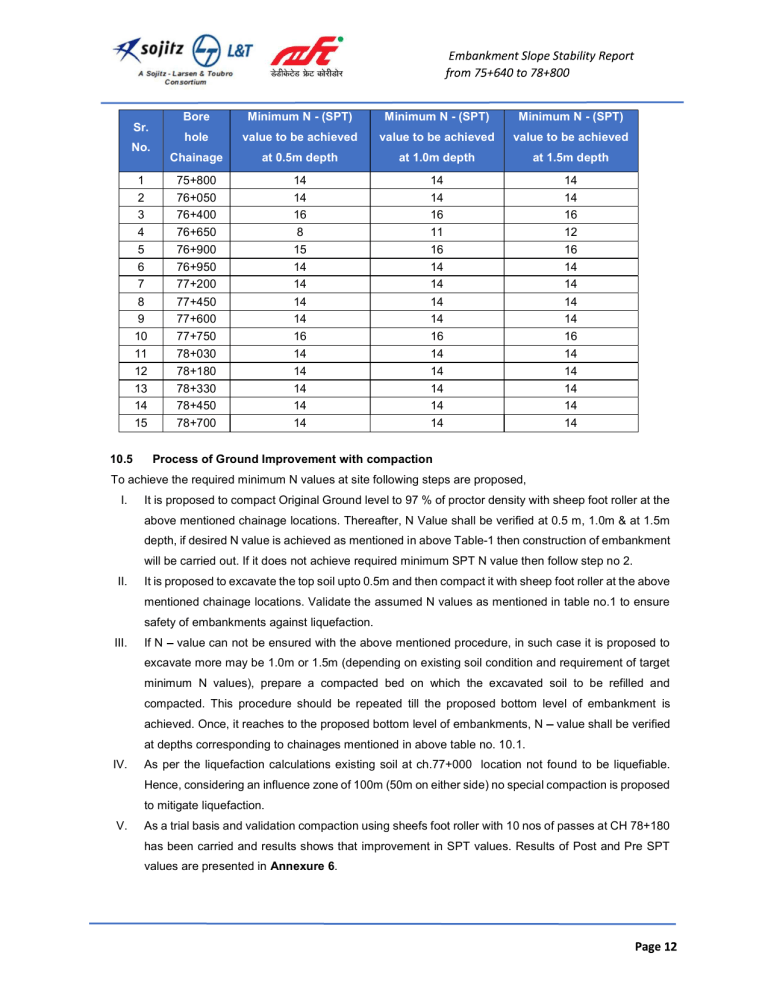

Bore Sr. No. 10.5 Minimum N - (SPT) Minimum N - (SPT) hole value to be achieved value to be achieved value to be achieved 75+800 76+050 76+400 76+650 76+900 76+950 77+200 77+450 77+600 77+750 78+030 78+180 78+330 78+450 78+700 14 14 16 8 15 14 14 14 14 16 14 14 14 14 14 14 14 16 11 16 14 14 14 14 16 14 14 14 14 14 14 14 16 12 16 14 14 14 14 16 14 14 14 14 14 Chainage 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Minimum N - (SPT) at 0.5m depth at 1.0m depth at 1.5m depth Process of Ground Improvement with compaction To achieve the required minimum N values at site following steps are proposed, I. It is proposed to compact Original Ground level to 97 % of proctor density with sheep foot roller at the above mentioned chainage locations. Thereafter, N Value shall be verified at 0.5 m, 1.0m & at 1.5m depth, if desired N value is achieved as mentioned in above Table-1 then construction of embankment II. III. will be carried out. If it does not achieve required minimum SPT N value then follow step no 2. It is proposed to excavate the top soil upto 0.5m and then compact it with sheep foot roller at the above mentioned chainage locations. Validate the assumed N values as mentioned in table no.1 to ensure safety of embankments against liquefaction. If N value can not be ensured with the above mentioned procedure, in such case it is proposed to excavate more may be 1.0m or 1.5m (depending on existing soil condition and requirement of target minimum N values), prepare a compacted bed on which the excavated soil to be refilled and compacted. This procedure should be repeated till the proposed bottom level of embankment is achieved. Once, it reaches to the proposed bottom level of embankments, N IV. V. at depths corresponding to chainages mentioned in above table no. 10.1. value shall be verified As per the liquefaction calculations existing soil at ch.77+000 location not found to be liquefiable. Hence, considering an influence zone of 100m (50m on either side) no special compaction is proposed to mitigate liquefaction. As a trial basis and validation compaction using sheefs foot roller with 10 nos of passes at CH 78+180 has been carried and results shows that improvement in SPT values. Results of Post and Pre SPT values are presented in Annexure 6.