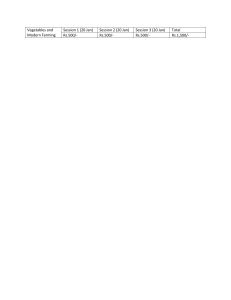

Topic: Modern approaches to improve the post-harvest life of horticultural commodities. Submitted by: Taj Nabi (17-arid-4776) Submitted to: Dr. Irfan Date of submission: 5th June, 2020 BSc (Hons) Agriculture Faculty of food and crop sciences. Department of horticulture 6th semester Pir Meher Ali Shah Arid Agriculture University Rawalpindi. 1 Introduction: The total vegetable and fruit production in the world is 486 million and 392 million tons. About 30-40% of fruits and vegetables are lost due to lack of post-harvest handling. The horticultural commodities are perishable products that are are diversified in terms of form, composition and in their general appearance due to which commodity requirement for improved post-harvest life also vary The horticultural commodities in their fresh form contain higher percentage of water due to which they are subjected to deterioration and mechanical harm. The commodities are also exposed to the immense spread of diseases caused by fungi, bacteria and viral diseases. The internal causes for the deterioration of produce are respiration rate, ethylene production, rate of change in color, texture, flavor, nutritive value, water stress and sprouting. The factors affecting shelf life of fruits and vegetables are classified as: 1:Intrinsic factors: These are the possession of final produce and affected by genetic makeup of crop and cultural practices. 2:Extrinsic factors: These are those factors that a product come across when it moves through a food chain. These include temperature, relative humidity, light control during processing, storage, distribution and composition of atmosphere within packaging and consumer handling is to be done. The application of different post-harvest measure result in the reduction of post-harvest losses of horticulture commodities by maintaining their quality which results in increased shelf life. These measure include pre-cooling, heating, coating, ethylene treatment, irradiation, decontamination, chemical treatment etc. Approaches to extend the shelf life of fruits and vegetables: Cooling: Low temperature: It is an important approach to preserve the horticultural commodity especially the fruit and vegetables. Low temperature results in the reduction in respiration rate, ethylene production and its action, cause an increase in the resistivity of tissue towards ethylene action, delay senescence, control the pest and disease infestation. These all result in the extension of post-harvest life of fruits and vegetables. 2 15℃ 0℃ 5℃ 10℃ 20℃ Storage of banana at different low temperatures Pre-cooling: It is done either before or after the packaging to remove the field heat. The methods of precooling include room cooling, forced-air cooling, hydro cooling, vacuum cooling, evaporative cooling, and top icing. All methods aim to preserve the products some time. Chilling injury: The sensitivity of horticultural crops vary to low temperature. The temperate and sub-tropical crops can withstand low temperature just above their freezing point. The range of temperature for chilling injury varies from 0-18℃ depending on the type of crop and their resistivity. The physiological changes concerned with chilling injury include an increase in respiration rate, ethylene production, activation energy, reduce photosynthetic activity, cellular changes and inactivation of important enzyme activity. Heating: Drying treatment: This strategy of heating is implemented to extend the shelf life of fruits and vegetables for the long term availability. It is mostly applied to extend the shelf life of bulb crops such as onion and garlic. This treatment results in the formation of a barrier on the surface which not only avoid the loss of water but also inhibit microbial infestation. This treatment is done at a temperature of 30℃ and 70% relative humidity for 7-10 days. Hot water treatment: The main purpose of this treatment is to get rid of microbes that are both pathogenic and spoilage causing on frits and vegetables. Spray machine is used to apply hot water on commodities. After harvesting the treatment with appropriate fungicide and along with hot water treatment is very effective in extending the shelf life of fruits and vegetables. The solution of Sulphur dioxide, ethanol, and sodium carbonate are heated at 45℃ and are applied to citrus to control green mold disease. 