Heat Transfer via Liquid Jet Impingement: A Review

advertisement

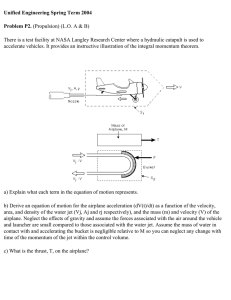

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 10 | Oct 2019 p-ISSN: 2395-0072 www.irjet.net A Review: HEAT TRANSFER THROUGH LIQUID JET IMPINGEMENT Kumbhar Adesh1, Kadam Ranjeet2, Patil Sandeep3, Mile Aniket4, Deshmukh S.A5 1,2,3,4Student of Mechanical Engineering, SBPCOE, Indapur, Maharashtra, India. Professor of Mechanical Engineering, SBPCOE, Indapur, Maharashtra, India. --------------------------------------------------------------------------***---------------------------------------------------------------------------utilized and contemplated. These methods are accustomed Abstract - As innovation created in the different field, 5Ass. there is need better cooling systems utilized for different mechanical application like electronic part cooling, steelmaking, atomic power plants and numerous other high heat transfer rate applications. Presently a day's water jet impingement is utilized for cooling of hot surface plates and other building application. Impingement of water liquid jet on a surface to expel heat from the surface is a powerful technique for high heat flux transfer. In this paper, the heat transfer of water planes strikes on a hot level plate was examined under temperatures beneath the breaking point to comprehend convection heat transfer. There are different parameters that influencing the heat transfer in the jet impingement procedure including the warmth transition, jet rate, channel weight, spout geometry, spout to plate separation and working medium properties, and so on there are two arrangements of limit conditions in particular as consistent temperature and steady warmth motion were applied at the outside of the plate and assessed. The two planes warm execution was seen as unaffected on account of planes are excessively far away from the each other to produce any extra warm communication. The outcomes demonstrates that as we increment the Reynolds number of one jet than the other jet it increments both local and normal Nusselt numbers. Likewise in the event that we increasing the jet to jet spacing at a similar Reynolds number it builds the normal Nusselt number. Keywords - jet impingement, Reynolds number, Heat transfer. Nusselt number, 1. INTRODUCTION The fluid jet impingement is a viable procedure utilized for cooling in a numerous applications because of its ability to move high warmth motions. Impinging fluid planes are for the most part utilized in different modern applications to accomplish exceptionally high heat transfer rate. Impinging fluid jet heat transfer is a fascinating point thus it draws in light of a legitimate concern for some heat transfer designers and specialists. Because of expanding request of heat transfer upgrade in numerous mechanical applications, jet impingements are comprehensively © 2019, IRJET | Impact Factor value: 7.34 | to getting superior cooling, warming or drying of a surface any place required. Different significant modern applications like cooling or warming of electrical types of gear, drying required different material and paper businesses, cooling of turbine sharp edges, solidifying of tissues in cryosurgery, tempering of glass, quick cooling/warming associated with glass assembling and short departure or vertical landing air ships and so forth. In 2017, Anuj K. Shukla et.al [1] contemplated that the Impinging fluid planes offering a successful and adaptable way to deal with exchange energy\mass in different mechanical applications by changing the jet and geometric parameters, for example, jet Reynolds number (Re), spout geometry or shape, get together of jet exhibit, spout to plate separating, point of jet impingement, disturbance properties at the exit of the jet, ribbed surfaces and jet throb, and so forth there are a wide range of procedures are utilized to cool hot steel plates at the ROT. for example, impinging water at various edges with various kinds of spouts and splashes and fluid draperies. Likewise fluid impinging planes opposite to the plate with a roundabout spout are normally utilized because of their basic structure, high heat transfer rates. Impinging air\water cooling methods are extremely helpful for different applications like cooling of ignition motors and electronic microchips. Cooling the hot level strip under the ROT conditions is exceptionally troublesome and as often as possible arrangements with investigations and models. This wonder is partners with the strip development to the bubbling marvels. In this examination we chose to concentrate for the most part on the planes connection and impacts of the fluid jet rate, excluding by that the surface development and the stage change. 