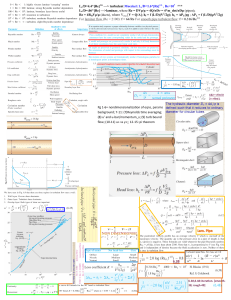

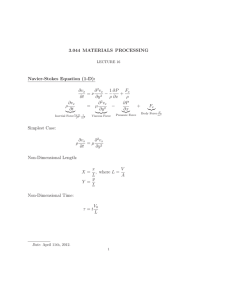

By Dr. Ajit Pratap Singh, Civil Engineering Department, BITS, Pilani-333031 Turbulent Flow through Pipes Objective ➤ Theoretical discussion on Turbulent flow including turbulent shear stress and Prandtl’s mixing length theory. ➤ To explain the development of velocity boundary layer in pipe and to explain how to get length required to establish a fully developed flow. ➤ To study Velocity Distribution in a pipe for turbulent flow and to obtain velocity profile. ➤ To classify hydrodynamically smooth and rough pipes. ➤ To measure the pressure drop in the straight section of smooth, rough, and packed pipes as a function of flow rate. ➤ To correlate this in terms of the friction factor and Reynolds number. ➤ To compare results with available theories and correlations. ➤ To determine the influence of pipe fittings on pressure drop. 1 Theoretical Discussion Fluid flow in pipes is of considerable importance in process. •Animals and Plants circulation systems. •In our homes. •City water. •Irrigation system. •Sewer water system Turbulent flow ØWhen fluid flow at higher flowrates, the streamlines are not steady and straight and the flow is not laminar. Generally, the flow field will vary in both space and time with fluctuations that comprise "turbulence” ØIn turbulent flow the fluid particles are in extreme state of disorder, their movement is haphazard and large scale eddies are developed which results in complete mixing of the fluid. ØFor this case almost all terms in the NavierStokes equations are important and there is no simple solution DP = DP (D, µ, r, L, U,) uz úz Uz average ur úr Ur average p p average P’ Time 2 Laminar vs Turbulent Flow • Laminar • Turbulent Turbulent flow Laminar Flow Turbulent Flow 3 Definition of turbulent flow(Hinze) “Turbulent fluid motion is an irregular condition of flow in which the various quantities show a random variation in time and space, so that statistically distinct average values can be discerned” 4 Reynolds Experiment ì • • • < 2000 Laminar flow hf µV rVD ï Re = Reynolds Number í2000 - 4000 Transition flow µ ï Turbulent f low h f µ V 2 Laminar flow: Fluid moves in î > 4000 smooth streamlines Turbulent flow: Violent mixing, fluid velocity at a point varies randomly with time Laminar Turbulent Boundary layer buildup in a pipe Because of the shear force near the pipe wall, a boundary layer forms on the inside surface and occupies a large portion of the flow area as the distance downstream from the pipe entrance increase. At some value of this distance the boundary layer fills the flow area. The velocity profile becomes independent of the axis in the direction of flow, and the flow is said to be fully developed. Pipe Entrance v v v 5 • Developing flow – Includes boundary layer and core, – viscous effects grow inward from the wall • Fully developed flow – In between the entrance section and section AA, where Pressure the boundary layer thickness equal to the radius of the pipe, Entrance the velocity of pipe will vary pressure drop from section to section due to variation in thickness of BL – Shape of velocity profile is same at all points along pipe after a section AA. The flow in Le pipe will be then truly uniform D and the flow is said to be established. Pipe Entrance Fully developed flow region Entrance length Le Region of linear pressure drop ì0.07 R e ï » í4.4Re 1/6 or ï50 î Le for Laminar flow x ü ýfor Turbulent flow þ Problem • A 15-mm-diameter water pipe is 20 m long and delivers water at 0.0005 m3/sec at 20 0C. What fraction of this pipe is taken up by the entrance region so that after this region fluid flow becomes fully developed? Take ν = 1.01x10-6 m2/sec. 