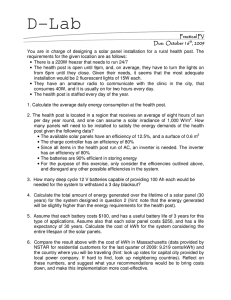

Auto Power Supply Control From Four Different Sources ( Solar,Wind,Main and Generator) To ensure No Power Interruptions. Abdimalik, Abdikarim,Mubarik,Khadan,Saynab,Ridwan and Ahmed Department of Electrical Engineering University Of Hargeisa Hargeisa, Somaliland Year: 2019 i Certificate of originality We hereby declare that this report, submitted to the College of Engineering of the University of Hargeisa as a partial fulfillment of the requirements for the Energy conversion and rural electrification course in Electrical Engineering has been submitted as an exercise in the university. We also certify that the work described here is entirely our own except for excerpts and summaries whose sources are appropriately cited in the references. This report may be made available within the university library for the purposes of consultation. Date: 20-january-2019 1:- Abdikarim Awale Dool ID : 1512094 ________________________________ 2:-Abdimalik Mohamed Mecad ID: 1512681 _______________________________ 3:-Mubarki Yuusuf Ibrahim ID: 1512781 ________________________________ 4: Saynab Hassan Nuh ID: 1513149 _____________________________ 5: Khadan Abdi Muhumed ID: 1513215 ____________________________________ 6: Ahmed Abdisamed Abdilahi ID:1512034 ___________________________________ 7: Ridwan Mukhtar Dayib ID : 1512952 ___________________________________ ii Approval sheet This is to certify that this project report entitled “Auto power supply control from four different sources such as main, solar, inverter, generator intended to Hargeisa Group Hospital” submitted by: 1: Abdikarim Awale Dool ID : 1512094 2:Abdimalik Mohamed Mecad ID: 1512681 3:Mubarik Yuusuf Ibrahim ID: 1512781 4: Saynab Hassan Nuh ID: 1513149 5: Khadan Abdi Muhumed ID: 1513215 6: Ahmed Abdisamed Abdilahi ID:1512034 7: Ridwan Mukhtar Dayib ID : 1512952 In partial fulfillment of the requirements for the degree of Bachelor of Science in Electrical Engineering of the College of Engineering, University of Hargeisa during the academic year 2018-19 has been accepted. Supervisor: Bewnet Getachew Signature: _______________ Date: ___________________ iii Acknowledgement We would like to express our sincere gratitude towards all the people who have contributed their precious time and effort to help us, without them it would have been a great difficulty for us to understand and complete the project. We would especially like to thank our supervisor Eng Bewnet Getachew, for his guidance, support, motivation, and encouragement throughout the period this work was carried out. His readiness for consultation at all times, his educative comments, his concern, and assistance even with practical things have been invaluable. iv ABSTRACT The main objective of this project is to provide uninterrupted power supply to a load, by selecting the supply source automatically from any available one out of 4 such as: mains, generator, inverter and solar in the absence of power supply. The demand for electricity is increasing every day and frequent power cut is causing many problems in various areas like industries, hospitals and houses. An alternative arrangement for power source is thus desirable. This project employs four switches to demonstrate / activate respective failure of the source of power supply. When any of the switches is pressed, it shows the absence of that particular source. Switches are connected to the microcontroller as input signals. A microcontroller of the PIC16F8 family is used. The output of the microcontroller is given to the relay driver IC, which switches appropriate relay to maintain uninterrupted supply to the load. Output is observed using a lamp drawing power from the mains initially. On the failure of the mains supply (which is actuated by pressing appropriate switch) the load gets supply from the next available source i.e. an inverter. If the inverter also fails, it switches over to the next available source, and so on. The current status, like which source is supplying power to the load is also displayed on an LCD. As it is not feasible to provide all 4 different sources of supply, one source with an alternate parallel arrangement is provided to get the same function for demo purposes. However 4 different sources if available they can be used. The project can be further enhanced by using other sources like wind power also, and then can take into consideration the best possible power source – the one whose tariff remains lowest at a given moment. v Content table Certificate of originality …………………………………………………………i Approval sheet ……………………………………………………………………..ii Acknowledgement………………………………………………………………..iii ABSTRACT…………………………………………………………………………….iv 1. Introduction……………………………………………..1 1.1 Motivation……………………………………………1 1.2 Statement of