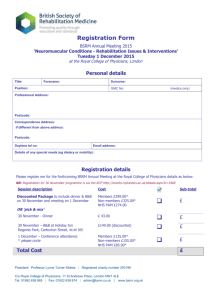

1 CHAPTER ONE INTRODUCTION Due to globalization and open market economy, business is now growing rapidly all over the world. In this way, Bangladesh is trying to develop its industries and economy. Many local and foreign investors are investing in different sectors. Steel industry is growing faster as well as other industries. It is very potential sector for our country because in Bangladesh maximum people are using steel bars for houses, shops and building, hospitals, mosque etc. In this context some of the companies in our country are now producing steel. KSRM, SARM, BSIL are known of them. In this report showing the overall picture about the BSRM. 1.1ORIGIN OF THE STUDY This report is the presentation of one-day industrial tour program as a part of academic requirement of the B.B.A. program, Department of Management, University of Chittagong. The part of this report is organization part, which is an overall focus of Bangladesh Steel Re-Rolling Mills Ltd. 1.2 OBJECTIVES OF THE STUDY The main purpose of the industrial tour is to acquire knowledge about the internal and external environment of an industry and find out the consistency and inconsistency between theoretical practical knowledge that we acquired from an industry that is live. We also try to adjust with the gap to be competent at the modern job market. The areas on which we will give emphasis are: To know about the profile of BSRM To examine the management segment of the company To know about the supply chain management of BSRM To know the production systems of Bangladesh Steel Re-Rolling Mills Ltd. To know about the quality control system of BSRM To have an idea about products and markets of BSRM To have an idea about marketing segment of BSRM To indicate HRM practice in BSRM To give insist into financial practice in BSRM To locate the problems of BSRM To provide suggestion to BSRM 2 CHAPTER TWO METHODOLOGY OF THE STUDY This industrial tour is conclusive as well as descriptive in nature. Necessary statistical tools have been applied to carry out the assigned study. • A visit to the industry’s production process • Making a formal questionnaire. • Questionnaire has been designed through department wise. • Discussion with high officials. • Practical experience gained by studying. • Finally, the collected data are classified, tabulated, interpreted, analyzed and Presented in the form of research report there after. 2.1 SOURCE OF DATA: • Published books, govt. publication, library • Annual report of BSRM • bOffice records • Logging on the internet at www.bsrm.com • Data supplied by the accounting department and other concerned portfolios 2.2 Type of Data 2.2.1 Primary Data I) Direct observations II) Face to face conversation with the respective manager and the official III) Making a formal questionnair IV) Interview V) Questionnaire 2.2.2 Secondary Data I) Study of files and Documents. II) Information from Wikipedia. III) Information from official website of BSRM Group. 3 2.3 Limitation of the Study I tried my best to collect the maximum information from Bangladesh Steel ReRolling Mills Ltd. But this report is not free from short faults. While I preparing this report I faced some problems. These are as follows: • My industrial tour is for only one day that is not enough to make a study successfully. • Lack of adequate time also caused some constraints to my study. • The rate of success of my study may be limited, as we may have failed to collect proper information due to lack of our experience. • Some data could not be collected for their confidentiality and official secrecy. • Time is not sufficient for such type research. • Internet cost is so high. So we cannot collect huge information. • It is very difficult to discuss there marketing practices in separately. • My personal limitation also contributes greatly in making the study less perfect then desired. I, therefore, hope that the study will be evaluated subject to the recognition of the abovementioned shortcomings. 4 CHAPTER THREE HISTORICAL BACKGROUND AND ANALYSIS 3.1 OVERVIEW OF BSRM Name of the Company Year of the establishment Beginning of Production : BSRM Steels Limited Formally, the Company is established in 1960. The industry started its production first in 1961 Type of the organization Ownership of the organization Authorized Capital Paid up Capital of the Company Manufacturing 100% private BD Tk. 500.00 Crore BD Tk. 341.775 Crore Location It has factory at 4 Fouzderhat Industrial Estate, Sitakuinda, Chittagong Head office Rate of production capacity The head office is situated at Sadarghat, Senior manager (Procurement) and Manager (Industry) deal production sector. The M.S. Billets are the raw materials of BSRM’s Products that are imported and procured by the Megna Engineering Works (MEW) a sister concern of BSRM. The production capacity is 375,000 MT per annum. The utilization rate is near about 93%. Machineries have been imported Management Employees: system & The management system follows managerial pattern. It has 116 skilled workers, 60 officers and 40 staff.Ioperates the productions in 03 shiftsconsisting of 8 hours per shift. BSRM is successful in ensuring the workers job satisfaction. BSRM has set up another steel factory at Baizid Bostami in Chittagong to meet the increasing demand. Branch office Name of product Marketing philosophy The brand name of their products is BSRM BSRM follows direct marketing philosophy. The marketing department executes plan on the weekly, monthly, and yearly basis. In order to promote their products, they normally use print, audio and video advertisement media. Since they sell their products directly, they do not use any middle distributor. BSRM has some foreign customers. 5 Registered office Mr. Tapan Sengupta (GM) Ali Mansion, 1173/1207 Sadarghat Road, Chittagong Tel: (031)-616402,613759,613282 Fax: 88-031-610101 Dhaka office Mahbub Castle (2nd & 4th Floor) 35, PuranaPaltan Line, Inner Circular Road (VIP Road) Dhaka-1000 Tel: 02-8311994, 8313135 Fax: 88-02-8312905 Factory: Mr. Sankar Roy (AGM) 4, Fouzderhat Industrial Estate Latifpur, Sitakunda, Chittagong. Tel: 031-2770192-3 Fax: 88-031-751452 Auditors: Rahman RahmanHuq Chartered Accountants 102, Agrabad, Chittagong Legal Advisers 9 Mohakhali C/A, 9th Floor, Dhaka - 1212Phone: 873085, 871960 Fax: 880-2-872871 6 3.1.1 BACKGROUND OF THE COMPANY Bangladesh steel Re-Rolling mills Ltd is a unit of well known H. Akber Ali group of industries, having 59 years experience exclusively in steel making, is fully automatic steel re-rolling mill in the country. The mill was imported from U.K and commissions at the sea port of Chittagong. The founder of the group was late Mr. Akberali A. Africawala and is now managed by his sons and nephews. BSRM was established in 1952.In 1947-BSRM start sole trader comes to pakishtan.In 1952 a set of four manual rolling mills, the first of its kind of the country was set up to produce plain bar for the construction history. In 1960 the hand-rolling mill (manual) was running with a small capacity.1984 --Introduced high strength cold twisted steel bars to the construction industry. The present mill was bought from UK and became the first automatic rolling mill in the country in 1984. Old machinery was dismantled and fully automatic mill machinery was imported from U.K which enhanced production capacity from 15000m tones to 60000m tones per annum in 1985. Milestone in 1987: The four old manual mills were scrapped and an automatic billetbased rolling mill was installed with continuous up gradation. The two highway bridges over the rivers Meghna and Gumti, the Chittagong Airport, the KAFCO fertilizer factory, most of the country’s large prestigious projects. Introduced Grade 60 reinforced steel bars. Achievement-1996: Commissioned the largest billet making plant in the country. A Captive billet-making plant was commissioned, under the name of Megna Engineering works. 1997: BSRM were a regular customer of CHITTAGONG STEEL MILLS. Following its shut-down/lay-off, BSRM started Continuous Billets Casting Plant in the name of Meghna Engineering Works Limited (MEW) with a production capacity of 60,000m tones per annum. Its production capacity will be increased to 120,000m tones per annum after completing its on-going BMRE program. 2004: Massive BMRE program was taken and 20 TPH Re-heating furnace, 3 Hiroughing Mill, High-speed Fly share and Twin channel to increase production capacity to 120,000m tones per annum. 2006: cost-saving technology: The first and only ribbed wire cold-rolling plant in the country started operations using European technology to make 500 MPA yield strength 7 wire reinforcement in sizes 4.5mm, 5.7mm and 7.1mm, significantly reducing construction costs. BSRM wires are the first and only company to produce high strength wires in Bangladesh. The plant is located in Sholoshahar industrial area, Nasirabad, Chittagong. 2008: Crowing glory:BSRM Steels Limited started producing internationally recognized Grade 500 steel bars branded as Xtreme 500W. With the commissioning of the state-ofthe-art rolling mill built by Danieli, Italy, in a greenfield site at Fouzderhat, Chittagong, The company accomplished yet another milestone not only for itself but also for the nation. BSRM steels ltd is now a local name in rebar manufacturing and is a public limited company registered with both the Dhaka and Chittagong Stock Exchanges. 2010 –BSRM Iron & Steel Co. Ltd. started billet production in March 2010 having the capacity of 250,000 MT per annum; operating 24 hours a day; it has become the largest billet plant in the country. 2011- Share split off both the Dhaka and Chittagong Stock Exchanges. Set up factory at Fouzderhat which increase production of product. 2012- Net Asset Value par share 19.53 and Dividend 10% for C and 5 % for B. 2013- Net Asset Value per share 21.75 and Dividend 15% for C. 2014- Oracle e-BS -12 went GO LIVE on 1st March 2014. Oracle Financials, Costing, purchasing, Manufacturing, EAM, Inventory & Order Management are now integrated on a single platform which ensures the accuracy, accountability and reliability of the Group. 