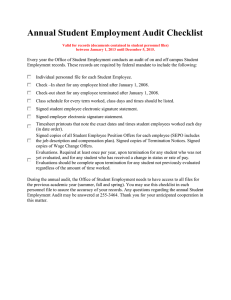

List of important documents (SOP’S) QUALITY ASSURANCE S/N 1 TITLE Good Laboratory Practice 2. Document Signatory in the Laboratory 3. Cleaning in the Laboratory and Glassware used in the Laboratory area 4. Workbook Procedure and Validation 5. Air and Environmental Contamination 6. Contract Manufacturing and Analysis 7 Product Complaints 8. Batch Review 9. Product Recall 10. Handling of Returned Drug Product 11. Preparation of Bench Solutions and Reagents 12. Preparation and Standardization of Volumetric Solutions and Reagents 13. Preparation of Media for Microbiological Use 14. Disposal of Reagents in the Laboratory 15. Receiving Manufacturing and Testing Instructions For New Process from Overseas 16. Documentation 17. Batch Documentation 18. Retesting and Re-sampling of Materials 19. Handling of Retention Samples 20. In-Process Inspection of Area pmgman - audit checklist 1 21. Identification of Raw Materials Before Weighing 22. In-process Control (General) 23. In-Process Control (Weighing) 24. In-Process Control (Mixing and Blending) 25. In- Process Control (Compression) 26. In-Process Control (Packaging) 27. Care of Instrument Room 28. Maintenance, Operation and Calibration of Weighing Balances 29. Calibration of Weighing Scales in the Plant 30. Maintenance and Calibration of Equipment and Laboratory Instruments 31. Maintenance, Calibration and Operation of Dissolution Rate Tester (Type DT6) 32. Operation and Maintenance of Tablet Hardness Tester 33. Validation Exercise 34. Validation Committee 35. Analytical Validation 36. Cleaning Validation 37. Retrospective Validation 38. Monitoring of Relative Humidity and Temperature (Procedure/Validation) 39. Stability Testing 40. Audit Check (Packaging) 41. Evaluating Out-of- Specification (OOS) Laboratory Results 42. Microbiological Control of Manufacturing pmgman - audit checklist 2 Environment 43. Microbial Analysis of Water Samples 44. Disinfection of the Floors and Surfaces in the Manufacturing Areas 45. Operating Instruction for various lab equipment 45. Validation Procedure for Autoclave 46. Tube Coagulase Test 47. Use and Care of Microscope 48. Keeping Reference Samples and Standard Cultures 49. Microbiological Examination of Washed Securitainers 50. Microbiological Tests for Sterility of Bottles 51. Sampling of Products for Microbiological Tests 52. Regulations of the Microbiology Laboratory 53. Use and Care of various lab equipments 54. Sampling Plan for Raw Materials & Auxiliaries 55. In-Process Control (Liquid Packaging) 56. Annual Product Review 57. Monitoring and Fumigation of the Manufacturing Areas 58. in-Process Control (Water) 59. Sanitization of Water Pipe lines & Storage Vessels 60. Release of Finished Products for Sale pmgman - audit checklist 3 WAREHOUSE S/N TITLE 1. Cleaning Procedure in Warehouse 2. Storage and Warehousing Conditions 3. Material and Equipment Handling Procedures 4. Receiving and Handling of Raw and Packaging Materials 5. Supply of Raw Materials to Other Party 6. Collection of Finished Goods 7. Dispatches of Finished Goods 8. Safety In Warehouse 9. Materials Returns Procedure 10. Storage and Materials Movement ( FIFO Principle ) 11. Air control sampling room pmgman - audit checklist 4 PRODUCTION AND PACKAGING S/N 1. TITLE Facilities in the Locker Room 2. Cleaning of the Changing Room 3. Painting of Facilities in the Factory (Production Areas) 4. Entry into Manufacturing Area 5. Preventing Contamination 6. Maintenance of Equipment 7. Fixing Manufacturing Parameter 8. Batch Identification 9. Manufacturing and Packaging Protocols 10. Yield 11. Coating Operations 12. Process Validation 13. Process Change 14. Re-processing 15. Retrospective Batch Review 16. Product Change 17. Recovered Materials/ Reprocessing 18. Removal of Waste from Production Department 19. Weighing Process 20. Material Flow 21. Manufacturing Procedures for Various Stages of Production 22. Manufacturing of New Drug products pmgman - audit checklist 5 23. Cleaning of oven 24. Transfer of Raw Materials 25. Cleaning of Manufacturing Utensils and other containers (each) 26. Cleaning of Stainless Steel containers 27 Cleaning of Floor Drainage Sinks 28 Cleaning Procedure for Different processing areas 29 Cleaning of Aluminium Pallets 30 Line Clearance and Line Release 31 Line Release for Production 32 Written Instructions for Packaging 33 General Hygiene For Packaging Staff 34 Removal of Packaging Waste 35 Packaging Plan 36 Operation of various Machines (individually) 37 Validation of various packaging machines 38 Mistake/Mix-Up/Contamination 39 Printing Exercise 40 Transfer of Finished Products 41 Line Release for Packaging Operations 42 Manual Packaging Line Operation 43 Batch Identification in Packaging 44 Yield Determination in Packaging pmgman - audit checklist 6 GENERAL S/N 1. TITLE Guidelines for Writing Standard Operating Procedure 2. G.M.P Committee 3. Working Conditions of Personnel 4. Training 5. Qualification of Newly Recruited Employees 6. Follow-up/Refresher Courses 7. Staff Clinic / first aid 8. Drug Safety 9. Guidelines for Self Inspection 10. Removal of Detergent Residue after Cleaning 11. Clearing of Septic Tanks 12. Control Procedure for Pest Control and Fumigation Materials 13. Pest Control and Fumigation Exercise 14. Destruction of Materials 