6 Fully Developed Turbulent Flow: Overview One see fluctuation or randomness on the macroscopic scale. mean fluctuating One of the few ways we can describe turbulent flow is by describing it in terms of time-averaged means and fluctuating parts. Turbulent Flow – Shear stresses There are several theoretical models available for the prediction of shear stresses in turbulent flow. However, there is no general, useful model that can accurately predict the shear stress for turbulent flow. Ø We estimate shear stress by using experimental data, semiempirical formulas and dimensional analysis 7 Modelling turbulent flow • Why not solve the Navier-Stokes equations? – No analytical solution possible – In a computer, every small whirl would need to be modelled. Even a 10cm3 volume would require ~ 100,000,000 nodes • Need to simplify – Crossing of streamlines transfers momentum between parts of the flow Fully Developed Turbulent Flow: Overview Now, shear stress: However, Laminar Flow: Shear relates to random motion as particles glide smoothly past each other. for turbulent flow. Turbulent Flow: Shear comes from eddy motion which have a more random motion and transfer momentum. For turbulent flow: Is the combination of laminar and turbulent shear. If there are no fluctuations, the result goes back to the laminar case. The turbulent shear stresses are positive, thus turbulent flows have more shear stress. 8 Fully Developed Turbulent Flow: Overview The turbulent shear components are known as Reynolds Stresses. Shear Stress in Turbulent Flows: Turbulent Velocity Profile: In viscous sublayer: tlaminar > tturb 100 to 1000 times greater. In the outer layer: ttirb > tlaminar 100 to 1000 time greater. The viscous sublayer is extremely small. Apparent shear stress • Apparent shear stress - Boussinesq(1877) – Turbulence provides a shear in the flow in addition to viscous shear – Even in low viscosity fluids, there will be a shear du τ = µ T T – Propose an apparent viscosity dy – In general µT>µ , so ordinary viscosity can be neglected 9 Reynolds stresses Object: to include the random fluctuations in the Navier-Stokes equations for the mean flow. Method: represent all quantities by the mean plus fluctuation. u = u + u¢ p = p + p¢ and so on (T and r must also be considered for compressible flow) Putting these into the Navier-Stokes equations and separating out the time averaged and variable terms leads to a modified set of equations Reynolds stresses-continuity Continuity - what goes in must come out! ¶u ¶v ¶w + + =0 ¶x ¶y ¶z ¶ (u + u ¢) ¶ (v + v¢) ¶ (w + w ¢) In turbulent flow: + + =0 ¶x ¶y ¶z ¶u ¶v ¶w ¶u ¢ ¶v¢ ¶w ¢ Separating: + + + + + =0 ¶x ¶y ¶z ¶x ¶y ¶z ¶u ¶v ¶w Taking a time average: + + =0 ¶x ¶y ¶z ¶u¢ ¶v¢ ¶w¢ Therefore, the fluctuating part + + =0 also satisfies the continuity equation ¶x ¶y ¶z In laminar flow: 10 Reynolds stresses - Navier Stokes Similarly, the N-S equations become (Schlichting, Ch 18) ρg x - æ ¶ 2 u ¶ 2 u ¶ 2 u ö æ ¶ u ¢2 ¶ u ¢v¢ ¶ u ¢w ¢ ö÷ ¶p + µçç 2 + 2 + 2 ÷÷ - ρç + + ç ¶x ¶ x ¶ y ¶ z ¶ x ¶ y ¶z ÷ø è ø è æ ¶u ¶u ¶u ö = ρçç u + v + w ÷÷ ¶y ¶z ø è ¶x Shear stresses Direct stress Reynolds stresses • Compared to the laminar Navier-Stokes equation, one new term has been added. The other terms have been averaged to remove the time dependency. • The terms on the left are the forcing terms, gravity, pressure, viscosity and turbulence • The terms on the right are the response terms du ¶u ¶u (remember : dt = ¶t +u ¶s ) 11 Reynolds stresses in 2D •No z,w terms y u •Steady, turbulent flow in x direction •Ignore gravity x ¶p æ ¶ 2 u ¶ 2 u ¶ 2 u ö æç ¶ u¢2 ¶ u¢v¢ ¶ u¢w ¢ ö÷ ρg x - + µçç 2 + 2 + 2 ÷÷ - ρ + + ¶x è ¶x ¶y ¶z ø çè ¶x ¶y ¶z ÷ø æ ¶u ¶u ¶u ö = ρçç u + v + w ÷÷ ¶y ¶z ø è ¶x