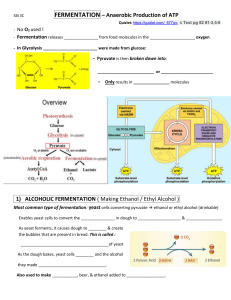

Begin Fermentation “Wild Yeasts” Dominate Grape Skins • Kloeckera and Hanseniospora (50-75%), and at lesser levels, Candida, Cryptococcus, Rhodotorula, Pichia, Kluyveromyces and Hansenula Fermentation Yeast Saccharomyces cerevisiae Number of S. cerevisiae yeast on a grape: 1-10 Cells = 40 thousand cells per gallon of juice Number of S. cerevisiae yeast in a gallon of fermenting wine: 2 x 10 12 or 2 Trillion Cells Alcoholic Fermentation • Grape Sugars Ethanol + Carbon Dioxide + Heat • • • • Yeast tolerance limits: – Ethanol up to about 16% – Pressurized up to about 120 psi – Heat above 110 F Purpose of Inoculation • Domination by the “good guys” Starter Yeast Cultures ferment 25-30% sugar to dryness tolerate 50-100 mg/L free SO2 produce minimum amounts of acetic acid, hydrogen sulfide or sulfur dioxide tolerate cool (50º F) to very warm (100ºF) fermentation temperatures • tolerate low pH musts (<3.0) • • • • • Happy Yeast • • • • • • • Replication – Oxygen – Nitrogen – Sugar Fermentation – Temperature 75F – Sugar Yeast Food • Nitrogen deficiencies in juice – diammonium phosphate (DAP) &/or Yeastex or Fermaid • proprietary formulations – Add up to 2 grams/gallon at inoculation – Helps avoid stuck fermentations and hydrogen sulfide formation Starter Culture Preparation • • • • • 1 gram yeast per gallon juice Warm 10 ml of water per 1 gram yeast to 104 F Sprinkle yeast on top Hold at 100-102F for 15-30 minutes Add to juice, temperature compensated, and stir in well Typical profile of yeast growth versus sugar utilization Monitor Fermentation • atch for signs • Reinoculate if no activity after 48 hours • Take hydrometer readings – Determine when to press red wines –Watch for stuck fermentations You’’re a Winner!! Indy International Wine Competition Industrial fermentation Production with microbes • Industrial microbiology – The use of microbes in the production – Start from an ancient time – Large scale production – • Early 20th century – beverage industry, vinegar, baking yeast, citric and lactic acid • Late 20th century – development of biotechnology from the antibiotic industrial Production with microbes • Fermentation industry – Microbes to produce ‘useful’ product – Usually a naturally produce substances for growth, and maintenance. – Metabolites • Primary metabolite – produce during growth • Secondary metabolite – produce after growth stage Secondary metabolite Primary metabolite Products I. Foods and foods related – Fermented meat, Cheeses and milk products, mushrooms, baker’s yeast, coffee, pickles, single cell-proteins, vinegar, amino acids, vitamins, alcoholic beverages Products II. Organic acids – Citric acids, Itaconic acid III. Enzymes and microbial transformation – Commercial enzyme, sterol conversion IV. Engineered microbes – Insulin, human growth factor Production with microbes • Steps in Industrial fermentation – Isolation of microbes that produce your interested product – Screen for the best producing strain: naturally or mutation. – Optimize production condition (growth – basically) → in lab – Scale up from lab scale (up to 10 L) to industrail scale (>10,000 L) (raw material?) Food and food related products • Whole cells products – Including – mushrooms and Single-cell protein (SCP) • Mushrooms – fruiting body of mold! – Highly consumed every year – high nutrition. – Grow on decaying organic matter in soil or wood. • Stalk and cap = compact mycelium • Gills = site of reproductive spores – E.g. Agaricus bisporus (botton mushroom), Lentinus edulus (Shitake mushroom) Food and food related products • Single-cell protein – yeast, and cyanobacteria – Alternative food sources – mostly used now as supplementary diet e.g. yeast is a source for B Vitamins. – Organisms: yeast, Spirulina – Growing biomass and freeze dry – Raw material from other industrial, farming Food and food related products • Baker’s yeast – Same process as in single cell protein Food and food related products • Cheese production – Can produce from any milk. – 4 phases: coagulation, separation, shaping and ripening • Coagulation: rennin enzyme or acids precipitate casein – From calves’s stomachs, engineered bacteria – Acid production by lactic acid bacteria – Curd entrap bacteria, fat globules and other material. • Cheese production – Separation & Shaping • Additives (salt and herbs) may be added after seperation • or shaping: effect property of cheese product – Ripening – add flavor and look – Natural or inoculation of microbes e.g. Penicillium roquefortii (spores are usually added into blue cheese), and Penicillium camemberti is added to the surface of a cheese known as Camenbert Blue cheese Brie Gorgonzola Swiss Food and food related products • Yogurt and other fermented milk products – Yogurt, kefir, buttermilk, sourcream – Yogurt usually use mixture of 2 cultures: • Streptococcus thermophilus: ini. acid production • Lactobacillus