15. Installation and Qualification of Equipment 16. Manufacturing Prescription 17. Suppliers’ Audit 18. General Principles: Change Handling Procedures 19. SOP Actualization Programme 20. Time Limits For Various Processes 21. Document Change Control & Actualization 22. Documentation: General Principles 23. Handling Deviations pmgman - audit checklist 7 24. Treatment of Personnel with Infectious Diseases 25. Returned Goods 26. Training on SOP 27. Protective Clothing Guidelines 28. Product Recall 29. Product Complaints 30. Maintenance and Calibration of Equipment pmgman - audit checklist 8 ENGINEERING S/N TITLE 1. Engineering Maintenance Programme 2. Preventive Maintenance 3. Preventive Maintenance Programme for the Plant Building 4. Lubrication 5. Cleaning and Maintenance of Air Filters in the Manufacturing area 6. Cleaning of the Generator Plant and the Room 7. Air Handling Units 8. Changes/Modification in the Air Handling Unit 9. Water Treatment Process and Plant Maintenance 10. Cold room Cleaning, Maintenance and Validation 11. Maintenance equipments 12. Boiler Operations 13. Cleaning of Drainage within Production & Packaging Area pmgman - audit checklist 9 LIST OF REQUIREMENTS 1. Personnel Details 2. Organogram 3. List of Products 4. List of Equipment for Production 5. List of Equipment for Quality Assurance/Control 6. Quality Policy 7. Sample Batch Manufacturing Records (BMR) 8. Evidence of Training 9. Evidence of Medical/Clinic Services 10. Evidence of Medical Check-up 11. Evidence of Fumigation & Pest Control 12. Evidence of Food Handling Certification 13. Evidence of Environment, Health and Safety (EHS) Policy pmgman - audit checklist 10 QUALITY AUDIT – CHECKLIST INSPECTION OF MANUFACTURING PLANT INTRODUCTION: This Quality Audit is performed on behalf of the Pharmaceutical Manufacturers Group of the Manufacturers Association of Nigeria (PMG-MAN). As an active member of the Group, we believe that every member company will maintain at least the minimum standard of the requirements of current Good Manufacturing Practices (GMP) and Good Laboratory Practices (GLP). The planning and effective performance of this audit is aimed at ensuring these minimum standards. The non-conformities detected during this audit must be corrected within the agreed time frame. pmgman - audit checklist 11 QUALITY AUDIT – CHECKLIST INSPECTION OF MANUFACTURING PLANT Name /Address of Factory: Product Lines: Date of Audit: Auditors: Audited Persons/Units: pmgman - audit checklist 12 QUALITY AUDIT – CHECKLIST INSPECTION OF MANUFACTURING PLANT GENERAL IMPRESSION pmgman - audit checklist 13 QUALITY AUDIT – CHECKLIST INSPECTION OF MANUFACTURING PLANT PRIORITY ACTIONS pmgman - audit checklist 14 QUALITY AUDIT – CHECKLIST INSPECTION OF MANUFACTURING PLANT pmgman - audit checklist 15 PMG-MAN STANDARD QUALITY AUDIT QUALITY RATING SYSTEM RATING MEANING INTERPRETATION 3 Excellent Item/Area/System/Knowledge is Superior 2 Adequate Item/Area/System/Knowledge Meets Basic Minimum Requirements 1 Poor Item/Area/System/Knowledge is weak and not up to Acceptable Standard 0 Unacceptable Item/Area/System/Knowledge is Missing or of such Nature to Warrant Serious Quality/Compliance Concerns pmgman - audit checklist 16 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE SECURITY 1. Is the environment very clean? 2. Are the toilets and changing rooms clean and devoid of offensive odour? 3. Do the personnel appear neat and properly dressed? 4. Is there evidence of regular disposal of waste in the refuse drum? 5. Are the windows, walls and floors clean and properly maintained? 6. Is there evidence of growth of mould and fungi or presence of rodents in the area? pmgman - audit checklist R A T I 3 2 1 N 0 G REMARKS N/A 17 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE R A T I 3 2 1 N 0 G REMARKS N/A RAW AND PACKAGING MATERIALS WAREHOUSE 1. When was the last inspection conducted? 2. Are the walls, floors and shelves cleans? Is there absence of rodents, vermin fungi and mould? Are there physically separated areas for: - Raw materials - Semi finished products - Packaging materials? Is there a quarantine area for raw materials and active ingredients under test? Is there a separated area for rejected materials? 3. 4. 5. 6. 7. Are there identification labels on all containers that have materials in them? 8. Are the warehouse lightning and ventilation adequate? 9. Is there any programme for pest control and is such documented? 10. Are there warehouse operating instructions and procedures and are they followed? 11. Are untested drug components, drug product containers and closures separated from the tested and certified ones? 12. Is the arrangement of materials in the warehouse adequate? 13. Is there evidence of safety consciousness in the personnel working in this area? 14. Is incoming materials “Quarantined” until it is checked, analysed and released? Is it properly stored? Is there sufficient accountability system for labels? 15. 16. Are there written procedures on inventory control and reconciliation and are these followed? pmgman - audit checklist 18 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. 17. 18. 19. 20. 21. 22. 23. 24. 