Reynolds stresses in 2D In 2D, the turbulent N-S equation therefore reduces to: ¶p ¶2u ¶ u¢v¢ ¶u +µ 2 -ρ = ρv ¶x ¶y ¶y ¶y Note that there are now two shear stress terms. Re-writing: - ö ¶p ¶ æ ¶u ¶u + çç µ - ρ u ¢v¢ ÷÷ = ρv ¶x ¶y è ¶y ¶y ø In turbulent flow, therefore the shear stress is given by τ=µ ¶u - ρ u ¢v¢ ¶y 12 Reynolds and Boussinesq Boussinesq proposed an additive turbulent shear stress: τ=µ ¶u ¶u + µT ¶y ¶y So the additive term is equivalent to the Reynolds’ stress. However, we need to know values for u¢v¢ in order to use this Are the Reynolds’ stresses related to the flow velocity? Prandtl‘s Mixing Length Theory • That distance in the transverse direction which must be covered by a lump of fluid particles traveling with its original mean velocity in order to make the difference between its velocity and the velocity of new layer equal to the mean transverse fluctuation in turbulent flow 13 Prandtl‘s Mixing Length Theory u( y) mean velocity lump of turbulence lump of turbulence (mixed) ~ v¢ ~ u¢ y,v ¶u ¶y x,u turbulent shear flow along solid wall (not valid close to the wall) mixing length l v¢ ~ + l1 × ¶u ¶y Þ u ¢ ~ ± l2 × ¶u ¶y defined as that downstream distance, which is needed for the lump of turbulence to be completely mixed with the surrounding fluid l1 = l2 = l Prandtl’s Mixing Length… •Analogous to the kinetic theory of gases •Used because ‘it works’ u(y) y y2 y1 l Suppose ‘lumps’ of fluid move randomly from one shear layer to another, a distance l apart. This carries momentum and the velocity difference must therefore be related to the turbulence 14 Prandtl’s Mixing Length u¢ µ l ¶u ¶y Turbulence is even in all directions (homogeneous) v¢ µ u ¢ µ l ¶u ¶y So the Reynolds shear stress must be proportional to the square of the mixing length times the velocity gradient: æ ¶u ö u ¢v¢ µ l çç ÷÷ è ¶y ø 2 2 Prandtl’s Mixing Length… Returning to the equation for the shear stress: τ=µ ¶u - ρ u ¢v¢ ¶y τ=µ ¶u ¶u + µT ¶y ¶y æ ¶u ö ¶u µT = - r u ¢v¢ µ ρl 2 çç ÷÷ ¶y è ¶y ø 2 This gives a direct relationship between turbulent ‘viscosity’ and velocity gradient in the flow ¶u µ T = ρl ¶y 2 2 15 Total Shear stress at any point • Total Shear stress at any point is the sum of the viscous shear stress and turbulent shear stress and may be expressed as æ dv ö dv τ=µ + ρl 2 çç ÷÷ dy è dy ø 2 • The significance of Prandtl’s turbulent shear stress equation is that it is possible to make suitable assumptions regarding the variation of the mixing length Prantdl’s Mixing Length • We still need a value for the mixing length, l. • In free turbulence, l will be constant. • In wall generated turbulence, l will vary as the distance from the wall. (l=ky) • For a smooth wall y=0, l=0 • For a rough wall y=0, l=k (the surface roughness) 16 Mixing length measurement in pipes CE C371: Hydraulics & Fluid Mechanics by Dr. A. P. Singh The Universal Law of The Wall CE CF312: Hydraulics by Dr. A. P. Singh 17 The Universal Law of The Wall The Universal Law of The Wall æ dv ö τ 0 = ρk 2 y 2 çç ÷÷ è dy ø 2 æyö v = v max + 2.5V* Log e ç ÷ èRø v max - v æRö = 2.5V* Log e çç ÷÷ V* èyø CE CF312: Hydraulics by Dr. A. P. Singh 18 Hydrodynamically Smooth and Rough Pipe Boundaries • In general a boundary with irregularities of large average height k, on its surface is considered to be rough boundary and the one with smaller k values is considered as smooth boundary. • Hopf found two types of roughness: – Coarse, dense roughness where f is a function of roughness ratio, k/D, and is independent of the Reynolds number – Gentle, less dense roughness, where f is a function of both Re and roughness ratio – The significant factor is the roughness height compared to the laminar sub-layer. Hydrodynamically Smooth and Rough