ISSN 0036-0244, Russian Journal of Physical Chemistry A, 2020, Vol. 94, No. 1, pp. 30–40. © Pleiades Publishing, Ltd., 2020.

CHEMICAL THERMODYNAMICS

AND THERMOCHEMISTRY

Hyperbolic Correlation Between the Viscosity Arrhenius Parameters

at Liquid Phase of Some Pure Newtonian Fluids and their Normal

Boiling Temperature

E. Mlikia,b, T. K. Srinivasac,*, A. Messaâdid, N. O. Alzamela,b, Z. H. A. Alsunaidia, and N. Ouerfellia,b

aDepartments

of Mathematics and Chemistry, College of Science, Imam Abdulrahman Bin Faisal University,

P.O. Box 1982, Dammam, 31441 Saudi Arabia

b

Basic and Applied Scientific Research Center, Imam Abdulrahman Bin Faisal University,

P.O. Box 1982, Dammam, 31441 Saudi Arabia

cDepartment of Physics, A.S.N Women’s Engineering College Tenali, Andhra Pradesh, 522 201 India

dUniversité de Tunis El Manar, Laboratoire de Biophysique et Technologies Médicales,

LR13ES07, Institut Supérieur des Technologies Médicales de Tunis, Tunis, 1006 Tunisia

*e-mail: sritadikonda@gmail.com

Received April 29, 2019; revised April 29, 2019; accepted May 14, 2019

Abstract—Viscosity is the most important characteristic of hydraulic fluid and which is influenced by pressure and temperature. Using statistical methods for correlation analysis and regression, eventual causal relationship between parameters of the Arrhenius-type equation and principally the boiling point of some classical Newtonian liquids is attempted. Empirical validation utilizing data on viscositabty of pure Newtonian liquids studied at atmospheric pressure and at different ranges of temperature gives excellent statistical results.

Indeed, we found a significant strong correlation between the Arrhenius activation energy (Ea), the Arrhenius

temperature (TA) and the boiling point (Tb). Consequently, an original hyperbole-type equation modeling

this relationship is proposed which allows the prediction of the boiling temperature and the type of isobaric

liquid-vapor diagram through information on viscosity Arrhenius parameters values, only in liquid phase,

and will be thus very useful in the handling of engineering data especially for the study of hydraulic components and systems efficiency.

Keywords: Viscosity, Arrhenius behavior, Boiling temperature, Newtonian liquids, Correlation

DOI: 10.1134/S0036024420010239

Effectively, this will be very gainful for hydraulic

fluid properties simulation in the design and optimization of several industrial processes, such as in Food

Industry, Chemical Industry, Pharmaceuticals, Cosmetics and Hydraulic-Mechanics, etc.

INTRODUCTION

Liquids viscosity is one key transport property

embroiled in chemical engineering, process design

and development [1–6]. Numerous empirical and

semi-theoretical equations of liquid viscosity have

been suggested based generally on three principal theories: the theory of reaction rate [7–9], the molecular

dynamic approach [10] and the distribution function

theory [11]. Several semi-empirical expressions have

been proposed in literature [12–17] and investigated in

previous works to discuss the viscosity-temperature

dependence [18–22].

The present study focuses on analyzing the existence of any eventual causal association between the

Arrhenius-type equation parameters and boiling

points of some classical Newtonian liquids. This relationship may allow estimating these phase change

temperatures through the study of variation of viscosity versus temperature of a pure solvent only in its liquid phase.

LITERATURE REVIEW ON THE LIQUID

VISCOSITY-TEMPERATURE DEPENDENCE

Explicit Dependence and Newtonian Behavior

As the temperature increases, the thermal agitation

increase and consequently the mean free path

decreases. Hence, numerous expressions, generally

classified under three types: two-, three- and multiconstant equations, have been suggested in the literature for describing the liquid shear viscosity (η) versus

temperature (T) through available experimental data

of literature for interpolation methods.

30

HYPERBOLIC CORRELATION BETWEEN

The simplest form of representation of Newtonian

fluid viscosity versus temperature is a relationship with

1 two parameters where the neperian logarithm form

becomes the most popular and it is the so called

Arrhenius type-equation which may be linearly formulated as follows [18–22]:

()

Ea 1

(1)

,

R T

where R is the perfect gas constant, As and Ea, the preexponential factor and the Arrhenius activation energy

for the pure fluid system respectively.

ln η = ln As +

For the Newtonian fluids not obeying to the viscosity Arrhenius behavior, the most popular nonlinear

equation is suggested firstly by Vogel and lately known

as Vogel-Fulcher-Tammann-type model [18–22]:

B ,

T −C

where A, B and C are constants.

ln η = A −

(2)

Notice that in this work we focus on the Arrhenius

type-equation for studying any eventual relationship

between its parameters and boiling points (Tb) of some

classical Newtonian liquids in the hope to predict its

value through information on viscosity Arrhenius

parameters only in liquid phase.

Implicit Dependence and Derived Temperatures

From thermodynamic quantities and similar

amounts, certain specific temperatures can be determined by manipulating certain derivatives as well as

those of the Maxwell equations. Noting that there are

certain common points with the definition of the

enthalpy of vaporization and the enthalpy of activation

viscous flow (ΔH*) as well as the viscosity activation

energy (Ea) [23–37]. This leads us to think that the

specific temperatures derived from the previous quantities are causally correlated with the boiling temperature of the fluid that we studied its dynamic viscosity.