25. TITLE R A T I 3 2 1 N 0 G REMARKS N/A RAW AND PACKAGING MATERIALS WAREHOUSE Is there a written procedure describing the scheduled for retesting of materials in the inventory and is it followed? Are the records of retesting available? Is a separate sampling room available? Is the sampling room designed to prevent microbial and/or product contamination? Is a returned material store available? Is a cold store available? Is an area available for storing of reference samples? Is a separate room available for explosive substances? Is it ensured that for all materials a “First in First out” system is followed? 26. Are all containers legibly and completely labeled? 27. Are there SOPs describing in detail the receipt, identification and handling of starting materials, packaging and auxiliary materials as well as the status of the material after testing? 28. Is rejected materials adequately controlled? 29. Are SOPs available for the general storage and handling procedures and are these followed? 30. Are there material storage and handling procedures documented? 31. Are SOPs available describing the material flow to manufacturing areas and vice-versa and are these followed? 32. Are obsolete and outdated materials destroyed? Any record of such destructions? pmgman - audit checklist 19 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE FINISHED GOODS WAREHOUSE 1. When was the last inspection conducted? 2. Are the walls, floors and shelves cleans? Is there absence of rodents, vermin’s, fungi and mould? Are there physically separated areas for: - Finished goods - Returned items? Is there a separated area for rejected materials? Are there identification labels on all containers that have materials in them? 3. 4. 5. 6. 7. Is there any programme for past control and is such documented? 8. Is the arrangement of materials in the warehouse adequate? 9. Is there evidence of safety consciousness in the personnel working in this area? 10. Do distribution records indicate the: - Name and address of the consignee - Loading date - Name, quality and control number of the item? Is the establishment system sufficient to facilitate the recall of the finished product, if necessary? 11. 12. Is there materials nearing expiry? 13. Are such materials reported for necessary action? Any written evidence? 14. 15. 16. Has a positive action been taken? Are warehouse lighting and ventilation adequate? Are different batches of finished products separated physically? 17. Is there a system to ensure that only products released for sale are distributed? 18. Are the trucks conveying the goods to their destinations able to project the goods from rain and sunshine? pmgman - audit checklist R A T I 3 2 1 N 0 G REMARKS N/A 20 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE PRODUCTION AREA - LIQUIDS WEIGHING 1. Are raw materials properly identified during weighing? 2. Is the weighing area clear of other materials that are not necessary for this operation? 3. Are materials for weighing checked physically before and after? Are such checks confirmed by a second person and such record weighed? 4. R A T I 3 2 1 N 0 G REMARKS N/A Is the balance for the weighing the appropriate one for the material(s) being weighed? 5. Are there records for the periodic calibration of the balances in the weighing room? 6. Where measurement instead of weighing is involved are the appropriate containers used? Are there such containers well calibrated? 7. Are the personnel wearing appropriate uniforms for the operation - Nose masks, Hand gloves, Safety-shoes etc? 8. Is there any personnel in the weighing area that has open sore or lesion that may pose problem to the product under processing? 9. Is there any material in the weighing area that can shed fiber or other contaminations or wooden pallets and are such close to clean containers? MIXING 10. Is the production area effectively ventilated with filtered air? 11. Are there systems for processing and transfer that can protect the products from contamination? 12. Are Tanks, Containers, Pipe works and Pumps designed and installed to facilitate easy cleaning and sanitation if necessary? pmgman - audit checklist 21 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE MIXING 13. Any device to ensure that materials transferred through pipes are delivered to their correct destination? 14. Are there presence of materials likely to shed fibers into the mixing tank(s) in the preparation area? 15. Are all processes documented at the time of performance? 16. Is there a step-by-step procedure for this operation and is such a protocol followed? 17. Where procedures are altered, are such alterations recorded and reasons adduced for the alterations? 18. Are there records of unplanned deviations from manufacturing specifications? Are such brought to the attention of the head of Quality and Production? 19. Are laid down criteria for acceptance of such deviations devised by the Quality Control? R A T I 3 2 1 N 0 G REMARKS N/A FILLING 20. Are the glass bottles maintaining an appropriate degree of cleanliness at the time of filling? 21. Any device to detects presence of particulate matter in the bottle before and after filling and is such a device effected? If bright background illumination is used, are observers changed frequently? 22. Is the working area where liquids are prepared disinfected periodically and records of such kept? Is efficacy of such disinfectant assured? 23. Are the filling constantly monitored to assure uniformity of volume? 