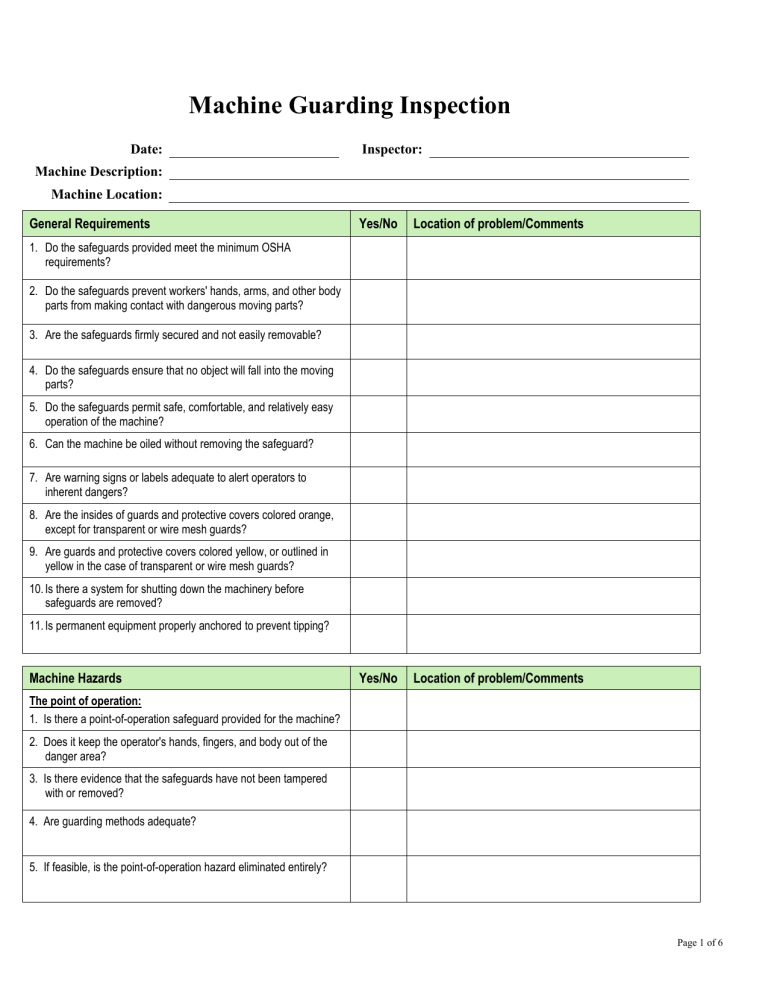

Machine Guarding Inspection Date: Inspector: Machine Description: Machine Location: General Requirements Yes/No Location of problem/Comments Yes/No Location of problem/Comments 1. Do the safeguards provided meet the minimum OSHA requirements? 2. Do the safeguards prevent workers' hands, arms, and other body parts from making contact with dangerous moving parts? 3. Are the safeguards firmly secured and not easily removable? 4. Do the safeguards ensure that no object will fall into the moving parts? 5. Do the safeguards permit safe, comfortable, and relatively easy operation of the machine? 6. Can the machine be oiled without removing the safeguard? 7. Are warning signs or labels adequate to alert operators to inherent dangers? 8. Are the insides of guards and protective covers colored orange, except for transparent or wire mesh guards? 9. Are guards and protective covers colored yellow, or outlined in yellow in the case of transparent or wire mesh guards? 10. Is there a system for shutting down the machinery before safeguards are removed? 11. Is permanent equipment properly anchored to prevent tipping? Machine Hazards The point of operation: 1. Is there a point-of-operation safeguard provided for the machine? 2. Does it keep the operator's hands, fingers, and body out of the danger area? 3. Is there evidence that the safeguards have not been tampered with or removed? 4. Are guarding methods adequate? 5. If feasible, is the point-of-operation hazard eliminated entirely? Page 1 of 6 Machine Guarding Inspection Machine Hazards Yes/No Location of problem/Comments Yes/No Location of problem/Comments Yes/No Location of problem/Comments Power transmission apparatus: 1. Are gears, sprockets, pulleys, or flywheels adequately guarded? 2. Are exposed belts or chain drives guarded adequately? 3. Are exposed shafts protruding more than half their diameter, or having screws, keyways, collars, etc., guarded? 4. Are starting and stopping controls within easy reach of the operator? 5. If there is more than one operator, are separate controls provided? Other moving parts: 1. Are safeguards provided for all hazardous moving parts of the machine including auxiliary parts? Non-mechanical Hazards 1. Have appropriate measures been taken to safeguard workers against noise hazards? 2. Have special guards, enclosures, or personal protective equipment been provided, where necessary, to protect workers from exposure to harmful substances used in machine operation? Electrical Hazards 1. Is the machine installed in accordance with National Fire Protection Association and National Electrical Code requirements? 2. Is the equipment free from loose conduit fittings? 3. Is the machine properly grounded? 4. Is the power supply correctly fused and protected? 5. Do workers indicate that they never receive minor shocks while operating or maintaining the machines? Additional comments: Page 2 of 6 Machine Guarding Inspection Training Yes/No Location of problem/Comments Yes/No Location of problem/Comments Yes/No Location of problem/Comments 1. Do operators and maintenance workers have the necessary training in how to use the safeguards and why? 2. Have operators and maintenance workers been trained in where the safeguards are located, how they provide protection, and what hazards they protect against? 3. Have operators and maintenance workers been trained in how and under what circumstance guards can be removed? 4. Have workers been trained in the procedures to follow if they notice guards that are damaged, missing, or inadequate? PPE and Proper Clothing 1. Is required protective equipment in use? 2. If protective equipment is required, is it appropriate for the job, in good condition, kept clean and sanitary, and stored carefully when not in use? 3. Is the operator dressed safely for the job (i.e., no loose-fitting clothing or jewelry)? Machinery Maintenance and Repair 1. Have maintenance workers received up-to-date instruction on the machines they service? 2. Do maintenance workers lock out the machine from its power sources before beginning repairs? 3. Where several maintenance persons work on the same machine, are multiple lockout devices used? 4. Do maintenance persons use appropriate and safe equipment in their repair work? 5. Is the maintenance equipment itself properly guarded? 