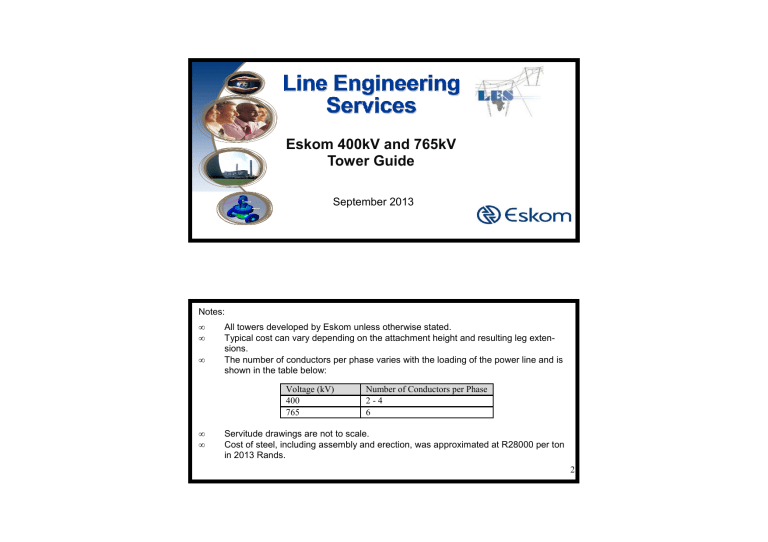

Eskom 400kV and 765kV Tower Guide September 2013 Notes: • • • All towers developed by Eskom unless otherwise stated. Typical cost can vary depending on the attachment height and resulting leg extensions. The number of conductors per phase varies with the loading of the power line and is shown in the table below: Voltage (kV) 400 765 • • Number of Conductors per Phase 2-4 6 Servitude drawings are not to scale. Cost of steel, including assembly and erection, was approximated at R28000 per ton in 2013 Rands. 2 Notes on drawings: • All fences should be outside the servitude. If this is not possible, consult with LES. • If the fence is running parallel, and even inside the servitude for less than a complete span, then this is deemed to be acceptable. • Engineering team must be consulted on pipelines, houses and other encroachments within, and close to the servitude. • Towers are shown from the top view with solid lines illustrating tower bases, guy wires and cross ropes, and dotted lines illustrating the top part of the tower structure. 3 4 5 Servitude requirements for a 518H: 400kV self-supporting suspension tower Fence Servitude 55m Width: 23.4m Recommended distance to fence: 40m Centre Line Footprint 8.95x8.95m 6 518H: Self - Supporting Suspension Tower Voltage: 400kV Servitude: 55m* Developed: 1988 Max Wind Span: 500m Typical Cost: R291 600 Max Ground Slope: 45° Insulator Configuration: V-V-V (Horizontal) Optimal Conductor: Quad Zebra This tower will be used instead of the 529A,C when there are space, slope or loading constraints. • *If 55m servitude not feasable , contact LES team. • Mainly for 3 x Bersfort and 4 x Tern, can take large earthwire (also has sugar cane structures). 7 Servitude requirements for a 517A: 400kV self-support suspension tower Fence Recommended distance to fence: 40m Width 22.4m Servitude 55m Footprint 8.2x8.2m 8 517A: Self - Supporting Suspension Tower Voltage: 400kV Servitude: 55m* Developed: 1985 Max Wind Span: 500m Typical Cost: R238 000 Max Slope: 45 ° Insulator Configuration: V-V-V (Horizontal) Optimal Conductor: Twin Dino The 517A is an Eskom designed self supporting suspension and is the successor to the 506A designed by Powerlines (Babcock). • *If 55m servitude not feasible, contact LES team. • Mainly for 3 x Tern, for higher fault currents (may need sugar cane structure). 9 Servitude 55m Width: 19.8m Servitude requirements for a 515H: 400kV self-supporting suspension tower Fence Recommended distance to fence: 40m Footprint 8.8x8.8m 10 515H: Self - Supporting Suspension Tower Voltage: 400kV Servitude: 55m* Developed: 1983 Max Wind Span: 500m Typical Cost: R290 000 Max Ground Slope: 45° Insulator Configuration: I-V-I (Horizontal) Optimal Conductor: Quad Wolf The 515 H tower has an IVI insulator configuration. This configuration was developed due to a reduction in cost of the structure depending on various aspects. This structure was used on the Beta Delphi 1 line. • • *If 55m servitude not feasible, contact LES team Mainly for 3 x kingbird or light configurations. 11 Servitude requirements for a 510A: 400kV self-support suspension tower Fence Recommended distance to fence: 40m Width 18.0m Servitude 55m Footprint 7.7x7.7m 12 510A: Self - Supporting Suspension Tower Voltage: 400kV Servitude: 55m Developed: 1976 Max Wind Span: 500m Cost: N/A Max Slope: 45° Insulator Configuration: I-V-I (Horizontal) Optimal Conductor: Twin Dinosaur This structure is currently the second most common structure in the Eskom network. It was designed by Powerlines (Babcock). It is replaced by the 517A and 518H. 13 Servitude requirements for a 506A: 400kV self-support suspension tower Fence Recommended distance to fence: 40m Width 16.6m Servitude 55m Footprint 7.8x7.8m 14 506A: Self - Supporting Suspension Tower Voltage: 400kV Servitude: 55m Developed: 1974 Max Wind Span: 500m Cost: N/A Max Slope: 45° Insulator Configuration: V-V-V (Horizontal) Optimal Conductor: Twin Dinosaur This structure is typical of most single circuit structures in use at that time, having been developed to support Eskom’s introduction of 400kV lines to the national grid. The use of V-string assembly allows for compaction of phase spacing, which in turn results in both structural and electrical efficiency. 