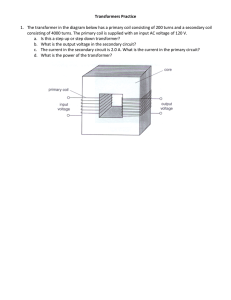

CHAPTER 1 INTRODUCTION This chapter covers the motivation, objectives and general introduction to the thesis. 1.1 Problem Statement Electrical power is being transmitted from one place to another in the whole world. Generally, the transmission voltages are kept high to keep the transmission losses minimum. This is because the current is low at high voltages. Lower current means lower copper loss or heat loss or in simple words, saves our electrical power. Voltages are being varied for different reasons. We also know that high power consumption devices take more current. When more current is being drawn, then voltages are also dropped. This can be observed from the equation: 𝑉 = 𝐸 − 𝐼𝑅 Here, V is the output voltage of the source, or the supply voltage, E is the internally generated EMF, I is the current being drawn and R is the internal resistance or the internal resistance plus the resistance to support end. As the current drawn increases, the value of IR increases and so, receiving end voltages are dropped. Now this drop-in voltage at the receiving side, is a problem for the equipment as well as the transmission. The equipment may be voltage sensitive. Low voltages can cause burnouts and many other problems. As the power to be consumed is an approximate constant i.e. JHON.SMITH87@YAHOO.COM 𝑃 = 𝑉𝐼 Where P is the power rating of the equipment, V is the voltage rating of the equipment and I is the current that will flow due to the load impedance. As V drops, I must increase in order to feed the load its required power. Higher I not only, is bad for the equipment but is also bad for transmission. As seen above, higher currents cause source voltages to drop, and now higher voltage drops with occur in the transmission line as well and energy will be lost in the form of heat. More energy will be lost in the transmission line than before. Moreover, the transmission line’s current rating might get exceeded and the wire may burn or get damaged. As seen from the above examples, low voltages at the receiving end are a big problem. The problem can be solved by the use of Autotransformers in particular. 1.2 Transformer A transformer is a static (no moving parts involved) electrical device that transfers electrical power from one circuit to another. It works on the principle of mutual induction. A transformer can either be used to step up the voltage (step-up transformer) or reduce voltage levels (step-down transformer). In some cases, the transformer may also be used for isolation purposes. This is done by keeping the same turn ratio on primary and secondary side. The voltage level is directly proportional to the turns on a certain coil. Such a transformer is also termed as one to one transformer. The electrical power transferred from one circuit to another is the same, the variation is just in the voltage levels. If voltage increases, current decreases and if voltage decreases, current increases. The power being transmitted, is the same in both cases. JHON.SMITH87@YAHOO.COM This is the device that is used to increase AC voltage levels at the supply end to reduce transmission losses. The transformer used at the supply end is called a step-up transformer and consequently, a step-down transformer is used at the receiving side. There is no electrical link between the primary and secondary sides of a transformer. Both sides are linked through magnetic flux. A general transformer schematic is presented in Figure 1. The transformer power relation can be seen from the equation below. JHON.SMITH87@YAHOO.COM 𝑁𝑠 𝑉𝑠 𝐼𝑝 = = 𝑁𝑝 𝑉𝑠 𝐼𝑠 Here, Ns = Number of turns of secondary coil Np = Number of turns of primary coil Vs = Secondary voltage level Vp = Primary voltage level Ip = Primary circuit current Is = Secondary circuit current ZL= Load Impedance Figure 1-1: Simple Transformer Schematic 1.3 Auto Transformer Auto transformer is a transformer with one winding only. The same winding acts both, as primary and secondary winding. Auto transformers have several electrical contact points also called tappings or taps. An auto transformer has at least 3 taps. The more taps a transformer has, the more voltage levels can it be adjusted to. Taps are made on certain turns of the coil. As turns are directly proportional to voltage levels, connecting to each turns gives a different voltage level. The most basic structure of an auto transformer can be found in Figure 1-2. JHON.SMITH87@YAHOO.COM Figure 1-2 Structure of an Auto Transformer As seen in Figure 1-2, the transformer has only one winding and has several taps on the same winding. The secondary side may be connected to any of the taps and that is how voltage levels are varied with the use of an Auto transformer. 1.4 Variable Transformer (Variac) A variable transformer, also called a Variac, is a device that is used to provide smooth varying output voltages. Variac (Variable AC) has just a single primary winding as it is an auto transformer. On top of that winding, is a tapping or a contact point connected to a knob that can be moved over the primary winding. The knob is the variable selector switch that can slide across any portion of the primary winding. The voltages at output side will be continuously updated as the position of the knob changes. The Variac may go up to 300% or even more of their mains value. This means that the output voltage levels can be anywhere between zero and three times the value of supply voltage. The difference between Variac and having different taps, is that of output voltage variation. Using JHON.SMITH87@YAHOO.COM taps, the transformer can only vary between specific voltage levels and cannot transition smoothly from one voltage level to another. Variac can do the same job smoothly and the exact desired voltage level can be obtained that lies within the working capacity of the Variac. Figure 1-3: VARIAC Schematic Here, Vp = Primary Supply Voltage Np = Number of turns of primary coil Ip = Current flowing from primary coil Ns = Number of turns of secondary coil Vs = Secondary Output Voltage Isp = Current in primary coil due to secondary tapping RL Load = Resistive Inductive Load The secondary tapping point can be moved on the primary turns smoothly. This results in JHON.SMITH87@YAHOO.COM a continuously updated varying output voltages. The contact point tapping is a carbon brush which has its own wear and tear. When a current Ip flows through the single winding, the secondary current Is flows in a direction opposite to Ip. A portion of this winding generates the Vs. The current flowing in the portion is therefore Ip – Is. Like conventional transformers, there is no electrical isolation in auto transformer as there is only one physical winding. Also, short circuits in an auto transformer are worse than short circuit in a normal transformer. JHON.SMITH87@YAHOO.COM