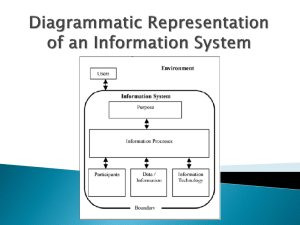

BTMP 2233 Quality Management 1.0 Acknowledgement We would like to express our greatest appreciation to those who have helped and supported us throughout our report with the title, Quality Management of Kentucky Fried Chicken (KFC) in our Quality Management subject. We are very grateful to our lecturer, Dr. Mohd Syaiful Rizal Bin Abdul Hamid for his continuous advice, support and guidelines for our report, from initial simple advices through ongoing advice and encouragement on how to complete our report. A significant thanks goes to every group members who’ve helped each other in completing the report, and exchanging our ideas and thoughts in our report with easier and more accurate ways to present our research on our report. We would also like to wish a very sincere thank you to our parents for their continuous support and encouraged us to complete this report. Their moral support to us is our motivation to complete this report fully in this limited time given. 1 BTMP 2233 Quality Management 2.0 Company Profile of KFC 2.1 KFC Restaurant in Malaysia The first KFC restaurant in Malaysia was established in 1st January in 1973 on Jalan Tunku Abdul Rahman according to ''Malaysia Fact book". Today there are more than 500 KFC Restaurants nationwide and still counting. Great tasting chicken has become synonymous with KFC and has been enjoyed by Malaysians ever since. In fact, KFC Malaysia has developed a distinctive Malaysian personality of its own.Malaysia is strictly toward the quality management and Halal policy presence in KFC’s Malaysia. 2.2 KFC Restaurant in Melaka Our group had conducted an analysis on KFC at Batu Berendam which located at No. 35, Jalan BBP 1 Taman Batu Berendam Putra 75350 Melaka to further understand about the quality management of KFC. . Below are principles of KFC: (1) Our Passion: “To satisfy our customers every time they visit our restaurants and to doit better than our competitors”. (2) Our Formula for Success: “People capability comes first - satisfied customers and profitability follow”. (3) How We Lead: “Know and drive the business, and build and align teams”. (4) How We Win: “Be the best at providing customers with branded restaurant choice and branded products”. (5) How We Work Together: “Our leadership principles”. 2 BTMP 2233 Quality Management 3.0 Research Summary Questions: 1. What are the main dimension of Quality Management in KFC? 2. Which area will be your company focus on in doing quality analysis 3. What do you do to improve the quality of the product or services? 4. What are the techniques or tools do you used in improving the quality? 5. Why do you think your product is in very good quality? 6. What is the difficult part in order to improve your quality management? 7. What is your plan to do to improve your quality of product? 8. Where do you get the idea to improve the quality of your product? 9. Is the quality of product or services, or quality of management in the company most important? 3.1 Dimension of Quality Management in KFC Eight dimensions of product quality management can be used at a strategic level to analyze quality characteristics by Garvin: Managing Quality (1988). Through understanding the trade-offs desired by the customers among these dimensions can help build a competitive advantage to company. Dimension of quality management in KFC World as well as KFC Malaysia plays essential and prominent role to assure the quality of KFC to be ratified and endorses as qualified as possible by the customers as well as their accreditors. There are eight main dimensions of quality management in KFC which will be conveyed as follows: Performance Dimension Performance refers to a product’s primary operating characteristics. Since KFC as a restaurant business, the grading of materials and resources in KFC is complying with performance dimension. Besides, friendliness and courtesy of the sales personnel, officers and waiters are also important to support the brand. Aesthetic Dimension Aesthetics is the subjective dimension indicating the kind of response a user has to a product. Thus, KFC company design how the layout facility, outlets cleanliness, 3 BTMP 2233 Quality Management interior design as well as the food packaging to satisfy every individual’s personal preference. Reliability Dimension Reliability is the likelihood that a product will not fail within a specific time period. The reliability includes the ability of KFC’s machine to be reliable into certain period and the food services are well done by right people. KFC will provide training for every franchisor and carry out periodic checking the status of machines. Conformance Dimension Conformance is the precision with which the product or service meets the specific standard. This is the most essential dimension for KFC’s customers since this is tangibly measure the how well KFC’s products and services