Pipe Boundaries A systematic study is complicated by different types: 1. Shape 2. Height 3. Density 19 Hydrodynamically Smooth and Rough Pipe Boundaries • We should also consider flow and fluid characteristics for proper classification of smooth and rough boundaries. • If k is the average height of rough projections on the surface of the plate and δ is the thickness of the boundary layer, then the relative roughness (k/ δ) is a significant parameter indicating the behavior the boundary surface of a plate. • If the boundary layer is turbulent from the leading edge of the plate, the front portion of the plate will act as hydrodynamically rough followed by transition region and the downstream portion of the plate will be hydrodynamically smooth if the plate is sufficiently long. Hydrodynamically Smooth and Rough Pipe Boundaries Turbulent Laminar d • As the flow outside the laminar sub-layer is turbulent, eddies of various sizes are present which try to penetrate through the laminar sub-layer. But due to greater thickness of the laminar sub-layer the eddies cannot reach the surface irregularities and thus the boundary act as a smooth boundary. • In the laminar sub-layer, any vortices generated by the roughness is damped out, so if k<d, then the law of friction for smooth pipes will apply 20 Hydrodynamically Smooth and Rough Pipe Boundaries • With the increase in Reynolds number, the thickness of the laminar sub-layer decreases, and it can even become much smaller than the average height k, of surface irregularities. The irregularities will then project through the laminar sub-layer and laminar sublayer is completely destroyed. The eddies will thus come in contact with the surface irregularities and large amount of energy loss will take place and thus the boundary act as a rough boundary. From Nikuradse’s experiment • Hydrodynamically smooth pipe • Transition region in a pipe • Hydrodynamically Rough Pipe k < 0.25 δ' 0.25 < k < 6.0 δ' k > 6.0 δ' 21 • Hydrodynamically smooth Plate V*k s <5 υ • Plate in Transition region 5< V*k s < 70 υ • Hydrodynamically Rough V*k s > 70 υ Where ks is equivalent sand grains roughness defined as that value of the roughness which would offer the same resistance to the flow past the plate as that of due to the actual roughness on the surface of the plate. From Nikuradse’s experiment • Hydrodynamically smooth pipe k æ V*k ö £ 0.2 5 or ç ÷£3 δ' u è ø • Transition region in a k æVkö 0.25 < ' < 6.0 or 3 < ç * ÷ < 70 pipe δ è u ø • Hydrodynamically Rough Pipe k æVkö ³ 6.0 or ç * ÷ ³ 70 ' δ è u ø CE C371: Hydraulics & Fluid Mechanics by Dr. A. P. Singh 22 Nikuradse’s experimental studies of turbulent flow in smooth pipes have also shown that • In smooth pipes of any size the value of the parameter V* y 11.6υ = 11.6 for y = δ ' Þ δ ' = υ V* V* y ' 0.108υ = 0.108 for y = y ' Þ y ' = υ V* Þ y' = δ' 107 CE C371: Hydraulics & Fluid Mechanics by Dr. A. P. Singh Velocity Distribution in Smooth Pipes • • In the vicinity of a smooth boundary there exists a laminar sublayer. The flow in the laminar sublayer being laminar has a parabolic velocity distribution. As such the velocity which is zero at the pipe boundary increases parabolically in the zone of laminar motion, which extends up to certain distance from the boundary. Above the zone of laminar motion there exists a transition zone where the flow changes from laminar to turbulent Beyond the transition zone the flow is turbulent having logarithmic velocity distribution. Since the change from parabolic to logarithm i.e. distribution is gradual, the zone of laminar motion will extend well beyond the distance y', as shown in Fig.. However, in the absence of any specific line of demarcation between the different zones