24. Are there constant physical inspections of closures for firmness or otherwise? pmgman - audit checklist 22 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE LABELLING AND PACKAGING 25. Is the labeling constantly monitored and rough and squeezed ones on the containers replaced manually? 26. If labeling is not automated, are the filled bottles properly stored and identified awaiting manual labeling? 27. Is the Batch Packaging Record employed at the time of exercise and are appropriate documentation made? 28. Are any deviations from the standard operating procedures for packaging documented? 29. Is there adequate separation of packaging lines to avoid mix-up? 30. Is Batch identity maintained throughout the packaging operation? 31. Are there records of reconciliation for quantity of packaging material issued, used, destroyed and returned? pmgman - audit checklist R A T I 3 2 1 N 0 G REMARKS N/A 23 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE PRODUCTION AREA - TABLETTING 1. 2. Is dust extraction device available at an appropriate area and is it functional? 4. Do the personnel use the protective clothing (gloves, caps, nose masks, etc) in these working areas? 5. Are the personnel clothing clean? 6. Is there absence of other materials not necessary for operation in? - Weighing - Mixing - Granulation and - Tableting rooms 7. 8. Are the utensils in-use clean? Are these utensils kept in an adequate place free from contamination? 9. If weighing was carried out during the inspections, are the containers of raw materials to be weighed cleaned before being opened? During weighing, are weights and raw materials double-checked and is the in-process inspector present? Are raw materials and components for each batch segregated after weighing? 11. 12. 13. A T I 3 2 1 N 0 G REMARKS N/A Are the following areas clean? -Weighing room - Mixing room - Granulation -Tableting room -Washing room Are lighting and ventilation adequate in: - Weighing - Mixing - Granulation and - Tableting areas 3. 10. R Does these identification include - the name of raw materials - the batch number of the raw material - the quantity that was weighed Are weighing record sheets filled and duly signed during weighing? pmgman - audit checklist 24 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE PRODUCTION AREA 14. Are processing areas clean and properly maintained according to standard operating procedures? 15. Is the air supply system for all processing areas adequate to eliminate cross-contamination of drug products? Are equipment identified as to their status (clean, duty, batch contents)? 16. 17. 18. R A T I 3 2 1 N 0 G REMARKS N/A Are written operating procedures for equipment readily available to operators and are they in-use? Are written procedures available for cleaning, maintenance and sanitizing of equipment? Are they followed? 19. In mixing and granulation rooms is the adding of raw materials components verified separately by two individuals? Is it documented at the time of performance? Any records? 20. Are there physical separation or other measures to avoid cross-contamination during production of different batches and different products? Is there any lesion or wound on any operator handling materials which can affect the product adversely? Are correct documentations done in the batch manufacturing protocols at the time of performance of operations? 21. 22. 23. 24. 25. 26. 27. Are there adequate areas for the orderly storage of semi-finished and bulk products? Do SOPs exist for the cleaning of the various equipment and machines used in the production area? Are they followed? Does SOP exist for reprocessing of production? Are frequent calibration and servicing of balances performed and documented? Are BMPRs kept at the work stations during the entire operation? pmgman - audit checklist 25 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE PRODUCTION AREA 28. Are Master and BMPRs properly assembled? 29. Are process parameters for each step laid down in writing? 30. Are yield limits established at each significant step of production? 31. Are all yield calculations and reconciliation’s documented in the BMPRs? Are adequate procedures utilized to reconcile the quantities of starting materials issues, used and returned, are these followed? 32. 33. 34. 35. 36. 37. R A T I 3 2 1 N 0 G REMARKS N/A Are written product related in-process control procedures available? Is the processing procedure approved by Quality Control/Quality Assurance? Is change control performed in the case of:-Changes in starting Materials? - changes in packaging materials? - changes in processes? - changes in equipment - change of standard batch size? - changes in production area and support system? - changes in environmental conditions - changes in suppliers Unexpected changes Are products quarantine between their manufacture and packaging Are products quarantine between their manufacture and release Do these manufacture/Packaging protocols include the followings: - and control records include also the followings: - Name and strength of the product? - Description of the dosage form? - Batch product number and pack size? - Name/weight (measure) of each ingredient per dosage form? - Total weight (measure) of each dosage unit? - Standard batch size? Specifications and compendia reference of ingredients? pmgman - audit checklist 26 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE PRODUCTION AREA 38. Any calculated excess ingredient and packaging materials? - Statement of theoretical weight (measure) quantity at appropriate phases of manufacturing? - Statement of theoretical yield at appropriate phases of manufacturing, including the minimum and maximum allowed limits? 