conform with customer delight and expectations. Thus, normally survey will carry out to evaluate the performance. Durability Dimension Durability measures the length of a product’s life. KFC’s durability for their processing machine such as frying machine, frozen materials are very important to be kept, since it determines their quality of maintaining their capitals. Perceived Quality Dimension Perceived Quality is the quality attributed to a good or service based on indirect measures. KFC is ratified by ISO 9000 because their sustainable qualified quality of product and services which they provide. Thus, ISO 9000 could continuously support KFC perceived quality dimension. Serviceability Dimension Serviceability is the speed with which the product can be put into service when it breaks down, as well as the competence and the behaviour of the serviceperson. KFC’s is considered as fast handler of customer problem about the service as well as product complaints. They do provided customers feedback via online and the speed for respond is fast and effective. 4 BTMP 2233 Quality Management 3.2 Product Quality Analysis KFC Nutritional Data Analysis Product Name Fiery Grilled Drum Pc Popcorn Chicken Chicken Snacker Hot & Crispy Chicken Drum pcs Hot wings Boneless Chicken Strips Chicken Zinger Burger (without cheese ) Toasted Twister Avera Energ ge y Portio (kcal) n Carbo hydra te (g) Protei n (g) Total Fat (g) MUF A (g) PUFA (g) Sat. Fat (g) Sodiu m (g) 77.3 g 131.7 0.52 19.43 5.77 2.78 1.30 1.69 0.61 64 g 273.4 20.45 11.67 16.10 7.04 1.94 7.04 0.63 257.5 31.61 12.68 8.93 3.03 3.12 2.78 0.50 246.0 7.68 17.83 16.00 7.43 2.48 6.08 0.51 342.3 8.44 25.48 22.96 9.93 4.56 8.46 1.08 353.7 16.93 32.14 17.48 6.86 3.30 7.31 0.76 195.8 g 463.0 42.63 25.20 21.30 7.56 7.15 6.60 0.97 204 g 455.1 59.41 19.66 15.42 5.37 4.10 5.96 1.26 105.3 g 91 g 110 g3 pcs 138 g-3 pcs) Above data briefly show the nutrition of the food sold by KFC. KFC always ensure their food nutrition by ensuring the combination of food contain balancing diet according to human need. Raw materials KFC use top quality raw materials from reputable suppliers like Ayamas Region Food. Ayamas is monitored closely by Department of Veterinary Service and has obtained the VHM (Veterinary Health Mark) Logo. It is also an ISO 9001 certificated company. All Ayamas chickens are slaughtered by personal certified by Jabatan Agama Islam Selangor to ensure Halal procedures are met. All raw materials supplier are also required to submit a statutory declaration to confirm that they comply with Halal requirements in relation to the manufacturing process, storage and transportation of product supplied. 5 BTMP 2233 Quality Management Compliance with Halal Foundation Halal food is food that complies with Islamic Law or Shariah. Halal stipulates that food consumed to be: - Derived from animals that are permissible and slaughtered according to Islamic Law. - Free from any forbidden parts of animal origin - Free from anything regarded as filth under Islamic law - Hygienic - Not harmful to health - Imported Products All imported products are certified Halal by the Islamic authorities in the source country in order to meet and comply with the legislation of the Islamic countries where only Halal products are permitted for import. Compliance with JAKIM (Department of Islamic Development Malaysia) JAKIM Malaysia issues one council which regulates about the halal products and foods presence in Malaysia. The council is called QSR Brands Shariah Advisory council which strictly and stringently monitors the overall flow and chain of halal food and product manufacturing processes to assure and ensure the Halal compliance with JAKIM’s Halal Certification Regulation. There are two way of controls that assure the Halal compliance of locally manufactured products by conducting Internal Control and External Certification. The internal controls must ascertain that all of KFC’s products in Malaysia must conform to Halal requirements, apart from obtaining Halal Food Certification for KFC’s internal operations. Internal controls of the raw materials procurement, manufacturing, packaging, storage, transportation and utensils. The Halal Certification Process - Locally-Manufactured Products by JAKIM 6 BTMP 2233 Quality Management Halal Compliance Control in KFC’s Manufactured Imported Products 3.3 Supplier quality analysis of KFC Suppliers’ performances are constantly monitored through regular submission of quality reports. KFC food technologists also conduct quarterly QA evaluations on their in-house suppliers. They use top quality raw materials from reputable suppliers such as Nestle, UBF, Kerry Ingredients, LambWeston, Simplot, McCain and Jomalina, as well as from their inhouse suppliers such as Ayamas, Region Food, KFC Bakery and KFC Commissary. KFC chicken supplier Ayamas is monitored closely by Department of Veterinary Service and has