of flow near the boundary, the intersection of the parabolic and the logarithmic velocity distribution curves, as shown in Fig. is arbitrarily chosen as nominal border line between the two types of flow. 23 Velocity Distribution for turbulent flow • Velocity Distribution v = 5.75 log in a hydrodynamically V* smooth pipe 10 • Velocity Distribution v = 5.75 log in a hydrodynamically V* Rough Pipes 10 V* y + 5.5 υ æyö ç ÷ + 8.5 èkø CE C371: Hydraulics & Fluid Mechanics by Dr. A. P. Singh Velocity Distribution for turbulent flow in terms of Mean Velocity (V) • Velocity Distribution V = 5.75 log in a hydrodynamically V smooth pipe * 10 • Velocity Distribution V = 5.75 log in a hydrodynamically V Rough Pipes * æRö ÷ + 4.75 10 ç èkø V*R + 1.75 υ 24 Law of the Wall u V* 5.5 Laminar sub-layer Buffer zone Turbulent layer yV* ln υ Turbulent Flow – Velocity Profile For turbulent flow in tubes the time-averaged velocity profile can be expressed in terms of the power law equation. n =7 is usually a good approximation. 1/ n u æ rö = ç1 - ÷ V è Rø where V is the velocity at the centerline 25 Losses due to Friction/The Friction Factor For turbulent flow there is no rigorous theoretical treatment available. In order to determine an expression for the losses due to friction we must resort to experimentation. L V2 hf µ D where L=length of the pipe, D=diameter of the pipe, V=velocity, By introducing the friction factor, f: L V2 hf = f D where f = hf ( L / D )(V 2 / 2 g ) Flow in Pipes Hopf found two types of roughness: •Coarse, dense roughness where f is a function of roughness ratio, k/D, and is independent of the Reynolds number •Gentle, less dense roughness, where f is a function of both Re and roughness ratio The significant factor is the roughness height compared to the laminar sub-layer. 26 Nikuradse’s Experiments • In general, friction factor • Function of Re and roughness f = F (Re, • • e ) D Laminar region – Independent of 64 roughness f = Re Turbulent region – Smooth pipe curve • All curves coincide @ ~Re=2300 – Rough pipe zone • All rough pipe curves flatten out and become independent of Re f = 0.25 é 5.74 öù æ k êlog 10 ç 3.7 D + Re 0.9 ÷ú è øû ë 2 f = f = k (Re )1 / 4 Rough Blausius 64 Re Blausius OK for smooth pipe Laminar Transition Smooth Turbulent CE F312: Hydraulics Engineering by Dr. A. P. Singh The Friction Factor The mechanical energy equation can be written: ( Wshaft æ P2 P1 V2 V2 L V 2 ö÷ - ) + ( 2 - 1 ) + g ( z 2 - z1 ) = -ç4 f ç r r 2 2 m! D 2 ÷ø è Or in terms of heads: ( Wshaft æ P2 P1 V2 V2 L V 2 ö÷ - ) + ( 2 - 1 ) + ( z 2 - z1 ) = -ç4 f ç rg rg 2g 2g m! g D 2 g ÷ø è Knowledge of the friction factor allows us to estimate the loss term in the energy equation 27 Friction factor: The Moody Chart The Moody Chart (Figure 14.10 textbook) provides a convenient representation of the functional dependence f = f(Re, k/D) Ø For laminar flow: f = 64 / Re Ø For turbulent flow: æ k/D 1 2.51 = -2 log ç + ç 3.7 Re f f è ö ÷ ÷ ø Colebrook formula 1/ 3 é æ k 106 ö ù ÷ ú f = 0.001375 × ê1 + çç 20,000 + D Re ÷ø ú êë è û Ø For turbulent flow, with Re<105 and for hydraulically smooth surfaces: f = 0.316 Re 1/ 4 Blasius formula Surface Roughness Additional dimensionless group k/D need to be characterize Thus more than one curve on friction factorReynolds number plot Fanning diagram or Moody diagram Depending on the laminar region. If, at the lowest Reynolds numbers, the laminar portion corresponds to f =16/Re Fanning Chart or f = 64/Re Moody chart CE F312: Hydraulics Engineering by Dr. A. P. Singh 28 Variation of friction factor for Commercial pipes White Equation R/K ö æ æRö - 2.0 log 10 ç ÷ = 1.74 - 2.0 log 10 ç1 + 18.7 ÷ f Re f ø èKø è 1 Colebrook formula 1 æ k/D 2.51 ö = -2.0 log 10 ç + ÷ 