the problem ……………………………..2 1.3 Objective of the project……………………………….2 1.4 Limitation of the project………………………………3 1.5 Organization of documentation……………………….3 2. Literature review...............................................................4 2.1 Definitions………………………………………………4 2.2 Diagrams………………………………………………5 2.2.1 Schematic circuit diagram……………………………5 2.2.2 Block diagram ………………………………………..6 2.3 components……………………………………………7 2.4 working principle ……………………………………..8 2.5 advantages …………………………………………….9 2.6 disadvantages………………………………………….9 2.7 Applications…………………………………………..9 2.8 Scope of the project…………………………………..10 3 Analysis and Design…………………………………11 3.1 Analysis………………………………………………11 vi 3.2 Design………………………………………………..12 3.2.1 Programming……………………………………….12 3.2.2 Hardware requirement…………………………… ..13 3.3 Recommended Solar System…………………………..13 3.3.1 Solar system ………………………………………….13 3.3.2 Overview……………………………………………...13 3.3.3 Stand-Alone Solar system…………………………….14 3.4 Solar system components………………………………15 3.5 Solar system sizing……………………………………. 18 4. Conclusion………………………………………………..21 Reference……………………………………………………22 Appendix A………………………………………………….23 Appendix B………………………………………………….24 vii CHAPTER ONE INTRODUCTION 1.1 MOTIVATION In this modern time the electricity became a part of life as there are more and more electronic and electrical machines around us which we use various ways.These electronics changed the way we life by easing communication and transport of the humans. Despite these technological victories, there is a problem of electricity and its utilization in many countries. In Somaliland the electrical energy is expensive in terms of cost that makes Somaliland one of the highest electricity payment around the world. The average cost of Somaliland electricity is $0.79kWh where the world’s average cost of electricity is between ($0.15 up to$0.30).This is due to usage of diesel generating methods that consume fuel which is also an expensive energy. We need to think of the energyresources that our country is rich like the sunlight intensity and the wind. If we install windmills and solar panels in the country we can harvest the clean and cheap electricity which will drive the industries and businesses in the country. If foreign investors find a cheap electricity in our country they may fund or move large scale industries into our country where we can find hundreds or thousands of jobs and it will be the beginning of economic growth in Somaliland. To achieve all above suggestion we must improve the usage and utility of the electricity into new means by analyzing the obstacles that opposed our power energy and also try to solve or minimize the impact of the problem . Every system has its weaknesses whether they are minimum or not, it is a must to solve that limitations as much as we can. If there is no challenges then there will not be new inventions because it was already said “the necessity is the mother of invention” which means after the problems arise, solution may be created. After these developments arrive there will be a need of control systems that improve the existing systems and also rise the quality of new systems. These control systems can be such as our topic’s one “Auto power supply control from 4 different sources”, that we are going to overcome the challenges of power breaks in some places which use interconnected electricity sources. 1 Auto power supply control from different sources will help the commercial sites, industries,hospitals,homes, government institution and also educational places to get uninterrupted and reliable electricity from their interconnected grid electricity supply. 1.2 STATEMENT OF THE PROBLEM Some places like Egal international airport uses a combined different electricity sources intended to escape power cut offs that will malfunction the services going on the airport . The main problem that faces these sites is Power interruptions If power interruption happens it may lose the data in computers or damage electronics and electric machines. In the case of this interruption occurs it needs a person that shifts the load source to another one, this involves a lot of human efforts which is another challenge. The commercial sites and industries uses database to do services and produce items for their customers which means they can’t tolerate power cut offs believed to effect the equipment and economy of the businesses and industries. Our recommendation of Auto power supply control from four different sources have the capability and strength to solve these challenges in the power supply control into new technological ways with cost effective. It will excellently increase the automation and efficiency of the system. This system will automatically shift the load supply if one of the supplies fails by