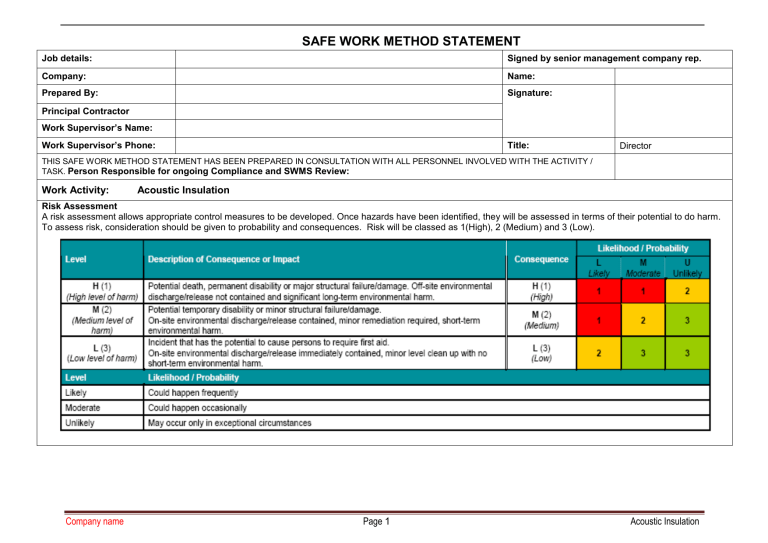

SAFE WORK METHOD STATEMENT Job details: Signed by senior management company rep. Company: Name: Prepared By: Signature: Principal Contractor Work Supervisor’s Name: Work Supervisor’s Phone: Title: Director THIS SAFE WORK METHOD STATEMENT HAS BEEN PREPARED IN CONSULTATION WITH ALL PERSONNEL INVOLVED WITH THE ACTIVITY / TASK. Person Responsible for ongoing Compliance and SWMS Review: Work Activity: Acoustic Insulation Risk Assessment A risk assessment allows appropriate control measures to be developed. Once hazards have been identified, they will be assessed in terms of their potential to do harm. To assess risk, consideration should be given to probability and consequences. Risk will be classed as 1(High), 2 (Medium) and 3 (Low). Company name Page 1 Acoustic Insulation SAFE WORK METHOD STATEMENT Risk Control Risk control is the process of eliminating or reducing risk factors. Control measures should be chosen and implemented to eliminate, or reduce the risk as far as practicable. When deciding on the most appropriate measures to use, practicality and acceptance of the control measures must be adopted. Hierarchy of Controls The following control measures will be considered beginning at the top of the list (in the order specified) when deciding on the appropriate control. A combination of these measures will be selected to control hazards to the lowest level reasonable practicable. 1. 2. 3. 4. 5. 6. Remove/eliminate the hazard Substitute the hazard with one that gives rise to a lesser risk (e.g. substituting chemicals for one that is less hazardous) Isolating the hazard the hazard from the person put at risk (e.g. relocating a noisy machine outside or enclosing it) Minimise using engineering means (e.g. installing a guard on a machine or redesigning it) Minimise using administrative means (e.g. training, supervision, safe work procedures) Using personal protective equipment PPE (e.g. gloves, glasses, foot wear) Personal Protective Equipment to be worn: Hard hat, Safety Footwear, and task specific PPE such as Safety Eyewear (Goggles and Glasses), Dust mask, Gloves, Hearing Protection, 30+Sunscreen and High Visibility Clothing where required. Qualifications and experience required to carry out the task: Qualified Lagger or apprentice with at least one (1) year actual site experience as a lagger Resources: Trade Involved Acoustic Insulation Equipment Used: Platform Ladder Maintenance Checks: Daily visual Hazardous Substances: None Frequency of Reviews: SWMS reviewed monthly or as required Environmental Health and Safety Legislation: Work Health and Safety Act 2011 Work Health and Safety Regulation 2011 Company name Codes of Practice (COP) or Australian Standards appliciable to the works: AS/NZS 1892 / Potable Ladder Part 1: Metal AS/NZS 1892.5 2000 Portable Ladders Paret 5: Safe Use and Care Page 2 Acoustic Insulation SAFE WORK METHOD STATEMENT Step Activity Step Hazards Identification Residual Risk Risk Rating Control Measures 1 Tool Box Talk General inspection of work area General risk due to unfamiliarity with site conditions and situations Low P1 Leading hand and/or tradesperson to inspect and Tool Box Meeting mus tne conducted prior to commencement. 2 Inspect and set up work area - Low P1 - - penetration inadequate lifhting, causing trip/fall hazard fall from heights exposure to noise/dust manual handling fall over perimeter edge - 3 Set up platform ladder - 4 Measure and cut to size insulation materials - Request builder to secure all penetration in work area Light up area Do not work until areas clean and clear of trip hazards Use correct PPE Ensure correct lifting techniqes. Do not carry more than 20kg at any given time. Ensure ladder has stable frames. Mo ladders in perimeter exclusion zone 3 mtrs from edge. fall from height due to poorly maintained ladder topple over due to uneven surface Low P1 - Ladders are checked daily for adequacy Platform ladder will only be used on level and clean surfaces. severe cuts dust from surrounding area Low P1 - Take extreme precaution in handling knife when cutting Ensure knife is returned to its sheath when not in use Ensure knife is in sheath and left on a safe area on the ground before going up the platform ladder Wear dust mask when dust is present in work area. - 5 Wrap and tape insulaton materials around pipe - finger cuts fall from height Low P1 - Wear gloves when taping insulation materials Platform ladder should be positioned and being set up level on ground 6 Clean up work area and remove waste materials - trip hazards dust pollution Low P1 - Clean and clear trip hazards Use correct PPE Ensure correct disposal of waste to allocated waster provider as per Fluid Contracting waste minimisation guide. Company name Page 3 Person Responsible Acoustic Insulation SAFE WORK METHOD STATEMENT Qualifications and experience required to complete the task: Actual site experience as Lagger for at least one (1) year Personnel, Duties and Responsibilities (Supervisory Staff and Other) 1. 2. Qualified Lagger, Apprentice Training required to complete the work: at least one (1) year actual site experience as a lagger Strict compliance with OH&S and site safety rules Lagging of pipes as per specification System Industries (Aust) Pty Ltd supervisor to ensure this work activity is monitored and carried out in accordance with this SWMS WHS Industry Inductions; Company policies and procedures; Site-specific induction; Induction to SWMS. Declaration by contractors and subcontractors I have been consulted and have assisted in the development of this SWMS I have been given the opportunity to comment on the content of this SWMS I have read and understand how I am to carry out the activiites listed in this SWMS I have been supplied with the Personal Protective Equipment identified on this SWMS and I have been given training in the safe use of this equipment I have read and understand the requirements set out in the mateial safety data sheets (MSDS) for the hazardous substances identified in this SWMS. Company name Page 4 Acoustic Insulation SAFE WORK METHOD STATEMENT This SWMS has been developed through consultation with our employees and has been read, understood and signed by all employees undertaking the works: Print Name Qualifications Experience Signature Date I have been inducted into and understand this SWMS. I was given the opportunity to value add to the content Print Name Review No Qualifications 01 02 03 04 Experience 05 06 07 Signature 08 09 Date 10 Initial: Date: Company name Page 5 Acoustic Insulation 11