3 Vapor heat treatment: In this method of heating air saturated with water are used on products at 40–50 °C to kill insect pest and their larva as a quarantine measure. It involves a holding step when the interior temperature of the produce attain the desired temperature for specific time required for killing the insect. Then it is cooled either by air cooling or hydro-cooling. Radio frequency treatment: It is an integrated approach for the blanching of vegetables and as a quarantine measure for fruits. Radio-frequency is produced when alternating electric field is developed between electrodes where the product is placed. The molecules re-orient themselves, causing friction which results in rapid heating through the commodity. Coating: Fruits and vegetables naturally possess an upper waxy layer which act a as self defence. It function for the gaseous exchange and water loss. This layer is mainly lost during harvesting and post-harvest operations. Wax or coating provides a shiny appearance to fruits and vegetables and provide a barrier to insects attack. Wax is the primary material to be used a coating material. Edible coating are the preferable choice which provide a barrier to oxygen, insect and solute flow within the food. Edible coatings are the innovative and eco-friendly approach to extend the shelf life of horticultural commodities. In the present scenario there are four types of materials that are used as edible coatings viz. polysaccharides, resins, proteins, lipids or a mixture of these compounds. In case of lipids paraffin oil, mineral oil, and vegetable oil are used. while resins include shellac wood resin and coumarone indene resin. They play a role to conserve the color, texture and volatile components of fresh fruits and vegetables. However thick coating results in the formation of barrier between the internal and external environment by restricting the gaseous exchange and also in the conditions favorable for anaerobic respiration. There is a limitation for using lipid based coating for RTU products because of their effect on the taste and oily appearance. The treatment of edible coating results in the retention of 15% of carotene pigment in case of carrots and also retard surface whitening. Ethylene treatment and control: It is a natural gaseous ripening hormone. It is commercially used to accelerate the ripening process of fruits and to improve the color development in fruits and vegetables. At the same time it creates a problem such as softening of tissues, abscission, and lead to the opening of flowers. Its removal will result in the delay of ripening and senescence. It can be eliminated in several ways including ventilation, cooling, use of scrubber and ethylene synthesis inhibitor. Smart fresh (1-methylcyclopropene ): 1-methylcyclopropene is an artificial cyclic olefin which hinders the ethylene binding receptor due to which ethylene is unable to perform its function properly. The application of 1- 4 methylcyclopropene on avocado results less weight loss and promote the retention of green color of avocado even after ripe stage. Its application control the pitting that occurs after harvesting, blue mold rot, reduce internal ethylene production. Control package of co release of ethanol and 1-MCP The application of 1-methylcyclopropene after harvesting operation will reduce the ethylene production in climacteric fruits. But the use of 1-methylcyclopropene have some limitation these include: Lack of uniformity in ripening Reduced flavor quality Irradiation: It is a physical approach which involve the use of gamma rays, x-rays, electrons and microwaves which are high energy and ionizing radiation on the horticultural commodities. The isotopes cobalt 60 or cesium 137 of gamma radiation is the most commonly used form of irradiation. Purpose of irradiation: For the prevent germination and sprouting in potatoes, onions and garlic, To disinfest by killing insects that infest grains, dried fruit, vegetables or nuts, To retard ripening and aging of fruits and vegetables, To prolong the shelf life and to prevent food-borne diseases in spices and herbs It is a quarantine measure for fruits and vegetables. The maximum range of dose of radiations to be applied is between 1 and 2 kGy. The commercial application of radiation to extend the shelf life of potatoes is very economical. Potential use of irradiation on the food crops: Type of food crop Perishable food Effect of irradiation Reduction in spoilage, mould growth and microorganism Reduce rehydration time, disinfestation of dehydrated fruits and spices Grains, fruit 5 Onions, carrots, Inhibits sprouting potatoes, garlic, ginger. Bananas, mangos, papayas, Delays ripening guavas, other non-citrus fruits Hinders sprouting Delay in ripening process. Food crops that can be irradiated Product White potatoes Spices Fruits Purpose Extend shelf life Decontamination Delay maturation Dose to be applied 0.2-0.5 0.05-0.15 Up to 1 Chemical treatments: Antimicrobial and anti-browning agents: The level of microbes and the various enzymatic factors have great impact on the post-harvest life of