obtained the VHM (Veterinary Health Mark) Logo. It is also an ISO 9001 certified company. All Ayamas chickens are slaughtered by personnel certified by Jabatan Agama Islam Selangor to ensure Halal procedures are met. In house inspection and control of KFC Inspection: It is mean of ensuring that an operation of producing at the quality level expected. Its goal is to detect a bad process immediately. When and where to inspect: Deciding when and where to inspect depends on the type of process and the value added at each stage. Inspection can take place at any of the following points, such as: At the supplier’s plant while the supplier is producing. At the facility upon the receipt of good from the supplier. Before costly. Before delivery to the customer and at the point of customer contact. 7 BTMP 2233 Quality Management During the step by step production process. When production or service is complete. Quality control begins from the supply of all the raw materials. KFC conduct an annual supplier audit, namely the STAR Audit, which is a YUM proprietary programme, similar in many ways to the ISO approach. The STAR Audit comprises two versions; the Food Safety and the Quality Systems Audits. The STAR Audit is either conducted by a third party international auditing company appointed by YUM or our very own team of professional food technologists from the KFC Quality Assurance Department. ISO 9001 certification ISO 9001 is the registrar and international standard requirement for management systems implemented by any organisation and sector of activity. It is applying for the processes that an organisation employs to realise its products or services by accomplishes its work and meets the customers’ requirements. ISO 9001 does not deal with product or service quality issues. ISO 9001 is all about management of processes and procedures. Veterinarian health logo Veterinary Health Mark Logo KFC chicken supplier Ayamas is monitored closely by Department of Veterinary Service and has obtained the VHM (Veterinary Health Mark) Logo. It is also an ISO 9001 certified company. All Ayamas chickens are slaughtered by personnel certified by Jabatan Agama Islam Selangor to ensure Halal procedures are met. KFC VETERINARY INSPECTED LOGO 8 AYAMAS LOGO BTMP 2233 Quality Management Food Safety Quality in KFC HACCP Programme KFC established a Hazard Analysis Critical Control Point (HACCP) Programme for KFC restaurants. HACCP is a management system for the assurance of food safety. The process includes identifying, evaluating and controlling hazards i.e. physical, biological and chemical to ensure food safety. It is applied from receiving of raw materials at their restaurant until serving to customers. KFC KLCC has been audited and certified by a reputable certification body since 2005. All the established Critical Control Points (CCPs) are included in their Daily Operations Checklist which is used by all the KFC restaurants in the country. KFC HACCP Logo 3.4 Restaurant Quality Analysis Personal hygiene KFC Malaysia daily operations manual clearly highlights each step of the sanitation procedure to ensure strict compliance to the KFC requirement. Each staff has to undergo the Food Handler’s Course conducted internally by KFC which is recognized by the Ministry of Health. KFC Malaysia have implemented a hand washing procedure to ensure each staff washes his/her hands at least once every hour and whenever necessary. The procedures include wetting hands first, then rubbing the hands together, fingers between fingers, around the wrist and up to the elbow with liquid antibacterial hand soap, for 30 seconds. Then the hands are rinsed with clean water under the handsfree tap, and dried with single-use paper towels. No bare hands are allowed to touch any finished products. Instead, KFC constantly stress on the importance of using disposable gloves, sanitized scoops or tongs. All KFC restaurant teams including managers are immunized against Typhoid upon employment. Besides, the product safety is also very important for KFC. KFC took their products well above the minimum temperature recommended by WHO. KFC has developed standards procedure that 9 BTMP 2233 Quality Management would minimize risk of cross contamination between raw and products that ready to eat. KFC provide information on then nutritional values of KFC products to assist customers on planning a wholesome and balanced meal. CHAMPS Concept The main attributes for KFC restaurant excellence are CHAMPS. C is for clean restaurants, to provide clean environment for customers having their meals. H is for hospitable employees, to provide greet and serve customers always with a smile. A is for accurate orders, to provide accurate order as possible as to prevent bad impression. M is for maintained facilities, to provide nice looking restaurant on the inside and the outside, being sure the lights work and the building is in good