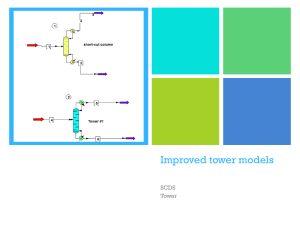

GROUP B FALL 2002 DISTILLATION STARTUP Pre-Lab: Fill out paperwork for the lab-technicians to startup the distillation column at total reflux for the day of experimentation. Initial Checklist: Verify column is at steady state. The guidelines for steady state are listed in Determination of Steady State. Verify the reflux tank level exceeds 20% in Labview, or ¼ of the reflux tank meter, otherwise see Reflux/Reboil Tank Level Adjustments. Verify the reboil tank level is within the designated “green” zone, otherwise see Reflux/Reboil Tank Level Adjustments. Verify the temperature profile of the column is similar to that shown in Figure 1A, initial. If the reboiler temperature exceeds 91 ºC, It will be necessary to reduce the temperature of the reboiler. Refer to Reboiler Temperature Reduction for instructions. Select the 9th feed tray by turning the valve on. The valve handle on the 9th tray must be horizontal. Verify that no other feed tray is turned on, i.e. the other feed tray valve handles are vertical. Turn the feed direction valve, located above the feed tank, to “Feed”. Note: The feed direction valve usually set initially to “Reboiler”. After completion of the initial checklist proceed to the Start-up Procedure. Determining Steady State: Total Reflux: Tray temperatures do not change more than 1 degrees in 5 minutes. Reflux tank level does not change more than 1% in 5 minutes. Reboil tank level does not change more than 1% in 5 minutes Continuous: Conditions from Total Reflux must be satisfied. Feed, Distillate, and Bottoms streams must be balanced. Reflux/Reboil Tank Level Adjustments: Reflux Tank Level High: Reflux Tank Level Low: Reboil Tank Level High: Reboil Tank Level Low: Notes: Increase distillate valve setting. Decrease distillate/reflux valve setting. Increase bottoms valve setting. Decrease bottoms/steam valve setting. If both tanks are low or decreasing valve settings do not significantly change the tank levels, a feed stream may be added to increase the volume of liquid in the column. If the reboiler needs additional liquid quickly, the feed direction valve may be changed to send the feed directly into the reboiler. Make sure that the feed valve is turned OFF while changing the feed direction valve. This should only be done between runs due to the drastic changes that will take place in the column. Reboiler Temperature Reduction: 1. Make sure that the feed and steam valves are set to 0. 2. Turn the feed direction valve, located above the feed tank, to “Reboiler”. The feed will now be sent directly to the reboiler and not to the feed tray. 3. Set the feed/bottoms valves to 50 and 25 respectively. Pay close attention to the level in the reboiler. Adjustments may be necessary if the level changes more than +/- 2% or approaches the limits of the “green” zone. To raise/lower the amount of liquid in the reboiler, decrease/increase the bottoms valve setting respectively. The optimal reboiler level is approximately 39%. The temperature of the reboiler will usually appear to fall below 85 ºC. This is a false reading due to insufficient mixing of the cold feed and hot reboiler liquid. 4. After a couple of minutes set the feed and bottoms valves to 25 and ~10. Watch the temperature of the reboiler closely. If it should begin to rise above 91 ºC, step 3 must be repeated. 5. Once the temperature of the reboiler begins to slow its approach to steady state, set the feed and bottoms valves to 0. 6. If the temperature begins to approach a steady state temperature lower than 91 ºC, let the column come to steady state according to Determining Steady State, and return to the initial checklist. Start-up Procedure: Note: The specific values in this manual, used to determine times at which valve settings must be changed, pertain specifically to the steady state achieved with final valve settings of: Steam: 25 1. Feed: 42 Distillate: 32 Bottoms: 25 The column should be in total reflux at steady state with the initial valve settings of: Steam: 31.1 Feed: 0 2. Set steam valve to 100. Steam: 100 Feed: 0 3. Reflux: 44 Reflux: 66 Distillate: 0 Bottoms: 0 Reflux: 66 Distillate: 0 Bottoms: 0 At ~90.5-91 ºC set the feed valve to 42, ~13 minutes to step 3. Steam: 100 4. 5. Feed: 42 Reflux: 66 Distillate: 0 Wait for the temperature profile to be approximately that of the steady state position, shown in Figure 1B, transition. This will occur approximately when the reboiler temperature has reached its steady state temperature, ~92.0-93.0 ºC. However it is necessary to make sure that the rectifying section trays have surpassed their respective steady state temperatures to create a convex curve demonstrated in Figure 1B, transition. It is also necessary to ensure that the stripping section trays have reached or are slightly elevated from their respective steady state temperatures. The Tray 7 temperature is the decisive condition for the final transition. Once the prior conditions are met, tray 7 will begin to increase significantly past its steady state temperature, ~68.5-69.0 ºC. DO NOT let the stripping section tray temperatures raise more than 1-2 ºC above their respective steady state temperatures. At this point change the steam, reflux, distillate, and bottoms to the following, ~4 minutes from step 3 to step 4: Steam: 25 Feed: 42 Reflux: 44 Distillate: 33 Bottoms: 25 Let the system come to steady state, ~7 minutes from step 4 to step 5. Verify according to Determining Steady State. A) Initial B) Transition C) Final Temperature Profiles on Startup 100 o Temperature ( C) Bottoms: 0 90 80 70 60 50 0 2 4 6 8 10 12 14 Tray Number Figure 1. Typical temperature profiles during startup with only steam or feed/steam together. A) Initial profile at time 0. B) Transition profile at a t when the final valve settings are set. C) The final steady state profile achieved when both the profile and the reflux/reboil tank levels are constant. Troubleshooting/Helpful Hints: If the initial reboiler temperature is above that of the steady state, and specifically 91 ºC in this experiment, follow the steps outlined in Reboiler Temperature Reduction. If the temperature profile is allowed to pass the transition profile outline in Figure 1B, two possible solutions exist: I If the temperature profile of the rectifying section appears horizontal, then follow Reboiler Temperature Reduction. Instead of aiming for a temperature lower than 91 ºC the target temperature will be the steady state reboiler temperature of ~92.5 ºC. II If the temperature profile is only slightly above the target transition profile, then the column can be left to arrive at steady state over a longer period or forced down by following the steps in Reboiler Temperature Reduction with a target temperature of ~92.5 ºC. Reflux/Reboil tank levels must be closely watched and may be adjusted according to Reflux/Reboil Tank Level Adjustments. BE SURE TO TURN ON THE DATA LOGGING SYSTEM. Pay extreme attention to the profile changes early on. Experience in determining transition times is critical to reducing the column startup time. G.C. Calibration Make up methanol/water solutions with concentrations of 5, 20, 40, 60, 80, and 95 mole percent methanol. Run each solution through the G.C. noting the peak areas for water and methanol (methanol will be the first peak). Plot concentration versus peak area for both water and methanol. Linearly regress the data and use the resulting equation to accurately determine concentrations from future G.C. runs.