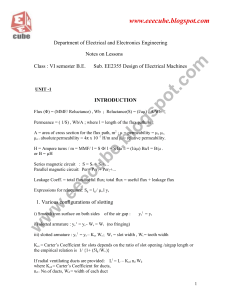

1. Calculate the apparent flux density at a section of the teeth of an armature of a D.C machine from the following data at that section. Slot pitch=24mm, slot width=tooth width =12 mm, length of armature core including five ducts of 10 mm each=0.38m, iron stacking factor=0.92. True flux density in the teeth at that section is 2.2T for which the MMF is 70000AT/m. 2. A 6-pole D.C. machine has the following design data. Armature diameter=30cm, armature core length=15 cm, length of air gap at pole center =0.25cm, flux per pole=12 mWb. Field form factor=0.65. Calculate the amp. turns required for the air gap a) if the armature surface is smooth b) if the armature surface is slotted and the gap expansion factor is 1.2 3. Find the apparent flux density at a section of the tooth in the following case when the real tooth flux density at that section is 2.157. Gross armature length =32 cm. Number of ventilating ducts =4,each 1 cm wide, tooth width at the section=1.2 cm, slot width with parallel sides=1 cm. Permeability of the tooth corresponding to real tooth density=35.8x10-6 4. Determine the air gap length of a D.C machine from the following data. Gross core length =0.12 m, no.of ducts =one of 10 mm width, slot pitchy =25 mm, Carters coefficient for slots and ducts =0.32, gap density at pole center =0.7 T. Field MMF per pole = 3900 AT, MMF require for iron parts of magnetic circuit =800 AT. 5. A D.C machine has the following data: pole arc =30 cm, length of the machine =36 cm, length of air gap =0.5 cm. Slot pitch at the air gap surface =2.5 cm, slot pitch at the bottom of slots =2.2cm, depth of slot =6cm, width of slot =1.2 cm. There are 4 ventilating ducts in the armature each 1 cm width. Flux per pole =7.2mWb. Estimate a) the MMF for air gap) MMF required for tooth. 6. Find the permeability at the root of the tooth of a D.C machine armature with the following data. Slot pitch 2.1cm, tooth width at the root 1.07cm, gross length 32cm, stacking factor 0.9, real flux density 2.25T, and apparent flux density at the root 2.36T. 7. Explain in detail about the MMF calculation for Teeth. 8. Discuss in detail about the real and apparent flux densities. 9. Explain about the air gap reluctances in different types of armature slots. 10. Derive an equation for the slot leakage reactance. 11. What are the direct and indirect cooling methods used in electrical machines. 12. Determine the dimension of the core, the number of turns, the cross-section area of conductors in primary and secondary windings of a 100 kVA, 2200/480 V, single phase, core type transformer, to operate at a frequency of 50 Hz, by assuming the following data. Approximate Volt per turn = 7.5 V, Maximum flux density = 1.2 Wb/m2. Ratio of effective cross-sectional area of core to square of diameter of circumscribing circle is 0.6. Ratio of height to width of window is 2. Window space factor =0.28. Current density = 2.5 A/mm2. 13. Explain the design of transformer tank with cooling tubes. 14. i) Determine the main dimensions of the core, the no of turns, the cross sectional area of conductors in primary and secondary windings of a 100kVA, 2200/480 V, 1 phase, core type transformer, to operate at a frequency of 50 Hz, by assuming the following data. Approximate volt per turn = 7.5 volts. Maximum flux density = 1.2 Wb/m2 ratio of effective cross sectional area of core to square of diameter of circumscribing circle is 0.6. ratio of height to width of window is 2. Window space factor = 0.28 current density = 2.5 A.mm2. ii). Explain how to estimate the no load current of a three phase transformer. 15. i). Derive the voltage per turn equation of a transformer. ii). Discuss about the various methods of cooling of power transformer. 16. The tank of 1250 kVA, natural oil cooled transformer has the dimensions length, width and height as 0.65x1.55x1.85 m respectively. The full load loss =13.1 kW, loss dissipation due to radiations = 6 W/m2 – Degree C, loss dissipation due to convection =6.5 W/m2 – degree C, improvement in convection due to provision of tubes =40 %, temperature rise =40 degreeC, length of each tube = 1 m, diameter of tube = 50 mm. find the no of tubes for this transformer. Neglect the top and bottom surface of the tank as regards the cooling. 17. Estimate the main dimensions including winding conductor areas of a 3 phase delta/star core type transformer rated at 300 kVA, 6600/440 V, 50 Hz. A suitable core with three steps having a circumscribing circle of 0.25 m diameter and a leg spacing of 0.4 m is available. The emf per turn is 8.5 V. Assume a current density of 2.5 A/mm2, a window space factor of 0.28 and stack factor of 0.9. 18. Discuss the steps for design of wave winding for a dc machines. 19. Explain the procedure for shunt field winding design of DC machine. 20. A 4 pole, 25 HP, 500 V, 600 rpm series motor has an efficiency of 82%.The pole faces are square and the ratio of pole arc to pole pitch is 0.67.Take Bav = 0.58 Wb/m2 and ac = 17000 amp.cond/m. Obtain the main dimensions of the core particular of a suitable armature winding. Enumerate the procedure for shunt field design. 21. Find the main dimension and number of poles of a 37 kW, 230V, 1400 RPM, shunt motor so that a square pole face is obtained. The average gap density is 0.5 wb/m 2 and the ampere conductors / meter are 22000. The ratio of pole arc to pole pitch is 0.7 and the full load efficiency is 90% 22. A 4 pole, 400V, 960 rpm shunt motor has an armature of 0.3 m. in diameter and 0.2 m. in length. The commutator diameter is 0.22m. Give the full details of a suitable winding including the number of slots, number of commutator segments and number of conductor in each slot for an average flux density of approximately 0.55wb/m 2 in the air gap. 23. A 4 pole, 500V, 600rpm, series motor has an efficiency of 82%. The pole face is square and the ratio of pole arc to pole pitch is 0.67. Take Bav is 0.55wb/ m2 and ac = 17000 amp conductor/m. obtain the main diameters of the core and particulars of a suitable armature winding. 24. Determine the total commutator losses for a 1000kw, 500V, 800rpm,10 poles generator. Given that commutator diameter is 1.0m, current density at brush contact =75x103A/mm2 brush pressure = 14.7kv/ m2, co efficiency of friction = 0.28, brush contact drop= 2.2V. 25. Discuss in detail about the design of commutator and brushes. 26. Explain the various factors that are affected by the selection of number of poles in DC machines. 27. Calculate the size of the conductor and number turns for the field coil of a 6 poles 460V micro-ohm meter. The length of the inside turn is 0.74m,the length available for the winding is 0.13m, the space factor of the winding is 0.52 and the permissible dissipation per m2 of external surface (excluding two ends) is 1200 watts. Solution should not be attempted by assuming a numerical value for the winding depth.