repair. P is for product quality, to provide hot and fresh product to customers. Last, S is for speed of service, to provide as fast as possible service and product to customers. CHAMPS Recognition Specialist conducts regular evaluations in every KFC restaurants throughout the country. The evaluation covers all aspects of CHAMPS including the cleanliness and sanitation of the premises and equipment, personal hygiene, hospitality as well as the friendliness in service, accuracy in the serving order, good maintenance, product quality standards and speed of service. For example, every KFC restaurants throughout the country used the CHAMPS Concept to ensure the food served to customers is fresh and safe. KFC cook their products well above the minimum temperature recommended by WHO. KFC have developed standard procedure that would minimize risk of cross contamination between raw and ready-to-eat products. Besides, KFC provide also information on the nutritional values of KFC products to assist their customers in planning a wholesome and balanced meal. For frying all of their products, we use nonhydrogenated palm oil that contains insignificant amount of trans fat and it is 100% cholesterol free. The CHAMPS Concept makes the KFC restaurant to gain the respect and good reputation from the customers because this concept is the social responsibility undermines businesses’ profitability goal. KFC have set up a Mystery Customer Program known as CHAMPSCHECK which evaluates customers experience in every KFC restaurants. They appointed a reputable surveillance company to check against the CHAMPS concept. Every restaurant is subjected to a visit by a Mystery Customer and the dine-in / take-away experience is evaluated and scored. KFC sets a minimum standard of 90% as passing score for this evaluation. Feedbacks taken from this evaluation is used and studied for continuous improvement in their restaurants. This 10 BTMP 2233 Quality Management actually helps in generating profit through customer loyalty and good company image. For Kentucky Fried Chicken, the company must be able to ensure that the products that they offer are healthy and nutritional, so as to ensure also that their gain customer trust, loyalty and respect. Maintenance and Convenient KFC Malaysia has become very populous and well known since 1980s. The outlets are mostly located in the strategic area where the customers can reach those outlets as well as possible. Thus, strategic locations of the outlets become a competitive advantage of KFC. Besides, the KFCs outlets in Malaysia have reached the total number of approximately more than 500 outlets. It is easy and convenient for customers to reach the KFC outlets. Maintenance of KFC will focus on the Equipment Collectramatic. Fryer Collectramatic Fryer was machine that use to fried chicken in KFC. For each time of used of this equipment, there will a small piece of chicken and fla (chicken crust) left in fryer. Each days, in KFC, for one Collectramatic Fryer, it been used about 60 to 70 times a day. For sure there is a lot of ‘kerak ayam’ will be left inside the fryer. If there are too many chicken crusts, it will affect the efficiency and performance of machine. So to ensure collectramatic fryer well perform for each time they use it, once a day, KFC will clean up all equipment, machine and tools inside KFC. Cleanliness Most KFC outlets have fallen way below the standards when it comes to cleanliness and is characterized by distinct distasteful smell rather than the aroma of freshly friend chicken. This phenomenon is due to reasons pointed below: Garbage of the entire outlet is thrown either right outside or very near the entrance therefore causing repulsion in customers entering the arena. KFC sees a high rate of customers every hour, with more guests coming in for breakfast, lunch or dinner more will be the need to maintain the floors and the bathrooms due to increased frequency of guests. 11 BTMP 2233 Quality Management 4.0 Quality Management Theory 4.1 Fishbone (Ishikawa) Diagram Fishbone diagram also called Cause–and–Effect Diagram or Ishikawa Diagram. The fishbone diagram identifies many possible causes for an effect or problem. It can be used to structure a brainstorming session. It immediately sorts ideas into useful categories. One can use a fishbone diagram when identifying possible causes for a problem especially when a team’s thinking tends to fall into ruts. Below is the example of service quality of KFC that mapped into fishbone diagram. Service Quality of KFC Fishbone Diagram People In people section there are motivated worker and work time division. For motivated worker, the people that work in one of the KFC branches are acting as a team to produce excellent working output by introducing the feast ceremony for workers on every closing time. Not only it helps in building strong motivation and relationship among workers, but it