3.7 f Re f è ø CE F312: Hydraulics Engineering by Dr. A. P. Singh • The Colebrook equation is implicit in f, and thus the determination of the friction factor requires some iteration. An approximate explicit relation for was given by S.E. Haaland in 1983. • The results obtained from this relation are within 2 percent of those obtained from the Colebrook equation. é 6.9 æ k / D ö1.11 ù 1 @ 1.8 log ê +ç ÷ ú Re f è 3.7 ø ûú ëê CE F312: Hydraulics Engineering by Dr. A. P. Singh 29 Moody Diagram CE C371: Hydraulics & Fluid Mechanics by Dr. A. P. Singh Fanning Diagram é ù 1 D D/e = 4.0 * log + 2.28 - 4.0 * logê4.67 + 1ú e f Re f ë û 1 D = 4.0 * log + 2.28 e f f =16/Re CE C371: Hydraulics & Fluid Mechanics by Dr. A. P. Singh 30 Following observations from the Moody chart: • For laminar flow, the friction factor decreases with increasing Reynolds number, and it is independent of surface roughness. • The friction factor is a minimum for a smooth pipe (but still not zero because of the no-slip condition) and increases with roughness. The Colebrook equation in this case (k=0) reduces to the Prandtl equation • The transition region from the laminar to turbulent regime (2300 < Re < 4000) is indicated by the shaded area in the Moody chart. The flow in this region may be laminar or turbulent, depending on flow disturbances, or it may alternate between laminar and turbulent, and thus the friction factor may also alternate between the values for laminar and turbulent flow. The data in this range are the least reliable. At small relative rougnesses, the friction factor increases in the transition region and approaches the value for smooth pipes. 31 Equivalent roughness values for new commercial pipes Material Roughness, k (mm) Glass, plastic 0 (smooth) Concrete 0.9 to 9 Wood stave 0.5 Rubber, smoothed 0.01 Copper or brass tubing 0.0015 Cast iron 0.26 Galvanized iron 0.15 Wrought iron 0.046 Stainless steel 0.002 Commercial steel 0.045 Type of Problems • Determining the head-loss or pressure drop from the given values of Q, L, D, pipe roughness κ, kinematic viscosity ν. • Determining the Q from the given values of headloss or pressure drop due to friction, L, D, pipe roughness κ, kinematic viscosity ν. • Determining the dia of pipe from the given values of head-loss or pressure drop due to friction, Q, L, pipe roughness κ, kinematic viscosity ν. 32 • Type 1 – Calculate Re and k/D from the given data – Obtain f from the Moody’s chart • Type 2 – Calculate k/D from the given data and Re√f æ 2gh D ö from Re f = VD ç ÷ υ è V L ø – Using Coolebrook formula and the above equation, Obtain f – Obtain Re from the Moody’s chart and hence Q 1/2 f 2 • Type 3: Dia is unknown – Assume a suitable value of f and calculate Dia from Darcy-Weisbatch equation – With this trial value of D, calculate k/D and Re – With this k/D and Re, calculate f from Moody’s diagram – Repeat the process till f becomes same 33 Swamee and Jain in 1986 proposed the following explicit relations that are accurate to within 2% of the Moody chart 0.5 0.5 é k æ 3.17u 2 L ö ù æ gD 5 h L ö ÷÷ ú ÷÷ ln ê Q = -0.965çç + çç 3 êë 3.7D è gD h L ø úû è L ø 4.75 5.2 é æ LQ 2 ö æLö ù ÷÷ + υQ 9.4 çç ÷÷ ú D = 0.66 êk1.25 çç êë è gh ø úû è gh L ø 0.04 Re > 2000 10 -6 < k/D < 10 - 2 5000 < Re < 3 ´108 APPARATUS Pipe Network Rotameters Manometers CE C371: Hydraulics & Fluid Mechanics by Dr. A. P. Singh 34 Problem 1 • Water at 15 0C is flowing steadily in a 5 cm-diameter horizontal pipe made of stainless steel at a rate of 0.34 m3/min. Determine the pressure drop, the head loss, and the required pumping power input for flow over a 61m-long section of the pipe. Dynamic viscosity = 1.138x10-3 kg/m-sec Problem 2 • A person with no experience in fluid mechanics wants