horticultural commodities. To extend post-harvest life of fruits and vegetables various antimicrobial and anti-browning agent are used including hydrogen peroxide (H2O2), peroxyacetic acid (PAA), organic acids, and electrolyzed water. Hydrogen peroxide possess bactericidal and inhibitory activity due to its oxidant nature and capacity to generate cytotoxic oxidizing species such as hydroxyl radicals. The disinfectant that are commonly used are chlorine based are cost effective. The treatment with hydrogen peroxide is posed to play a major role in extending the shelf life by eliminating natural microbial population in melons, oranges, apples, mangoes and grapes. Use of 5% hydrogen peroxide with acidic surfactants at 50 °C produced a 3 to 4 log reduction of nonpathogenic E. coli inoculated onto the surfaces of un-waxed ‘Golden Delicious’. In the current scenario the use of ascorbic acid is very economical against browning agents. Organic acids are applied to control browning caused by different enzymes results in the deterioration of fruits and vegetables. Chelating agent viz. sorbic acid, polycarboxylic acids, polyphosphates, macromolecules and ethylene diamine tetra-acetic acid (EDTA), are used for a variety of food processing applications. Nitric oxide: It is a multifunctional molecule which play a major role in various processes such as fruit ripening and senescence of fruits and vegetables. It is a new emerging technology to control the post-harvest losses in the fruits and vegetables. External application through the use of gas fumigation will help to reduce the ethylene production, rate of respiration, and ion linkage, reduce stress caused by oxidation, and promote the activity of antioxidant enzymes. Now a days it is used in combination with cold storage and modified storage conditions to improve or to extend the shelf life of horticultural commodities. 6 Calcium chloride: The main physiological disorder known as blossom rot is caused by calcium deficiency. And the other physiological disorders caused by calcium deficiency include These include bitter pit, cork spot, water core, and internal breakdown in apples, blossom end rot in tomatoes and melons, tipburn of cabbages, black heart of celery etc. To reduce physiological disorders and chilling injuries, to suppress the senescence and to improve storage and marketing life of fruits and vegetables it is better to apply calcium chloride. The application of calcium chloride after harvest can extend the storage life of pear up to 2 months, plum up to 4 weeks and apple up to 6 months at 0-2ºC with excellent color and quality. Ozone: The oxygen in its active form known as ozone is now an emerging innovative technique that is alternative to sanitizing agents. It is strong and ideal, germicide, sanitizer, sterilizer, antimicrobial, fungicide and deodorizer and detoxifying agent. It perform a function by oxidizing the ethylene. It most effective strategy than chlorine because it causes death to microorganisms in a shorter time, but because of its short half time, the water can become re-infected easily. The Occupational Health and Safety Act limits the exposure to gaseous ozone to a time weighted average of 0.1 ppm over 8 hr work day, and short-term exposure limit is 0.3 ppm for more than 10 minutes over 4 times work day. Modified atmospheric packaging: It involve the sealing of fruits and vegetables in a specialized sealing that is meant to improve the shelf life of that particular commodity. It involve the modification of oxygen and carbon dioxide within the atmosphere of packaging material. The purpose of using MAP is to reduce the respiration rate, oxidative decomposition and the spoilage in fruits and vegetables. Film packaging can reduce the moisture loss and keep the commodities in their fresh form and also supplement the refrigeration. Films that are commonly used for fresh fruits and vegetables include low-density polyethylene, poly-vinyl chloride, polypropylne, and polystyrene.The crops that cannot withstand chilling temperatures, high humidity, reduce oxygen and increased carbon dioxide are preferable to be stored within MAP to extend their life. It can also hinders senescence and browning reactions. It is mostly used for long term storage of apples, pear, kiwifruit, strawberries, banana, guava etc. Selection of MAP depends on: Type food Composition of food Deterioration factor Quality changes Shelf life requirement 7 Ultrasound: It is an innovative and a non-descriptive method to disinfest the fruits and vegetables and to improve their shelf life. Sound waves can be classified into three categories i.e. Supersonic (frequency< 20 Hz) Audible (20 Hz <frequency>20 kHz) Ultrasound (frequency>20 kHz. Effect of ultrasound on strawberry quality