15 Servitude 55m Width: 18.8m Servitude requirements for a 501A: 400kV self-supporting suspension tower Fence Recommended distance to fence: 40m Footprint 7.8x7.8m 16 501A: Self - Supporting Suspension Tower Voltage: 400kV Servitude: 55m Developed: 1971 Max Wind Span: 500m Typical Cost: N/A Max Ground Slope: 45° Insulator Configuration: I-V-I (Horizontal) Optimal Conductor: Twin Dino This tower is currently the most common tower structure in the Eskom Network. It was designed by Powerlines (Babcock). • It is not used anymore and is replaced by the 517A or 518H structure. 17 18 Servitude requirements for a 517E: 400kV self-supporting strain tower Fence Width 21.4m Recommended distance to fence: 40m Footprint 9.1m x 9.1m Servitude 55m 19 517 E and F: Self - Supporting Strain tower Voltage: 400kV Servitude: 55m Developed: 1985 Max Wind Span: 500m Typical Cost: R440 000 Max Ground Slope: 45° Insulator Configuration: Strain (Horizontal) Optimal Conductor: Twin Dino This tower was developed by Eskom. This tower is used to make bends in the line, between 10° and 60° and it can also be used as a 0° terminal tower. • Strain towers are considerably more expensive than their Self Supporting suspension counterparts. • Mainly for 3 x Tern, for higher fault currents (may need 20 sugar cane structure). • Servitude requirements for a 515E: 400kV self-supporting strain tower Fence Width 24.7m Recommended distance to fence: 40m Footprint 10.5x 10.5m Servitude 55m 21 515 C,D,E and F: Self - Supporting Strain tower Voltage: 400kV Servitude: 55m Developed: 1986 Max Wind Span: 500m Typical Cost: R520 000 Max Ground Slope: 45° Insulator Configuration: Strain (Horizontal) Optimal Conductor: Quad Wolf This tower was developed by Eskom. This tower is used to make bends in the line, between 10° and 60° and it can also be used as a 0° terminal tower. • Strain towers are considerably more expensive than their Self Supporting suspension counterparts. • Mainly for 3 x kingbird or light configurations. 22 23 Servitude requirements for a 529A: 400kV cross-rope suspension tower Fence Length 46.6 m Servitude 55m Width: 74.6m Recommended distance to fence: 40m 28 m Centre Line 24 529A - Standard Cross-Rope suspension Voltage: 400kV Servitude: 55m (74.6m at tower location) Developed: 2004 Max Wind Span: 560m Typical Cost: R105 000 Max Ground Slope: 15° Insulator Configuration: I-I-I (Delta) Optimal Conductor: Triple Term This design utilizes optimal guyed mast design, making it lighter and more efficient. • Cost effective, high performance tower. • Typical Cost can vary between R80 000 and R125 000, depending on the attachment height. • Midspan clearance to ground, 8.1m or higher. • Narrow phase spacing, used at low altitudes. 25 Servitude requirements for a 529C: 400kV cross-rope suspension tower Fence Length 46.6 m Servitude 55m Width: 81.6m Recommended distance to fence: 40m 35 m Centre Line 26 529C - Standard Cross-Rope suspension Voltage: 400kV Servitude: 55m (81.6m at tower location) Developed: 2004 Max Wind Span: 560m Typical Cost: R105 000 Max Ground Slope: 15° Insulator Configuration: I-I-I (Delta) Optimal Conductor: Triple Tern This tower is used at higher altitudes due to its broad phase spacing to improve Corona and Noise performance. • Midspan clearance to ground, 8.1m or higher. • Broad phase spacing, used at altitudes 1800m or higher. • Small Cost Increase