20151. Enhanced capacity of BSRM Steels Limited from 600,000 MT to 700,000 MT per annum. 2. Announced a new product namely “BSRM Maxima” 3. Increased capacity of Bangladesh Steel Re-Rolling Mills from 120,000 MT to 450,000 MT per annum which will be the first and largest merchant mill in Bangladesh. 4. Listing of Bangladesh Steel Re-Rolling Mills Limited with the stock exchanges (DSE & CSE). 5. Start of trial production of world’s largest induction furnace based billet casting project –“BSRM Steel Mills Limited”. The company moved to expand its production capacity to five lakh tones a year from its present capacity of 3.56 lakh tones. 8 3.1.2 BSRM VISION Maintain leadership poison in the steel industry by – producing the best quality steel products, continuously enhancing customer satisfaction and becoming a reliable business partner of our customers and suppliers. Be an employer choice, with focus on nurturing talent developing future leaders of the organization. Protect the interest of our shareholders through sustainable growth and value creation. Preserve the trust of all our stakeholders by adopting ethical business practices. Support the society through Corporate Social Responsibility initiative. 3.1.3 BSRM VALUE Sustainable growth: Consistent improvement in the quality of products and services, Efficiency of process and profitability of business, continuously anticipating and responding to the changing business and environmental needs using innovation , sharing knowledge and experience within the organization. Quality: Creating products and services valued by our customers , constantly improving our processes through innovation and adopting best practices; reducing wastage ; minimizing cost; investing in systems and technology and developing our people to build a highly capable workforce. Reliability: Be the preferred business partner of our customers and suppliers by offering quality products; providing our best and timely services before, during and after the business transactions; and honoring all our commitment despite challenges. Trust: Preserve the faith and goodwill of all our stakeholders- customers, shareholders, suppliers, employees, regulatory bodies, and society by adopting ethical and transparent business practices. Leadership: Be a role model, setting benchmark through our products, Processes and people; constantly moving ahead of competition by differentiating our products, innovating our process, increasing our market share and nurturing talent to develop leaders within the organization. Social Responsibility: Acknowledge and fulfill our obligation towards the society by undertaking initiatives for the general upliftment of the society, building capability and making facilities available to the underprivileged. 9 Customer Satisfaction: Delight our external and internal customers at every stage of our interaction with them by duly understanding their needs, offering them our best products and services treating them respect and actively seeking. 3.1.4 SWOT analysis of BSRM 3.6 SWOT Analysis for BSRM On the analysis of the organization’s environment the following external opportunities and threats and internal strengths and weaknesses are identified: Environmental Opportunities for BSRM: Low cost supply of labour 1. High demand of steel products 2. Easy access to foreign markets 3. Favourable export facilities by the GOB Environmental Threats for BSRM: 1 High competition in local market 2. Government laws and regulations to control labour management 3. Rising concern for quality with lower prices Internal Strengths for BSRM: 1 Larger financial base 2. The largest industry manufacturer in the country 3. Commitment of workforce 4. Goodwill as quality product provider 5. Modern production plant 6. Efficient network of the transformation process from raw materials procurement to final output. Internal Weaknesses for BSRM: 1 Low use of IT 2. Lack of training facilities for production workers. 3. Dependency on suppliers for raw materials 4. Lack of efficient use of large financial base 10 3.1.5 products of BSRM SL.No. Products DEFORMED BARS Xtreme-500 W Size 8 mm 10 mm to 25 mm 1 2 DEFORMED BARS (GR-400) 3 DEFORMED BARS (GR-300 28 mm & 32 mm 8 mm 10 mm to 25 mm 28 mm & 32 mm 8 mm DEFORMED BARS (GR-75) 10 mm to 25 mm 7 mm DEFORMED BARS (GR-75 DEFORMED BARS (GR-75) M.S. ANGLE 5.7 mm 4.5 mm 38x38x3,4,5,&6 mm M.S. ANGLE 50x50x4,5 &6 mm M.S. ANGLE 63x63x5 &6 mm M.S. ANGLE 75x75x5 & 6 mm M.S. ANGLE M.S. CHANNEL 75x75x8 & 9mm 100x50x5 mm M.S. CHANNEL 75x50x5 mm 7 SHAFT SHAFT SHAFT 40 46 52 8 Wire Rod (Commercial) 5.5,6,6.35 & 8 mm Wire Rod (WR-8) 70,76 & 80 mm Spring Steel Flat Bar 70,76 & 80 mm 4 5 6 9 11 3.2 COMPANY PROFILE Bangladesh Steel Re-Rolling Mills Ltd (BSRM) group is the largest and leading industrial conglomerate in the still sector of Bangladesh. BSRM was established by late TaheraliAfricawala and H. AkberaliAfricawala in the year 1960, with a very small capacity. Steel and steel related trading was their primary business. They set up their first manual rolling mill in 1961. There after, continuous investments were made to increase capacities by setting up more rolling mills in Khulna and Chittagong. It was in 1986 that group first Ventured into an automatic billet-based rolling mill, the first of its kind in Bangladesh and produce better quality bars, namely Tor Steel and Grade 60 bars, Quality bars were produced entirely from billets and the plant was imported from U.K. Currently, the plant is still running tremendously modernization. When first started in 1986, the company produced only 600 tons of bars per month. Today the company produced up to ten thousand bars par month. It produced may different types of steel under one shed. The founder of the group was the Mr. Akbarali, A Africawala and now managed by his sons and nephews. In today's highly technological world, there cannot be any compromise on quality. At BSRM, this realization has led to ensuring that every product measures up to the highest International Standards. This is the main reason why most of the quality conscious buyers and in particular most foreign construction firms working in Bangladesh buy steel from BSRM. Strict adherence to buyers' specifications in terms of steel grade, profile and close tolerances on unit mass have enabled BSRM to supply steel to a number of national projects. Under the umbrella of BSRM group, there are mainly seven companies now running smoothly. This are(1) (2) (3) (4) (5) (6) (7) Bangladesh Still Re-Rolling Mills. (BSRM) Magna Engineering Works Limited. (MEWL) BSRM Recycling Industries Limited (BSRM RIL) BSRM Wires Limited. (BSRM WL) BSRM Steels Limited. (BSRM SL) Karnafully Engineering Works limited (KEWL) H. Akberali and CO. Limited. A visit to the mill is sure to impress any visitor by the huge range of activities going on there and the enormous facilities the mill possesses. Bangladesh Steel Re-Rolling Mills Ltd has a higher long-term strength than an Ordinary rod. The long-term strength will continue to increase as time progresses. 12 There are seven distinctive features of BSRM: Quality Customer satisfaction Sustainable growth Reliability Trust Leadership Social Responsibility 3.1.1 LOCATION AND LAYOUT It has favorable labor climate. It is near the see. There for product can easily transfer to other country. Raw materials is found very easily. It has the great chance of expansion. The communication system with districts is very well. Here the climate 13 3.1.2 MANAGEMENT OF BSRM 14 3.1.3 Key Management Hasan Zafar Chowdhury, Executive Director (BSRM Steel Mills Ltd.) Kazi Anwar Ahmed, Head Dhaka Corporate Office M. Firoze, Head of Marketing & Product Development Shekhar Ranjan Kar FCA, Group CFO & Company Secretary Sunil Kumar Das, Head of Operations Jamil Ahmed, Head of HR Abdul Gaffar, Head of HR Operations Baldeo Sharma, Head of Project (BSRM Steel Mills Ltd.) Shobhon Mahbub Shahabuddin, Head of National Sales F. M. Mizanur Rahman, Plant Head (BSRM Steels) Nikhil Ranjan Das, Plant Head (BSRM Wires) Surendra Jagdale, General Manager - Projects Md. Azizul Haque, Plant Head (BISCO) Jasim Uddin Ahmed, Head of Technical Projects Sankar Roy, Group Head T&D Mohinder Singh Hanspal, Plant Head (BSRM) Madani M. Imtiaz Hossain, Plant Head (BSRM-SMW) Md. Zahiduzzaman, Head Recycling Mohammed ReazulKabir FCA, Head of Finance & Accounts M Harunur Rashid, Lead ERP A.Md. HabibUllah, CFO (BSRM) Mohammad Arif ACA, CFO(BSRM Steels) Mohammad Imtiaz Uddin Chowdhury, Head of Supply Chain Management Abdur Rahim, Head of Internal Audit Mohammed Tamim Wahid Al-Helal, Head of IT Md. AbulHasnat, Lead Branding & Market Outreach A.K. M. Saifuddin Khan, Head of Administration 15 ADVISERS MoizeHussain, Group Adviser Tapan K. Poddar FCA, FCMA, Financial Consultant MANAGEMENT COMMITTEET apan Sengupta, Executive Director Kazi Anwar Ahmed, Head Dhaka Corporate Office M. Firoze, Head of Marketing & Product Development Shekhar Ranjan Kar FCA, Group CFO & Company Secretary Sunil Kumar Das, Head of Operations Mohammed ReazulKabir FCA, Head of Finance & Accounts Mohammad Imtiaz Uddin Chowdhury, Head of Supply Chain Managemen 16 CHAPTER FOUR SUPPLY CHAIN MANAGEMENT DEPARTMENT 4.1BSRM SCM IS DIVIDED AS FOLLOWS The Purchase, Commercial and Logistics are further divided as follows: SCM Department Logistics Purchase Foreign Local Commercial Import Export Inbound Outbound Internal logistics Managemen t Local Purchase procedure Receive Purchase Requisition/Indent Send ‘Request For Quotation’ (RFQ) to the suppliers Receive quotation against RFQ Prepare Comparative Statement (CS) Approve CS from Head of the department Prepare Purchase Order (PO) / Work Order (WO) Receive materials Inspection Report by users Material Receiving Report (MRR) Bill Forward Payment release Supplier Evaluation can be done based on the following issues: Previous Performance Lowest Price Credit facility Quality of Products Other Facilities such as Loading, Unloading, Carrying and other miscellaneous charges 17 Purchase Order (PO) A purchase order (PO) is a commercial document issued by a buyer to a seller, indicating types, quantities, and agreed prices for products or services the seller will provide to the buyer. Sending a purchase order to a supplier constitutes a legal offer to buy products or services. Acceptance of a purchase order by a seller usually forms a one-off contract between the buyer and seller, so no contract exists until the purchase order is accepted. It is used to control the purchasing of products and services from external suppliers. Purchase Order (PO) Creation: Purchase Order refers to a final massage to supplier to arrange delivery of the required product, After final approval of Comparative Statement then PO shall be raised for the respective items and finally approved form Head of Supply chain. Types of Purchase Order: General PO Repeat P Revised PO PO for Price Confirmation Content of Purchase Order: Reference and Date. Vender name and address. Materials Description. Delivery Conditions. Relevant other condition. Payment terms and conditions. Foreign purchase Foreign Purchase is done in two ways: 1. Indent Wise 2. Auto Procurement Foreign Purchased Items: 1. 