to estimate the friction factor for 2.5-cm-diameter commercial galvanized iron pipe (k=0.150 mm) at a Reynolds number of 8000. They stumble across the simple equation of f = 64/Re and use this to calculate the friction factor. Explain the problem with this approach and determine percentage error in evaluating friction factor by the person. (Answer: 80%) 35 Problem 3 • After 15 years of service a steel pipe main 0.6 m in diameter is found to require 40% more power to deliver the 300 liters/second for which it was originally designed. Determine the corresponding magnitude of the rate of roughness increase α. Take kinematic viscosity of water ν = 0.015 Stokes roughness protrusions height for new steel pipe = 0.045 mm. Problem 4 • A 15-mm-diameter water pipe is 20 m long and delivers water at 0.0005 m3/sec at 20 0C. What fraction of this pipe is taken up by the entrance region so that after this region fluid flow becomes fully developed? Take ν = 1.01x10-6 m2/sec. 36 Problem 5 • A new reservoir will use gravity to supply drinking water to a water treatment plant serving several surrounding towns as shown in Figure. The required flow rate is 0.315 m3/sec. The surface of the reservoir is 61 m above the plain where the water treatment plant is located, and the supply pipe is commercial steel, 914.4 mm in diameter. If the minimum pressure required at the water treatment plant is 347.7 kpa (gage), how far away can the reservoir be located with this size pipe? Assume that minor losses are negligible and that the water is at 283.1 K. The average height of the pipe wall roughness protrusions may be taken as 0.0458 mm. Take kinematic viscosity of water ν = 0.13x10-5 m2/sec . 37 Problem • For flow in open channels assume turbulent shear to the constant т = тo and the mixing length variation with y is given by l = 0.40 y for y ≤ 0.20 D, and l = 0.08D for y ≥ 0.20D where D is the depth of flow. Obtain the velocity distribution law which will satisfy the boundary condition, v = V at y = D. • A commercial new galvanized iron service pipe from a water main is required to deliver 200 L/s of water during a fire. If the length of the service pipe is 35 m, the allowable head loss in the pipe is 50 m and kinematic viscosity of water at 20 0C is 1.00 x 10-6 m2/sec, what will the pipe diameter to be used for this purpose? 38 • Water at 200C is to be pumped from a reservoir (ZA = 2 m) to another reservoir at a higher elevation (ZB = 9 m) through two 25-m long plastic pipes connected in parallel. The diameters of the two pipes are 3 cm and 5 cm. Water is to be pumped by a 68 percent efficient motor-pump unit that draws 7 kW of electric power during operation. The minor losses and the head loss in the smaller single pipes that connect both the parallel pipes to the two reservoirs are considered to be negligible. Determine the total flow rate between the reservoirs and the flow rates through each of the parallel pipes. 39 Pipe Flow Summary ØThe statement of conservation of mass, momentum and energy becomes the Bernoulli equation for steady state constant density of flows. Ø Dimensional analysis gives the relation between flow rate and pressure drop. ØTurbulent flow losses and velocity distributions require experimental results. ØExperiments give the relationship between the fraction factor and the Reynolds number. Ø Head loss becomes minor when fluid flows at high flow rate (fraction factor is constant at high Reynolds numbers). Images - Laminar/Turbulent Flows Laser - induced florescence image of an incompressible turbulent boundary layer Laminar flow (Blood Flow) Simulation of turbulent flow coming out of a tailpipe Turbulent flow CE C371: Hydraulics & Fluid Mechanics by Dr. A. P. Singh Laminar flow 40