It is in this context that we will present certain correlations and try to reduce a way of predicting the boiling

temperature.

Among the derived temperatures we cite the Arrhenius temperature (TA) of a pure liquid (Eqs.1 and 3),

the Arrhenius mean temperature (TAm) of a liquid

binary mixture (Eq. 4), the current temperature of

Arrhenius (TAc) deduced from partial molar magnitudes (Eq. 5) and the thermodynamic temperature

(T#) deduced from Maxwell’s equations (Eq. 11).

TA = −

Ea

.

R ln As

(3)

quasi-linear behavior where the slop gives the Arrhenius mean temperature (TAm) expressed as follows:

Ea

(4)

=TAm ln As + B.

R

Where B is the intercept of the ordinate when ln(As) is

mathematically null and it is thoroughly related to the

shear viscosity of the binary fluid system at boiling

point; we remark that the Tam value is close to the

boiling temperature Tb of one of the two pure constituting components of the binary mixture [23–37].

Nonetheless, if we eliminate the hypothesis of

Eq. (4) that the Arrhenius mean temperature (TAm)

nothing is more constant over the whole domain of

molar composition, we can review it as variable Arrhenius’ current temperatures (TAci ) related to the pure

component (i). It can be determinate from the following partial derivatives at selected molar composition

(x1):

−

⎛ ∂(Eai ) ⎞

(5)

TAci = ⎜

⎟ .

⎝ ∂(−R ln( Asi )) ⎠P

Whereas in several cases of previously studied binary

liquid mixtures, we have observed a strong correlation

existing between the limiting Arrhenius’ current temperatures (TAci ) and the vaporization temperature of

the isobaric liquid vapor equilibrium of the corresponding binary system [23–37]. The following equation asserts all these observations,

⎛ ∂(Eai ) ⎞

⎜

⎟

∂xi ⎟

(6)

lim ⎜

≈ −RΔTbi ,

xi →1 ⎜ ∂ ( ln A ) ⎟

si

⎜ ∂x ⎟

⎝

⎠

i

and from which we have estimated in previous works

with a good approximation the boiling point (Tbi) of

some pure liquid constituents (i).

In addition, the free energy (ΔG*) of activation of

viscous flow are related as follows [7–9, 38]:

⎛ η( x ,T , P )V ( x1,T , P ) ⎞

ΔG *( x1,T , P ) = RT ln ⎜ 1

⎟ , (7)

hN A

⎝

⎠

where R, η, h, NA and V are the perfect gas constant,

dynamic viscosity of binary fluid system, Plank’s constant, Avogadro’s number and molar volume of fluid

system at molar composition (x1), absolute temperature T and pressure P respectively, and:

(8)

ΔG * = ΔH * − T ΔS *.

Where ΔH* and ΔS* are the enthalpy and the entropy

of activation of viscous flow of binary fluid system at

molar composition (x1) and can be calculated in the

general case as follows:

⎛ ∂(ΔG */T ) ⎞

ΔH * = ⎜

⎟ ,

⎝ ∂(1/T ) ⎠P

Generally for binary mixtures the plot (Ea) as a function of (ln As) at different compositions exhibit a

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

31

Vol. 94

No. 1

2020

(9)

32

MLIKI et al.

100

1000

T*

Tm

TA

Ti/K

Tb

100

1000

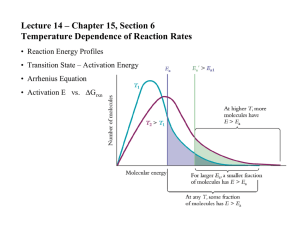

Fig. 1. (Color online) Classification of different mean temperatures (Ti ) used in this statistical investigation. Great vertical bar (|):

Average value and the small vertical bar (l): delimitation of the Confidence Interval (CI).

⎛ ∂(ΔG *) ⎞

ΔS * = ⎜

⎟ .

⎝ ∂(T ) ⎠P

(10)

Moreover, considering the partial derivatives functions of Maxwell equations and the Gibbs free energy

expression (Eq. (7)), we can determinate the thermodynamic temperature (T#) at constant pressure by the

partial derivative (ΔH*) with respect to (ΔS*) as follows:

⎛ ∂(ΔH *) ⎞

#

⎜

⎟ =T .

⎝ ∂(ΔS *) ⎠P

(11)

RESULTS AND DISCUSSION

Arrhenius and Temperature Parameters

A sample of 103 experimental data provided previous works and from the literature [14–19, 23–37] on

viscosity of pure Newtonian liquids studied at atmospheric pressure and at different temperature ranges is

used in this paper in order to analyze the existence of

any eventual correlation between parameters of the

Arrhenius type-equation, such as the activation energy

(Ea) and the entropic factor (ln As), and the melting

temperature (Tm) and boiling temperature (Tb).

Table 1 presents the experimental values of these

parameters. Also, the table provides experimental values of additional temperature parameters which are

the Arrhenius temperature (TA) and the Arrhenius

activation temperature (T*= Ea/R) as introduced by

Ouerfelli et al. [23–35]. We note that the existence of

some samples’ repetitions, that’s because the data are

provided from different references of the literature and

it are realized at different ranges of temperature, which

it’s statistically considered as different and independent observations and it will well enrich the investigated set of samples, and lead to reliable statistical dispersion.