2. 3. 4. Raw Materials Consumable Items Spare Parts Machineries 18 4.1.2 Commercial Regulation of Import: Import of goods under IMPORT POLICY ORDER 2009-2012 shall be regulated as follows: List of restricted items- Unless otherwise specified the items banned for import in this list shall not be importable. But those items which are importable on fulfillment of certain conditions specified in the list shall be importable on fulfillment of those conditions. Freely importable items- Unless otherwise specified, any item, which does not appear either in the restricted list or which has been mentioned as importable subject to certain condition shall be freely importable. If, while determining the import status of an item mentioned in the ‘Control List’, the description of goods does not conform to the H. S. Code mentioned against the item or any discrepancy arises between the H. S. Code and the description of goods, in that case the description of goods shall prevail. Sequence of Import Work: A) Receiving necessary documents from purchase department for LC opening. B) PI (Proforma Invoice) needs to be checked. C) Find out HS code and cover note for insurance. D) Sending LCA, LC application, IMP, LC draft, bank forwarding letter including TIN, VAT. E) LC receives from bank and provides a copy of it to supplier. F) BDS no. collection from PSI co.(if necessary). G) Insurance bill payment. H) Shipment follows up. I) Check a copy from supplier and hand over to C & F. J) CRF (Clean Report Finding) collection and checked, raise complain if necessary. K) Invoice and PL have to send to PSI for attestation/endorsement. L) After receiving Invoice and PL all copies have to send to bank for endorsement. M) Collecting insurance policy. N) All documents to handed over to C & F. O) PL and test certificate/catalogue to be sent to the mill with ETA information. P)Receiving MRR from mill Q) C & F and carrying bill to be checked. R) Bill of entry submission to bank. S) Payment advice to be sent to supplier Name of some Imported Items (Consumable)Purposes of Use Consumable for Induction furnace 1. Quartzite Powder -------It is used in lining purpose to safe copper coil of Induction furnace . 2. Quartz Powder---------------- It is used in lining purpose to safe copper coil of Induction furnace . 19 3. Ferro Manganese--------------------------It is a source of manganese 4. Ferro Silicon----------------It is a source of silicon 5. Met Coke--------------------------Used as a source of Carbon Consumable for L. R. F (Ladle Refining Furnace) 1. Graphite Electrode---------------------------------------------------------used in L. R. F. for stirring the material in the Ladle through Arking. 2. Graphite Nipple--------------------------------------------------------------used to attached two graphite electrodes. 3. Fluorspar-----------------------------------------------------------------------To remove sulphur from molten metal. 4. Calcium Carbide-------------------------------------------------------------- To remove sulphur from molten metal. 5. Calcium Silicide (Ca) Wire--------------------------------------------------To deoxidize the material the material for removing oxyzen from molten metal. Consumable for C. C. M (Continuous Casting Machine) 1. Alu. Wire 3MM---------------------------------------------------------To deoxidize the molten metal. 2.C. Mould Tube---------------------------------------------------------We use different sizes of C. Mould Tube for getting specific sizes of billet which is established just the bottom of tundish. 3. Full Cone Nozzle----------------------------------------------------4. Mould Powder---------------------------------------------------------For smooth casting 5. “O” Ring------------------------------------------------------------------Used to absorb the extra pressure of copper mould tube. Consumable for Tundish 1. Tundish Nozzle----------------------------------------------------------It is established at the bottom line of tundish well block for proper casting of the material through C. Moulded tube, but there is a little gap between Nozzle and C. Mould tube. 2. Nozzlex-------------------------------------------------------------------- Used to fill up the ladle Nozzle so that the material can not be penetrate before casting. 3. Zircon Sand--------------------------------------------------------------Use for making Nozzlex+Quartzite powder 4. Monocast-1800--------------------------------------------------------It is a castable cement used in between safety layer & working layer of the ladle. Consumable for Ladle 1. Ladle Well Block--------------------------------------------------Used to carry slide casting gate 2. Ladle Well Mix----------------------------------------------------Used to fill up the ladle Nozzle so that the material can not be penetrate before casting. 3. Tata Ram-84/85--------------------------------------------------Used in between workable bricks of ladle. 20 4. Metal Zone---------------------------------------------------------Alumina bricks used in just under slag zone of ladle Consumable for Laboratory 1. Aloxite Paper---------------------------------------------------It is used for smoothing the sample of materials before measuring the composition. 2. Combustion Tube----------------------------------------------Lab Item 3. Combustion Boat---------------------------------------------Lab Item 4. Silicon Carbide Rod------------------------------------------ LRF (Ladle Refining Furnace The molten metal generated in the furnace will be further processed in a 30 ton ladle refining furnace whose Electric Furnace technology will improve the metallurgical quality of the steel to comply with the strictest of international standards. The LRF will be supplied with latest technologies for monitoring and controlling the refining process. CCM (Continuous Casting Machine) After the LRF, the metal will be handled by the CCM to cast the molten metal into prime quality billets of 12 meters length with 100- 150mm cross section. The CCM will be equipped with the latest Programmable Logic Controlled (PLC) technologies for ensuring smooth productivity by reducing the chances of human error. The result will be a metallurgic ally superior billet to that being produced by any other manufacturer in the nation. Scrap will be charged to the furnaces using the most advanced PLC controlled vibratory feeders to charge the furnaces at a controlled speed allowing for optimal utilization of melting capacity. Name of some imported items (Machinery and Spare Parts) 1. Air Compressor and Parts 2. Panel Box/HT Panel/Control Board and Parts 3. Pumps and Parts 4. Transformer and Parts 5. Valve 6. Generator and Parts 7. APC Panel System and Parts 8. CCM and Parts 9. Fume Extension and parts 10. Furnace and Parts 11. Metal Detector 12. Pumps and Parts 13. Sample Preparation Machine and Parts 14. Scrap Charging Vibrator and Parts 15. Band Saw Machine and Parts 21 16. Crane and Parts 17. Lathe Machine and parts 18. Magnet and Parts 19.Magnetic Contactor 20. Motor/Gear Box and Parts 21. Scrap handling equipment and Parts 22. Shaping Machine and Parts 23. Transformer and Parts 24. Water treatment Plant and Parts 25. Weigh-Bridge and Parts etc. Export procedure: 1. Purchase Order (PO) receive from buyer 2. Issue Proforma Invoice (PI) to buyer 3. LC open by buyer 4. LC receive by exporter 5. After receiving LC from buyer exporter shall check all clause as per PI 6. LC amendment (if necessary) 7. Exporter shall issue D/O (Delivery Order) 8. P/L, commercial invoice, EXP Form, COO. Prepared by exporter 9. Documents handover to exporter’s C & F Agent 10. C & F Agent shall take COO. and endorsement on COO. from Chamber Of Commerce 11. C & F Agent shall take EXP Form and shipping documents to Custom House for Assessment 12. Buyer will take Import Permit and send to exporter 13. Delivery with Mushok 11 and Mushok 20 for Customs purpose 14. Exporter’s C & F Agent shall hand over all documents to buyer’s C & F Agent for material release 15. Receive payment from buyer’s LC opening bank 16. Clear C & F Agent bill 17. Receive PRC for duty draw back Purchase Order Receive: Receive Purchase Order from buyer through e-mail or letter from buyer’s office. Send Proforma Invoice: Send PI (in case of LC) or Sales Contract (Cheque) to buyer. Receive LC: LC opened by buyer’s LC issuing bank. LC Amendment: Amendment of LC if necessary. Preparing Shipping documents :Preparing shipping documents- Packing List, Commercial Invoice, EXP Form, Certificate of Origin (COO.). Certificate of Origin is issued from Chamber of Commerce. Handover documents to C & F: Documents- Commercial Invoice, Packing List, Proforma Invoice, DeliveryChallan have to hand over to Exporter’s C & F. 22 Bill Of Export: C & F Agent goes to Custom House with shipping documents and EXP Form for Bill of Export. Import Permit: Buyer’s have to collect Import Permit from BEPZA (Bangladesh Export Processing Zone Authority) and send a copy to exporter. Delivery: Delivery of goods with Mushak -11 and Mushak -20. Goods and documents handover: Exporter’s C & F Agent willhandover documents to importer’s C & F Agent. Payment receive: Payment is received through bank. Duty Drawback: Submission of PRC (Proceed Realization Certificate) along with MRC, PRC, Sales Contract/PI, B/E, C/I duly attested by Custom, P/L, VAT Challan 11 & 20, LC copy attested by bank for Duty Drawback. Control for Export of products: Under Export Policy 2009-12, export of products will be controlled in the following ways such as:Export Prohibited Products: Unless otherwise stated, products prohibited under this Export Policy cannot be exported. Exportable Products: Unless otherwise stated, all other products except export prohibited products and the products whose export is contingent upon certain conditions shall be freely exportable. Export opportunities without L/C: Export without L/C can be done through buying contract, agreement, purchase order or advance payment subject to the submission of EXP Form and Shipping Bill. In case of Advance Cash Payment, export without L/C will be allowed on consignment basis. “Buying Contract” means a signed agreement between an exporter and an importer for the purpose of exporting a product. Deemed Export: Deemed exporters, like Direct exporters, will enjoy all export facilities including dutydraw-back. Local raw materials used for producing exports and local raw materials used in industries/ projects funded by foreign investment will be considered as “deemed export”. 