2. LITERATURE REVIEW In 2015, Mohamed M. Khairat et.al [2] examined that expanding the Reynolds number of one jet than the other jet increments both nearby and normal Nusselt numbers. Additionally, expanding the jet to jet spacing at a similar Reynolds number builds the normal Nusselt number. At the point when tests are completed it covers a range for ISO 9001:2008 Certified Journal | Page 492 International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 10 | Oct 2019 p-ISSN: 2395-0072 www.irjet.net Reynolds number from 7100 to 30,800 for each jet, the dimensionless jet to jet spacing from 22.73 to 90.1. While contemplating, right jet Reynolds number was higher than the left jet Reynolds number. In 2016, Bingxing Wang et.al [3] examined on the top surface warmth transition is sure higher than the base in the deliberate cooling district. The warmth motion increments with the water jet rate and diminishes with the spout to surface separation. Likewise with the expansion in spiral separation, top surface wet front growing velocity is seriously not as much as that of the base surface. The outcome demonstrates that jet speed is the basic factor to create higher cooling execution during both impinging forms. In 2016, Kyosung Choo et.al [4] tentatively researched that the Nusselt number and weight are characterized into three areas; district (I) jet redirection locale (H/d ≤ 0.6), district (II) potential center locale (0.6 < H/d ≤7), and locale (III) free jet area (7 < H/d ≤40). In area I, the Nusselt number and weight increment with diminishing the spout to plate separating. In district II, the impact of the spout to plate spacing is unimportant on the Nusselt number and weight. In district III, the Nusselt number and weight decline with expanding the spout to plate dispersing. In 2016, S.V. Kalinina et.al [5] concentrated on concentrate the jet and heat transfer in an impinging annular jet. Result showed that the heat transfer of the impinging annular jet is higher than that of the round jet and the level of heat transfer relies upon the annular hole size and good ways from the spout to the deterrents. In 2016, Bin Sun et.al [6] found that the utilization of nanofluids in impinging plane cooling frameworks genuinely improved heat transfer effectiveness and that the weight drops in the framework didn't change. At the point when nanofluids are utilizes as the working liquid, the convective heat transfer coefficient was higher in round spouts than in square spouts. As the bigger the jet edge, more grounded the heat transfer impact. Likewise, a specific spout size boosts the heat transfer impact at a similar jet conditions. In 2017, Abdullah M. Kuraan, et.al [7] examined that heat transfer and liquid jet attributes of a free water jet impinging a level plate surface The impacts of low spout to plate separating (H/d = 0.08–1) on the standardized stagnation Nusselt number, weight, and pressure driven hop breadth are considered. They found that the standardized stagnation Nusselt number, weight, and pressure driven bounce distance across are isolated into two districts: Region (I) jet redirection locale (H/d ≤ 0.4) and Region (II) inactivity predominant area (0.4 < H/d ≤ 1). In 2017, C.Y. Zhao et.al [8] contemplated that the heat transfers qualities of a water jet impinging a surface with a moving spout. They called attention to primarily that moving spout improves the heat transfer consistency, which prompts an increasingly uniform temperature circulation, with expanded consistency as the spout speed increments. In © 2019, IRJET | Impact Factor value: 7.34 | 2015, G. Nasif et.al [9] found that the warm impacts of a pivot symmetric oil jet impinging on a fast responding plate exposed to uniform warmth transition and limited by a barrel shaped divider. They utilized the volume of liquid (VOF) technique. They presumed that jet impingement onto the moving limit, the most extreme Nusselt number is accomplished a brief span after the relative speed between the plate and the jet arrives at its greatest. In 2016, Amir Hossein Nobari et.al [10] explored technique to build up a robotic heat transfer model for cooling of steel. They examined the cooling conduct of stationary steel