going in to another active supply and also if the failed one becomes active again it will immediately shift the load supply to the previous one. 2 .3 OBJECTIVE OF THE PROJECT Our project will focus on constructing a control system of an integrated renewable and other power sources to contribute a good electricity control system. The objectives of the project will be provide uninterrupted power supply increase the rate of interconnected power sources promote the use renewable energy technologies reduce the damage of customer’s equipment totally remove the role of human load shift operator increase the efficiency and reliability of the grid system 1.4 LIMITATION OF THE PROJECT The limitation of our project are Shortage of time Lack of books Some electrical components in the project can’t be found in the market Lack of experience for preparing this proposal 1.5 ORGANIZATION OF DOCUMENTATION In our project we start chapter one which contains motivation, problem statement, objective of the project,and limitations of the project. In chapter two we will talk about the definition of the project , circuit and block diagrams , advantages and disadvantages of the our project and the last application and their scope. In chapter three we will see calculations, software and hardware requirements, material and components, the design and finally the implementation and testing. The last chapter four will be conclusion and recommendation of the project. 3 CHAPTER TWO LITERATURE REVIEW 2.1 Definitions This auto power supply control system works on the principle of auto function for switch over the load to other available source without wasting any time or switch off the load. Here for the demonstration purposes we have used the selection keys for switch off any source of supply. In this system, the microcontroller which is very essential component of this system always, keep sensing the whole available sources. When any source is switched off through the selection keys then the microcontroller shifted the load to the other supply source by giving the signal to the relay driver IC then the relay driver IC switched on the appropriate load relay. The whole function is done by the microcontroller in micro seconds and this shifted time can be changed during the programming of microcontroller. Here 4 load relays are used which are connected in parallel with load and 4 sources of supplies are also connected in parallel with these load relays. These load relays consist of normally open and close contacts and are operated through the relay driver IC. We have checked this system by connecting the lamp at output side as a load when any interruption is take place during the shifted time then the lamp is blinking but here there is no any blinking take place during the shifted time means there is no any interruption in supplying the power at output side. The project can be further enhanced by using other sources like wind power also and then taking into consideration for using the possible whose tariff remains lowest. Therefore, this project provides an effective solution to provide an alternative power supply during frequent power cuts. 4 2.2 Diagrams 2.2.1 Circuit Diagram The circuit diagram of a simple 100 watt inverter using IC CD4047 and MOSFET IRF540. CD4047 is low power CMOS a stable multi vibrator IC. Here is wired as an a stable multi vbrator producing two pulse trains of 0.01s which are 180 degree out of phase at the pins 10 and 11 of the IC. Figure 1 wring diagram 5 2.2.2 Block Diagram Here is the block diagram of the auto power supply control system from 4 different sources using pic microcontroller with all the essential components. The Block Diagram of the auto power supply control system from 4 different sources using pic microcontroller: Figure 2 Blocking diagram 6 2.3: Components Transformer:In this auto power supply control system, the transformer is used for connecting this system directly to the 220V ac. It steps down the 220V ac into 12V ac .it consists of two windings and work on the principle of mutual induction. Bridge rectifier:In this auto power supply control system, the bridge rectifier is used for converting the 12V ac voltages into dc voltages for supplying the power to the other electronics components. Voltage Regulator:In this auto power supply control system, the voltage regulator is used for regulating the 12V dc voltages into 5V dc voltages for supplying the power to the LCD display, microcontroller and relay driver IC. In this system LM 7805 voltage regulator is used for regulating the bridge rectifier the voltages. LCD Display: In this auto power supply control system, the LCD display is used for displaying thesource of supply on which the whole system or load has shifted. It also displays the voltages which are coming