6. Are maintenance and servicing workers trained in the requirements of 29 CFR 1910.147, lockout/tagout hazard, and do the procedures for lockout/tagout exist before they attempt their tasks? Additional comments: Page 3 of 6 Machine Guarding Inspection Requirements for Fixed Guarding Yes/No Location of problem/Comments Yes/No Location of problem/Comments Yes/No Location of problem/Comments 1. Is the guarding a permanent part of the machine, or is it attached in a substantial manner requiring tools to remove it? 2. Is the guarding constructed of substantial material (e.g., steel plate, steel mesh, lexan, etc.)? 3. Are all moving parts protected and free from gaps, holes, or penetrations, in such a manner that they cannot be reached? (A guard opening scale should be used to make this determination.) Requirements for Interlocked Guarding 1. Does the machine shut off and all moving parts in the protected area stop immediately when the guard is opened or removed? 2. Is the machine configured so that it cannot cycle or be started until the guard is replaced? 3. Is the machine configured so that replacing the guard will not automatically restart it? (It is necessary for the machine to be reset before it is able to start.) 4. Are all easily movable guards interlocked? 5. If necessary, can the machine be “inched” even when the interlock is activated? 6. Are interlocks tested regularly and included on a PM schedule? Requirements for Adjustable and Self-Adjusting Guards 1. Is the range of movement adequate to allow only the minimum amount of the danger area to be exposed, preventing worker contact with any moving parts? (The stock being worked should fill any gaps not covered by guarding.) 2. Is the guarding adjusted and used properly? 3. Is the guarding functioning properly? Page 4 of 6 Machine Guarding Inspection Requirements for Presence-Sensing Devices Yes/No Location of problem/Comments Yes/No Location of problem/Comments Yes/No Location of problem/Comments 1. Do the devices protect the entire danger zone not otherwise safeguarded? 2. When the field is broken, is the machine’s operating cycle interrupted? 3. Is all protected machine movement stopped before the worker can reach into the danger zone? 4. Are devices tested regularly and included on a PM schedule? Requirements for Pullback Devices 1. Does the device provide an adequate means of attachment to the arms, hands, or wrists? 2. Are the operator’s hands allowed to travel within a safe area, but prevented from accessing the point of operation? 3. Are hand-feeding tools adequate and used properly? Requirements for Restraint Devices 1. Does the device provide an adequate means of attachment to the arms, hands, or wrists? 2. Does the device render the operator’s hands in a safe position when the machine cycles? 3. Are hand-feeding tools used where feasible? Additional comments: Page 5 of 6 Machine Guarding Inspection Requirements for Safety Control Devices Yes/No Location of problem/Comments Yes/No Location of problem/Comments 1. Do trip controls deactivate the machine quickly in an emergency? 2. Are trip controls positioned properly? (Bars must stop the machine before the employee’s body reaches the danger area. Cables and triprods must be positioned within easy reach of either hand.) 3. Are guarding methods in addition to trip cables and rods used whenever feasible? 4. Do two-hand trip devices require concurrent application of both control buttons to activate a machine cycle? 5. Are two-hand trip devices located far enough from the point of operation to make it impossible for the operator to move the hands from the trip buttons into the point of operation before the first half of the machine cycle is completed? 6. Do two-hand control devices require constant, concurrent pressure by the operator to activate the machine? 7. Are two-hand control devices positioned at a safe distance from the danger area? 8. Are safety control devices checked frequently and included in a PM schedule? Requirements for Location and Distance Guarding 1. Does feeding and ejection equipment allow the operator to always maintain adequate distance from the point of operation? 2. Are moving parts on feeding and ejection equipment adequately guarded? 3. Are dangerous moving parts surrounded by a wall, railing, or other apparatus, preventing employee access or contact while the parts are in motion - or Are dangerous moving parts located at least 7 feet from floor height? 4. Is there a safe procedure established for un-jamming feeding and ejection equipment? Additional comments: Page 6 of 6