Table 2 reports the principle descriptive statistics of

temperature parameters for the 103 studied observations, such as the Arithmetic mean (Ti ), the Confidence Interval (CI) of the mean and the coefficient of

variation (CV) from which we can admit the following

classification, also show by Fig. 1 which confirms that

there is no net intersection between any consecutive

(CI).

TA < Tm < Tb < T *.

Moreover, according to the (CV) values, the (T*)parameter is the most dispersed variable, inversely to

the boiling temperature (Tb) which is the most

2

homogenous.

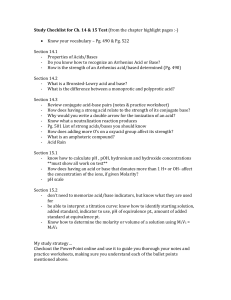

Analysis of Correlation

Firstly, we investigate direct mutual correlation

between the three parameters of Arrhenius (TA, ln As

and Ea) and, the melting temperature Tm and boiling

temperature Tb. For that, in order to measure and test

any eventual association between the target parameters, we have applied the correlations tests of Spearman’s rank [39], where the null hypothesis supposes

the independence of the variables. Table 3 presents the

result of the test for all possible pairs. Also, we present

in Fig. 2 the pairwise scatter plots, which is a good

graphical method to show any possible correlation.

Based on the graphs of Fig. 2, we deduce that there

is no clear direct relationship between any of the pairwise analysis. In addition, the results of the Spearman’s rank correlations tests show that there is no

relationship between any of the target parameters.

Thus, we deduce that there is no direct correlation

between the Arrhenius parameters (TA, ln As and Ea)

and the temperatures Tm and Tb.

Nevertheless, instead of that, we think that a complicated association may exist. For that, we have tried

several possible complicated relationships between

two or more transformed parameters from which we

found the most interesting result indicating a strong

nonlinear correlation (Fig. 3) may exist between Ea

and (1/TA – 1/Tb). Regarding results given in Figs. 1

and 2b, Tables 2 and 3, and the finite values of the two

parameters of Arrhenius straight line (Eq. 1) whether

T tends to zero or to infinity, we can ascertain that the

curvature of Fig. 3 mathematically admits two asymptotes, one vertical very near of zero and a horizontal

one at infinity.

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

Vol. 94

No. 1

2020

HYPERBOLIC CORRELATION BETWEEN

33

Table 1. Arrhenius parameters of some pure solvents studied at previous works and from the literature [14–19, 23–37],

Arrhenius activation energy Ea (kJ mol–1), the logarithm of the entropic factor ln(As/Pa s), the melting point (Tm/K), the

boiling point (Tb/K), the Arrhenius temperature (TA/K) and Arrhenius activation temperature (T*/K)

