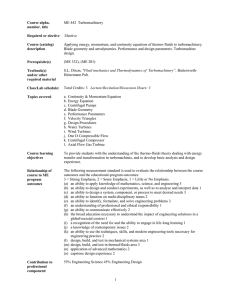

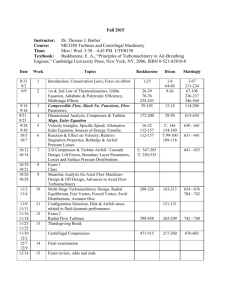

Turbomachinery Design and Analysis AE4803 Turbomachinery -1 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. Turbomachinery Design • So let’s say you completed a simple, single-point design of a turbofan engine for an aircraft flying at M=0.85 at 30 kft with the outcome Cycle Design – Prc = 54 – T4 = 1420 K Black Box – wt = 632 kJ/kg Analysis (no help) • How do you design the turbomachinery: compressor(s), turbine(s) that can achieve this performance? – begin with review of what turbomachinery looks like Turbomachinery -2 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. AE4803 1 Axial (Flow) Compressors and Turbines • Turbomachinery made up of many parts – compressor Stator/Stator Vanes Inlet Guide Vanes Shaft Casing Rotor/Rotor blades – turbine Stage=Rotor/Stator Pair Rotor Nozzle Elements of Gas Turbine Propulsion, Mattingly AE4803 Turbomachinery -3 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. Axial Compressors and Turbines • Turbomachinery made up of many parts Disk (blades attached to it) • Blisk if blades integrated into disk (Turbine) Rotor Blade Spool - compressor and turbine rotors on common shaft braytonenergy.net Elements of Gas Turbine Propulsion, Mattingly Turbomachinery -4 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. AE4803 2 Axial Compressors and Turbines • Turbomachinery made up of many parts Spool • compressor and turbine rotors on common shaft GE F404 LP spool turbine 1 rotor (1 stage) compressor 3 rotors (3 stages) Mechanics and Thermodynamics of Propulsion, Hill and Peterson AE4803 Turbomachinery -5 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. Axial Compressors and Turbines • Turbomachinery made up of many parts – most engines have at least two spools – e.g., concentric shafts 3 stage LP compressor 7 stage HP compressor Elements of Gas Turbine Propulsion, Mattingly GE F404 Prc~26 Prstage~1.4 Mechanics and Thermodynamics of Propulsion, Hill and Peterson Turbomachinery -6 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. AE4803 3 Turbomachinery Aerothermodynamics AE4803 Turbomachinery -7 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. Turbomachinery Conservation Equations • How to analyze the performance of turbomachinery to enable design? • Start by developing Shaft conservation equations Turbomachinery -8 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. Tip Hub or Root Rotor Blades AE4803 4 Coordinate System • First need to define appropriate control volume and coordinate system for rotating machinery – axisymmetric r z Casing Mechanics and Thermodynamics of Propulsion, Hill and Peterson Turbomachinery -9 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. AE4803 Fixed vs. Rotating Frames of Reference • Since some blades are rotating (rotors) and some are stationary (stators), we will find it helpful to use 2 Radial c reference frames Velocity r for defining cz Axial velocity c Velocity Azimuthal 1. fixed (“lab” Velocity or engine) ref. frame c 2. rotating ref. frame w Turbomachinery -10 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. AE4803 5 Fixed vs. Rotating Frames of Reference • How to we convert velocities from one ref. frame to another? – Galilean transform v new v old v rel vrel is relative velocity of new reference frame with respect to old u • What is the relative velocity between our 2 ref. frames? – the (local) blade velocity! u r r w c u Turbomachinery -11 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. AE4803 Euler Turbomachinery Equations • Mass CV for one blade row d 0 dV c nˆ dA CS dt CV steady 0 0 m 2 m 1 m 2 m 1 m • Angular Momentum(engine frame) torque – CM law d mrc dt d rc dV rc c nˆ dA CV CS dt 0 for steady…if we time avg. over high freq. fluctuations that result from blades going by rc c nˆ dA m rc 2 rc 1 CS Turbomachinery -12 blade disk rh rm rt for prelim. design, typically use the “mean” radius location (between tip and hub) pitchline (or meanline) (rc) represents a spatially reasonable starting point if rm>>rt-rh averaged (integrated) property Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. AE4803 6 Euler Turbomachinery Equations • So m rc 2 rc 1 – what about power? • Power/Energy – from mechanics rc 2 rc 1 W m W m rc 1, 2 r = blade speed u W m uc 1, 2 – from thermodynamics W m h?o 2 ho1 h0 1, 2 uc 1, 2 steady, adiabatic, uniform for equations as written , W 0 for compressor rev min 2 N min 60sec rev N rpm 30 , W 0 for turbine AE4803 Turbomachinery -13 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. Euler Turbomachinery Equations • So having used both mechanics (mass & momentum) and thermodynamics (energy) across our control volume W m uc ho we can relate the TD property changes across turbomachinery blade rows to the induced azimuthal velocity changes • Using a constant pitchline approach (r1 r2) uc ho Turbomachinery -14 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. for axial machines AE4803 7 Other Important Definitions • Reaction (Degree of Reaction) R hrotor energy change across rotor hstage energy change across stage ~ protor pstage – balance torque, p gradient between rotor/stator • Flowfields (axial machines) – while real machines have 3-d flows, easier to consider 2-d flows (different “planes”) • Throughflow Field (r-z plane) r – not including variations z – disk replaces blades (actuator disk theory) AE4803 Turbomachinery -15 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. Other Important Definitions • Cascade Field (-z plane) – not including r variations – like unwrapping blade to look at array of airfoil sections – will focus on this for 2-d design • Secondary Field (r- plane) – not including z variations – low velocity in boundary layers blade along blades/walls – pressure gradients produce secondary (rotational) flows – leads to reduced performance (efficiency loss) Turbomachinery -16 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. blade z r AE4803 8 Turbomachinery Cascade Analysis Turbomachinery -17 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. AE4803 Cascade Analysis • Historically, much of turbomachinery blade design was based on measurements of cascade data in wind tunnels • Extrapolating this to real turbomachinery assumes quasi-steady, 2-d flow – not really true, but cascade results still relevant and characteristics derived from cascade analysis often satisfactory for preliminary design • Modern design based on CFD analysis combined with experimental testing Turbomachinery -18 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. z AE4803 9 2 Cascade Geometry • Typical airfoil properties – camber line shape and angle, – chord, b – thickness (t) profile and tmax/b – leading and trailing edge radii • Cascade properties 1 – pitch, s ( 2r / # blades) – solidity, b / s – stagger angle, (between chord and axial*) s – blade inlet angle,* 1 – blade exit angle,* 2 camber b line chord line suction surface pressure surface z 1 2 Turbomachinery -19 Copyright © 2014,2015, 2018, 2019 by Jerry M. Seitzman. All rights reserved. *some engine companies use normal ( direction) as reference AE4803 10