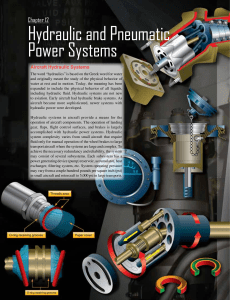

Lesson Objectives • Revisit basic legislations and regulation related to Fluid power systems • Explain the safety precautions related to fluid power systems • Understand the concept of hazards and risks in the context of fluid power systems • Perform risk assessment for the given scenarios Risk Assessment • Identify hazards and risk factors that have the potential to cause harm (hazard identification). • Analyze and evaluate the risk associated with that hazard (risk analysis, and risk evaluation). • Determine appropriate ways to eliminate the hazard, or control the risk when the hazard cannot be eliminated (risk control). Components of Hydraulic Systems • Reservoir Oil/Tank • Hydraulic Pump • Hydraulic Motor • Hydraulic Cylinder • Directional Control valve • Pressure/Flow Control Valve • Hoses Components of Pneumatic Systems • Compressor- makes compressed air • A reservoir-stores air Accumulator, Air Filter, Air Lubricator,Air Pressure Regulator • Air Service Unit • Directional Control valve, Check Valve and other valves • A Circuit- moves air between the components • An Actuator or motor- uses air to do something https://www.lunchboxsessions.com/materials/hyd raulic-hazards-safety/fluid-power-safety-lesson • Before performing service, repair, or troubleshooting, on a hydraulic system, the technician or operator must ensure that there’s no stored energy in the system. • The hydraulic system MUST be equipped with some type of device which makes it safe and simple to remove stored energy. Pneumatic Safety Precautions https://www.hydraulicspneumatics.com/maintenance/if ps-summarizes-fluid-power-safety-guidelines • Never blow compressed air at anyone. • Don't turn the main air supply on until the circuit is connected up. ... • If air is leaking from a joint – turn the air off. • Always turn air off before altering the circuit. • Keep fingers clear of the piston rods. • Wear safety glasses when building and operating pneumatic systems. • https://www.hydraulicspneumatics.com/maintenance/fluid-power-safetyworkplace-part-2 • https://www.hydraulicspneumatics.com/maintenance/fluid-power-safetyworkplace-part-1 • https://www.hydraulicspneumatics.com/maintenance/fluid-power-safetyworkplace-part-3 • http://www.fluidpowersafety.com/fpsi_alert-03.html • http://www.fluidpowersafety.com/fpsi_alert-02.html • http://www.fluidpowersafety.com/fpsi_alert-16.html • http://safehydraulics.blogspot.com/2016/08/would-you-allow-peoplethat-assembled.html