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Tm

Tb

lnAs

Ea

TA

T*

K

K

–

kJ mol–1

K

K

257.15

273.15

288.35

191.15

165.15

183.15

158.15

150.05

260.65

279.62

178.15

182.60

278.65

228.15

178.15

248.65

182.55

143.45

180.15

225.35

250.23

189.55

156.85

289.75

178.45

183.35

266.85

257.15

214.15

293.15

159.15

293.15

293.15

159.15

159.15

214.15

212.15

275.65

253.15

468.15

373.15

478.45

289.75

339.15

390.85

372.15

351.65

475.75

353.89

341.88

371.15

353.15

405.15

409.15

417.15

371.15

309.25

383.75

412.25

349.87

350.15

307.75

391.15

329.20

390.85

457.28

468.15

461.35

503.15

465.15

503.15

503.15

465.15

465.15

461.35

425.00

483.15

438.55

–14.945

24.955

200.83

3001.4

–13.414

–16.486

–15.048

–10.474

–13.925

–15.860

–10.699

–12.404

–12.831

–11.798

–12.367

–11.812

–10.695

–11.027

–11.145

–11.302

–10.886

–11.135

–10.975

–11.152

–11.728

–11.446

–11.308

–11.097

–13.689

–13.564

–14.945

–22.128

–16.210

–20.681

–16.438

–16.485

–21.510

–21.857

–18.266

–10.780

–12.442

–10.914

15.835

26.777

20.025

6.9072

19.742

24.852

7.2626

15.142

14.461

9.1501

11.292

10.940

8.7094

9.1110

9.8360

8.6196

6.0998

9.0229

8.7485

10.329

9.9183

7.5203

11.213

7.4406

19.114

19.997

24.955

47.765

33.359

43.910

33.904

34.033

45.933

46.763

37.551

9.0530

16.410

9.7590

141.98

195.34

160.05

79.310

170.52

188.46

81.639

146.82

135.56

93.281

98.023

111.39

97.939

99.375

106.14

91.723

67.393

97.461

95.872

111.39

101.72

79.021

119.26

80.643

167.94

177.32

200.83

259.62

247.51

255.36

248.07

248.31

256.84

257.32

247.25

101.00

158.63

107.54

1904.5

3220.5

2408.5

830.74

2374.4

2989.0

873.49

1821.2

1739.3

1100.5

1358.1

1315.8

1047.5

1095.8

1183.0

1036.7

733.64

1085.2

1052.2

1242.3

1192.9

904.48

1348.6

894.9

2298.9

2405.1

3001.4

5744.8

4012.2

5281.1

4077.7

4093.3

5524.5

5624.3

4516.3

1088.8

1973.7

1173.7

Pure Solvent

n-octanol

Water

Benzyl alcohol

Ethylamine

Tetrahydrofuran

1-butanol

2-butanol

1-chlorobutane

Methyl benzoate

Cyclohexane

n-hexane

Heptane

Benzene

Chlorobenzene

ethylbenzene

o-xylene

n-heptane

n-pentane

Toluene

m-xylene

Carbone tetrachloride

Ethylacetate

Diethylether

Aceticacid

Acetone

Butyl Alcohol

Aniline

n-octanol

Propylene Glycol

Butane-1,4-diol

Butane-1,2-diol

1,4-Butanediol

1,4-Butanediol

1,2-Butanediol

1,2-Butanediol

Propylene Glycol

N,N-dimethylformamide

Formamide

N,N-dimethylacetamide

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

Vol. 94

No. 1

2020

34

MLIKI et al.

Table 1. (Contd.)

No.

Tm

Tb

lnAs

Ea

TA

T*

K

K

–

kJ mol–1

K

K

Pure Solvent

40

41

42

2-Methoxyethanol

Water

N,N-dimethylacetamide

188.15

273.15

253.15

397.65

373.15

438.55

–12.602

–13.284

–10.896

15.185

15.510

9.4260

144.93

140.42

104.05

1826.3

1865.4

1133.7

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

2-Ethoxyethanol

N,N-dimethylacetamide

1,4-dioxane

Water

Isobutyric acid

Water

Ethanol

Water

Methanol

Water

p-xylene

Dimethylsulfoxide

o-xylene

Dimethylsulfoxide

Ethylene glycol

1,4-dioxane

Water

Triethyl amine

Water

Glycerol

TEGMME*

n-Heptane

Propargylalcohol

Allylalcohol

t-butanol

2-propanol

1-propanol

Bromobenzene

Chlorobenzene

Ethylbenzene

Benzene

Dimethylsulfoxide

3-amino-1-propanol

Isoamylalcohol

2-propanol

Ethanol

1,4-dioxane

N-methylacetamide

183.15

253.15

284.15

273.15

226.15

273.15

159.15

273.15

175.55

273.15

285.65

290.65

248.65

290.65

260.15

284.15

273.15

158.15

273.15

293.15

229.15

182.15

220.15

144.15

298.84

183.65

149.15

242.15

228.15

178.15

278.65

290.65

284.15

156.15

183.65

159.15

284.15

300.15

408.15

438.55

374.15

373.15

426.65

373.15

351.15

373.15

337.75

373.15

411.15

462.15

417.15

462.15

470.15

374.15

373.15

361.95

373.15

455.15

395.15

371.15

387.65

370.15

355.55

355.15

370.15

429.15

405.15

409.15

353.15

462.15

458.65

403.15

355.15

351.15

374.15

478.15

–12.682

–10.934

–11.853

–13.443

–11.200

–13.383

–12.166

–13.232

–11.528

–13.334

–10.761

–11.872

–11.044

–12.002

–16.146

–11.430

–13.742

–11.248

–13.389

–24.143

–13.638

–12.613

–12.607

–12.866

–18.476

–15.032

–13.415

–13.450

–10.406

–10.807

–13.254

–10.975

–18.036

–14.322

–16.403

–12.997

–11.607

–13.155

15.803

9.7973

12.660

15.920

11.126

15.749

13.204

15.433

9.9340

15.640

8.3920

14.058

9.5730

14.333

29.941

11.669

16.684

8.2120

15.786

59.608

21.245

14.344

15.105

15.305

32.029

21.950

17.792

16.771

7.9331

8.5016

14.955

11.721

36.059

21.640

25.430

15.680

12.074

19.128

149.87

107.77

128.47

142.43

119.48

141.54

130.50

140.28

103.64

141.07

93.800

142.42

104.26

143.63

223.03

122.78

146.02

87.810

141.80

296.95

187.36

136.78

144.10

143.07

208.50

175.63

159.51

149.98

91.687

94.617

135.71

128.44

240.46

181.72

186.46

145.10

125.11

174.88

1900.7

1178.3

1522.6

1914.7

1338.1

1894.2

1588.1

1856.2

1194.8

1881.1

1009.3

1690.8

1151.4

1723.9

3601.1

1403.5

2006.6

987.68

1898.6

7169.2

2555.2

1725.2

1816.7

1840.8

3852.2

2640.0

2139.9

2017.1

954.13

1022.5

1798.7

1409.7

4336.9

2602.7

3058.5

1885.9

1452.2

2300.6

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

Vol. 94

No. 1

2020

HYPERBOLIC CORRELATION BETWEEN

35

Table 1. (Contd.)

No.