23 4.1.3 Logistics Logistics Outbound Inbound Internal Logistics Management Process Flow—Outbound 1. Receive D/O from Sales. 2. Do D/O segregation (C&F, Ex-Mill) 3. Prepare ‘Dispatch Program’ as per clean C&F D/O mentioning transporter name. 4. Send ‘Dispatch Program’ to CSD (Customer Service Department), Sales, Transport Agency. 5. Do follow up with transporter to report vehicles on time. 6. Receive vehicles at factory. 7. Move vehicles to the loading point. 8. Prepare W/S (weighment slip) and challan after finishing load. 9. Instruct vehicles to move to the customers (Vehicle shall not be driven during the night to minimize risk of hijack and theft. Loading of goods may be done during the evening, and the vehicle shall start for destination in the morning). 10. Receive the consignment at customer point. 11. Put acknowledgement sign on challan by the receiving person of the consignment. 12. Receive Invoice along with acknowledged challan at logistics end. 13. Approve Invoice. 14. Send Invoice to F&A for payment. 15. Do follow up with F&A department for payment. Dispatch program shall be based on the following: # Dispatch quantity # Material type # Cost analysis # D/O validity # Material availability # Availability of owned trucks 24 As per BSRM practice, all Corporate Customers, Real Estate Developers and Customers based in Export Processing Zones (EPZs), are treated as priority customers, i. e. delivery of goods to such customers shall take place ahead of others. The D/O may be on the following broad categories: a) C&F delivery b) Ex-Mill delivery C&F Site: C&F means cost and freight charge. In this mode, BSRM delivers the product to the buyers’ yard by their own transport and add this carrying and loading charge in commercial invoice. C&F delivery may any of the three types as follows: a) District b) Local c) Export Ex-Mill Rate: buyer receives the products from BSRM mill gate using their own transport. Usually this delivery mode is applicable only for Chittagong, because BSRM mills are situated in Chittagong. The D/O’s shall go through two further stages of segregation. First, straight barsand Second, bent barsVehicles shall be selected in the following order of preference: a) Trucks owned by the company b) Contractor owned trucks/trailers c) 3rd party hired trucks/trailers Freight chart preparation: • Logistics Control Cell shall first arrive upon the logistics spread based on inward and outward movement of goods i. e. Port to Mill/ Yard, Yard to Production Unit, Plant to Depot, Depot to Customer and Plant to Market. It shall be proposed to In-charge Control cell for review and subsequent approval by Lead Logistics. Logistics spread shall cover all the destinations and sources which are relevant from the Logistics viewpoint of the company. • Based on the spread the logistic cell shall finalize the locations and update in ERP. • After receiving approval from Lead Logistics, the Logistics Control Cell Team shall prepare ‘Freight Chart’ which shall begin with the mapping of all destinations served by the company along with the plants from where materials shall be dispatched. • On a monthly basis, freight figures shall be ascertained by Lead Logistics through market survey results and monthly statement of freight paid from source to destination. • Handling charges such as loading cost, unloading cost, etc. shall be ascertained by Logistic Control Cell team and approved by Lead Logistics. All the above figures shall be added to arrive at the landed cost. 25 • Upon receiving a request/ identifying a need for fixation of freight for a new destination or revision of freight for an existing destination, Lead Logistics shall collect information from market with existing or potential transporters. • Freight Economy Chart shall be prepared by Lead Logistics based on the rates finalied with the transporters. The same shall be maintained in ERP after approval of Head SCM. Inbound Inbound logistics is done in the following two ways: a) Port to Plant/Yard b) Yard to plant In case of imported items, commercial completes customs formalities, inform plant inventory about arrival/delivery, and follow different process for different ports. a) Imports by Land (Benapole) – trucks are hired by contractors who are basically commissioned agents enlisted with association as authorized transporter for that port. C&F agents in consultation with BSRM representative working in Benapole, gives program to contractors who hire trucks from curb market as prevailing rate on that day. Contractors’ commission is fixed irrespective of market rates, quantities or number of trucks, etc. Process flow: a) Truck list receive from Benapole. b)Follow up with transport. c)Co-ordinate with unloading point for ensuring smooth unloading. d)co-ordinate with receiving end and plant accounts to release the truck fair. e)Instruct to deduct any amount from truck fair if receiving end found any anomaly. f)Re-concile the receiving report. i. Imports by Air (Dhaka Airport) – generally small items are imported by Air, and C&F deliver those materials through private courier services. In case of very urgent materials, they send it by domestic cargo flight or by pick-up depending on convenience. ii. Imports by Sea (Chittagong port) – trucks are placed through enlisted contractor, and trailers are placed under contract. C&F agents coordinate with transport contractor for vehicle placement, and in case transport delays to respond or to place vehicle, they bring such delay to the notice of commercial who in turns ensure timely placement of vehicle. Internal logistic Management: Process Flow 1. Vehicle need assessment 2. Vehicle scheduling and monitoring 3. Logistical equipment and vehicle management a) Contractor maintenance and monitoring b) Cost monitoring of logistical equipment and vehicle c) Logistical equipment management Vehicle need assessment The internal logistic management shall be managed by the logistic department of corporate office. Lead logistics shall list down the required vehicles and assess the fund required for obtaining the same. Lead logistics shall list down the vehicles needed to be purchased and the vehicles need to be hired. Upon approval, the list shall be sent to the purchase team. 26 Vehicle scheduling and monitoring Plant logistics maintain day to day monitoring and if any problem occurs and if they need more vehicle then they inform corporate logistics. The vehicle schedule and status shall be maintained in the system by the logistics control cell. The cell may receive requests from the HOD’s of individual department on a weekly basis. If they receives such requests, they shall check whether any vehicles are available for open slot. If the vehicle is not available in the open slot (i. e. owned vehicle) or there is a clash in the timing then a vehicle shall be hired by the cell. Logistical equipment and vehicle management Logistics team shall be responsible for the maintenance of all the logistics equipments and vehicles owned by the company. a) Contractor maintenance and monitoring Contractor maintenance and monitoring is done by BSRM Logistics Ltd. b) Cost monitoring of logistical equipment and vehicle All the cost incurred for maintenance activities, fuel cost, vehicle hiring cost, driver costs and other costs incident to such equipment and vehicle shall be allocated to the respective department. c) Logistical equipment management Logistical equipment management means the monitoring of logistical equipment such as mobile crane, fork lift, excavator, dozer, pay loader etc. 4.2 PROBLEMS OF BSRM SUPPLY CHAIN DEPARTMENT Without problems no organization can exist. They have to face troubles in daily business activities. Because of that, they need to have a well organized and controlled management which let them to know their duties and span of work. BSRM supply chain department doing quite well in their way with an outstanding environment as well as excellent management. However, BSRM faces some difficulties as like as other import dependent companies, 1. To purchase best consumables & raw materials with good economy. 2. Sometimes, BSRM has to struggle with Customs regarding proper HS Code. 3. Maximum importers are getting their materials via Benapole& via Chittagong. Accordingly, sometimes BSRM faces problems to get their materials in time due to congestion in port. 4. BSRM has to struggle to import some rain sensitive materials in rainy season in want of proper transportation from port. 27 CHAPTER FIVE PRODUCTION DEPARTMENT The name of the production manager is KollanBortaachaza. Senior manager is the production department. This company has now 2000 workers are working in the production department. Each and every worker is expertise of the production procedure. Some workers are working in the hazardous environment. Sources of raw material: Import and local production by their sister concern Meghan Engineering Works. Production Capacity the machines: 10000 ton per month. Computerized technologies are used in production system. 