due to bigger servitude used at tower footprint and more towers used on line due to lower CAH. 27 Servitude requirements for a 528A: 400kV cross-rope suspension tower Fence Servitude 55m Width: 59.8m Length 47.4 m 20 m Recommended distance to fence: 40m 28 528A: Insulated Cross-rope Suspension Voltage: 400kV Servitude: 55m (59.8m at tower location) Developed: 2002 Max Wind Span: 550m Typical Cost: R140 000 Max Ground Slope: 15° Insulator Configuration: I-V-I (Inverted Delta) Optimal Conductor: Quad Tern This structure is a improvement on the 525A Compact Cross -rope Structure. It uses taller masts to increase the range of attachment heights, and allows for longer spans. The Insulated Suspension assembly was also modified by removing the floating point. 29 Servitude requirements for a 525A: 400kV compact cross-rope suspension tower Fence Servitude 55m Width: 48.8m Length: 29.8 m Recommended distance to fence: 40m 19 m 30 525A: Compact Cross-rope Suspension Voltage: 400kV Servitude: 55m Developed: 1997 Max Wind Span: 500m Typical Cost: R106 400 Max Ground Slope: 15° Insulator Configuration: Optimal Conductor: I-I-I (Inverted Delta) Triple Bersfort The compact cross-rope tower concept was modified from the 524A in a unique design which introduces an inverted delta configuration, in which all phases are approximately equally spaced. This configuration results in: • Greater electrical efficiency over long distance lines. 31 Servitude requirements for a 524A: 400kV cross-rope suspension tower Fence Length 41.6 m Servitude 55m Width: 70.6 m Recommended distance to fence: 40m 29 m 32 524A: Cross-rope Suspension Voltage: 400kV Servitude: 55m (70.6m at tower location) Developed: 1994 Max Wind Span: 500m Typical Cost: R108 000 Max Ground Slope: 15° Insulator Configuration: I-I-I (Delta) Optimal Conductor: Triple Bersfort The 524A was the first cross-rope tower to be developed in SA. This concept embodies a highly efficient solution for High Voltage structures. This design results in cost savings in the order of 50% per tower, compared to its self-supporting alternatives. • This tower is now obsolete and has been surpassed by the 529A. 33 34 Servitude requirements for a 520B: 400kV guyed-V tower Fence Servitude 55m Width: 28.6m Length 40.6 m 23.4 m Recommended distance to fence: 40m 35 520B: Guyed-V suspension Tower Voltage: 400kV Servitude: 55m Developed: 1988 Max Wind Span: 500m Typical Cost: R200 000 Max Ground Slope: 15° Insulator Configuration: V-V-V (Horizontal) Optimal Conductor: Quad Zebra The Guyed-V tower has one mast foundation and four guy foundations. • • • • Designed to carry heavier conductors than the 515B. Guys are within the servitude on this tower. Good to use where space is limited. Costs less than the 518H. 36 Servitude requirements for a 515B: 400kV guyed-V suspension tower Fence Servitude 55m Width: 26.8m Length 40.8 m 19.8 m Recommended distance to fence: 40m 37 515B: Guyed-V suspension Tower Voltage: 400kV Servitude: 55m Developed: 1986 Max Wind Span: 500m Typical Cost: R134 400 Max Ground Slope: 15° Insulator Configuration: I-V-I (Horizontal) Optimal Conductor: Quad Wolf The Guyed-V tower has one mast foundation and four guy foundations. • • • • Tower beam helps with the live line maintenance. Guys are within the servitude on this tower. Good to use where space is limited. Replaced by 520B. 38 39 Servitude 35m (narrow) Width: 28.7m Servitude requirements for a 540A: 400kV multi circuit suspension tower Fence Recommended distance to fence: 40m Centre Line Footprint 14.8x14.8m 40 540 Series: Multi Suspension Tower This structure is currently being developed by Eskom (LES) and Joyti Engineering. The 540 Series is capable of carrying 2x400kV (designed for 500kV) as well as 2x 132kV lines. Designed to be used in narrow servitudes, the 540D can be used in servitudes of