from current source. It is interfaced with microcontroller and powered up with 5V dc. Selection Keys:In this auto power supply control system, the selection keys are the basically push buttons which are used for checking the working function of this system. These are pushed up one by one for demonstration purposes. PIC Microcontroller 18F452: In this auto power supply control system, the Pic 18F452 microcontroller is used for the auto selection of the available source. It shifted the load to the other power supply source automatically without any interruption. It is programmed in C language with help of micro C software and is powered up with 5V dc voltages. It is interfaced with LCD display and relay driver IC. 7 Relay Driver: In this auto power supply control system, the relay driver IC is used for driving the load relays. This relay receives the signal from microcontroller for shifted the load on another supply source. It is powered up with 5V dc and interfaced with microcontroller. Load:In this auto power supply control system, the lamp is used here as an output load for demonstration purposes. 2.4 Working Principle This project uses an arrangement of 4 different sources of supply which are channelized to a load so as to have uninterrupted operation of the load. As it is not practicable to get 4 sources of supply such as mains supply, generator supply, inverter supply and solar supply we used one sources and set of relays. We have taken first source with mains supply and assumed as if being fed from 4 different source by connecting all the 4 incoming source in parallel The ac source to the lamp is connected to four relays by making the entire normal open contacts parallel and all the common contacts in parallel. 4 push button switches are used which represent failure of corresponding supply respectively and are interfaced to the controller. Initially we have given high input singles to the microcontroller, so as result the controller generates a low output to active the first relay driver. This will result in the relay being energized and the lamp glows. While the push button for mains is pressed that represent failure of mains supply as a result the supply is provide from the next source. And the microcontroller receives high input and generates low output to active the second relay driver. This will result in the second relay being energized and the lamp glows. When we press the generator button, it indicates the generator fails to operate and the supply comes from the next source. 8 The next source will supply high input to the controller and which will provide low signal to the third relay and the lamp switches on When we press the third push button the supply will chose next source now the fourth source will provide input to the microcontroller. Controller activates the fourth relay and the load will get the supply and the lamp continues to glow. When all the relay are off leaving no supply to the lamp, the lamp is switched off 2.5 Advantages Controlling Power supply from four different sources if any problem occurred in one sources then the other sources can be used. This system is more compact and reliable as compared to the electrical ATS panels. This system is less costly as compared to the other power control system. Simplicity of design. Fast transient response. 2.6 Disadvantages Switching noise and ripple exist My require a heat sink 2.7 Application This system could be used in that places where we have different sources of supply such as solar, main and generator. This system could be used in industrial for supplying the uninterrupted power supply to industrial machines. 9 This system could be used in educational institutes and hospitals for supplying the uninterruptable power supply to hospital or educational equipment. Banks are also other uses of this system. Hotel also need no break power. Commercial sites can’t tolerate power cut offs so it is a solution there. 2.8 Scope statement The scope of our project is every place that uses four different sources of power supply. This can be Airports Hospitals Colleges or educational institutes Industries Commercial sites such as malls Hotels Government institutes Auto power supply control system of four different sources can help these above places to get reliable and uninterrupted power system. This will boost the effectiveness of functions done by these above sites. 10 CHAPTER THREE Analysis and Design 3.1Analysis The site of the project is HargeisaGeneral Hospital, after many assessments on how many power sources the hospital uses and also how they control these supplies, we noticed that the hospital is a victim of power interruptions. As they use change over to shift power supply from back-up generators to the government grid or Sompower grid. Our project’s auto power supply control will offer the hospital a smooth uninterrupted power supply. At the end of this chapter , to get four power sources for the hospital we are recommending a standalone solar system capable to power the hospital. 