Tm

Tb

lnAs

Ea

TA

T*

K

K

–

kJ mol–1

K

K

Pure Solvent

81

82

83

84

85

2-Methoxyethanol

Water

Propylene carbonate

1,2-diethoxyethane

Acetonitrile

188.15

273.15

218.15

199.15

222.15

397.65

373.15

513.15

394.15

354.65

–12.662

–13.307

–11.729

–10.819

–10.793

14.504

15.568

14.192

7.5690

6.9895

137.77

140.70

145.53

84.142

77.885

1744.4

1872.4

1706.9

910.34

840.64

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

Tetrahydrofuran

Methanol

Octane

Pyridine

Benzene

Water

Propylene Glycol

N, N-dimethylacetamide

Water

2-propanol

2-mehoxyethanol

Isoamyl alcohol

Glycerol

1,4-Dimethylbezene

n-decane

n-eicosane

Benzene

n-tetracosane

165.15

175.55

216.15

232.00

278.65

273.15

214.15

253.15

273.15

183.65

397.65

156.00

563.00

286.30

243.30

310.00

278.65

324.00

339.15

337.75

398.75

388.55

353.15

373.15

461.35

438.55

373.15

355.15

397.65

403.15

455.15

411.15

447.25

616.25

353.15

664.55

–10.393

–11.629

–12.886

–12.635

–9.7233

–11.900

–18.266

–10.914

–13.443

–15.030

–12.822

–14.320

–24.140

–10.760

–11.355

–12.675

–13.250

–12.253

6.7382

10.198

13.275

14.925

5.5473

12.043

37.551

9.7590

15.920

21.950

15.704

21.640

59.610

8.3920

10.633

18.630

14.960

18.962

77.977

105.47

123.90

142.08

68.618

121.71

247.25

107.54

142.43

175.63

147.31

181.72

296.95

93.800

112.63

176.78

1135.7

186.13

810.42

1226.5

1596.6

1795.1

667.20

1448.4

4516.3

1173.7

1914.7

2640.0

1888.8

2602.7

7169.4

1009.3

1278.9

2240.7

1799.3

2280.6

* TEGMME is an abbreviation of triethylene glycol monomethyl ether.

Thus, using statistical modeling techniques to find

the expression which best fits this relationship, we suggest the following general equations relying Ea and

(1/TA – 1/Tb) for both directions which may hold well.

a1

Ea =

+ a3,

⎛1

⎞

1

⎜T − T ⎟ − a2

⎝ A

b⎠

(12)

Table 2. Descriptive statistics of temperatures` parameters:

Arithmetic mean (T1), Confidence Interval (CI) and coefficient of variation (CV)

Parameters

T1/K

CI (mean)

CV (%)

Tm

229.16

217.72–240.60

22

Tb

403.23

391.87–414.58

12

TA

146.19

133.89–158.49

37

T*

2093.55

1784.59–2402.52

65

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

⎛1

b1

1⎞

⎜T − T ⎟ = E − b + b3,

⎝ A

b⎠

a

2

(13)

where ai (I = 1,2,3) and bj (j = 1,2,3) are the models’

parameters.

Indeed, according to the Table 4, which presents

the result of statistical estimations of suggested models, only a3 is statistically non-significant and tend

thus to zero, all the other estimated parameters are statistically significant, the R-squared tends to one and

the value of Fisher statistics are very high for both

models. This result allows as expecting a very good

predictive power and quality of approximation during

their practical use.

Note that their relationship is not necessarily bijective i.e., the equations resuming their relationship in

the two directions are not necessarily inverse functions

(Ea = f(1/TA – 1/Tb) or 1/TA – 1/Tb = g(Ea)). For that

Vol. 94

No. 1

2020

36

MLIKI et al.

we have presented a best model for each direction

independently.

To confirming the good quality of approximation

of the suggested equations, Eq. (12) and Eq. (13), we

have estimated Ea by replacing the experimental values

of (1/TA – 1/Tb) in the Eq. (12) and we have estimated

(1/TA – 1/Tb) by replacing the experimental values of

Ea in Eq. (13). Table 5 provides descriptive statistics of

estimated versus experimental values for the two variables, in addition to the Average Percentage Deviation

(APD) which is an excellent indicator of the approximation quality.

The descriptive statistics indicates distinctly that

the experimental data values are close to the corresponding ones estimated from Eqs. (12) and (13).

Also, the values of the Average Percentage Deviations

(APD) are very low, 3.7% and 3.2% for Ea and (1/TA –

1/Tb) respectively, showing the small discrepancy

between the estimated and the experimental values

(Table 5).

Nevertheless, in order to affirm the obtained

results, we have to apply some statistical test of populations’ comparison. So, we have compared the estimated values with the experimental ones of the two

variables using the Wilcoxon signed-rank test [40],

which is an equality tests on matched data. Note that

the null hypothesis supposes that the distributions of

estimated and experimental values are the same.

Result of the test is presented in the Table 6.

The test of signed-rank of Wilcoxon leads to agree

the null hypothesis for all variables showing that the

estimated and the experimental distributions of both

variables are significantly and statistically the same,

which justify the excellent predictive power of the

Eqs. (12) and (13).

Table 3. Spearman rank correlation tests

Parameters

Ea

lnAs

TA

Prob > |t |

Tm

0.25

0.03

Tb

0.41

0.00

Tm

–0.16

0.18

Tb

–0.25

0.03

Tm

0.24

0.06

Tb

0.49

0.00

These results can also be revealed graphically. In

fact, we display in Figs. 4 and 5 the experimental

observations of one variable on the x-axis versus

simultaneously the estimated and experimental observations of the other variable on the y-axis. Thus, we

can see frankly that the gap between estimated and

experimental values is showing a small discrepancy.