only 35m. • • Designed for quad tern conductors. Tall expensive tower, used where servitude costs are at a premium. Tower Code Tower Description 540A 540B 540C Suspension Angle Strain Angle Strain, terminal Narrow servitude suspension 540D Line angle (in deg.) 0 0-20 20-60, 0 terminal 0 Wind Span Weight (Tons) Cost (Rands) 400m 500m 500m 350m 400m 48.9 98 136.7 R2.74mil R3.83mil TBD TBD R1.37mil 41 Servitude requirements for a 531A: 400kV steel pole suspension Fence Width 8.7m Diameter 1.5m Recommended distance to fence: 40m Servitude 40m 42 531A: Steel pole Suspension Voltage: 400kV Servitude: 40m Developed: 2007 Max Wind Span: 300m Typical Cost: R252 000 Max Ground Slope: Unrestricted Insulator Configuration: V-V-V (Delta) Optimal Conductor: Triple Kingbird This was an Eskom developed tower for use in the Palmiet Stikland line. The tower comprises of several galvanized steel shafts joined together and assembled on the ground. • Ideally suited to urban areas where servitude is limited. 43 Servitude requirements for a 530A: 400kV single mast guyed suspension tower Fence Length: 44.5 m Width 36.5m 17 m Recommended distance to fence: 40m Servitude 40m 44 530A: Single Mast Guyed Suspension tower Voltage: 400kV Servitude: 40m Developed: 2004 Average Span: 400m Typical Cost: R160 400 Max Ground Slope: 15° Insulator Configuration: V-V-V (Delta) Optimal Conductor: Triple Kingbird This compact solution was developed by Eskom, to be used on the Palmiet-Stikland line, due to servitude restrictions. 45 Servitude requirements for a 527B: 400kV guyed multi-circuit suspension tower Fence Length 30.2 m Width 30.2m 14 m Recommended distance to fence: 40m Servitude 55m 46 527B: Single mast Guyed Multi-circuit Suspension Tower Voltage: 400/132kV Servitude: 55m Developed: 1997 Max Wind Span: 500m Typical Cost: R233 800 Max Ground Slope: 15° Insulator Configuration: 400kV: V-V-V (Delta) 132kV: V-I-I (Horizontal) Optimal Conductor: 400kV: Triple Kingbird 132kV: Single Kingbird This tower holds both one 400kV and one 132KV lines, thereby reducing the need for parallel lines and large servitude widths, whilst power transfer is not compromised. Eskom developed and used this tower on the Ariadne Eros line. 47 Servitude requirements for a 513A: 400kV self-support suspension tower Fence Recommended distance to fence: 40m Width 16m Servitude 55m Footprint 8.6x8.6m 48 513A: Double Circuit Self - Supporting Suspension Voltage: 400kV Servitude: 55m Developed: 1978 Max Wind Span: 300m Typical Cost: R322 000 Max Ground Slope: 45° Insulator Configuration: Optimal Conductor: V-V-V (Vertical) Twin Dinosaur This tower was developed by Powerlines (Babcock). The double circuit tower was developed to reduce servitude needed by two lines running in parallel. • The 523A tower (developed by Transdeco) can be used for the same applications. 49 50 Emergency Response to Line Failures Response Level Condition Action Strategic Spare Required • Minor/Major Loss of Supply • Loss of Substation • Islanded • Loss of Grid Restore power ASAP, irrespective of cost. Lifting Bridge Level 1 Level 2 • Forced System Alert Outages • Planned Outage with Risk of Loss of Grid Build a bypass around the affected area, allowing permanent structures to be restored using conventional methods. ERS (Emergency Restoration System) Tower Forced Outages Calculated Risk Restore the permanent structure by using fast track methods. 