also help to prevent wasting unsold food. For work time division, the people that work in one of the KFC branches are working in their respective shift that had been agreed by both the worker and the manager. This 12 BTMP 2233 Quality Management helps in preventing workers from collapse or becoming too tired during working hour that will decrease the working output. Method In method section there are distance of supply and variety of meals. For distance of supply, the range between the supplier and the KFC branches are low and the distance between the two of them are near. This is to provide a faster supply, transportation from the supplier to the KFC branches to help the rotation of the products and to decrease the decay level of the supply during the transportation of the supply.For a variety of meals, the arrangement of the food in every meal is unique to provide a wide range of selection product and interesting meal set. The variety is included for every age respectively, and for a different number of customers such as Chicky Meal with toys are targeted for the children while the Kentucky Bucket with many foods are aimed to the customer that comes to their family. Measurement In method section there are responsiveness and food assurance. For responsiveness, every staff in the KFC branches is particularly responsive to provide a quick response for any questions and quick food preparation service. This helps in improving the customer satisfaction since most of the customers are in a rush with time due to work or other personal matter so to the majority of the customer the faster the service the better. For food assurance, the safety of every product in the KFC branches has been ensured since all raw material suppliers are required to submit a statutory declaration to confirm that they comply with Halal requirements in relation to the manufacturing process, storage and transportation of product supplied. The products of the KFC branches had been passed through The Halal Certification Process - LocallyManufactured Products that being endorsed by JAKIM. Machine In method section there are multiple machine and auto-timed machine. For multiple machine, every machine in the KFC branches are not only one, but there are many machines being provided. This is to ensure the faster food production with the usage of many machines simultaneously and also to prevent the machine from 13 BTMP 2233 Quality Management being broken so easily due to singular usage of only one machine to produce many foods. For auto-timed machine, every machine in the KFC branches has been provided with an auto-timed machine to ensure the accuracy of the cooked food time and to prevent overcooking. This helps in providing a food that not only fast to be served but also tasty due to being cooked with a suitable time period. Environment In method section there are courtesy and convenience. For courtesy, every staff in the KFC branches has been reminded to be very courtesy to every customer to provide an excellent service to the customer since the aim are not only to give quick service but also a nice service to the customer so that the customer do not feel reluctant to come again since they had already feel comfortable when coming to the KFC branches. For convenience, every machine in the KFC branches has been provided with an easy list of order and service so that every customer that comes will feel at ease and not stressed with the service. The convenience model that had been introduced by the KFC branches are the simple meal order selection, take away service, drive-thru service, food delivery service and fast food production provided. Materials In method section there are recipe secrecy and food from own farm. For recipe secrecy, every meal in the KFC branches according to guy, Ron Douglas, the author of the book America's Most Wanted Recipes (2011) just as most people already know has been kept their recipe as a secret to maintain the uniqueness of the product that do not have any substitutes that can have the same deliciousness as the product. This help in keeping the quality of the foods and the tasty feeling that cannot be duplicated so that the customer can feel satisfied with the food goodness and uniqueness. For food from own farm, every chicken food that has been produced in every KFC branches are taken from the KFC farm itself. This help to ensure the quality of the supply by growing the resource material itself so the power to choose the best quality of the material are in KFC own hands since the farm are also in their own and help to 14 BTMP 2233 Quality Management reduce the liability cost since the material can be produced itself and do not need to import or buy the material from others. 