For providing some physical meaning to the suggested empirical equations (Eq. (12) and Eq. (13)),

fruitful for Chemical Engineering, we can propose

some variable transformations to provide new semiempirical equations interesting for theoreticians as follows:

Ea =

Rα1

+ E01,

⎛1

1⎞− 1

−

⎜T T ⎟ T

⎝ A

b⎠

01

(14)

Rβ1

⎛1

1⎞

1

(15)

⎜T − T ⎟ = E − E + T ,

⎝ A

b⎠

a

02

02

where R is the ideal gas constant, α1 and β1 are dimensionless constants, E01 and E02 are the minimal values

70

600

Tm, K

Tb, K

(a)

Spearman rho

60

Ea, kJ mol−1

(b)

- R.lnAs/3

Ea and - R.lnAs/3

(Tm and Tb)/K

500

400

300

200

100

50

40

30

20

10

0

10

20

30

40

50

60

0

50

100

150

200

250

300

TA/K

Fig. 2. Scatter plots of the direct mutual correlation between the Arrhenius parameters (TA, ln As and Ea) and the melting temperature Tm and boiling temperature Tb of some pure liquids. (Ea/kJ mol–1; –Rln(As/Pa s)/3 in J K–1 mol–1).

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

Vol. 94

No. 1

2020

HYPERBOLIC CORRELATION BETWEEN

37

0.015

12

1/TA − 1/Tb

(1/TA − 1/Tb)exp

0.010

8

(1/TA − 1/Tb)est

A

(1/TA − 1/Tb)/kK−1

10

0.005

6

4

0

0

20

2

10

20

30

40

50

60

Ea, kJ mol−1

Fig. 3. Scatter plots for correlations between Ea and

(1/TA – 1/Tb).

that the activation energy can theoretically take for the

set of studied viscous liquids, and T01 and T02 are the

minimal values that the difference between the reciprocal of Arrhenius and boiling temperatures (1/TA –

1/Tb) in Eqs. (14) and (15) can theoretically be taken

3 for the set of studied liquids group and which it is schematized by the dashed line in Fig. 3.

For practical use of the Eq. (14) and the Eq. (15),

we report in the Table 7 the estimated values of the

new parameters. Thus, the practical form of the proposed equations, Eq. (14) and Eq. (15), can be defined

as follows:

Ea =

0.0661

,

⎛1

⎞

−4

1

⎜T − T ⎟ − 1.36 × 10

⎝ A

b⎠

Ea, kJ mol−1

60

Fig. 4. Graphical comparison between the experimental

and the estimated values of (1/TA – 1/Tb) as function of

the experimental values (Ea)exp.

0

0

40

(16)

We add that mathematically, the relationship

between the two equations (14) and (15) requires that

there is equality by couple of similar parameters, i.e.

(α1 = β1), (E01 = E02) and (T01 = T02). Nevertheless,

the small and negligible difference between estimated

values of each of these couples of parameters is due to

several reasons such as the measurement and estimation errors, the heterogeneity of the studied temperature range and the implicit dependence of these

parameters to specific properties of the studied solvents. Also, though the quality of the estimates is very

good, the values are very small for which the error of

the estimates does not make it possible to obtain them

with such precision. In addition, there is a distinct difference between the theoretical and experimental values of {(1/TA – 1/Tb)th and (1/TA – 1/Tb)exp}, where

these last ones are due principally to statistical distribution of observations, errors of calculation and measurements, and to the nature of the studied group of

fluids for which its specific features can play an substantial role in this fact.

Causal Correlation Origin

⎛1

−4

1⎞

0.0596

⎜T − T ⎟ = E − 0.8521 + 2.6 × 10 ,

⎝ A

b⎠

a

(17)

where Ea is in (kJ mol–1) and Ti in K.

As a preliminary theoretical explanation of the

causal correlation between the boiling point (Tb/K)

and the Arrhenius temperature (TA/K) we can give the

Table 4. Result of econometric estimations of the models (12) and (13)

Equation

(3)

(4)

Parameter

a1/kJ K–1 mol–1

a2/K–1

a3/kJ mol–1

0.0661 (53.21)

0.000136 (3.99)

tends to 0

b1/J

K–1

mol–1

0.0596 (30.220)

b2/kJ

mol–1

0.8521 (4.84)

b3/K–1

0.00026 (3.2)

Values between parentheses are t-statistics

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

Vol. 94

No. 1

2020

R-squared

F-statistics

0.994

7467

0.995

7471

38

MLIKI et al.

Table 5. Descriptive statistics on experimental versus estimated values

Mean

σ

Experimental

17.41

11.24

6.10

59.61

Estimated

17.43

11.10

5.76

63.89

APD (%)

3.7

3.3

0.2

16.5

Experimental

0.0052

0.0024

0.0012

0.0116

Estimated

0.0052

0.0025

0.0013

0.0116

APD (%)

3.2

2.7

0.1

Variables

Ea/kJ mol–1

(1/TA – 1/Tb)

following points: (i). The vaporization phenomenon is

a transition between two thermodynamic states where

molecules escape from the free surface layer of liquid

towards the free space [12, 13]. (ii). The activation

energy (Ea) value is necessary to the transfer between

two transition states where molecules move from one

layer to another adjacent layer in the frame of shear

flow of Newtonian fluid [14–17]. (iii). Similar causal

correlation is observed in previous works suggesting an

estimation of the boiling temperature of some liquid

components forming some binary fluid mixtures

through the viscosity-temperature and viscosity-composition dependences [23–37] and using some mathematical derivations of partial molar activation energies. (iv). We precise that the novel notion of partial

molar activation energies is justified, as a first approximation, by the observation of similar compositiondependence between the variation of the viscosity activation energy (Ea) and the enthalpy (ΔH*) of activation of viscous flow deduced from the temperatureGibbs free energy dependence for each mole fraction

of fifteen studied binary mixtures in previous works

[23–37].

