 2019, 9, 1900710. 30 V. Soundharrajan, B. Sambandam, S. Kim, M. H. Alfaruqi, D. Y. Putro, J. Jo, S. Kim, V. Mathew, Y.-K. Sun and J. Kim, Nano Lett., 2018, 18, 145–153. 31 P. Giannozzi, S. Baroni, N. Bonini, M. Calandra, R. Car, C. Cavazzoni, D. Ceresoli, G. L. Chiarotti, M. Cococcioni, I. Dabo, A. Dal Corso, S. De Gironcoli, S. Fabris, G. Fratesi, R. Gebauer, U. Gerstmann, C. Gougoussis, A. Kokalj, M. Lazzeri, L. Martin-Samos, N. Marzari, F. Mauri, R. Mazzarello, S. Paolini, A. Pasquarello, L. Paulatto, C. Sbraccia, S. Scandolo, G. Sclauzero, A. P. Seitsonen, A. Smogunov, P. Umari and R. M. Wentzcovitch, J. Phys. Condens. Matter, 2009, 21, 395502. 32 J. P. Perdew, K. Burke and M. Ernzerhof, Phys. Rev. Lett., 1996, 77, 3865–3868. 33 A. Jain, G. Hautier, C. J. Moore, S. Ping Ong, C. C. Fischer, T. Mueller, K. A. Persson and G. Ceder, Comput. Mater. Sci., 2011, 50, 2295–2310. 34 J. Gim, V. Mathew, J. Lim, J. Song, S. Baek, J. Kang, D. Ahn, S. J. Song, H. Yoon and J. Kim, Sci. Rep., 2012, 2, 946. J. Mater. Chem. A, 2020, 8, 12055–12068 | 12067 View Article Online Published on 29 May 2020. Downloaded by CHONNAM NATIONAL UNIVERSITY on 9/1/2020 6:55:24 AM. Journal of Materials Chemistry A 35 J. Song, S. Park, S. Kim, V. Mathew, M. H. Alfaruqi, J. Jo and J. Kim, ACS Sustain. Chem. Eng., 2019, 7, 18826–18834. 36 K. Momma and F. Izumi, J. Appl. Crystallogr., 2011, 44, 1272. 37 V. Soundharrajan, B. Sambandam, S. Kim, V. Mathew, J. Jo, S. Kim, J. Lee, S. Islam, K. Kim, Y.-K. Sun and J. Kim, ACS Energy Lett., 2018, 3, 1998. 38 D. Wang, Q. Liu, C. Chen, M. Li, X. Meng, X. Bie, Y. Wei, Y. Huang, F. Du, C. Wang and G. Chen, ACS Appl. Mater. Interfaces, 2016, 8, 2238–2246. 39 R. Klee, M. J. Aragón, P. Lavela, R. Alcántara and J. L. Tirado, ACS Appl. Mater. Interfaces, 2016, 8, 23151–23159. 40 B. Sambandam, V. Soundharrajan, J. Song, S. Kim, J. Jo, D. P. Tung, S. Kim, V. Mathew and J. Kim, Inorg. Chem. Front., 2016, 3, 1609–1615. 41 B. Sambandam, V. Soundharrajan, J. Song, S. Kim, J. Jo, P. T. Duong, S. Kim, V. Mathew and J. Kim, J. Power Sources, 2017, 350, 80–86. 42 V. Soundharrajan, B. Sambandam, J. Song, S. Kim, J. Jo, P. T. Duong, S. Kim, V. Mathew and J. Kim, J. Colloid Interface Sci., 2017, 501, 133–141. 43 U. Nisar, R. A. Shakoor, R. Essehli, R. Amin, B. Orayech, Z. Ahmad, P. R. Kumar, R. Kahraman, S. Al-Qaradawi and A. Soliman, Electrochim. Acta, 2018, 292, 98–106. 44 Q. An, F. Xiong, Q. Wei, J. Sheng, L. He, D. Ma, Y. Yao and L. Mai, Adv. Energy Mater., 2015, 5, 1401963. 45 B. Sambandam, V. Soundharrajan, S. Kim, M. H. Alfaruqi, J. Jo, S. Kim, V. Mathew, Y. Sun and J. Kim, J. Mater. Chem. A, 2018, 6, 15530–15539. 12068 | J. Mater. Chem. A, 2020, 8, 12055–12068 Paper 46 H. Gao, Y. Li, K. Park and J. B. Goodenough, Chem. Mater., 2016, 28, 6553–6559. 47 X. Chen, K. Du, Y. Lai, G. Shang, H. Li, Z. Xiao, Y. Chen, J. Li and Z. Zhang, J. Power Sources, 2017, 357, 164–172. 48 D. Wang, X. Bie, Q. Fu, D. Dixon, N. Bramnik, Y. S. Hu, F. Fauth, Y. Wei, H. Ehrenberg, G. Chen and F. Du, Nat. Commun., 2017, 8, 15888. 49 M. Chen, L. Chen, Z. Hu, Q. Liu, B. Zhang, Y. Hu, Q. Gu, J.-L. Wang, L.-Z. Wang, X. Guo, S.-L. Chou and S.-X. Dou, Adv. Mater., 2017, 29, 1605535. 50 S. Zhang, C. Deng and Y. Meng, J. Mater. Chem. A, 2014, 2, 20538–20544. 51 Y. Fang, Q. Liu, L. Xiao, Y. Rong, Y. Liu, Z. Chen, X. Ai, Y. Cao, H. Yang, J. Xie, C. Sun, X. Zhang, B. Aoun, X. Xing, X. Xiao and Y. Ren, Chem, 2018, 4, 1167–1180. 52 Z. Peng, Q. Wei, S. Tan, P. He, W. Luo, Q. An and L. Mai, Chem. Commun., 2018, 54, 4041–4044. 53 D. W. Dees, S. Kawauchi, D. P. Abraham and J. Prakash, J. Power Sources, 2009, 189, 263–268. 54 V. Soundharrajan, B. Sambandam, M. H. Alfaruqi, S. Kim, J. Jo, S. Kim, V. Mathew, Y. Sun and J. Kim, J. Mater. Chem. A, 2020, 8, 770–778. 55 W. Song, X. Ji, Z. Wu, Y. Zhu, Y. Yang, J. Chen, M. Jing, F. Li and C. E. Banks, J. Mater. Chem. A, 2014, 2, 5358–5362. 56 X. Rui, W. Sun, C. Wu, Y. Yu and Q. Yan, Adv. Mater., 2015, 27, 6670–6676. This journal is © The Royal Society of Chemistry 2020