RDSO Specification: Integrated Passenger Information System

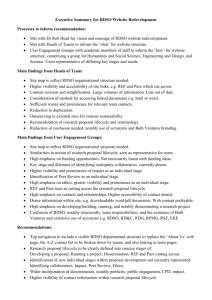

advertisement