3.1.1 Current Power supply sources of the hospital Government utility grid 75 kw Sompower grid 75 kw Two backup generators 75 kw Table 1 of power sources of the hospital (current) 3.2 Design As we mentioned previous chapters , our project consist of electronic components such as microcontroller, transformer, relays , LCD ,regulator , relay driver and etc. in this chapter we consider the programming, hardware requirement and software requirement of the project , its cost and implementation. 11 3.2.1 Programming The full programe is in the appendix part of the but here it is a part of the programing Figure 3 a part of the programming 3.2.2 Hardware requirement List of components Quantity Cost per Total cost per component in USD component 1. Resistor 11 $ 2.25 $ 24.75 2. Capacitor 5 $3 $15 3. Intergated Circuit 3 $ 17 $ 51 4. Microcontroller 1 $ 5.09 $ 5.09 $ 6.1 $ 6.1 PIC16F877A 5. Crystal oscillator 1 4MHz 6. Voltage regulator 1 $ 1.95 $ 1.95 7. Relays 4 $ 4.16 $ 16.64 8. Transformer 1 $ 1.68 $ 1.68 9. 16*2 LCD 1 $7 $7 10. Plain PCB 1 $ 12.95 $ 12.95 12 Total 29 items $ 142.16 Table 3 cost analysis of the Autopower supply control 3.3 Addition to a four power source to the Hargeisa general hospital 3.3.1 Solar power system 3.3.2 Overview The total electrical power consumption of the Hospital is 75kw the Hospital gains electricity from the utility of Sompower and Government utility . The cost energy is very high one dollar per one unit which is 0.75$, also Hargeisa general hospital has two backup generators which use 3000 litter per week as it costs 7800$ each month. The Hargeisa general hospital will get cheap and reliable electricity that has not any power interruption, so we are designing solar power system project in the Hospital. 3.3.3 A stand-alone Solar system To be able to power the whole hospital independent when the other sources are off or out , we are proposing a stand-alone solar system. 13 Figure 4 A simple stand-alone solar power system 3.4 Solar system components In this project we prefer to use install polycrystalline type of solar panels. These panel can withstand if it is partially covered so they are reliable. The basic components of a Stand-alone PV system is Solar photovoltaic modules Array mounting racks Grounding equipment Combiner box Surge protection (often part of the combiner box) Inverter Meters – system meter and kilowatt-hour meter Disconnects: Array DC disconnect Inverter DC disconnect Inverter AC disconnect Exterior AC disconnects Battery bank 14 3.4.1 Solar photovoltaic modules Photovoltaic modules use light energy (photons) from the Sun to generate electricity through the photovoltaic effect. The majority of modules use wafer-based crystalline silicon cells or thin-film cells. The structural (load carrying) member of a module can either be the top layer or the back layer. Cells must also be protected from mechanical damage and moisture. Most modules are rigid, but semi-flexible ones based on thin-film cells are also available. The cells must be connected electrically in series, one to another. Figure1 Solar photovoltaic modules 3.4.2 Array mounting racks Arrays are most commonly mounted on roofs or on steel poles set in concrete. In certain applications, they may be mounted at ground level or on building walls. In our project we are using ground mount solar installation method. Figure: 2 Ground mount solar installation 3.4.3 Combiner Box 15 Wires from individual PV modules or strings are run to the combiner box, typically located on the control room. These wires may be single conductor pigtails with connectors that are pre-wired onto the PV modules. The output of the combiner box is one larger two wire conductor in conduit. A combiner box typically includes a safety fuse or breaker for each string and may include a surge protector. 3.4.4 Surge protection Surge protectors help to protect your system from power surges that may occur if the PV system or nearby power lines are struck by lightning. A power surge is an increase in voltage significantly above the design voltage. 