5.1 ORGAN OF THE PRODUCTION DEPARTMENT The organ gram of the production department is given below. GM Production Kollan Bortaachaza. Manager Production Assistat Manager Shift Manager -1 Rolling mill oprater-1 Shift Manager-2 Rolling mill oprater-2 Shift Manager-3 Rolling mill oprater-3 Rolling mill oprater-4 Shift Manager-4 28 ORGAN OF THE PRODUCTION DEPARTMENT The organ of the production department is given below. Direct Oprative on Shift: Gr-1 Gr-2 Gr-3 Gr4 G Total GM - Operation 1 1 Manager Production 1 1 Shift Foreman 1 1 1 1 4 Charging Foreman 1 1 1 1 4 Furnace oprator 1 1 1 1 4 Billet Crane#1Oprator for Furnace Charging 1 1 1 1 4 Rolling mill operator 1 1 1 1 4 Mill Assistant 1 1 1 1 4 Mill Pulpit Operator 1 1 1 1 4 Finish Area Pulpit Operator 1 1 1 1 4 Bundling + Tying Machine Operator Bundle Crane#1Operator for Finished Product 1 1 1 1 4 1 1 1 1 4 Reserve 2 2 2 2 8 Billet Crane # 2 Operator for billet handling 1 1 1 1 4 Water treatment operator 1 1 1 1 4 Assistants Cooling Bed Area 1 1 1 1 4 TOTAL 13 13 13 13 2 54 0 MILL PREPARATION SHOP:Manager 1 1 Guide Shop Technician 2 2 2 6 Stand Assembly Technician 2 2 2 6 Assistant 2 2 2 6 TOTAL 6 6 6 1 19 0 WORKSHOP (ROLL SHOP):- 0 29 Roll lathe operator 1 1 1 Lug cutting & Grinding 1 1 1 3 Extra/Reserve 1 1 1 3 TOTAL 2 2 1 1 2 4 7 0 MECHANICAL MAINTENANCE:Manager, Mechanical 1 1 Foreman/Mechanical Engineer 1 1 1 1 4 Technician 2 2 2 2 8 Assistant 1 1 1 1 4 0 0 Reserve/Reviver 1 TOTAL 4 1 1 4 1 4 4 4 1 17 0 0 ELECTRICAL MAINTENANCE:Manager, Electrical Foreman/Electrical Engineer 1 1 1 1 1 1 4 Software Engineer 1 1 Technician (Software) 1 1 Technician 2 2 2 2 8 Assistant 1 1 1 1 4 Reserve/Reviver 1 1 1 1 4 TOTAL 4 4 4 4 3 19 0 LABORATORY AND QUALITY INSPECTION:- 0 Metallurgist/Quality Manager 1 1 Laboratory Assistant/Inspector 1 1 1 1 4 Assistant 1 1 1 1 4 TOTAL 2 2 2 2 1 9 30 5.2 PICTORIAL OPERATIONS IN BRIEF Twin Channel Roughing Mill Wire Roin Tensile Testing Machine Stock of MS Billets progress Controlled Cooling bed 5.5mm rod production Reheating Furnace Continuous Block Mill Weighing bridge 31 5.3 PRODUCTS OF THE COMPANY 5.3.1 ANGLES Details of Dimensions, Masses Etc. 32 MILD STEEL ANGLES – SQUARE ROOTEQUAL FLANGES SPECIFICATION : BS 4 : Part 1 : 1962 DETAILS OF DIMENSIONS, WEIGHTS ETC Size Nominal mass Leg (Inch) (mm) Inch (mm) 3 x 3 3/8 (9.525) 76.2 x 76.2) 5/16 (7.837) ¼ (6.350) 2 ½ x 2 ½ 3/8 (9.525)* (63.5 x 63.5) 5/16 (7.937)* ¼ (6.350) Thickness Lb / ft Kg / m Lengths per ton M. ton Feet Metre 7.10 6.00 4.80 310 112.0 459 140.0 374 441 551 114.0 134.5 168.0 5.90 5.00 4.00 10.56 8.93 7.14 8.78 7.44 5.95 4.60 3/8 (9.525)* 2 x 2 5/16 (7.937)* (50.8 x 50.8) ¼ (6.350) 3/16 (4.762) 1 ½ x 1 ½ 5/16 (7.937)* (38.1 x 38.1) ¼ (6.350) 3/16 (4.762) 6.84 3.90 3.20 2.44 479 565 5.80 689 903 146.0 172.5 210.0 275.5 Max. Lengths rolled Feet Metre 50-60 15-18 Do Do 60-70 18-21 Do Do 70-80 2124.5 Do Do 80-90 24.5-27.5 4.76 3.63 2.85 4.24 2.35 1.80 94.5 367 Normally available Lengths Feet Metre 20-22 6.06.7 3.49 2.68 773 938 1224 235.5 286.0 373.0 33 ROLLING TOLERANCES ON NOMINAL MASS Up to and including 3/16” thickness 5.0% Over 3/16” thickness 2.5% Note 1. These sizes are produced against specific order only. Note 2. Angles of other thickness & varying physical properties can be made to customer needs. Note 3. Some of the thicknesses given in the tables are obtained by raising the rolls. In such cases the flanges will be slightly longer and the back of the toes will be slightly rounded. 34 CHANNELS Designation Mass M Sectional Area, a Dimensions D B I Flange Slope, a deg R1 R2 Sectional Properties Cy Ix Iy Rx T Kg / m Cm2 mm mm mm mm mm mm mm cm4 cm4 cm cm cm3 cm3 (1) MC 75 (2) 7.14 (3) 9.10 (4) 75 (5) 40 (6) 4.8 (7) 7.5 (8) 96 (9) 8.5 (10) 2.4 (11) 1.32 (12) 78.5 (13) 12.9 (14) 2.94 (15) 1.19 (16) 20.9 (17) 4.81 MC 100 9.56 12.2 100 50 5.0 7.7 96 9.0 2.4 1.54 192 26.7 3.97 1.48 33.5 7.71 Ry Zx Zy 35 SPECIFICATION OF PLAIN ROUND BAR: NEAREST EQUIVALENT STANDARDS ASTM A 575, A 576, A 615; BS 4360, 4449; JIS G 3101, 3112; IS 226; ISO 1052; BDS 1313; 1990 MECHANICAL PROPERTIES TENSILE PROPERTIES Psi Strength 40,000 Kg / cm2 2,815 Yield min. Ultimate Strength min. 70,000 4,925 Elongation in G.L. 5d (d = Nominal 20% min. bar dia) BENDING&REBENDING Rebend Test PROPERTIES Bend Test DETAILS OF DIMENSIONS, MASSES ETC. Bar nominal CrossUnit mass dia sectional inch area Lb / ft Kg / m in2 3/8 0.11 0.376 0.560 ½ 0.20 0.668 0.994 5/8 0.31 1.043 1.552 ¾ 0.44 1.502 2.235 7/8 0.60 2.044 3.042 1 0.79 2.670 3.974 1 1/8 1.00 3.400 5.060 1¼ 1.27 4.303 6.403 N / mm2 276 485 App. Lengths Per M. Ton Feet Metre 5,862 3,300 2,113 1,468 1,079 826 648 512 ROLLING TOLERANCE ON MASS (BS 4449 : 1988) Nominal dia (inch) Tolerance (%) 3/8 6.5 ½ & over 4.5 1,786 1,006 644 447 329 252 198 156 36 5.3.2 LOW CARBON WIRE RODS Specification of Low Car Chemical Composition (Percent) Grade Carbon Sulphur Phosphorous Low Carbon Wire Drawing 0.09 max max 0.02 max (WR-8) Electrode Core Wire 0.10 max max 0.05 max Commercial Grade 0.25 max max 0.06 max Silicon 0.03 max Manganese 0.40 to 0.60 0.023 0.10 max 0.25 to 0.50 0.05 0.30 max 0.45 to 0.90 0.05 Physical properties WR-8 Grade Commercial Grade Yield Strength Ultimate Tensile Strength Elongation on G.L. 5 dia - Electrode Core Wire 20.0 Kg / mm2 min 22.86-24.0 Kg / mm2 40.0-44.0 Kg / mm2 39.0-42.0 Kg / mm2 20% min. 25% min. 37 Details of Dimensions, Masses etc. Nominal Dia Area of Crosssection Nominal mass App. weight per coil App. diameter OD ID coil App. lengths coil App.lengths per M. Ton Mm mm2 Kg / m Kg mm mm Metre Feet Metre Feet 5.5 6.0 6.35 23.77 28.28 31.67 0.186 0.222 0.249 135 135 135 1200 1200 1200 890 890 890 725 608 542 2,378 1,995 1,778 5,376 4,505 4,016 17,638 14,778 13,172 DIMENSIONAL TOLERANCES Tolerance on dia -0.27 mm +0.27 mm 5.3.3 TORSTEEL Tolerance on mass 8.0 % 38 Major Advantages of Torsteel compared to mild steel round bars Chemical Composition Details of Dimensions, Masses Etc. The introduction of high yield strength deformed bar as reinforcing steel has revolutionized the world of reinforced concrete design. Rebbed - Torsteel bar or in short TORSTEEL - a high strength cold - twisted deformed bar, originally developed by TORISTEG STEEL CORPORATION of Luxembourg, Germany is now a widely accepted re-bar in most countries of the world. BSRM was the foremost in Bangladesh to produce and market Torsteel under licence from its inventors who possess the patent right in Bangladesh for its manufacturing process with various profile combination. Torsteel is produced from mild steel billets with limited carbon content (0.30% max.) by controlled cold - twisting of hot-rolled deformed bar with its characteristic configuration. Each bar is cold-twisted individually. The cold twisting works the steel beyond its elastic limit and a bar with normally inherent defect breaks during twisting. Every piece of Torsteel bar thus undergoes this severe automatic test during its twisting process. Use of Torsteel bar results in 40% steel saving and 30% saving in steel cost compared to mild steel round bars of 36,000 psi (250 N/mm2) yield poin. Major Advantages of Torsteel compared to mild steel Round Bars. 65% higher yield strength 100% higher bond strength Satisfactory weld ability due to limited carbon content Lesser crack width of RCC members 20% extra factor of safety due to elimination of definite yield point Net economy in reinforcing cost: 35% in tension, 30% in compression End hooks not required due to 100% higher bond capacity Saves labor, transportation, supervision costs due to reduction in steel consumption Being a licensed product the quality is guaranteed 39 Specification of Torsteel Bar Chemical Composition Carbon 0.30% Max Sulphur 0.06% Max Phosphorous 0.06% Max S+P 0.11% Max Physical Properties Yields or 0.2% Proof Strength (Min) 415 N/mm2 4,225 Kg /cm2 60,000 Psi Ultimate Tensile Elongation on Bend Test Strength G.L.5d* (Min) (Min) 485 N/mm2 4,925 Kg /cm2 70,000 Psi 14.50% Rebend Test Around a Around a mandrel mandrel of dia 5d* through of dia 3d* 45° and reverse through 180° d = Nominal dia of bar Details of Dimensions, Masses etc. Nominal Dia (mm) 8 10 12 16 20 22 25 28 32 Area of Cross Section (mm2) 50.3 78.5 113.1 201.1 314.2 380.3 490.9 616 804.2 Nominal Weight (kg/m) 0.395 0.616 0.888 1.579 2.466 2.985 3.854 4.836 6.313 Approx. Lengths per Metre 2,532 1,623 1,126 633 405 335 259 207 158 M.Ton Feet 8,307 5,325 3,694 2,077 1,330 1,100 850 680 518 40 ROLLING TOLERANCES ON NOMINAL MASS (BS 4449 : 1988) 8 & 10 Over 10 5.4 PRODUCT INFORMATION Products Nearest Equivalent International & National Standards. BS 4461, 4449; DIN 488, 1045; JIS G 3112; BA 1968; IS 1786; GOST 25 G2C; BDS 1313 : 1990 Intended use Ideally suitable for all kinds of reinforced concrete works, especially where high strength & high bond value with concrete is desired. Ideally suitable for all kinds of ASTM A-615; BS 4449; JIS reinforced concrete where high bond DEFORMED BARS G-3112; BA 1968; DIN 488, (Hot-rolled) value with concrete (and high 1045; IS 1786; BDS 1313 : Grade 40 & Grade 60 strength in case of Gr.60 bars) is 1990 desired. ASTM A-575, A-576, ASuitable for ordinary reinforced 615; BS 4360, 4449; JIS G concrete where high bond value is PLAIN ROUND BARS 3101, 3112; IS 226; BDS not essential. Also suitable for 1313 : 1990 manufacturing bolts and nuts. Ideal for all structural works where weldability is the prime factor. Also BS 4 : Part 1 : 1962 EQUAL ANGLES suitable for bridges, towers etc. where rivetted joints are important. Ideal for structures like steel columns & beams in factories, bridges etc. IS 808 : 1989 CHANNELS and base frames for machinery &equipments. TORSTEEL BARS (Cold - twisted high strength deformed bars) ASTM A-111; BS 970; JIS LOW CARBON WIRE G 3505; DIN 17140; * JIS G RODS 3503; (5.5 mm/6.0 mm/6.35 mm) * SWRY - 11; * SWRM - 8 Specially suitable for wire drawing for G.I. wire, binding wire, railway signalling&armoured wire etc. * Electrode core wire. 41 5.5 QUALITY CONTROL PROCESS OF BSRM BSRM collects most of the raw material from abroad.They try to use best qualified raw material for producing their product. For maintaining quality of the product they use qualified machines which are mainly imported from abroad. Final product testing is done in a modern testing lab equipped with computerized testing machines to ensure chemical and mechanical properties. Finished goods are stored in intermediate quarantine until clearance from quality control and then stored in the finished goods storage area ready for delivery. Product traceability is ensured through a label that shows tionthe date of production and other information such as diameter, length, weight of bundle and grade. This quality system ensures the best way to trace any product back to its date of production to verify the different production conditions at that time and the source of raw materials used. This traceability is an integral part of the prestigious CARES certification scheme. CARES have total of 199 test among which BSRM has already passed 185 test and BSRM has on the hard line to get CARES certificate. 