4.2 The Flowchart Diagram Quality control requires the business to create an environment in which both management and employees strive for perfection. This is done by training personnel, creating benchmarks for product quality, and testing products to check for statistically significant variations. KFC Quality control is started from the chain of supply of all the raw materials whether the raw materials can be taken from local manufactured resources and imported manufactured resources. There are several prominent and essential programs of quality control and quality assurance which are conducted by KFC to assure their quality to be the top quality of first fast-food chained in global scale especially in Malaysia. Below is customer dine-in, delivery and customer drive thru flowchart. Customer dine-in flowchart start greetings ask choices of order take order end give order payment repeat order Delivery flowchart customer calling order Drive thru flowchart 15 nearest outlet prepare food take out/ delivery feedback payment BTMP 2233 Quality Management customer drive thru prepare food order payment receive order 16 BTMP 2233 Quality Management 5.0 Comparison of Quality Management Tool and Technique 5.1 Comparison of Fishbone diagram Figure 5.1.1 Fishbone diagram used by KFC People Materials Work Methods Primary Cause Quality Characteristic Secondary Cause Environment Equipment Measurement Figure 5.1.2 Fishbone diagram learnt from Quality Management subject According to KFC’s fishbone diagram that used for manage the service quality. We found that the method that they used is exactly the same as we learned in quality management this subject as shown in Figure 5.1.1 and Figure 5.1.2. They use this Cause and Effect Diagram to point out the real problems that could lead in big problems 17 BTMP 2233 Quality Management and looking for the best solution to solve these problems. The area of the cause is based on the people, materials, methods, environment, equipment and measurement. 5.2 Comparison of Flow Chart diagram Customer dine-in flowchart start greetings ask choices of order take order end give order payment repeat order Delivery flowchart customer calling nearest outlet prepare food order take out/ delivery payment feedback Drive thru flowchart customer drive thru prepare food order payment receive order Figure 5.2.1 Flowchart used by KFC 18 BTMP 2233 Quality Management Figure 5.2.2 Flowchart learnt from Quality Management subject Compared with flowchart that learnt from Quality Management subject (Figure5.2.2), KFC flowchart (Figure 5.2.1) seems simpler and it split into 3 part for their process flow, which is split into Customer Dine-in, Delivery and Drive-thru flowchart. It doesn’t put all together as flowchart that we learnt. As a comparison, KFC flowchart is much easier to see and it’s clear to understand how the company process flow from the 3 flowchart provide above. It does same as what we studied for the flowchart in some aspect but KFC flow chart make it simpler than ordinary flowchart. Therefore, KFC flowchart has the slightly different structure with the normal flowchart in this comparison. 19 BTMP 2233 Quality Management 6.0 Discussion After we do the comparison, we define the quality tool management that use by KFC is almost same with we learn in the lecture. According from our observation, KFC just uses Cause-and-effect diagram and Stratification in their quality management. In the quality tool management have Seven Basic Tools of Quality that are designed for various sets of graphical techniques for identified as the most helpful in troubleshooting issues that related to quality. Seven Basic Tools of Quality are very basic because suitable use by people that with little formal training in statistics to solve the vast majority of quality-related issues. The seven tools are as shown below: Cause-and-effect diagram (also known as the "fishbone" or Ishikawa diagram) Check sheet Control chart Histogram Pareto chart Scatter diagram Flow chart Besides that, the Seven Basic Tools stand in contrast to more advanced statistical methods such as survey sampling, acceptance sampling, statistical hypothesis testing, design of experiments, multivariate analysis, and various methods developed in the field of operations research. So that, the Seven Basic Tools have almost been the guide for the Knowledge of Project Management as an example of a set of general tools that useful for planning or controlling project quality. 