39 Date of preparation (initiation of operation) of the updated Master Formular edition number? - Date and edition number of updated, original product and manufacturing prescriptions? - Product related procedures? - Statement of important steps to be signed during manufacturing? - Product related precautions to be followed - Process – related precautions to be followed - Product environmental specifications, where applicable? -Procedure for handling equipment and machines? - Cleaning Procedures? - In-process control procedures? - In-process bulk and drug product specifications? - Specification of primary and other packaging materials? - Quantity (weight) of packaging materials per dosage form? - Total quantity (weight) of packaging materials per batch? - Packaging and labeling procedures? - Quality Assurance/Quality Control approved specifications? - Quality Assurance/Quality Control approved and testing procedures? sampling - Storage conditions? - Shelf life information? 40. Are the manufacturing/Packaging Protocols, dated and signed by responsible person? 41. Are all the signatures full and hand written? pmgman - audit checklist R A T I 3 2 1 N 0 G REMARKS N/A 27 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE PACKAGING - BLISTERING 1. Is the blistering hall clean and orderly managed? 2. Is the blistering hall having adequate lighting and ventilation? 3. Are the batch packaging records kept at the work stations during the entire operation? 5. Is the printing room clean and well arranged? 6. Is one product printed at a time? 7. Is there line identified for such a product? 8. Is there risk of labels/inserts mix-up? 9. Are the personnel wearing appropriate uniforms in performing their duties? 10. Are the personnel in packaging hall wearing neat uniforms? Is each packaging line identified with product name, packaging size and batch number? Is there only one product, batch and packing size on a line at any given time? 12. 13. Is there presence of previous during product and labeling materials? 14. For container that have been used previously for a certain materials and now been used for another materials, are old labels removed before using them? Are drums containing blisters for packaging properly labeled at all times until the blisters in the drum are exhausted? Are blisters being left on the floor? Is the number of blisters in a pack size correct as declared? Is the number of pack size in outer carton correct as declared? 15. 16. 17. 18. A T I 3 2 1 N 0 G REMARKS N/A Is each blistering line identified with product name and batch number? 4. 11. R pmgman - audit checklist 28 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE PRODUCTION AREA 19. 20. R A T I 3 2 1 N 0 G REMARKS N/A Do SOPs exist for the cleaning of the various equipment and machines used in the production area? Are they followed Does SOP exist for reprocessing of products? 21. Are frequent calibrations and servicing of balances performed and documented? 22. Are validation procedures available for: - Procedures - Process - Machines and equipment in - Production and packaging areas? 23. Is there SOP for pre-clearance procedures employed in order to assure that any packaging material from the previous hatch has been removed and are these followed? 24. Are master and packaging records properly assembled? 25. Are batch packaging records kept at the work station during the entire operation? 26. Are process parameters laid down for every step in writing? 27. Are in-process control results available? 28. Is there a documented label instructions prior to use? 29. Are all containers, machines, installation and equipment used during and after packaging properly identified? 30. Are yield limit established at each significant step of packaging? 31. Are adequate procedures to reconcile the quantities of packaging materials issued, used and returned and are these followed? pmgman - audit checklist 29 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE ENGINEERING (WORKSHOP) 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. R A T I 3 2 1 N 0 G REMARKS N/A Does a written preventive maintenance programme exist for machine and equipment in production, packaging and laboratory as well as in Engineering? In all the Engineering sections, are risk of accidents due to carelessly placed wire, equipment and other obstacle? Are the sinks, toilets and bathrooms clean? Are these areas habouring cobwebs, insects and vermin’s? Are appropriate uniforms used for the performance of function? Are lubrication records available based on a lubrication manual for major machines and equipment? Are written records or log books maintained of maintenance and repairs? Do standard operating procedures exist for cleaning/ sterilizing of filters? Do records exist for cleaning/sterilizing of filters? Are all structural materials in the various sections of Engineering properly arranged? Is the entire environment generally clean and well arranged? Is