3.4.5 Inverter Inverters take care of four basic tasks of power conditioning: • Converting the DC power coming from the PV modules or battery bank to AC power • Ensuring that the frequency of the AC cycles is 60 cycles per second • Reducing voltage fluctuations • Ensuring that the shape of the AC wave is appropriate for the application, i.e. a pure sine wave for hybrid-connected systems 3.4.6 Meters – system meter and kilowatt-hour meter Essentially two types of meters are used in PV systems: • Utility Kilowatt-hour Meter • System Meter Utility Kilowatt-Hour Meter– The utility kilowatt-hour meter measures energy delivered to or from the grid. On homes with solar electric systems, utilities typically install bidirectional meters with a digital display that keeps separate track of energy in both directions. Some utilities will allow you to use a conventional meter that can spin in reverse. In this case, the utility meter spins forward when you are drawing electricity from the grid and backwards when your system is feeding or “pushing” electricity onto the grid. System Meter– The system meter measures and displays system performance and status. 16 Monitored points may include power production by modules, electricity used, and battery charge. It is possible to operate a system without a system meter, though meters are strongly recommended. Modern charge controllers incorporate system monitoring functions and so a separate system meter may not be necessary. 3.4.7 Grounding equipment Grounding equipment provides a well-defined, low-resistance path from your system to the ground to protect your system from current surges from lightning strikes or equipment malfunctions. Grounding also stabilizes voltages and provides a common reference point. The grounding harness is usually located on the roof. 3.4.8Disconnects Automatic and manual safety disconnects protect the wiring and components from power surges and other equipment malfunctions. They also ensure the system can be safely shut down and system components can be removed for maintenance and repair. For grid connected systems, safety disconnects ensure that the generating equipment is isolated from the grid, which is important for the safety of utility personnel. In general, a disconnection is needed for each source of power or energy storage device in the system. For each of the functions listed below, it is not always necessary to provide a separate disconnect Array DC Disconnect – The array DC disconnect, also called the PV disconnect, is used to safely interrupt the flow of electricity from the PV array for maintenance or troubleshooting. The array DC disconnects may also have integrated circuit breakers or fuses to protect against power surges. Inverter DC Disconnect – Along with the inverter AC disconnect, the inverter DC disconnect is used to safely disconnect the inverter from the rest of the system. In many cases, the inverter DC disconnects will also serve as the array DC disconnects. Inverter AC Disconnect – The inverter AC disconnects the PV system from both the building’s electrical wiring and the grid. Frequently, the AC disconnect is installed inside the building’s main electrical panel. However, if the inverter is not located near the electrical panel, an additional AC disconnect should be installed near the inverter. 17 Exterior AC Disconnect – Utilities commonly require an exterior AC disconnect that is lockable, has visible blades and is mounted next to the utility meter so that it is accessible to utility personnel. An AC disconnects located inside the electrical panel or integral to the inverter would not satisfy these requirements. One alternative that is as acceptable to some utilities as an accessible AC disconnect is the removal of the meter itself, but this is not the norm. Prior to purchasing equipment, consult the electric utility to determine their requirements for interconnection. 3.4.9 Battery Bank Batteries store direct current electrical energy for later use. This energy storage comes at a cost, however, since batteries reduce the efficiency and output of the PV system, typically by about 10 percent for lead-acid batteries. Batteries also increase the complexity and cost of the system. 3.5 Solar system sizing Daily demand of the hospital is 75 kw . On the other hand, the hours between 8:00 am upto 1:00 pm is used the most power. Daily demand 6×20 kw= 120 Kwh 6×30 kw=180 kwh 7×5kw=35 kwh Total = 335 kwh PV sizing daily power demand peak load ×1.3= 98 kw The system will powere the hospital 60% directly while the rest 40% will be stored in the battery bank. Energy Storage = 335 kwh +40% of 335 kw 18 = 335 kwh + 134 kwh = 469 Kwh = 40% of 335 kwh÷ 60% = 223 kwh = 223 kwh + 335 kwh= 558 kwh+5% storage loss = 558 kwh ×1.05= 586 kwh Energy storage= 363 kwh Solar PV for storage= 363 kwh÷6 hrs= 55.846 kw × 1.2 = 67 kw Number of solar panels to solar inverters= PV generator ÷ PV rating= 98000÷300W/panel= 327 pieces Inverter = 75 kw × 1.3= 100 kw Number of inverters = 100 kw ÷ 20 kw/inverter = 5 inverters Battery [ lithium ion] = 58 v × 68 k Ah = 3.944 kwh = 4 kwh Number of battery = Energy storage ÷ energy / battery = 363 kwh ÷ 4 kwh = 90 pieces Battery inverter = 100 kw Solar panels of the battery = 67 kw ÷ 300w/ panel= 224 pieces