20 BTMP 2233 Quality Management Cause-and-effect diagram Pareto chart Check sheet Scatter diagram Control chart Flow Chart Histogram 21 BTMP 2233 Quality Management 7.0 Recommendation After the discussion, we recommend KFC should fully use all of the seven basic tools for their quality management because seven of quality management tools are related and it will more function than two of quality management tools. Our recommendation is KFC should start with the Control chart because Control chart is the graphs that used to study how a process changes over time in their quality management. After Control chart, Flowchart is used for depicting the nature and flow of the steps in a process or every station in KFC quality management because it promotes process understanding, provide tools for training, and identify problem areas and improvement opportunities. Thirdly, Check sheet is needed in a structured, prepared form for collecting and analyzing data and it also is a generic tool that can be adapted for a wide variety of purposes in every process of the flow chart. Next is Histogram, the histogram is the most commonly used graph for showing frequency distributions, or how often each different value in a set of data occurs in KFC quality management. After showing the frequency distribution of quality management, Scatter diagram is used to look for a relationship by graphs pairs of numerical data and one variable on each axis for their quality management. After gathering and doing the all data analysis, KFC should make a data conclude by using a Pareto chart for shows on a bar graph which factors are more significant. Lastly is Cause-and-effect diagram, KFC will identify many possible causes for an effect or problem and sorts ideas into useful categories by using the data that the analysis and collect before. Cause-and-effect diagram will help to define the main problem that needs to solve firstly and define the most effective and accurate solution. In conclusion, we hope that our recommendation can help the KFC enhance their quality management. 22 BTMP 2233 Quality Management 8.0 Conclusion KFC is a profitable and a successful venture in Malaysia. It has been accepted and appreciated all over Malaysia due to which there are over 500 flourishing branches each doing commendable business. Basic of the responsibilities of an organization is to make ensure that all their actions and business operations adhere to the ethical standards provided by the law. For Kentucky Fried Chicken, the company must be able to ensure that the products that they offer are healthy and nutritional, so as to ensure also that their gain customer trust, loyalty and respect. KFC must also give importance to the management issues to build a healthy atmosphere for their employees to work in ensuring best quality and excellent service and also maintain customer-relationship. The main quality analysis practiced by KFC is based on product, supplier and restaurant. The three aspects are basically according to dimension of the quality in conjunction with their principal in KFC. The tools and techniques that used by KFC are fishbone diagram (cause-and-effect diagram) and flowchart. Comparison of Quality Management theory with real practice of KFC has shown similarity in fishbone diagram and slightly different in flowchart. It is recommended to fully use all of the seven basic tools for their quality management which are Cause-and-effect diagram, Check sheet, Control chart, Histogram, Pareto chart, Scatter diagram and Flow chart. It will definitely more effective than using two of quality management tools. 23 BTMP 2233 Quality Management 9.0 Reference 1. Internet sources QSR Brands (M) Holdings Sdn Bhd (2014).Quality Assurance [ONLINE] Available at: http://www.kfc.com.my/quality-assurance/.[Last Accessed 04/05/2014]. (2014). KFC Nutrition Information, Calories, Allergens. [ONLINE] Available at: http://www.nutritionix.com/kfc/menu. [Last Accessed 03/05/2014]. Anas Munir (2014). Quality Planning and Control. [ONLINE] Available at: http://www.slideshare.net/fanaticanas/report-qpc. [Last Accessed 29/04/2014]. 2. Book sources S.Thomas Foster, (2012). Managing Quality Integrating the Supply Chain. 5th ed. e.g. England: Prentice Hall 24 BTMP 2233 Quality Management TABLE OF CONTENT TITLE PAGES 1.0 Acknowledgement 1 2.0 Company Profile of KFC 2 2.1 KFC Restaurant in Malaysia 2 2.2 KFC Restaurant in Melaka 2 3.0 Research Summary 3 3.1 Dimension of Quality Management in KFC 3 3.2 Product Quality Analysis 5 3.3 Supplier Quality Analysis 7 3.4 Restaurant Quality Analysis 9 4.0 Quality Management Theory 12 4.1 Fishbone Diagram 12 4.2 Flowchart Diagram 15 5.0 Comparison of Quality Management Tool and Technique 17 5.1 Comparison of Fishbone diagram 17 5.2 Comparison of Flow Chart diagram 18 6.0 Discussion 20 7.0 Recommendation 22 8.0 Conclusion 23 9.0 References 24 25 BTMP 2233 Quality Management QUALITY MANAGEMENT BTMP 2233 Quality Management of Kentucky Fried Chicken (KFC) Bachelor of Technology Management (Innovation) Faculty of Technology Management and Technopreneurship Prepared for: Dr. Mohd Syaiful Rizal Bin Abdul Hamid Prepared by: NAME MATRIC NO SIAH JIA WEN CHIEW THIAM HUAT LOH CHAI LING FARHAN ISMAT BIN JAMALLUDIN MICHELLE VOON XIN YING MUHAMMAD SYAHIR BIN MOHD SANI SAN CHEE HOU TERENCE TAN KAH HAW OMAR SAIFUDDIN BIN AHMAD BASHIR MUHAMMAD IHSAN BIN YUSRI B061210183 B061210003 B061210093 B061210019 B061210009 B061210092 B061210064 B061210128 B061210136 B061210071 Date of Submission: 13 MAY 2014 26