there evidence that the personnel are safety conscious? Do updated schemes (drawings) of the air handling and distribution system exist, meeting current requirements? Is there an adequate system for dust extraction? Are air filtration systems (which include pre-filters and particulate filter) used on air supplied to the manufacturing areas? Is there an adequate system for dust extraction? Are updated SOPs available for all controls/monitoring, calibrations and validations performed and are these followed? Are adequately constructed waste containers located in appropriate areas? Does a preventive maintenance programme exist for the whole buildings in the plant? Are written records available? pmgman - audit checklist 30 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE R A T I 3 2 1 N 0 G REMARKS N/A GENERAL SERVICE 1. 2. Are the changing rooms for production personnel clean? Are the doors closed always to prevent entry or exit of dust to other area? 3. Is the tearoom clean and well arranged? 4. Are precautions taken to prevent microbiological contamination where necessary? 5. Do SOP exist regarding the policy for the entry of visitors to the different areas and are they followed? 6. Are measures taken to ensure that visitors do not jeopardise the quality of the products in any way? Are SOPs for good personal hygiene practices available and are these followed? 7. 8. 9. 10. Do SOP exist regarding the policy for the entry of visitors to the different areas and are they followed? Are measures taken to ensure that visitors do not jeopardize the quality of the products in any way? Are SOPs for good personal hygiene practices available and are these followed? 11. Are building and surrounding areas free from all and other unwanted materials? 12. Are waste and trash stored in an orderly manner? 13. Are the grounds attractively landscape and parking lots, fences and drive ways in a good state of repair? pmgman - audit checklist 31 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE R A T I 3 2 1 N 0 G REMARKS N/A CANTEEN 1. Is the store well arranged and is it clean? 2. Is the evidence of safety consciousness in the personnel working in this area? 3. Are the cooking utensils not in use properly kept? 4. Is there water/oil spillage on the floor that can cause accident? 5. Are the changing rooms and bathrooms clean? 6. Are the personnel wearing clean clothes and headgears? 7. Is the working environment kept clean? 8. Is regular waste disposal carried out in the canteen? 9. Are the waste containers kept far away from the cooking area? 10. If washing is being carried out during this inspection, are the utensils washed rinsed with copious clean pure water? 11. On inspection of the cleaned utensils, are they really clean? pmgman - audit checklist 32 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE R A T I QUALITY CONTROL DEPT. 3 2 1 1. Are there master control procedures? - Approved by Quality Control? Signed and dated by a responsible person? 2. Do established procedures include specifications, standard test procedures or other control procedures for: Raw materials and components - In-processing materials (semi-finished products)? Packaging and labeling materials? Finished products? - Test materials (reagents, media etc) 3. Are all procedures in written form and available to all Quality Control personnel? 4. Do test methods describe the sources such as pharmacopoeias? 5. Is each finished batch checked for compliance before being released? Does this final release include: - Identity and strength of active ingredient? - Identity and strength of effective and auxiliary raw materials? Acceptance and rejection levels? 6. 7. 8. 9. 10. 11. 12. 13. N 0 G REMARKS N/A Are any deviation from established procedures and specifications justified and recorded? Are test methods validated for accuracy and responsibility? Are all drug products failing to meet established standard and specifications rejected? Are there procedures and specifications for accepting reprocessed materials? Does Quality Control maintain written records of all tests conducted? Does these include: - Graph, charts, spectra, chromatograms etc? - Record of all calculations Are these established sampling procedures for: Raw materials - In-process materials - Packaging and labeling materials - Finished products? pmgman - audit checklist 33 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. 14. 15. TITLE R A T I QUALITY CONTROL DEPT. 3 2 1 In the room for sensitive instruments - Are temperature and humidity controlled? - Is there any vibration - proof bench for analytical balance? 17. Is there a programme for calibration of laboratory instruments? 18. Are instruments properly maintained? 19. 20. Are the calibration documented? Does Quality Control review and approve all production and control records to assure compliance with established written procedures before a batch is released? 21. Do retention samples meet the following criteria? - A representative sample of the batch - A quantity, at least two times the amount required for all tests 22. Is a written programme available for stability studies? Are containers of raw materials opened for sampling, securely closed after and marked after sampling? Are printer’s proofs checked and approved before mass production? Does a documented water testing/monitoring programme exist, indicating sampling schedule, microbiological, chemical, filter changes, regeneration, cleaning and distribution? Are SOPs available for all controls and validation of such controls on water supplied to plant? 