Total solar pv panels = 327 + 223 = 550 pieces Area/ panel = 2m2 Total area = 550 pcs × 2m2 + 20%( for spacing) = 1100 m2 + 220 m2 = 1,320 m2 550 panels ÷ 5 inverters= 110 panel/ inverter 110/ 18 panel/inverter = 6 string( series) = 6 parallel 19 18 × 36.8 v = 662 v – inverter rating voltage 3 phase Panels 20 kw 20 Kw inverter Battery connections = 558/ battery 11 series battery = 11 × 58 v = 638 v 90 battery ÷ 11 series battery = 8 parallel string batteries 400 v 100 kw Battery bank Inverter 600 v 20 400v 3.6 Solar system cost estimation The following table will be presented the overall initial cost of the proposed solar system. Hardware requirement specifications Quantity Unit cost Total cost Solar PV 300 W 550 $ 220 $ 121,000 Solar inverter ( SMA) Battery inverter 20KW 5 $ 5000 $ 25,000 100 KW 1 $ 18,000 $ 18,000 Cables Lumsun 1 $ 2,000 $ 2,000 CB Lumsun 1 $ 500 $ 500 Battery Lithium ion 90 $ 900 $ 81,000 Solar frame ground And mounting structures Transportation 550 $ 45 $ 24,750 1 $ 4000 $ 4,000 Installation 1 $ 10,000 $ 10,000 Accessories 1 $ 1000 $ 1,000 Total $ 287,250 Table 4 cost estimation of the proposed solar system to the hargeisa general hospital. 21 CHAPTER FOUR CONCLUSION This project of AUTOMATIC POWER SUPPLY FROM FOUR DIFFERENT SOURCES: Solar, Inverter, Main and Generator” USING A MICROCONTROLLER is used to handle power supply from Solar, Inverter, Main and Generator” automatically using microcontroller concept. The significance of this project lies in its various advantages and wide places of applications such as Industries, Hospitals, Banks; it has been developed by integrating Colleges/Schools, etc. It has been developed by integrating features of all the hardware components used. Presence of every module has been reasoned out and placed carefully thus contributing to the best working of the unit. This project provides 75KW stand-alone solar power system which is a practical solution to provide an alternative power supply or uninterrupted power supply in automated mode to the load during frequent power cuts or in cases where power cuts or power outages cannot be avoided. Now the hospital uses electricity from the Grid and diesel generator to generate electricity needed in special cases and as commonly known fossil fuels are the most expensive sources to generate electricity, costs more money and pollutes the environment, so in order to overcome these problems this project proposes stand-alone solar system with generator backup to be installed for the hospital, apart from their high initial investments, solar systems require less operation and maintenance costs, the system will last long and save money. 22 REFERENCES [1] Robert Dowuona-Owoo (2008), “Design and construction of three phase automatic transfer switch.” A thesis presented at regent university college of science and technology Ghana. PP100-120 [2] L S Ezema, B U Peter, O O Haris, “DESIGN OF AUTOMATIC CHANGE OVER SWITCH WITH GENERATOR CONTROL MECHANISM”, ISSN: 2223-9944, vol 3, No 3, November 2003. PP 230287 [3] Jonathan (2007), “Manually Controlled Changeover System.” Vol.2, No.5. November, 2011. PP 152 – 180 [4] Mbaocha C. (2012), “Smart Phase Changeover Switch using AT89C52 Microcontroller.” Journal of Electrical and Electronics Engineering vol.1; Issue 3: PP 31-44 [5] Katz R and Boriella G (2005), “Contemporary Logic Design. 2nd edition.” Prentice Hall, Italy. PP 445-589 [6] Shanmukha Nagaraj and Ramesh S (2013), “Programmable Logic Controlled Circuits.” International Journal of Research in Engineering and Technology Vol.1, issue 2, July 2013; PP 111-116. [7] L.S. Ezema, B.U. Peter, O.O. Harris (2012), “Design of Automatic Change Over Switch with Generator Control Mechanism.” Electrical Power and Electronic Development Department, Projects Development Institute (PRODA), Enugu: Natural and Applied Science, Vol.3, No.3. November, 2012. PP 125 – 130. [8] Charlie Hume, (effective march 2015), “Transfer switch 101: an introductory guide to picking the right transfer switch for your environment, White paper WP140001EN.” Retrieved from: www.eaton.com/ecm/group/public/@pub/@electrical/documents/.../wp140001en.pdf. 23 Appendix A Table 3 a cost analysis of Auto power supply control List of components Quantity Cost per Total cost per component in USD component 1. Resistor 11 $ 2.25 $ 24.75 2. Capacitor 5 $3 $15 3. Intergated Circuit 3 $ 17 $ 51 4. Microcontroller 1 $ 5.09 $ 5.09 $ 6.1 $ 6.1 PIC16F877A 5. Crystal oscillator 1 4MHz 6. Voltage regulator 1 $ 1.95 $ 1.95 7. Relays 4 $ 4.16 $ 16.64 8. Transformer 1 $ 1.68 $ 1.68 9. 