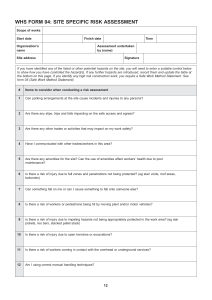

Hand-out on Module 1 Safe Work Principles Overview Hazard identification is a key part of any injury and illness prevention program within a business (especially small and medium sized companies). If hazards aren't identified, then they can't be solved. This tool is designed to help company leadership as well as workers practice more effectively identifying hazards. Tools Hazard identification can be broken into five key elements, four categories of identification tools and the prioritization step. Use the four types of tools to continuously identify hazards in your workplace. Once you have a list of hazards, continually evaluate and prioritize that list based on severity and exposure, mitigating as many hazards as possible. 1) Collect Information Review all information you may already have available to find hazards that have already been identified by others. Examples: Equipment manuals Safety data sheets Inspection reports Insurance reports Past incident data Relevant OSHA data Consultation reports 2) Inspect and Observe Inspect equipment and work areas when not in operation, using common sense and drawing on the knowledge of the operators to identify potential hazards. Be sure to observe processes in action as well; doing so may uncover additional hazards that would not be otherwise obvious. 3) Involve Workers Often, talking to your workers and listening to their feedback is the most effective way to quickly find hazards. Be sure to stay engaged with them and listen closely, as they may not always know that they are describing a hazard. 4) Investigate Incidents Although our goal is zero incidents, when one happens, it is important to take that as an opportunity to learn about hazards that may have been overlooked. Investigate to find true root causes and address systemic issues. 5) Prioritize Evaluate the hazards you have identified and mitigate the most hazardous first. Hazards can be assessed both in terms of severity (how bad is the potential outcome) and exposure (how likely is an occurrence). Typically, a combination of these two factors plays into the prioritization of mitigations. Page | 1 Hand-out on Module 1 The principles for workplace safety are as follows: 1. We value human life and well-being above all else and take action accordingly. 2. All incidents, injuries and workplace illnesses are preventable. 3. We are personally accountable for our own – and collectively responsible for each other’s – safety. 4. By committing to safety first, we advance our goals for quality, cost and schedule. Safety Signs Safety signs play a significant role in facility organisation to alert employees to potential hazards, simply provide directions, restricting smoking areas and restricting access or observing unsafe environments. When must safety signs be used? Safety signs must be used whenever a hazard or danger cannot be avoided adequately or reduced in another way. Before installing safety signs an employer should examine whether the hazard can be avoided or reduced by collective precautions (precautions that protect everybody) or safer ways of doing the work. What types of safety signs are there? A safety sign provides information about safety or health and can be a signboard, colour, acoustic signal, verbal communication, or hand signal. What is a signboard? A signboard is a sign that provides information or instruction using a combination of shape, colour and symbols but excludes information in writing. Why must safety signboards not contain text? Safety signboards should not contain text. This is because the symbols or pictograms on a signboard are intended to be understood, independently of the language ability of the worker viewing it. Page | 2 Hand-out on Module 1 How will workers understand the meaning of safety signs? Employers must provide information to employees on the meaning and requirements of any signs used in the workplace, especially where text on supplementary signboards is used. Can any text be included on a safety sign? Safety signboards put in place after 1 November 2007 should not contain text. Text may be included on a supplementary signboard provided that it does not adversely affect the effectiveness of the safety signboard. What is a Supplementary Signboard? A supplementary signboard (often with text) is used to give clarity to a signboard. A signboard and supplementary signboard can be located on one "carrier". A carrier could be a single sheet of metal, plywood, laminated plastic or other material as might be appropriate to a location. How will workers understand the meaning of safety signs? Employers must provide information to employees on the meaning and requirements of any signs used in the workplace, especially where text on supplementary signboards is used. Do existing safety signs containing text have to be replaced? Where a signboard is already in place before 1 November 2007 and it meets all the requirements of Part 7 and Schedule 9 to the General Application Regulations 2007, except that it contains text, an employer may leave that signboard in place until 1 January 2011. What colours and shapes should be used on safety signboards? Red for prohibition Yellow for caution Green for positive action Blue for mandatory actions O Discs for prohibitions and instructions Δ Triangles for warnings □ Squares and rectangles for emergency and information signs Manual Handling Operations are any transporting or supporting of a load (including the lifting, putting down, pushing, pulling, carrying or moving thereof) by hand or bodily force. Page | 3 Hand-out on Module 1 Identify hazards In order to control workplace hazards and eliminate or reduce the risk, you should take the following steps: identify the hazard by carrying out a workplace risk assessment; determine how employees might be at risk; evaluate the risks; record and review hazards at least annually, or earlier if something changes. Report hazards If you are aware of a hazard in your workplace, you should report it promptly to your supervisor, employer or health and safety representative. Once a hazard has been identified, your employer and/or supervisor has a duty to assess the problem and eliminate any hazard that could injure workers Page | 4