24. 25. 26. 27. 28. 0 G REMARKS N/A Do sampling procedure for finished products include numbers of units per batch to be tested? Are sample collected by Quality Control? - For testing - For retention? 16. 23. N Are there SOPs for in process control checks for Production and Packaging? Are in-process checks validated? pmgman - audit checklist 34 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE R A T I 3 2 1 N 0 G REMARKS N/A QUALITY CONTROL DEPT. 29. 30. 31. 32. 33. Are in-process results included in the batch record? How are in-process check results, which do not conform, dealt with? Do written procedures exist governing a document change control system to ensure that only updated documents are used and are these followed? Are written specifications for all starting, packaging and auxiliary materials available including updated acceptance criteria? Are SOPs available for handling of rejected raw materials auxiliaries and packaging materials and are they followed? 34. Does SOPs exist for handling of raw materials, auxiliaries and packaging materials and are they followed? 35. Are all manufacturing Protocols and Packaging Protocols approved by the Quality Assurance? 36. Are SOPs available for signatory to any document and are they followed? Does Quality Control department have enough qualified personnel for the jobs? Does documentation of written and oral complaints exist? Do SOPs exist for testing, reprocessing and destroying of returned drug products and are these followed? Do SOPs exist for operation of laboratory equipment and are these followed? Does an updated list of Laboratory equipment exist? Does SOP exist for discarding Laboratory reagents that are prepared in the Laboratory and are they followed? Are all Laboratory solvents/reagents properly labeled and stored? Do SOPs exist for preparation and standardization and expiry of volumetric solution and are these followed? 37. 38. 39. 40. 41. 42. 43. 44. pmgman - audit checklist 35 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE R A T I QUALITY CONTROL DEPT. 3 2 1 45. Does the Quality Control monitor the handling of approved materials in the warehouse (FIFO)? 46. Are the following documents available? - Sampling plan - Specifications - Analytical records including worksheets - Certificate of analysis - Data form environmental monitoring Records of calibration, maintenance and repair of instruments and equipment Are raw data retained to support results in the certificate of analysis? 47. 48. 49. Are these SOPs for general inspection of manufacturing areas for the in-process inspector? 51. Does a SOP exist for each of the processing steps for the in-process control inspector and are such followed? Do SOP exist for writing report of analysis in a work book and are they followed? 53. Is there SOP for batch review before a batch is finally released? 54. Is there SOP for regular microbiological testing and documentation with respect to airborne and surface contamination and is it followed? Does an approved sampling plan exist indicating the sampling procedure, sampling area, identification of sampled container, responsibilities and quantities, which have to be taken? Are there written procedures describing in detail testing, approval and rejection of starting and packaging materials? Is each material tested for conformity with the specification? 55. 56. 57. 0 G REMARKS N/A Are SOPs for investigation of out of specification laboratory results available and are these followed? Does SOP exist defining retesting/re-sampling conditions and responsibilities in case of out of specification results and is it followed? 50. 52. N pmgman - audit checklist 36 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE R A T I QUALITY CONTROL DEPT. 3 2 1 58. Is the material “released” in writing and are the containers marked accordingly and physically separated? 59. In case of specification discrepancies, is there a written procedure on how to handle it? Is the whole batch documentation including Laboratory data kept in one safe place accessible at all times? Who is responsible for that? 60. 61. 62. 63. 64. Are record sheets dated and signed by a responsible person? 66. In the case of using person dedicated notebook/logbook, how is dating and signing dealt with? How are exhausted person - dedicated notebooks handled? 67. Are corrections of raw data not caused by writing error justified, dated and signed by the analyst or responsible of the Laboratory? 68. Are corrections performed so that the previous data can be clearly identified? Are reading reported at the time of their performance? Is it assured that chromatograms, charts and printouts can be clearly related to the corresponding Laboratory equipment? 70. 71. 72. 73. 0 G REMARKS N/A Are the batch data reviewed on periodic basis? In Laboratory documentation, are raw data documented in adequate record sheets, notebooks, logbooks, print outs or drafts? If record sheets are used, are these updated and numbered consecutively by means of a paginating stamp in order to ensure their completeness? Are raw data reported and documented manually or by means of computerized system? 