16*2 LCD 1 $7 $7 10. Plain PCB 1 $ 12.95 $ 12.95 Total 29 items $ 142.16 24 Table 4 the cost estimation of the proposed Solar system to Hargeisa general hospital. Hardware requirement specifications Quantity Unit cost Total cost Solar PV 300 W 550 $ 220 $ 121,000 Solar inverter ( SMA) Battery inverter 20KW 5 $ 5000 $ 25,000 100 KW 1 $ 18,000 $ 18,000 Cables Lumsun 1 $ 2,000 $ 2,000 CB Lumsun 1 $ 500 $ 500 Battery Lithium ion 90 $ 900 $ 81,000 Solar frame ground And mounting structures Transportation 550 $ 45 $ 24,750 1 $ 4000 $ 4,000 Installation 1 $ 10,000 $ 10,000 Accessories 1 $ 1000 $ 1,000 Total $ 287,250 25 Appendix B Codes Written for the MCU in Assembly Language ;========================================================= ;========================================================= ; UNINTERRUPTED POWER SUPPLY ;========================================================== ;========================================================== ; DEFINATIONS ;========================================================== ;========================================================== ;REGISTERS Ctr Equ 02h ;BIT MEMORY ADCReg Equ 20h PPReg Equ 21h ;PORT ADCPort Equ P1 PPort Equ P3 ;BIT ADCReg0 Equ 00h ADCReg1 Equ 01h ADCReg2 Equ 02h ADCReg3 Equ 03h ADCReg4 Equ 04h ADCReg5 Equ 05h ADCReg6 Equ 06h ADCReg7 Equ 07h PPReg0 Equ 08h Charger Equ P3.7 Mains Equ P1.0 ;========================================================= ;========================================================= ; VECTOR ADDRESSES ;========================================================= ;========================================================= ;========================================================= Org 0000h ;RESET VECTOR ADDRESS ljmp Start ;Jump to start of program ;========================================================= Org 0003h ;EXTERNAL INTERRUPT0 VECTOR ADDRESS reti ;Return from Interrupt ;========================================================= Org 0Bh ;TIMER0 INTERRUPT VECTOR ADDRESS acall Timer reti ;========================================================= Org 13h ;EXTERNAL INTERRUPT1 VECTOR ADDRESS reti ;========================================================= Org 1Bh ;TIMER1 INTERRUPT VECTOR ADDRESS reti ;========================================================= Org 23h ;SERIAL INTERRUPT VECTOR ADDRESS reti ;Not used ;========================================================= Org 30h ;Program starts here 26 Start: mov SP,#40h ;Stack Pionter intialized 19 clr RS0 ;Bank0 selected clr RS1 mov PPort,#255 mov ADCPort,#255;Initialising ADCPort as input port setb Mains mov Ctr,#8 mov TMOD,#17 ;Timer0 (16bit Timers) mov TH0,#11 ;Timer0 reload value= 55535 mov TL0,#219 setb ET0 ;Timer0 Interrupt enabled setb TR0 ;Start Timer0 setb EA ;Global interrupt enabled jmp $ ;Wait ;========================================================= Timer: clr TR0 ;Stop Timer0 mov TH0,#11 ;Timer0 reload value= 3035 mov TL0,#219 setb TR0 ;Start Timer0 djnz Ctr, EndTimer mov Ctr,#8 mov ADCReg,ADCPort setb ADCReg0 acall ADConversion acall ChargeBattery acall UpdatePPort EndTimer: ret ;========================================================= ADConversion: mov dptr,#PPData mov A,ADCReg movc A,@A+dptr mov PPReg,A ret ;========================================================= ChargeBattery: mov A,ADCReg cjne A, #10,ChargeBat cjne A, #12,StopCharging ret ChargeBat: clr Charger ret StopCharging: setb Charger ret ;========================================================= UpdatePPort: jb Mains,lMains clr PPReg0 mov C,Charger mov PPort,PPReg mov Charger,C ret lMains: mov C,Charger mov PPort,#255 27 mov Charger,C 20 ret ;========================================================= ;========================================================= PPData: db 243,243,243,243,243 db 242,242,242,242,242 db 241,241,241,241,241 db 240,240,240,240,240 db 239,239,239,239,239 db 238,238,238,238,238 db 237,237,237,237,237 db 236,236,236,236,236 db 235,235,235,235,235 db 234,234,234,234,234 db 233,233,233,233,233 db 232,232,232,232,232 db 231,231,231,231,231 db 230,230,230,230,230 db 229,229,229,229,229 db 228,228,228,228,228 db 227,227,227,227,227 db 226,226,226,226,226 db 225,225,225,225,225 db 224,224,224,224,224 db 223,223,223,223,223 db 222,222,222,222,222 db 221,221,221,221,221 db 220,220,220,220,220 db 219,219,219,219,219 db 218,218,218,218,218 db 217,217,217,217,217 db 216,216,216,216,216 db 215,215,215,215,215 db 214,214,214,214,214 db 213,213,213,213,213 db 212,212,212,212,212 db 211,211,211,211,211 db 210,210,210,210,210 db 209,209,209,209,209 db 208,208,208,208,208 db 207,207,207,207,207 db 206,206,206,206,206 db 205,205,205,205,205 db 204,204,204,204,204 db 203,203,203,203,203 db 202,202,202,202,202 db 201,201,201,201,201 db 200,200,200,200,200 db 199,199,199,199,199 db 198,198,198,198,199 db 197,197,197,197,197 db 196,196,196,196,196 db 195,195,195,195,195 db 194,194,194,194,194 db 193,193,193,193,193 ;========================================================= ;========================================================= 28 End 29