5.5.1 ORGANOGRAM OF THE QUALITY CONTROL/ASSURANCE DEPARTMENT OF BSRM STEELS LTD. DGM/ GM Production. Maintenance Manager Assistant Engineer Sub. Assistant Engineer Quality Manager Quality Officer Production Manager Assistant Manager Technician 42 5.5.3 QUALITY TEST MACHINES For testing the steel that are finally produced BSRM used some world class machines that gives clear information about the products strength. Among all the machines Bar bending mandrel, CMC roll turning lathe, Universal testing machine and Computer attached with UTM is mostly used. A. Bar Bending Mandrel: It is a machine by which some specific properties of Reinforcement are tested. The tests are bend test. At the bend test the finish product’s sample is bended by 1800. 1. The result of bend test will be positive if the bended sample is not broken or cut. 2. The result of bend test will be negative if the bended sample is broken or cut. Bar Bending Mandrel: B. CNC Roll Turning Lathe: It is computer Numerical control Lathe machine. A vast quantity of controlling can be done machine. Such as: To decrease higher iron made objects to lower diameter objects, to make thread on iron made 43 CNC Roll Turning Lathe: C. Universal Testing Machine (UTM): It is a Machine by which tensile properties of Reinforcement are tested. Yield strength, Tensile strength & Elongation of Reinforcement are obtained from this machine. Universal Testing Machine (UTM) 44 D. Computer attached with UTM: A computer is attached with the Universal Testing Machine. The tested data’s of UTM are transferred to this computer. Then the computer shows the graphical representation of Yield Strength, Ultimate Tensile Strength & Elongation of Reinforcement. Computer attached with UTM 5.5.4 FEATURES OF ISO RELATED ISSUES OF BSRM BSRM obtained their ISO 9001: 2000 in the year 2000. BSRM is the first steel manufacturing organization that got ISO 9001: 2000 in Bangladesh. For BSRM the checking and observation authority is URS, which is affiliated by ISO. The inspector of URS is basically come from Pakistan. The inspection is done by every six months. 45 CHAPTER SIX The Marketing Department of the BSRM 6.1 CHANNEL RELATIONSHIP 6.1.1 Orders Receiving & Supply Channels Marketing channel decisions are among the most critical decision facing management. Marketing channel can be viewed as set of interdependent organizations involved here in the process. Total distribution/delivery system of BSRM is mainly in two types- a) Direct Orders & Direct Supply: BSRM takes direct orders by e-mail, telephone, etc. Basically some potential buyers are directly sending their orders to head office. Real estate companies, dealers are such kind of buyers. Order Receiving BSRM H.O. Customers BSRM Mills Customers Delivery of Goods 0 Level Channel a) Order & Supply Through Dealers: BSRM has more than 800 (eight hundred) dealers and distributors all over the country. They distribute their products to their customers through them against the orders which are received through them. 46 Order Receiving: BSRM H.O. Dealer Customer BSRM Mills Dealer Customer Delivery of Goods: 1 Level Channel a) Orders & Supply Through Local Offices : BSRM has 6 (six) local offices throughout the country by which they mainly control their sales and marketingactivities. The offices are located at Dhaka, Sylhet, Moulvibazar, Bogra, Khulna& Comlla. All the goods against direct marketing orders are being distributed through these offices. They also monitor their customer care activities through the local offices. Order Receiving: BSRM H.O. BSRM Local Office Customer BSRM Local Office Customer Delivery of Goods: BSRM Mills 2 Level Channel Internal Order Receiving & Follow Up Procedure: After receiving the order at any point of BSRM’s sales personnel of BSRM input the data to the central network at Head Office. After receiving the data the Customer Service Department (CSD) arrange checking with the respective office and get approval from the competent authority. If the receipt of payment is confirmed then the CSD Department arranges issuance of related Delivery Order (DO) in favour of the customer. Once the DO 47 is issued then the data has been transmitted to the respective CSD Department at mills for final delivery. Then the CSD Department arrange delivery of the materials to the customer accordingly. Materials to the customer accordingly. Customer Order Placed BSRM Local Office Information/Data sent BSRM H.O. Approval given BSRM H.O.CSD Delivery Order issued in favour of customer & data sent BSRM Mills CSD Arrangement for delivery of goods to Customer 6.2 PROMOTION MANAGEMENT Promotional Activities BSRM has a strong team of employee in their Marketing & Promotion Department headed by the Head of Business & Product Development. BSRM develop their branding and promotional activities with the help of M/s UnitrendLtd.,Dhaka. They are mainly 48 developing and circulating the promotional campaign for BSRM to various media. Promotional Budget Total promotional budget for “BSRM Xtreme 500W”was about Tk.8.00 crore in 2009 which is about 0.51% of their annual tern over and the budget is decided by the management on residual method. Selecting Effective Promotional Tools BSRM settled on a strong positioning statement, it develops various strategies for its marketing programs. For BSRM this means considering programs such as: Conference & Trade Show Direct Marketing Advertising Marketing Communications By BSRM Emarketing . Merchandisin g Promotion Public Relation Website Materials Advertising Work Shop Tele Marketing Seminar & Symposium Sign Board, Billboards Event Sponsorship At present BSRM adopt various advertising policy for promotion of their products. They use print media such as news papers, magazines and various TV channels for circulating their ads. Basically they circulate informative ads for their product. As they are in the line from 1952, sometimes they also circulate reminder ads for their products. Sometimes they distribute products brochures, leaflet, etc. among the engineers, users and general public. As a result they get huge coverage of their products to general public. In general BSRM expend 45% of their promotional budget on TV ads, 20% on daily newspapers ads on local & national,10% on billboards and signboards,10% on public relation activities (such as road dividers, donations, helping the poor on various occasion, etc.), 5% on merchandising promotions,5% on seminar, symposiums, conference, event sponsorship, etc. and 5% on others. 49 Mer.Promotion 5% Seminar,Sympo 5% Others 5% Public Relation 10% Billboard,Sgnbrd 20% TV Ads 20% New s Paper Ads 35% Public Relations: BSRM participate in various fairs organized by CSE, Organization of real estate companies to send the messages of their company. They have strong tie with various print media as they are circulating their ads by them. Sometimes news papers cover events or news of BSRM products where they discuss about the product of BSRM. Web Materials BSRM strongly believe that now-a-days without a web site no company will be successful. So they developed their website by putting information about their company & their products. They placed products brochures, usage instructions and other product related info on their web. They placed their price list and purchasing procedures to their web. Anybody can enquire by sending a message to them. As a result communication system has developed. SEMINARS & SYMPOSIUMS Sometimes bsrm arrange seminars and symposiums for their dealers, engineers and masons as they are the ultimate users of the bsrm products. By these seminar & symposiums they communicate their messages to the attendant. Conferences and trade shows Bsrm arranges various conferences for engineers and dealers where they communicate their messages to them. They attend various conference and trade show. Direct marketing As bsrm is the pioneer and renown company in the steel manufacturing industry they have a lot of loyal & potential customers all over the country. They place their orders with bsrm directly through their local offices. 50 Event sponsorships Bsrm sponsors various real estate fares, seminars and symposiums, donate food and cloth in flood effected area and many more. Bsrm provides road dividers to the traffic police department which is dividing the roads to control traffic jam. Merchandising promotions Bsrm gives various promotional gifts such as umbrella, table clock, t-shirts, mug, key ring etc. With their company logo and products information & ad to the dealers, engineers and masons as they are the ultimate users of bsrm products. They also give discount of tk.1,000.00 per ton to the dealers. E- marketing Bsrm sometimes communicate their promotional activities through e-mail correspondence. As most of the major buyer of bsrm are well educated and technologically advanced they really like to get promotional news by e-mail. Tele- marketing Bsrm sometimes takes telephonic-marketing procedures for their promotional activities. They communicate information of changes of their product by telephone to the sophisticated buyers as engineers, dealers, real estate companies other sophisticated customers of their products. 