with a power levels of 30-60W for 5-10 min treatment time has resulted in improved quality and can be used to enhance the shelf life of the product. Ultrasound waves (frequency range of 20 Hz to 18 kHz) disrupt biological structures and systems and when applied at sufficient intensity can cause cell death. Therefore it is applied in a very low concentration to extend the shelf life of horticultural commodities. Ultrasound alone is not effective against microorganism; hence it should be applied in combination with other treatments such as heat, pressure and chemical treatment will enhance its efficiency. Treatment effect on the shelf life of some important fruit crops: Fruit crop Treatments Shelf life Apple gamma irradiation (200–400 Gy)+ biocontrol agent MCP (0.5µl/l)+ polyethylene 1-MCP (1000 nL/ L for 4 h at 25 °C)+ non-perforated PE (MAP) UV-C and neutral electrolyzed water (pH 7.2, ORP 814 mV, and 300 mg L−1 of free chlorine) MAP+essential oil H2O2+hotwater+ hydrogen peroxide followed by potassium phosphate Dipping in hot 0·5% Na2S2O5+ packaging in boxes overwrapped with stretch PVC film Methyl jasmonateMJ at 10−5 M+ MAP (3–5 kPa O2 and 6–9 kPa CO2) at 10°C Ultrasound (40 kHz, 8.8 W/L, 10 min)+ salicylic acid (0.05 mM) Improved quality in 3 months storage period than control 58 days 100days Banana Dates Grape Lemon Mango Papaya Peach 8 30 days 56 days Control of mold and rot Delayed ripening 14-32 days 6 days Pear Gamma dose (1.5-1.7 kGy)+refrigerated storage (3±1 °C, RH 80%) 0.1 MPa pressure+ low temperature (13 °C) Tomato 8 days extension Retention of firmness after 5 days Approaches to extend the shelf life of ornamentals: In ornamentals the main response of ethylene is the reduction in the longevity and the display life of flower. There are two methods by witch ethylene production within plants can be managed: By treating the plants in a way that stop the production of ethylene By blocking the ethylene synthesis pathway The main strategy is to protect flowers from any stress. And second strategy is the breeding og ornamental flowers to reduce the ethylene production. AVG (1-Aminoethoxyvinylglicine) and AOA (aminooxyacetic acid), which block the conversion SAM (S-adenosyl-metionin) to ACC (1-Aminocyclopropane-1-Carboxylic acid), are especially effective techniques. As a chemical treatment silver thiosulphate is the commercially used compound to reduce the ethylene production in ornamental plants. Now the use of 1-Methylcyclopropene (1-MCP) is very successful and innovative approach against ethylene production. Conclusion: The need for horticultural commodities is increasing day by day due to increasing population. To cope with current world population there is a need to emphasize on the post harvesting handling of horticultural commodities to reduce the losses caused by different extrinsic and intrinsic factors. To reduce such loses or to extend the post-harvest life of horticultural commodities there is various method like physical, chemical and gaseous methods employed. So there is need to use such techniques in a sustainable way along with standard operating procedures we can minimize the huge losses which are occurring in the current scenario. 9 References: Yahia, E. M., Barry-Ryan, C., & Dris, R. (2004). Treatments and techniques to minimise the postharvest losses of perishable food crops. In Production practices and quality `assessment of food crops (pp. 95-133). Springer, Dordrecht. Sandarani, M. D. J. C., Dasanayaka, D. C. M. C. K., & Jayasinghe, C. V. L. (2018). Strategies used to prolong the shelf life of fresh commodities. J. Agric. Sci. Food Res, 9, 1-6. Kader, A. A. (2013). Postharvest technology of horticultural crops-An overview from farm to fork. Ethiop. J. Appl. Sci. Technol, 1, 1-8. Ščetar, M., Kurek, M., & Galić, K. (2010). Trends in fruit and vegetable packaging–a review. Hrvatski časopis za prehrambenu tehnologiju, biotehnologiju i nutricionizam, 5(3-4), 6986. Mohapatra, D., Mishra, S., Giri, S., & Kar, A. (2013). Application of hurdles for extending the shelf life of fresh fruits. Trends in Post-Harvest Technology, 1, 37-54. Toivonen, P. M., Mitcham, E. J., & Terry, L. A. (2014). Postharvest care and the treatment of fruits and vegetables. In Horticulture: Plants for People and Places, Volume 1 (pp. 465-483). Springer, Dordrecht. Kusumaningrum, D., Lee, S. H., Lee, W. H., Mo, C., & Cho, B. K. (2015). A review of technologies to prolong the shelf life of fresh tropical fruits in Southeast Asia. Journal of Biosystems Engineering, 40(4), 345-358. Serek, M., Sisler, E. C., Frello, S., & Sriskandarajah, S. (2006). Postharvest technologies for extending the shelf life of ornamental crops. International Journal of Postharvest Technology and Innovation, 1(1), 69-75. 10