plates. Fig 1: Impinging jet (a) impingement zone and (b) radial flow zone (Ref: Amir Hossein Nobari et.al) Fig. 1(a) demonstrates a commonplace setup of a hatchet symmetric jet. Fig 1(b) the thickness of the fluid film can differ altogether for laminar and fierce jet. In 2016,Md Lokman Hosain et.al [11] contemplated that a hot moving steel run out table case as for spout measurement, jet tojet separation, plate width, impingement point and water jet rates, and numerically explored the jet and heat transfer conduct of single and twofold flies. They grew new connection between's the outspread situation of the greatest nusselt number and least jet breadth. In 2016, Christopher Csernyei et.al [12] researched that constrained convective heat transfer on a flat round chamber because of various impinging roundabout planes. They examined convective heat transfer on an even chamber because of a bank of vertically situated round planes. In 1995, B. webb et.al [13] learned about the Impinging fluid planes have been exhibited to be a successful methods for giving high heat/mass exchange rates in modern vehicle forms. At the point when a fluid jet strikes a surface, slim hydrodynamic and warm limit layers structure in the area straightforwardly underneath because of the jet deceleration and the subsequent increment in weight. In 1991, X. Liu et.al [14] learned about uses of jet impingement cooling are changed, and incorporate handling of the two metals and shaped plastics, cooling of high-productivity (air ship) generator curls, and cooling of certain electronic modules. Such jets loan themselves to either convective bubbling or to no evaporative convection, yet in the two circumstances the ISO 9001:2008 Certified Journal | Page 493 International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 10 | Oct 2019 p-ISSN: 2395-0072 www.irjet.net cooling proficiency changes with the outspread good ways from the purpose of effect. In 2008, A. K. Singh et.al [15] considered that the noteworthy development in execution and usefulness of microelectronics joined with a scaling down pattern in MEMS has brought about an extraordinary increment in warmth stacks that exhibits an incredible test to warm builds. Nanofluids can possibly address these difficulties. In 1994, Sourav K. Bhunia et.al [16] fundamental thought process of this investigation is to give connection between jet surface harshness and the splattering during plane impingement. They utilized a laser-based optical method to quantify the amplitudes of changes on the free surface of a fierce jet noticeable all around. This instrument comprise of a laser light sheet, a photograph sensor and focal points is fit for estimating changes in jet width at frequencies up to around 1 MHz. In 1994, L. A. Gabour et.al [17] examined about Stagnationpoint heat transfer to an unsubmerged fierce jet impinging on an unpleasant surface. They inspected impacts of spout to target spacing, Reynolds number and divider unpleasantness. In 1982, J.F.Timmers et.al [18] in this investigation, they utilized of a typified fluid gem allows the representation of lines of steady temperature. With a steady warmth transition limit condition these isotherms convert into lines of consistent heat transfer coefficient. Shifting the extent of the warmth transition and watching just a solitary isotherm brings about a progression of bends which give forms of consistent heat transfer coefficient superficially. In 2000, Chandrakant D. Patel et.al [19] a test study was performed to decide the impact of the tendency of an impinging two-dimensional air jet on the heat transfer from a consistently warmed at plate. It utilizes the treated steel plate and Reynolds number in the scope of 4000-12000. In 1991, J. Stevens et.al [20] in this paper, they contemplated nearby heat transfer coefficients for an axisymmetric water jet impinging ordinarily against a level, consistent warmth motion plate. It was discovered that Nusselt number changed with Re1/3 for a given jet distance across. An area of consistent local heat transfer coefficient was found to win in the district limited by 0<r/d<0.15. of expanding the Reynolds quantities of one jet than other jet builds the local and normal Nusselt numbers. Likewise expanding the jet to jet spacing increments both the local and normal Nusselt numbers. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] [9] 3. CONCLUSION / DISCUSSION In this review paper, detail investigation of heat transfer through jet impingement has been displayed. In this review paper demonstrating support for structuring fluid jet impingement which is powerful cooling method for various mechanical application additionally for electronic gear. The review paper contains different investigations on heat transfer in jet impingement. In this review paper, we learned about what impact of various parameters on hot metal surface zone is broke down for greatest heat transfer rate. The outcome demonstrates obviously that the impact © 2019, IRJET | Impact Factor value: 7.34 | [10] [11] [12] Anuj K. Shukla, Anupam Dewan, “Flow and thermal characteristics of jet impingement: comprehensive review” Internatinal journal of heat and technology, vol.35, pp.153-166, March 2017-Elsevier. Mohamed Teamah, Mohamed Khairat, “Heat transfer due to impinging double free circular jet”,Alexandria Engineering Journal 54,2015,pp. 281–293. Bingxing Wang, Xitao Guo, Qian Xie, ZhaodongWang, Guodong Wang , “Heat transfer characteristic research during jet impinging on top/bottom hot steel plate”, International Journal of Heat and Mass Transfer 101 2016,pp. 844–851 Kyosung Choo , Brian K. Friedrich, Aspen W. Glaspell, Karen A. Schilling, “The influence of nozzle-to-plate spacing on heat transfer and fluid flow of submerged jet impingement”, International Journal of Heat and Mass Transfer 97 ,2016,pp. 66–69. V.I. Terekhov, S.V. Kalinina, K.A. Sharov, “An experimental investigation of flow structure and heat transfer in an impinging annular jet” , International Communications in Heat and Mass Transfer 79,2016,pp. 89–97 Bin Sun, Yi Qu, Di Yang, “Heat transfer of Single Impinging Jet with Cu Nanofluids”, Applied Thermal Engineering 102, 2016, pp. 701–707. Abdullah M. Kuraan, Stefan I. Moldovan, Kyosung Choo, “Heat transfer and hydrodynamics of free water jet impingement at low nozzle-to-plate spacings”, International Journal of Heat and Mass Transfer 108, 2017, pp. 2211–2216. X. Ai, Z.G. Xu, C.Y. Zhao, “Experimental study on heat transfer of jet impingement with a moving nozzle”, Applied Thermal Engineering 115, 2017, pp. 682–691. G. Nasif ,R.M. Barron, R. Balachandar, “Simulation of jet impingement heat transfer onto a moving disc”, International Journal of Heat and Mass Transfer 80, 2015, pp.539–550. Amir Hossein Nobari, Vladan Prodanovic, Matthias Militzer, “Heat transfer of a stationary steel plate during water jet impingement cooling”, International Journal of Heat and Mass Transfer 101,2016,pp. 1138– 1150. Md Lokman Hosain, Rebei Bel Fdhila, Anders Daneryd, “Heat transfer by liquid jets impinging on a hot flat surface” Applied Energy 164, 2016, pp. 934–943. Christopher Csernyei, Anthony G. Straatman, “Forced convective heat transfer on a horizontal circular ISO 9001:2008 Certified Journal | Page 494 [13] [14] [15] [16] [17] [18] [19] [20] [21] International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 10 | Oct 2019 p-ISSN: 2395-0072 www.irjet.net cylinder due to multiple impinging circular jets”, Applied Thermal Engineering 105, 2016,pp. 290–303. B. W. WEBB,” Single-Phase Liquid Jet Impingement Heat Transfer”,Advance In Heat Transfer Volume 26(1995). X. Liu, J. H. Lienhard V, J. S. Lombara,” Convective Heat Transfer by Impingement of Circular Liquid Jet”, Journal of Heat Transfer Volume 113,1991(Page No.571-582) A. K. Singh," Thermal Conductivity of Nanofluids",Defence Science Journal, Vol. 58, No. 5, September 2008, pp. 600-607. Sourav K. Bhunia, John H. Lienhard V, “Surface Disturbance Evolution and the Splattering of Turbulent Liquid Jet”, Journal of Fluids Engineering (1994), Vol. 116 / 721. L. A. Gabour J. H. Lienhard V,“Wall Roughness Effects on Stagnation-Point Heat Transfer Beneath an Impinging Liquid Jet”, Journal of Heat Transfer, (1994), Vol. 116/81. J.F.Timmers,R.J.Goldstein,” Visualzation Of Heat Transfer From Arrays Of Impingment Jets”,International Journal Of Heat And Mass Transfer,Volume 25,Page No.1857-1868,(1982). Abdlmonem H. Beitelma,Michel A. Saad,Chandrakant D. Patel,"The e€ect of inclination on the heat transfer between at surface and an impinging two-dimensional air jet”, International Journal of Heat and Fluid Flow 21 (2000)Page No. 156-163 J. Stevens, B. W. Webb"Local Heat Transfer Coefficients under an Axisymmetric, SinglePhase Liquid Jet ", Journal of Heat Transfer (1991), Vol. 113/71. John H. Lienhard “A heat transfer textbook", Phiogistion Press., 4 (2012). © 2019, IRJET | Impact Factor value: 7.34 | ISO 9001:2008 Certified Journal | Page 495