51 CHAPTER SEVEN 7.1 HUMAN RESOURCE MANAGEMENT OF BSRM “Main strength of the Progress” Human resources are the most important role in today’s competitive business environment. To build skilled manpower, Bangladesh Steel Re-Rolling Mills Ltd. continues to offer a wide range of internal and external personnel development programs and on the job training to its employees in developing individual, professional and technical skills. In this connection, the Company’s Human Resources Department continuously conducts and organizes extensive training programs. Emphasis is also given to improving career-oriented activities. The employees of Bangladesh Steel Re-Rolling Mills Ltd. believe in a collaborative spirit. They appreciate that working as a team multiplies the strength of the individuals involved, as well as the impact on the results. Industrial relationships are harmonious. There are various employees are working under human resource management. These are as follows: Sources of required candidates and advertisement: The organization usually searches external sources for required candidates. For recruiting employees, the company follows “Daily Newspaper” for advertisement. Collection of application form and preparing short list: The company collects application form from applicants by courier services. A short list of Candidates from among all candidates is prepared according to qualification &experience in the field. RECRUITING SOURCES FOR UNSKILLED JOBS: There are recruiting sources through unstructured. The popular sources of managerial jobs are press advertisement. Job analysis, job description and job specification: There is clear job analysis in this organization before recruitment. There is clear job description and job specification for every job in the organization. The organization selects employees according to job specification. 52 Barrier in employee selection: There is no barrier in case of selection the employees. Salary structure: The company has clear salary structure. Salary varies from employee to employee Number of employees: Officers- 60 Staffs- 40 Number of workers: Total number of employees- 750 Compensation facilities: this company has compensation facilities like clinic / medical & financial compensation. The followings criteria are the basis for setting basic pay: 1. Seniority 2. Experience 3. Performance 4. Position 5. Academic qualification In real sense bsrm believes that the employees of bsrm are the best resources of the organization and their motivation is a vital factor for the growth and development of the organization because of its direct impact on productivity. Bsrm hr focuses on valued employees to optimize their creativity, performance and sustainable improvement by ensuring a safe & healthy working environment, cohesive corporate culture, proper training, reward and recognition, various employee benefits scheme. Starting from selection of right man for the right post bsrm hr works to nurture its talent towards achievement of its goal. Human resources department of bsrm formulates and implements the best practices, policies, rules, guidelines to work strategically in identifying and responding to the company’s vision and needs. Bsrm thinks ahead along with its people. Reinforcing bsrm vision “be an employer of choice, with focus on nurturing talent and developing future 53 Leaders of the organization” human resources department is committed to achieve excellence in every steps of its operation through different functions & projects. Talent acquisition: This is a recruitment process rather human resources department follows the set recruitment and selection policy and strategy to attract qualified potential candidate who are committed to achieve the organizational goals. Key components of the process on hiring the potential applicants who demonstrate the attributes that include appearance & people focus, speech, expression & information handling, experience for work, qualification for work, maturity & dependability, leadership, energy & attitude, strength & weakness for the job. Human capital: Bsrm believes that human resources of the company are their best capital. This human capital push the organization towards achieving the goal. Bsrm nurture this human capital through different motivational projects & training. In-house, local & training abroad sharpen the trainee’s talent which ultimately result in productivity & success. Company’s domiciliary, hospitalization, maternity scheme are there to take care of the health of the human capital. Human resource accounting: Human resource department of the company maintain statistics through hris. Employee cost to the company, total salary cost, department wise salary benefit cost, percentage of increase, comprising to other organization in job market maintaining, the hr budget etc. Hr accounting of the company covers. Hr accounting helps as an indicator to match with the present job market to hire & retain talents in the organization. Training & development: In order for nurturing the talents management of bsrm believes that institutionalizing a learning culture positively helps safety, sustainability, quality and productivity of the organization. Our human resources department strives to provide training & development opportunities to all employees in a systematic process. The process ensures adequate competency of employees to fulfill their job responsibilities and provide a guideline for the identification of individual training needs to ensure that competency and qualifications to perform specific tasks are maintained. Through a planned training calendar BSRM hr arranges in house/external/outbound/foreign trainings for the employees. 54 Health, safety and environment [HSE]: We are also certified company. Bsrm management take utmost care in maintaining healthy & safe working condition & environment. All work place injuries and occupational disease are preventable. Providing and maintaining safe and healthy working conditions and following best operating practices that protect the environment, bsrm established a culture of the excellence in the organization. BSRM has its environment policy and the management systems which are implemented to ensure the safety and health of employees. Adequate safety equipment e.g. Personal protective equipment [ppe] are supplied to the employees to take proper precautions in certain areas, processes and jobs known to involve a risk of injury. Evacuation instructions are displayed at various points for the event of an emergency e.g. Fire. The team is utilizing their talents for sustainable improvement of injury free workplace and to ensure a healthy environment. Performance management system [PMS]: Key performance indicator (kpi) present mirror of the organizations performance. Employee evaluation is linked to individual performance aligning with the goals and priorities of the organization. Human resources department conducts a performance assessment at the end of the year on achievement results through assigned kpi/kra and individual competency. This ensures a fair and accurate evaluation to review an employee’s career development. Succession planning: To identify necessary competencies and to assess, develop and retain a talent pool of employees in order to ensure a continuity of leadership for all critical/significant positions bsrm sets a succession planning process. Succession planning process helps skilled employees to gain the experience and competencies so that they can move into vacant positions. Online hris: Online human resources information system is designed and developed to offer employees an extended level of service and flexibility by providing web-based, self service access to personal and official information. Employee benefits: To remain competitive in the industry and considering the welfare and needs of the employees bsrm focus on benefits structure. As part of employee benefits policy bsrm 55 employees are receiving different benefits and allowances other than remuneration like leave, festival bonuses, provident fund, gratuity, salary advance, interest free company loan for car scheme, children education scheme, employee education scheme, employee children education achievement award for distinct academic results, domiciliary scheme, executive health check-up scheme, hospitalization scheme, maternity benefits scheme, wedding gifts etc. Reward and recognitions: To recognize employees for their excellence in service, loyalty, ideas, dedication to the values and vision of the group and their contribution to change management the company present awards in recognition like long service award, living the value best award, best suggestion award, change catalyst award, significant contribution award, safety icon of the year, etc. Learning centre: Bsrm provides the opportunity to visit the industries to gather practical knowledge and enhance learning experience to nominated students from different universities/institutes as a part of their academic requirement. Using internship program of bsrm, students can complete their internship period under respective department to accomplish his/her academic/professional degree. After completion of academic studies students can join as apprentice or as trainee, which helps to be trained and develop skills, abilities at an early stage of their career. Bsrm publishes corporate brochure, newsletter “xtreme talk” periodically to share information to the employees and customers. Equal opportunity: Bsrm provides equal employment and advancement opportunities to all qualified persons based on their merit, qualifications and abilities without discrimination on the basis of age, sex, race, marital status or religion in accordance with laws, rules and regulations. 