528C, 529A towers, with insulators, hardware and grillage foundations Forced Outages no Calculated Risk Restore the permanent structure using conventional methods. Nil. (All material to be procured prior to repair Level 3 Level 4 51 52 53 Servitude requirements for a 701C: self-supporting suspension Servitude 80m Width: 44.35m Fence Recommended distance to fence: 55m Footprint 11.625x11.625m 54 701C: Self-Supporting Suspension Voltage: 765kV Servitude: 80m Developed: 1984 Max Wind Span: 500m Typical Cost: R710 000 Max Ground Slope: 45° Insulator Configuration: V-V-V (Horizontal) Optimal Conductor: Six Tern This self-supporting suspension tower is used in conjunction with the Guyed-V 702B and 703B towers, when the GuyedV’s cannot be used. 55 Servitude requirements for a 701F: self-supporting strain Servitude 80m Width: 44.35m Fence Recommended distance to fence: 55m Footprint 16x16m 56 701 D,E and F: Self-Supporting Strain Voltage: 765kV Servitude: 80m Developed: 1984 Max Wind Span: 500m Typical Cost: R1 316 000-1 498 000 Max Ground Slope: 45° Insulator Configuration: Strain (Horizontal) Optimal Conductor: Six Tern The 701F Self-Supporting Strain is the 15-35 ° angl e strain tower commonly used on the 765 kV networks. • Strain towers are considerably more expensive than their Self Supporting suspension counterparts. 57 58 Servitude requirements for a 702B: 765kV guyed-V tower Fence Length 53.5 m Width 39.5m 43.6 m Recommended distance to fence: 55m Servitude 80m 59 702B: Guyed-V Suspension Voltage: 765kV Servitude: 80m Developed: 1985 Max Wind Span: 500m Typical Cost: R434 000 Max Ground Slope: 15° Insulator Configuration: V-V-V (Horizontal) Optimal Conductor: Six Tern Eskom’s 765kV first implementation of Guyed-V towers. This type of tower is used for altitudes between 1000 and 1200 meters. There is a 702B-M (modified) for altitudes above 1500m. 60 Servitude requirements for a 703B: 765kV guyed-V tower Fence Servitude 80m Width: 36.8m Length 52.6 m 36.6 m Recommended distance to fence: 55m 61 703B: Guyed-V Suspension Voltage: 765kV Servitude: 80m Developed: 1991 Max Wind Span: 500m Typical Cost: R476 000 Max Ground Slope: 15° Insulator Configuration: V-V-V (Horizontal) Optimal Conductor: Six Tern The 703B is an alternative to the 702B to be used at altitudes below 1000m. It also has a more compact phase spacing than the 702B. 62 63 Servitude requirements for a 705C: 765kV cross-rope suspension tower Fence Length:43.1m Servitude 80m Width: 99.5m Recommended distance to fence: 40m 60m Centre Line 64 705C: Cross Rope Suspension Voltage: 765kV Servitude: 80m Developed: 2012 Max Wind Span: 465m Typical Cost: R250 000 Max Ground Slope: 15° Insulator Configuration: I-I-I (Semi-Delta) Optimal Conductor: Six Tern The 705A is to be a high performance, cost saving tower to be used on the 765kV network. • Cross Rope towers are slightly less expensive than Guyed-V towers and considerably less expensive than it’s Self-Supporting counterparts. 65 66 Older Common Towers in the Eskom Network (Replaced by newer towers) 67 Wind Turbine Clearances • Clearance from servitude should be minimum of 3 times the total height of the wind turbine. 68 Highest system r.m.s. voltage kV System nominal r.m.s. voltage kV Safety clearance phase-toearth m Safety clearance phase-tophase m 24 22 0,32 36 33 0,43 48 44 Minimum live-line clearances m Minimum vertical clearance m Outside townships In townships Roads in townships, and proclaimed roads, railways, tramways To communication lines or between power lines and cradles To buildings poles and structures, not part of power lines Phaseto-earth Phasetophase 0,4 5,2 5,5 6,4 0,9 3,0 - - 0,5 5,3 5,5 6,5 1,0 3,0 - - 0,54 0,61 5,4 5,5 6,6 1,1 3,0 0,8 1,1 72 66 0,77 0,89 5,7 5,7 6,9 1,4 3,2 0,9 1,3 100 88 1,00 1,14 5,9 5,9 7,1 1,6 3,4 1,0 1,5 145 132 1,45 1,68 6,3 6,3 7,5 2,0 3,8 1,2 1,9 245 220 2,1 2,7 7,0 7,0 8,2 2,7 4,5 1,7 2,8 300 275 2,5 3,6 7,4 7,4 8,6 3,1 4,9 2,0 3,4 362 330 2,9 4,3 7,8 7,8 9,0 3,5 5,3 2,3 4,1 420 400 3,2 4,8 8,1 8,1 9,3 3,8 5,6 2,8 4,8 800 765 5,5 8,9 10,4 10,4 11,6 6,1 8,5 5,5 9,7 d.c. 533 kV - 3,7 - 8,6 8,6 9,8 4,3 6,1 (1) Minimum clearances as per SABS 10280 and the OHS Act “Safety clearance phase-to-earth” 69 Contact Details: For any queries, additional information, or