Table 6. Results of Wilcoxon signed-rank test: experimental versus estimated values

Variable

z

Ea

(1/TA – 1/Tb)

Prob > |z|

–0.22

0.84

0.90

0.37

Table 7. The suggested parameters’ optimal values of the

Eq. (14) and Eq. (15)

Equation

Eq. 14

Eq. 15

Parameter

α1

T01/K

0.00795

7353

β1

T02/K

E02/kJ mol–1

0.00717

3846

0.8521

E01/kJ mol–1

0

Min

Max

13.4

CONCLUSION

Statistical and econometric techniques are used in

this paper in order to investigate the existence of any

eventual causal association between parameters of the

Arrhenius-type equation, the melting and boiling

points of some classical Newtonian liquids. For

empirical analysis, 103 data set of viscosity of pure

Newtonian fluids studied at atmospheric pressure and

at different temperatures from the literature is used.

Several analyses of mutual and complex possible correlations are made allowing as finding original and

interesting result. A significant strong nonlinear correlation between the Arrhenius activation energy (Ea),

the Arrhenius temperature (TA) and the boiling point

(Tb) is seen. Consequently, several statistical and

econometric estimations have been made to find the

model which best fit this association. Finally we have

suggested original equations modeling this relationship, Eqs. (12) and (13). In order to validate the proposed equation, we have made several statistical analyses for comparing the experimental values of parameters with the corresponding estimated values

obtained using the Eqs. (12) and (13). Indeed, a

descriptive statistics indicates clearly that the experimental data are close to the corresponding values

estimated from Eqs. (12) and (13). The values of the

Average Percentage Deviations (APD) are very low

showing the small discrepancy between the estimated

and the experimental values. The application of Wilcoxon signed-rank test confirmed that the experimental and the estimated distributions of the two

variables are significantly and statistically the same,

which justify the good predictive power of the suggested equations.

For giving some physical significance to the proposed empirical equations to be useful for chemical

engineering, we have made some variables transformations to obtain new semi-empirical equations,

Eqs. (14) and (15), which may be very interesting for

the theoreticians. Also, for practical use, we have proposed the Eqs. (14) and (15) which allow the predic-

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

Vol. 94

No. 1

2020

HYPERBOLIC CORRELATION BETWEEN

Ea, kJ mol

80

60

(Ea)exp

(Ea)est

40

20

0

0

0.005

0.010

0.015

(1/TA 1/Tb)exp

Fig. 5. Graphical comparison between the experimental

and the estimated values of (Ea) as function of the experimental values (1/TA – 1/Tb)exp.

tion of the boiling temperature through information

on viscosity Arrhenius parameters of liquid phase and

may be thus very useful in the handling of engineering

data especially for the study of hydraulic components

and systems efficiency.

Finally, we hope that this present work open a window for theoreticians to give some theoretical justifications for the understanding of the liquid state and

some meaningful insight into molecular interactions.

ACKNOWLEDGMENTS

Authors thank Dr. R.H. Kacem (FSEGN, University of

Carthage, Tunisia) for helpful discussions and for some

econometric and statistical calculations.

DISCLOSURE STATEMENT

Authors declare that there is no conflict of interest.

REFERENCES

1. N. Ouerfelli, M. Bouaziz, and J. V. Herráez, Phys.

Chem. Liq. 51, 55 (2013).

2. J. V. Herráez, R. Belda, O. Diez, and M. Herráez,

J. Solution Chem. 37, 233 (2008).

3. J. B. Irving, NEL Report Nos. 630, 631 (Glasgow, Nat.

Eng. Laboratory, East Kilbride, 1977).

4. S. W. Benson, Thermochemical Kinetics, 2nd ed. (Wiley,

New York, 1976).

5. J. A. Dean, Handbook of Organic Chemistry (McGrawHill, New York, 1987).

6. S. Glasstone, K. L. Laidler, and H. Eyring, The Theory

of Rate Process (McGraw-Hill, New York, 1941).

7. H. Eyring, J. Chem. Phys. 4, 283 (1936).

8. H. Eyring, and J. O. Hirschfelder, J. Phys. Chem. 41,

249 (1937).

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

39

9. H. Eyring and M. S. John, Significant Liquid Structure

(Wiley, New York, 1969).

10. P. T. Cummings and D. J. Evans, Ind. Eng. Chem. Res.

31, 1237 (1992).

11. J. G. Kirkwood, F. P. Buff, and M. S. Green, J. Chem.

Phys. 17, 988 (1949).

12. N. Dhouibi, A. Messaâdi, M. Bouaziz, N. Ouerfelli,

and A. H. Hamzaoui, Phys. Chem. Liq. 50, 750 (2012).