56 CHAPTER EIGHT 8.1 FINANCIAL DEPARTMENT 57 8.2 KEY PERFORMANCE INDICATOR 58 CHAPTER NINE 9.1 PROBLEM Without problems no organization can exist. They have to face troubles in daily business activities. Because of that, they need to have a well organized and controlled management which let them to know their duties and span of work. BSRM supply chain department doing quite well in their way with an outstanding environment as well as excellent management. However, BSRM faces some difficulties as like as other import dependent companies, 1) To purchase best consumables & raw materials with good economy. 2) Sometimes, BSRM has to struggle with Customs regarding proper HS Code. 3) Maximum importers are getting their materials via Benapole& via Chittagong. Accordingly, sometimes BSRM faces problems to get their materials in time due to congestion in port. 4) BSRM has to struggle to import some rain sensitive materials in rainy season in want of proper transportation from port. 5) Some customers are expecting competitive prices from BSRM. But to fix the prices at market level we found following problems: a) BSRMcharges premium prices which they think is logical in terms of their quality and goodwill. b) BSRM argues that to maintain the quality of their products they have to expend more in their production process and quality assurance; c) BSRM has achieved goodwill in the market for supplying standard products at a prestigious price. To bear the prestige they are keeping their prices high in the market. 4) Prices of steel rod in the markets are very unstable. It mainly depends on the scrap and billets rates of the international and home market. BSRM can not compete in the market with the lower prices for the following reasons: a) Some of the competitors have backward linkage industries for producing their raw materials, as a result their production cost is stands low. b) Competitors’ marketing channels are very strong as a result they have competitive advantages to deliver their products to the customers. But BSRM has no such facilities. c) Some of the major competitors are located at Dhaka which is the larger market for steel rod. As BSRM is located at Chittagong their delivery charges are on the high side. So customers at Dhaka market can buy products from local suppliers at the lower prices. d) As BSRM depends on imported raw materials which are sometimes expensive so they can not give their products to the customers at the lower prices. e) BSRM has very large establishment maintenance cost of which is very high. So it increases their products prices. 59 9.2 RECOMMENDATION OR SUGGESTION FOR SOLVING PROBLEM The following action plans may be recommended for the successful development, promotion and profitable sales of the BSRM: • To fill up the skill shortage of BSRM, they can appoint fresher and develop them at their mills by giving them in house training by the foreign experts. They can impose some bindings of leaving the company at the time of appointment. Then the migration habit will decrease among the employees. • To attract the appropriate persons from the steel rod industry BSRM can offer them handsome salary and other fringe benefits, so that people will be very much interested to join BSRM. • BSRM should build up backward linkage industries for their raw materials-billets. If they can build another two billet manufacturing industry then their import dependency will be decreased at large. It is hopeful that BSRM already established their new billets manufacturing plants in the name of BSRM Iron & Steel Co. Ltd. at Nasirabad I/A, Chittagong with the investment of Tk.350.00 crore to manufacture 25000 M/Tons of billets per month. The plant will go for production within 15th March, 2010. • Establishment cost of BSRM Steels Ltd. Is very high. As a result their products prices become on the high side. To re-fix the products prices at market level BSRM should reduce establishment cost by cutting down additional cost at their mills and others. If they could re fix their prices at market level BSRM’s total sales will increase which will add profit for the company in the long term. • BSRM should extend and accommodate their raw materials and finished products store so that they can store huge quantity of raw materials and finished goods for. 60 CHAPTER TEN CONCLUSION BSRM is the capital intensive mills. It is fully automated process. From my visiting Bangladesh Steel Re-Rolling Mills Ltd, it is obvious that, they are producing quality product. There is a great demand of their production the real estate business. It is also a pioneer and leading industry in the field of Steel. The several departments in this industry are operating their respective activities smoothly and efficiently. The production, sales and marketing activities of the company are expanding day by day in countrywide. The organization is a completely profit making organization. 61 CHAPTER ELEVEN REFERENCES Direct communication with inspection. Personal communication. E-mail: bsrm@globalctg.net(Head Office),Fax : 88-031-610101 bsrm@bangla.net(Dhaka Office) bsrm@spnetctg.com (Factory) Annual report of BSRM. Web Site: www.bsrm.com Chopra, Sunil and Peter Meindl. Supply Chain Management. 2 ed. Upper Saddle River: Pearson Prentice Hall, 2004. MIT Sloan, Management Review, Sunil Chopra and ManMohan S. Sodhi, FALL 2004 VOL. 46 No. 1 Sunil Chopra and Peter Meindl. (2006) “Supply Chain Management; Strategy, Planning and Operation” Third Edition. 62 CHAPTER TWELVE APPENDIX Questionnaires Company Profile: 1. Profile of the enterprise: 2. Name of the company: 3. Registered office: 4. Location of Factory: 5. Form of organization: 6. The year of establishment: 7. Year of commencement of production: 8. Line of products: 9. Initial capital: 10. Total Manpower Executives: Employees Workers(skilled- semi skilled – unskilled) Management of the company: 1. The management system of your company? 2. Type of Organizational structure? 3. Organogram of the enterprise/ company? Purchasing related information: 1. What is the designation of head of the procurement of materials and stores? 2. Types of raw materials used? 3. Sources of raw materials? 4. What is the production capacity of the stove house? 5. Responsibilities of procurement manager? 6. Requirements of materials per day / week / month/ year? 7. Procedure used for collecting materials? 8. Procedures for determining material requirement planning? 9. What is your economic order quantity, reorder point? 10. Process used for determining procurement requirements? 63 Production & operation related information: 1. Designation of the head of this department: 2. Factors considered in determining production targets: 3. Capacity of production : 4. Percentage of utilization of capacity: 5. Procedure for using quality: 6. Selecting quality requirements: 7. Production for the last five years: 8. Nature of technology used: 9. Maintenance procedure: Proactive Convective? 10. Maintenance is done: internally /externally. 11. Stock level of finished products: Production cycle time: 1. Process/ flow chart of production. 2. What about TQM in your organization? 3. Comply with international quality sample. Product pricing/Product data: 1. What are the products of your firm? 2. What is the brand name of your products? 3. Do your products have ISO standard? 4. What type of pricing policy do you use? Pricing strategy of your company? 5. What are the factors that influence pricing? 6. Is there any price discriminations? 7. Is there any seasonal variation of price of the products? Marketing related information data: 1. In which countries you're exporting your products? 2. What is the worth of your brand value? 3. What strategies are adopted to expand foreign market? 4. Is this organization involved in CSR activities? 5. Do you have any plan to adopt 'Green Marketing '? 6. How you collect customer feedback? 7. How you handle negative review of customers? 8. Does international steel industry has impact on your local business? 9. Do you have any affiliation with international steel industry associations? 10. What marketing philosophy do you follow? 64 11. What are the functions of your marketing department in your firm? 12. What are the advertisement media you use for the promotion of the products? 13. Types of series provided to the customer? 14. Do you export any products? 15. How do you select the channel members? 16. Is there any warehouse outside the factory? 17. What incentives do you provide to your channel members? 18. What is the amount of annual promotional budget? 19. What promotional strategy do you use in your company for products? 20. Please supply the annual reports for 2013, 2014, 2015? 21. What is the peak period for your products? 22. What is the target sale in the next 3 years? 23. Are there any sales incentives for the employee? 24. Percentage of market share covered by the company? 25. Sales for the last five years? Human Resource: 1. Are organization's HR executives fully aware of the business needs and strategies? 2. Effort are taken to generate awareness amongst the employees about the organization's financial position, customer’s needs, quality of product/service, cost etc. --- (please give your comment) 3. Are the organization's human resource requirements systematically ascertained and an appropriate plan is formulated for satisfying the requirements? What factors are usually considered for this? 4. Are all major jobs subjected to formal job analysis? 5. Are performance standards carefully developed on the basis of employee's opinion? 6. Is performance appraisal system extended to all members of the organization? 7. The organization has a formal policy of career planning and development --Yes or No (If so, given an idea) 8. How many shifts does your company operate? 9. What is the working hour? 10. What are the bases of employee promotion? 11. What type of incentive/motivation do you offer to your workers? 12. Do you think that your workers or stuff have job satisfaction? 65 Financial department: 1. 2. 3. 4. Who heads the finance department? What are his functions? What amount is contributes by you to the national revenue? Profitability for the last 5 years?