to report a mistake, the following persons can be contacted: • Ruaan Nel (Email: NelRa@eskom.co.za) • Riaz Vajeth (Email: riaz.vajeth@eskom.co.za) • Emile Peters (Email: PetersES@eskom.co.za) Published: September 2013 70 SUMMARY NOTES OF MEETING BETWEEN ESKOM & KIPOWER Date: 01 April 2015 Venue: Connect Boardroom, Eskom MWP Present: # Full Names Role Company 1 Charmaine Masehela GAU Senior IPP Executive Eskom GAU 2 Makoanyane Theku Chief Engineer –Grid Planning Eskom Grid Planning 3 John Geeringh GC: Land Development 4 Gregory Hearl Senior Consultant Environment Management Project Manager 5 Robert Wood Project Development KiPower (Black&Veatch) 6 Marius van Zyl Environmental Management Jones & Wagener 7 Mpumelelo Saliwa Engineer KiPower (Kuyasa Mining) KiPower (Black&Veatch) Apologies: Ms Nthabiseng Lukhozi (Eskom GAU) 1. Technical discussions noted: 1.1 KiPower applied for 600 MW power plant and the project construction is envisaged to commence in 2016. 1.2 The CEL will be issued to the customer by end of business of 01 April 2015 after approval. 1.3 The CEL quote includes two options; Eskom Build or Self-Build. 1.4 The validity of the CEL is 12 months. The Maximum Export Capacity of the Facility will be 600MW at a voltage level of 400kV. 1.5 The customer shall provide the relevant protection, synchronisation and control equipment at the KiPower facility which is compatible with the protection standard as required by Eskom this is included in the Standard for the Interconnection of Embedded Generation to be issued with the CEL. 1.6 This Cost Estimate Letter is based on the information provided by the customer and assumes that the Facility will be the only one connected to the Transmission(Tx) System in the area. 1.7 The recommended least cost integration option determined by the technical analysis and economical evaluation based on the Grid Code and the customer’s request is to establish a 400 kV substation at KiPower fed by looping in and out of the existing Matla-Glockner 400 kV line. 1.8 The Matla-Glockner line 1 is approximately 24km from the KiPower Power Station. 1.9 The Loop in/out gives KiPower the advantage of evacuate power through the other line if one line is down. 1.20 The revised proposed connection diagram for KiPower was presented and discussed and also mentioned was the construction of 2x24 km 400 kV lines to loop-in/out of Matla-Glockner 400 kV line as part of the Eskom connection works. 1 1.21 The customer desired to know why Matla-Glockner connection point was considered the best option instead of the Transmission line perceived to be closer to the KiPower plant. Eskom responded that the network studies are based on current network developments and do not consider planned infrastructure as this could have major impact on the planned plant if Eskom is unable to raise money to build that line in time. Also the least cost option is the one considered for such connection. 1.22 The customer enquired how the least cost option is determined, and Eskom responded that this is executed through the Network studies, Grid Code compliance and looking into different options and taking into consideration their respective likely life cycle Transmission line costs. The customer then requested privy to costs of other connections options evaluated, Eskom agreed to respond to the customer in due course. 