13. A. Messaâdi, N. Ouerfelli, D. Das, H. Hamda, and

A. H. Hamzaoui, J. Solution Chem. 41, 2186 (2012).

14. D. S. Viswanath and G. Natarajan, Databook on Viscosity of Liquids (Hemisphere, New York, 1989).

15. N. V. K. Dutt and G. H. L. Prasad, private commun

(Indian Inst. Chem. Technol., 2004).

16. D. S. Viswanath, T. K. Ghosh, G. H. L. Prasad,

N. V. K. Dutt, and K. Y. Rani, Viscosity of Liquids: Theory, Estimation, Experiment, and Data (Dordrecht,

Springer, 2007).

17. T. E. Daubert and R. P. Danner, Physical and Thermodynamic Properties of Pure Chemicals – Data Compilation Design (Inst. for Phys. Properties Data, AIChE,

Taylor and Francis, Washington DC, 1989–1994).

18. R. Ben Haj-Kacem, N. Ouerfelli, J. V. Herráez,

M. Guettari, H. Hamda, and M. Dallel, Fluid Phase

Equilib. 383, 11 (2014).

19. A. Messaâdi, N. Dhouibi, H. Hamda, F. B. M. Belgacem,

Y. H. Adbelkader, N. Ouerfelli, and A. H. Hamzaoui,

J. Chem. 2015, 163262 (2015).

20. R. Ben Haj-Kacem, N. Ouerfelli, and J. V. Herráez,

Phys. Chem. Liq. 53, 776 (2015).

21. A. A. Al-Arfaj, R. B. Haj-Kacem, L. Snoussi,

N. Vrinceanu, M. A. Alkhaldi, N. O. Alzamel, and

N. Ouerfelli, Mediterr. J. Chem. 6, 23 (2017).

22. R. Haj Kacem, M. Dallel, N. A. Al-Omair, A. A. AlArfaj, N. O. Alzamel, and N. Ouerfelli, Mediterr.

J. Chem. 6, 208 (2017).

23. N. A. Al-Omair, D. Das, L. Snoussi, B. Sinha,

R. Pradhan, K. Acharjee, K. Saoudi, and N. Ouerfelli,

Phys. Chem. Liq. 54, 615 (2016).

24. M. Dallel, A. A. Al-Zahrani, H. M. Al-Shahrani,

G. M. Al-Enzi, L. Snoussi, N. Vrinceanu, N. A. AlOmair, and N. Ouerfelli, Phys. Chem. Liq. 55, 541

(2017).

25. M. Dallel, A. A. Al-Arfaj, N. A. Al-Omair, M. A. Alkhaldi, N. O. Alzamel, A. A. Al-Zahrani, and N. Ouerfelli,

Asian J. Chem. 29, 2038 (2017).

26. H. Salhi, N. A. Al-Omair, A. A. Al-Arfaj, M. A. Alkhaldi,

N. O. Alzamel, K. Y. Alqahtani, and N. Ouerfelli,

Asian J. Chem. 28, 1972 (2016).

27. M. Hichri, D. Das, A. Messaâdi, E. S. Bel Hadj Hmida, N. Ouerfelli, and I. Khattech, Phys. Chem. Liq. 51,

721 (2013).

28. D. Das, A. Messaâdi, N. Dhouibi, N. Ouerfelli, and

A. H. Hamzaoui, Phys. Chem. Liq. 51, 677 (2013).

29. N. Ouerfelli, Z. Barhoumi, and O. Iulian, J. Solution

Chem. 41, 458 (2012).

Vol. 94

No. 1

2020

40

MLIKI et al.

30. Z. Trabelsi, M. Dallel, H. Salhi, D. Das, N. A. AlOmair, and N. Ouerfelli, Phys. Chem. Liq. 53, 529

(2015).

31. A. Messaâdi, H. Salhi, D. Das, N. O. Alzamil,

M. A. Alkhaldi, N. Ouerfelli, and A. H. Hamzaoui,

Phys. Chem. Liq. 53, 506 (2015).

32. D. Das, H. Salhi, M. Dallel, Z. Trabelsi, A. A. Al-Arfaj,

and N. Ouerfelli, J. Solution Chem. 44, 54 (2015).

33. N. Dhouibi, M. Dallel, D. Das, M. Bouaziz, and

N. Ouerfelli, Phys. Chem. Liq. 53, 275 (2015).

34. H. Salhi, M. Dallel, Z. Trabelsi, N. O. Alzamel,

M. A. Alkhaldi, and N. Ouerfelli, Phys. Chem. Liq. 53,

117 (2015).

35. M. Dallel, D. Das, E. S. Bel Hadj Hmida, N. A. AlOmair, A. A. Al-Arfaj, and N. Ouerfelli, Phys. Chem.

Liq. 52, 42 (2014).

36. M. A. Alkhaldi, Phys. Chem. Liq. 56, 250 (2018).

37. A. A. Al-Arfaj, Phys. Chem. Liq. 57, 19 (2019).

38. A. Ali, A. K. Nain, and S. Hyder, J. Indian Chem. Soc.

75, 501 (1998).

39. C. Spearman, Am. J. Psychol. 15, 72 (1904).

40. F. Wilcoxon, Biom. Bull. 1, 80 (1945).

SPELL: 1. neperian, 2. homogenous, 3. schematized

RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A

Vol. 94

No. 1

2020