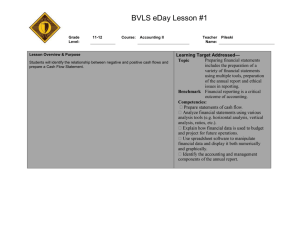

AFDEX Tutorial 1-8 Submission Report Assignment Submitted by Name: P Nagaraju Roll No.: 201723NT521 Course: Manufacturing Process Software: AFDEX Forging Simulation Work Integrated Learning Program BIRLA Institute of technology and Science, Pilani Tutorial 1 Tutorial 1 Forging Simulation : DOUBLE STAGE COLD FORGING PROCESS (2D) Tutorial 1 Observation & Report • Observation: In this tutorial I have learned how to simulate DOUBLE STAGE COLD FORGING PROCESS (2D) and observed following various parameters which helps to understand the Cold forging process in detail Parameter Maximum Value Minimum Value Effective Strain Rate (/s) 4.744E-001 1.5812E-001 Effective Strain 1.5006 1E-04 Von Mises Stress (MPa) 7.87E+002 1.02E-001 Principal Mean Stress (MPa) 5.13E-02 -3.616E03 Nodal Velocity (mm/s) 2.36 1.005 Tutorial 2 Tutorial 1 Forging Simulation : Single Stage Cold Forging Process (3D) Tutorial 2 Observation & Report • Observation: In this tutorial I have learned how to simulate Single Stage Cold Forging Process (3D) and observed following various parameters which helps to understand the Cold forging-3D process in detail Parameter Maximum Value Minimum Value Effective Strain Rate (/s) 3.682 1.738E-004 Effective Strain 4.24 1E-04 Von Mises Stress (MPa) 9.935E+002 0 Principal Mean Stress (MPa) 1.803E+002 -3.89E+003 Nodal Velocity (mm/s) 2.494 0 Tutorial 3 Tutorial 1 Forging Simulation : Automatic Multi stage hot forging process (3D) Tutorial 3 Observation & Report • Observation: In this tutorial I have learned how to simulate Automatic Multi stage hot forging process (3D) and observed following various parameters which helps to understand the Multi stage forging process in detail Parameter Maximum Value Minimum Value Effective Strain Rate (/s) 3.923E+002 1.620E-002 Effective Strain 5.695 1E-04 Von Mises Stress (MPa) 1.307E02 5.55E-04 Principal Mean Stress (MPa) -4.359E+001 -3.691E+002 Nodal Velocity (mm/s) 6.131E+02 0 Tutorial 4 Tutorial 1 Forging Simulation : PLATE FORGING PROCESS (3D) Tutorial 4 Observation & Report • Observation: In this tutorial I have learned how to simulate PLATE FORGING PROCESS (3D) and observed following various parameters which helps to understand the Plate forging process in detail Parameter Maximum Value Minimum Value Effective Strain Rate (/s) 2.572E+01 5.35E-003 Effective Strain 2.415 1E-04 Von Mises Stress (MPa) 8.761E+002 5.345E+002 Principal Mean Stress (MPa) -3.410E+002 -4.528E+003 Nodal Velocity (mm/s) 2.479E+01 0 Tutorial 5 Tutorial 1 Forging Simulation : SINGLE STAGE EXTRUSION PROCESS Tutorial 5 Observation & Report • Observation: In this tutorial I have learned how to simulate SINGLE STAGE EXTRUSION PROCESS and observed following various parameters which helps to understand the Extrusion process in detail Parameter Maximum Value Minimum Value Effective Strain Rate (/s) 1.066 0 Effective Strain 1.362 7.011E-03 Von Mises Stress (MPa) 7.352 -7.244E+002 Principal Mean Stress (MPa) 3.735E+002 -1.562E+003 Nodal Velocity (mm/s) 1.220 8.401E-001 Tutorial 6 Tutorial 1 Forging Simulation : ROLLING PROCESS Tutorial 6 Observation & Report • Observation: In this tutorial I have learned how to simulate ROLLING PROCESS and observed following various parameters which helps to understand the Rolling process in detail Parameter Maximum Value Minimum Value Effective Strain Rate (/s) 0 0 Effective Strain 1.654 1.521E-01 Von Mises Stress (MPa) 1.106E+02 0 Principal Mean Stress (MPa) 0 0 Nodal Velocity (mm/s) 0 0 Tutorial 7 Tutorial 1 Forging Simulation : HOT FORGING PROCESS WITH SLIDING DIE Tutorial 7 Observation & Report • Observation: In this tutorial I have learned how to simulate HOT FORGING PROCESS WITH SLIDING DIE and observed following various parameters which helps to understand the hot forging process in detail Parameter Maximum Value Minimum Value Effective Strain Rate (/s) 1.231E+002 2.823E-002 Effective Strain 2.331 1E-04 Von Mises Stress (MPa) 1.14E+03 3.44E+01 Principal Mean Stress (MPa) 3.823E+02 -6.985E+02 Nodal Velocity (mm/s) 2.975E+002 0 Tutorial 8 Tutorial 1 Forging Simulation : HOT FORGING OF PISTON HEAD WITH FLASH Tutorial 8 Observation & Report • Observation: In this tutorial I have learned how to simulate HOT FORGING OF PISTON HEAD WITH FLASH and observed following various parameters which helps to understand the hot forging process in detail Parameter Maximum Value Minimum Value Effective Strain Rate (/s) 2.918E+05 2.479 Effective Strain 3.844E+01 2.803E-01 Von Mises Stress (MPa) 2.866E+02 5.904E+01 Principal Mean Stress (MPa) 0 0 Nodal Velocity (mm/s) 9.525E+03 0