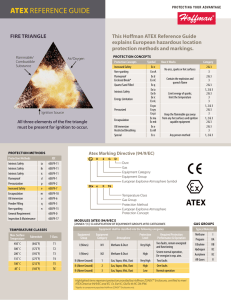

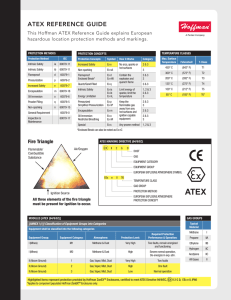

ATEX Reference Guide Fire Triangle This Hoffman ATEX Reference Guide explains European hazardous location protection methods and markings. Flammable/ Combustible Substance Protection concepts Air/Oxygen Protection Concepts Increased Safety Non-sparking Flameproof Enclosed Break* Quartz/Sand Filled Intrinsic Safety Energy Limitation Pressurized Ignition Source Encapsulation All three elements of the fire triangle must be present for ignition to occur. IEC Intrinsic Safety Intrinsic Safety Intrinsic Safety Flameproof Pressurization Increased Safety Encapsulation Oil Immersion Powder Filling Non-sparking General Requirement Inspection & Maintenance ia ib ic d p e m o q n How it Works No arcs, sparks or hot surfaces Contain the explosion and quench flame Limit energy of sparks; limit the temperature Keep the flammable gas away from any hot surfaces and ignition capable equipment Any proven method Category 2&3 3 2&3 3 2&3 1, 2 & 3 2&3 3 3 1, 2 & 3 2&3 3 1, 2 & 3 2&3 2&3 3 1, 2 & 3 Atex Marking Directive (94/9/EC) Protection Methods Protection Methods Oil Immersion Restricted Breathing Special Symbol Ex e Ex nA Ex d Ex nC Ex q Ex ia Ex ib Ex ic Ex nL Ex px Ex py Ex pz Ex ma Ex mb Ex o Ex nR Ex s 60079-11 60079-11 60079-11 60079-1 60079-2 60079-7 60079-18 60079-6 60079-5 60079-15 60079-0 60079-17 II 2 G D Dust Gas Equipment Category Equipment Group European Explosive Atmosphere Symbol EEx e II T6 Temperature Class Gas Group Protection Method European Explosive Atmosphere Protection Concept ATEX MODULES [ATEX (94/9/EC)] [ANNEX I (1)] Classification of Equipment Groups into Categories Equipment shall be classified into the following categories Temperature classes Max. Surface Temperature Fahrenheit T-Class 450˚ C 300˚ C 200˚ C 135˚ C 100˚ C 85˚ C (842˚F) (572˚F) (392˚F) (275˚F) (212˚F) (185˚F) T1 T2 T3 T4 T5 T6* Equipment Group Equipment Category I (Mines) M1 Methane & Dust Very High I (Mines) M2 Methane & Dust High II (Above Ground) II (Above Ground) II (Above Ground) 1 2 3 Gas, Vapor, Mist, Dust Gas, Vapor, Mist, Dust Gas, Vapor, Mist, Dust Atmosphere Protection Level Very High High Low Required Protection Performance & Operation Two faults, remain energized and functioning Severe normal operation, De-energize in exp. atm. Two faults One faults Normal operation Highlighted items represent protection provided by Hoffman ZONEX™ Enclosures, certified to meet ATEX Directive 94/9/EC and IEC Ex, Exe IIC, Gb/Ex tb IIIC Db IP66 *Applies to component populated Hoffman ZONEX™ Enclosures only. Gas Groups Typical Material Methane Propane Ethylene Hydrogen Acetylene All Gases I IIA IIB IIC IIC II ATEX Reference Guide Zones and Divisions Div 2 Zone 2 Vent Comparing Divisions, Zones & Categories Frequency of Occurrence Continuous Intermittent Periodically Abnormal Condition CEC, NEC Editions Division System Zone System Class I, CEC, NEC Category System ATEX Zone 0, 20 Category 1 Zone 1, 21 Category 2 Zone 2, 22 Category 3 Class I, Division 1 Class II, Division 1 Class I, Division 2 Class II, Division 2 Ingress Protection (IP) Codes First Number 1 Div 1 Zone 0 Div 1 Zone 1 Flammable Liquid or Dust 0 1 2 3 4 5 6 No Protection Objects Greater than 50mm Objects Greater than 12 mm Objects Greater than 2.5 mm Objects Greater than 1 mm Dust Protected Dust Tight Second Number 1 0 1 2 3 4 5 6 7 8 No Protection Vertically Dripping Water 75° to 90° F Dripping Water Sprayed Water Splashed Water Water Jets Powerful Water Jets Effects of Immersion Indefinite Immersion Enclosure Types Enclosure Type2,3 Intended Use 1 2 3 3R 3S 4 4X 5 6 6P 7 8 9 10 12 12K 13 Indoor use, limited amounts of falling dirt Indoor use, limited amounts of falling water and dirt Outdoor use, rain, sleet, wind blown dust, external formation of ice Outdoor use, rain, sleet, external formation of ice Outdoor use, rain, sleet, wind blown dust, external mechanisms operable when ice laden Indoor or outdoor use, wind blown dust and rain, splashing water, hose directed water, external formation of ice Indoor or outdoor use, wind blown dust and rain, splashing water, hose directed water, corrosion, external formation of ice Indoor use, settling airborne dust, falling dirt, non-corrosive liquids Indoor or outdoor use, hose directed water, temporary submersion, external formation of ice Indoor or outdoor use, hose directed water, prolonged submersion, external formation of ice Indoor use, Class I, Division 1, Groups A, B, C, and D hazardous locations, air-break equipment Indoor use, Class I, Division 1, Groups A, B, C, and D hazardous locations, oil-immersed equipment Indoor use, Class II, Division 1 Groups E, F, and G hazardous locations, air-break equipment Mining applications Indoor use, circulating dust, falling dirt, dripping noncorrosive liquids Indoor use, circulating dust, falling dirt, dripping noncorrosive liquids, provided with knockouts Indoor use, lint, dust, spraying of water, oil, and noncorrosive coolant Regional Headquarters North America Pentair Technical Products 2100 Hoffman Way Anoka, Minnesota 55303-1745 U.S.A. Tel: +1-763-421-2240 Brazil Pentair Technical Products (Taunus Metalurgica LTDA) Rua Joao Marcon, 165 18550.000 – Centro Boituva – SP Tel: +55 15 3363 9100 Europe Pentair Technical Products Langenalber Straße 96-100 75334 Straubenhardt, Germany Tel: +49 (0) 7082 794-0 Note: 1 Numbers can be replaced by ‘X’ when the characteristic number is not required Enclosure Types for US only 2 Enclosure Type can be converted to IP code rating; however, IP classified enclosures cannot be converted to Enclosure Type 3 China Pentair Technical Products 21st Floor of Cloud Nine Plaza No. 1118 West Yan‘an Road Changning District, Shanghai P.R. China Tel: +86 400 820 1133 Singapore Pentair Technical Products Hoffman Schroff Pte Ltd. 18 Boon Lay Way TradeHub 21, #04-110/111 Singapore 609966 Tel: +65 6795 2213 For worldwide locations, see pentairtechnicalproducts.com ©2010 Pentair Technical Products Tech-00057 B