1.23 The CEL costs are at high-level and will be a bit detailed at Budget Quote phase though they would not specify each item cost but will state the costs as follows i.e. cost of the Tx line, cost of substation etc. 2 Environmental issues discussed: 2.1 The customer is responsible for the environmental authorization on their land and should ensure that it is not undermined. John advised that he will assist the customer with their EIA application and also give guidance where needed. Eskom Technical design and surveyors may be involved if requested. The customer to set-up a meeting. John showed servitudes around KiPower plant and different Transmission tower types/designs were discussed at length. Eskom will provide technical designs and specifications to the customer if they opt for self- build option. EIA timeframe could be between 18-24months however if the scope of work is done properly it could lessen the time frame. John advised the customer to perhaps set-up a meeting with Department of Environment Affairs (DEA) and present their plans and proposal and get their inputs ahead of the submission of their application and then follow the DEA process. The customer to engage further with John regarding their EIA matters. 2.2 2.3 2.4 2.5 2.6 2.7 2.8 End//// N.B. Below is the Eskom response to point 1.22 2 Transmission Grid Planning uses the Economic Life Cycle Costing Model to determine which option to implement when integrating power stations. The main inputs into the model are the project capital costs and total system losses before and after integration. Total system losses are a function of the generation despatch assumed in the year of study and reinforcement plans tabled in the Transmission Development Plans for the various Eskom Operating Units. Below are extracts from the South African Grid Code showing the planning process and the cost reduction criteria. Planning process 1. The NTC (Transmission Company business unit within Eskom designated with responsibility for owning, operating and maintaining the Transmission System) shall follow a planning process divided into major activities as follows: • Identification of the problem • Formulation of alternative options to meet this need • Study of these options to ensure compliance with agreed technical limits and justifiable reliability and quality of supply standards • Costing of these options on the basis of approved procedures • Determination of the preferred option • Building of a business case for the preferred option using the approved justification criteria • Request for approval of the preferred option and initiation of execution. 7.7.2 Cost reduction investments (1) Proposed expenditure that is intended to reduce service providers’ costs (e.g. shunt capacitor installations, telecommunication projects and equipment replacement that reduce costs, external telephone service expenses and maintenance costs respectively) or the cost of losses or other ancillary services should be evaluated in the following manner: • First, it is necessary to calculate the NPV of the proposed investment using the DCF methods. This shall be done by considering all cost reductions (e.g. savings in system losses) as positive cash flows, off-setting the required capital expenditure. Once again, sensitivity analysis with respect to the amount of capital expenditure (estimated contingency amount), the AAICOG (when appropriate) and future load growth scenarios is required. As before, a resulting positive NPV indicates that the investment is justified over the expected life of the proposed new asset. 3 • However, a positive NPV does not always indicate the optimal timing for the investment. For this reason, the second portion of the cost reduction analysis is necessary – ascertaining whether the annual extra costs incurred by the service provider for owning (levelised) and operating the proposed asset is less than all cost reductions resulting from the new asset in the first year that it is in commission. In the case of the KiPower 600 MW plant integration studies, a total of 8 possible options were studied. The option to loop in and out of the existing Glockner-Matla 400 kV line was established to be the least cost. Please note that the South African Grid Code is accessible at the NERSA website should more details be needed. 4