65. 69. N Is the completeness of the run assured? Is it assured that equipment functions properly during runs? Are system suitability performed? pmgman - audit checklist 37 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE R A T I QUALITY CONTROL DEPT. 3 2 1 74. Are measures taken to ensure that manual raw data calculations are double checked by the responsible for final batch release? 75. Are test results transferred adequately on to the certificate of analysis? 76. Does the Certificate of Analysis include the followings? Name of product? - Dosage form? Batch number? Manufacturer? - Date of manufacturing? - Test results? - Date of testing? - Expiry date? - Clear statement of release or rejection? - Signature of responsible(s)? 77. Does the water used for production meet chemical and microbiological quality specified. Any record to show quality control approval of its use? 78 Is there a formal change control system that addresses changes to validation system including Quality Assurance/Quality control review and approval 79 Does validation team exist? Who are in the team and job titles? 80 Who is responsible for the validations? 81 Are validation procedures available for: - Procedures 82. 83. N 0 G REMARKS N/A - Process - Machines and equipment? Is a retrospective validation carried out on a periodic basis on a particular product? Does retrospective validation include trend analysis? pmgman - audit checklist 38 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE MICROBIOLOGICAL TESTING 84. 85. 86. 87. 88. 89. 90. 91. R A T I 3 2 1 N 0 G REMARKS N/A Are the following microbiological tests performed: - Microbiological testing of non-sterile products? - Microbiological testing of effectiveness of cleaning procedures? - Microbiological testing of effectiveness of disinfectant? - Microbiological testing of starting materials (bioburden)? Is the microbiological testing performed according to the updated procedure? Is special emphasis put on microbiological testing of sterile, topical, nasal and inhalation products, if applicable? Are total counts and identification of contaminants included? Are autoclaves, hot air sterilizers and incubators calibrated? Are facilitaties for sterility testing similar to facilities for sterile production? Does an SOP exist defining retesting conditions in the case of positive testing results and is it followed? Are incubation times in accordance with specifications? 92. Are microbiological testing procedures including identification of contaminants validated? 93. Do SOPs for preparation of media include expiry dating? Is growth promotion testing included? 94. Does the hygiene programme for the cleaning and disinfectation of the sterility-testing laboratory include personnel and is it followed? 95. Are microbiological testing results entered in lobook or analytical sheets? MICROBIOLOGICAL AND PARTICLE MONITORING 96. Is there a written microbial monitoring programme for the manufacture of sterile and nonsterile products (see section 2:5)? pmgman - audit checklist 39 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE 97 Does this monitoring programme include: - Air? - - Surface? - - Personnel? - - Machine and equipment? - - Disinfectant/cleaning? - Material? - Water? 98. Are the procedures for microbiological monitoring validated? 99. Is there a periodic identification of contaminants isolated in air, water, surfaces and personnel? 100. Is there a written particles monitoring programme for the manufacture of sterile and non-sterile products and is it followed? 101. Does the monitoring programme include: - Air? - Energy (water, steam, etc)? 102 Does alert/action limits exist for all these controls? 103 Does a statistical data register exist? 104 Is there a periodic analysis of data and trends? 105 Is corrective action documented? pmgman - audit checklist R A T I 3 2 1 N 0 G REMARKS N/A 40 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. TITLE R A T I 3 2 1 N 0 G REMARKS N/A MANAGEMENT 1. Are the responsibilities of the person who is responsible to the government clearly stated? 2. Is an updated organizational chart available? 3. Does the organizational chart include key personnel and their respective deputies? 4. Do the key personnel have the education, training and experience to perform their assigned functions? 5. Are the competent personnel available in sufficient number to supervise all stages of manufacture? 6. Are the deputies able to perform key personnel functions? 7. Does a Quality Control unit exist? 8. Does a Quality Assurance unit exist? 9. Is there a person responsible for GMP related aspects? 10. Do updated written job description exist for the key personnel? 11. Are areas of competence and responsibilities of the key personnel clearly stated and laid down in writing with special regard to Quality Assurance? 12. Are the procedures indicating clearly the responsible person for quality relevant activities who demonstrates them by checking and signing quality relevant documents? pmgman - audit checklist 41 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. pmgman - audit checklist TITLE R A T I 3 2 1 N 0 G REMARKS N/A 42 AUDIT - CHECKLIST INSPECTION OF MANUFACTURING PLANT GUIDE LINE No. pmgman - audit checklist TITLE R A T I 3 2 1 N 0 G REMARKS N/A 43