bulgaricus – – – – 0.5 - 1.0% lactic acid Fermented at 28-32 °C Taste due to acetaldehyde, diacetyl, and acetoin Product need to contains live cultures Some Foods Produced from Fermented Milk. Fermented Microorganisms Product Description Sour cream Streptococcus sp. Leuconostoc sp. Cream is inoculated and leave to develop acidity Cultured buttermilk Streptococcus sp. Leuconostoc sp. Made with skimmed or partly skimmed pasteurized milk. Acidophilus milk Lactobacillus acidophilus This milk product is used for its medicinal therapeutic value. Kefir Streptococcus lactis, Lactobacillus bulgaricus, yeasts A mixed lactic acid and alcoholic fermentation. Industrial production of yogurt Kefir Buttermilk Food and food related products • Alcoholic beverages – Accidental discovered from ancient human – Saccharomyces cerevisiae – Raw materials are regional….variety of products • • • • Wine – grapes, fruits Beer – cereal grain – barley, sorgum, wheat Other – rice wine (rice), teguila (agave cactus), vodka (corn), mead (honey). Food and food related products • Fermented meat – Use to preserve food E.g. salami, summer sausage, cured ham – Thailand – naam (fermented pork), fermented sausage, fermented fish, fish sauce…etc – Main organism – Pediococcus serevisiae, Lactobacillus plantarum, other lactic acid bacteria – Production of lactic acid to change pH of food – Production of probiotics in some strains Food and food related products • Fermented fruits and vegetables – Found around the world – With bacteria, yeast and mold – Depends mainly on native microbes associate with the plants. – Most included mixed culture Fermentation – Conditioning by human to favor growth of beneficial microbes - salting Products Organisms Sauerkraut Lactobacillus mesenteroids, Lactobacillus plantarum Pickles Pediococcus cerevisiae, Lactobacillus plantarum Soy sauce Rhizopus oligosporus, Rhizopus oryzae, Lactobacillus delbrueckii, Saccharomyces rouxii Coffee Leuconostoc mesenteroides, Saccharomyces marscianus, Flavobacterium spp., Fusarium spp. Cocoa products Leuconostoc mesenteroides, Candida sp. Food and food related products • Flavoring agents: amino acids and nucleotides – Monosodium glutamate, inosinic acid – flavor enhancers – Originally use seaweed, fish – Produce by enzymatic hydrolysis of yeast RNA (Candida utilis) – Now direct fermentation = monosodium glutamate and 5’-IMP (inosine monophosphate) – Brevibacterium ammoniagenes produce inosine and then chemically phosphorylated Non-food products • Enzyme production – Produce in large scale around the world – Major producer – Novozyme (44%), Genencor Intl, USA (18%) Enzyme Organisms Use Bacterial proteases Bacillus, Streptomyces Detergents Asparaginase Escherichia, Serratia Antitumor agent Glucoamylase Aspergillus Fructose syrup production Bacterial amylases Bacillus Starch liquefaction, brewing, baking, feed, detergents Glucose isomerase Bacillus, Streptomyces Sweeteners Rennin Alcaligenes, Aspergillus, Candida Cheese manufacture Pectinase Aspergillus Fruit juice clarification Lipases Micrococcus Cheese production Penicillin acylase Escherichia Semisynthetic penicillins Non-food product 1. Vitamins 2. Antibiotics 3. Alkaloids 4. Steroids 5. Non-Steroid Hormones/cell regulators (cytokines): 1. Epidermal growth factor 2. Proinsulin 3. Insulin 4. Human growth hormone 5. Somatostatin 6. Interferons 7. Platelet-derived growth factor 8. Fibroblast growth factor 9. Tumor Necrosis Factor 10. Other cytokines are coming on line all the time Non-food product • • • • 6. 7. 8. 9. Blood coagulating factor XIII The restriction enzymes Other enzymes (e.g. ligase, DNA polymerases etc.) Solvents How do the microbes produce these products? • Genetically modified microorganisms • Clone genes that encode protein of interest into vectors and express this genes in microbes used in production. • Able to produce high amount of compounds than in original organisms with ease of manipulation. • Microbes able to utilize waste from other process as a raw material for fermentation. • Antibiotics – Penicillin by Penicillium chrysogenum – Now most of the antibiotics were discover from soil microorganisms especially in Streptomyces spp. – Engineered genes into production strains. – Modification of existing antibiotics. Streptomycin from Streptomyces griseus • Alkaloids – Nitrogen containing organic compounds that derived from plants – Have medicinal purposes: • Atropine – dilates pupils of the eyes (some muscle disease) • Morphine and codeine – relief of pain • Cocaine – local anesthetic • Quinine, caffeine, nicotine, strychnine, serotonin , and LSD serotonin • Steroids – Types of products include cortisone and reproductive hormones • Human proteins • Biotech Drugs – Mainly recombinants proteins and monoclonal antibodies. – Highly active fields of biotech – Lots of new products each year • For list of product approve in US – www.bio.org – Timeline in drug development